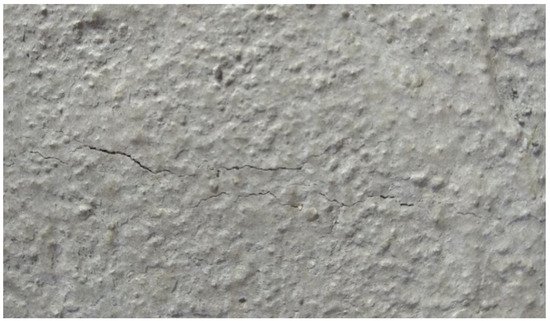

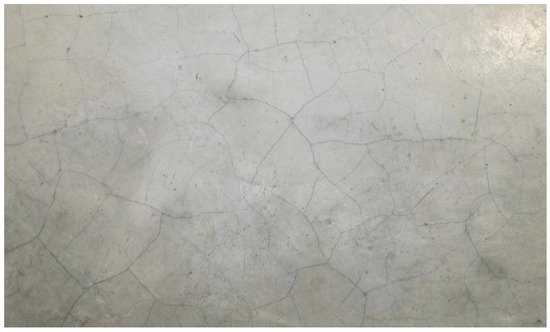

Cracking is a common problem in concrete structures in real-life service conditions. In fact, crack-free concrete structures are very rare to find in real world. Concrete can undergo early-age cracking depending on the mix composition, exposure environment, hydration rate, and curing conditions.

- concrete

- cracking mechanisms

- curing

- early-age cracking

- mix composition

- modeling

- service life

1. Introduction

2. Different Types of Early-Age Crack

3. Causes of Early-Age Cracking

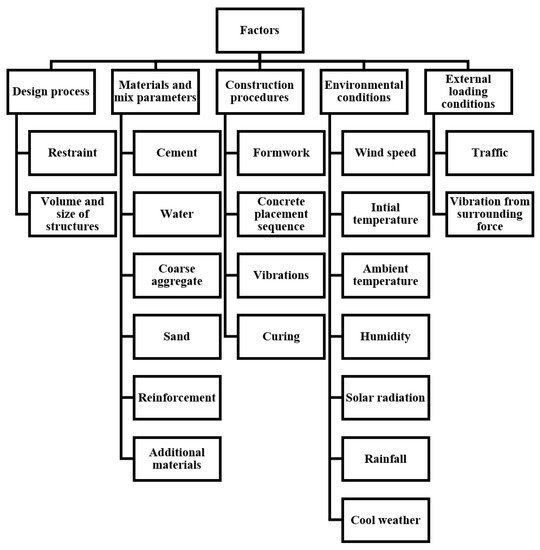

4. Factors Affecting Early-Age Cracking

5. Consequences of Early-Age Cracking

6. Remedial Measures for Early-Age Cracking

Early-age cracking always has some risks for concrete structures. However, these risks can be reduced through many remedial measures. The early-age cracking in concrete can be minimized by limiting temperature differences or using shrinkage reducing admixtures. Low-heat cement has been used to limit the temperature induced cracking in concrete. Also, shrinkage reducing admixtures have been used to decrease the stresses resulting from autogenous shrinkage [17]. Appropriate selection of the constituent materials for concrete, the correct mix design of concrete, the proper planning of concrete casting and construction sequence, the use of insulation for reducing thermal gradients, the installation of control joints, and the cooling of concrete before or after placing are some of the measures to minimize the risk of the early-age cracking in concrete structures [16]. Temperature or distribution reinforcement can be used to control cracks in hardening concrete structures. This type of reinforcement distributes early-age cracks and prevents the formation of through-cracks. Therefore, the strain capacity of reinforced concrete elements is significantly increased in the presence of distribution reinforcement. Also, the main reinforcement configuration is more important than the reinforcement ratio in controlling the cracking in reinforced concrete elements [17]. The probability of cracking is lower in heavily reinforced concrete (generally true for high-strength concrete) structures. Less cooling joints or fewer dilation joints are required to prevent the early-age through-cracking in reinforced concrete structures. The depth of plastic shrinkage cracks can be determined by coring. The extent of random, longitudinal, and transverse cracking over time can be determined by drawing crack map. The depth of cracking and aggregate breakage in the cases of transverse, longitudinal, and corner cracks as well as the bonding of slab with sub-base in the case of random crack can be determined by coring. The bonding of slab with sub-base can be examined by conducting push-off test in the cases of random, transverse, and longitudinal cracks. The joint function can be examined via the pull-out test while investigating transverse and corner cracks. Employing a good quality curing compound in an adequate amount may reduce the extent of plastic shrinkage, random, longitudinal, transverse, and corner cracking [1]. Well-graded sand and combined aggregates are also conducive to decrease the degree of severity of plastic shrinkage and number of random, longitudinal, and transverse cracks. From literature survey, the remedial measures can be classified into two groups: materials- and design-based remedial methods and construction-based remedial methods (refer to Table 1). Constituent materials, concrete mix design, and structural design are classed as materials- and design-based remedial measures. In the case of construction-based remedial measures, curing, placing sequence and environmental conditions, vibration, cooling method, and formwork are emphasized.No | Reference | Designing | Construction | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

A | B | C | D | E | F | G | H | ||||||||||||||||||||||

1 | Holt [24] | Y | Y | - | - | - | - | - | - | ||||||||||||||||||||

2 | Klemczak and Knoppik-Wróbel [10] | Y | Y | - | Y | Y | - | Y | - | ||||||||||||||||||||

3 | Krauss and Rogalla [28] | - | Y | - | Y | Y | - | - | - | ||||||||||||||||||||

4 | Emborg and Bernander [9] | - | Y | - | - | - | - | Y | - | ||||||||||||||||||||

5 | Shing and Abu-Hejleh [105] | [41] |

Y | Y | - | Y | Y | - | - | - | |||||||||||||||||||

6 | Babaei and Purvis [106] | [42] |

Y | Y | - | - | Y | - | - | - | |||||||||||||||||||

7 | French et al. [107] | [43] |

Y | Y | Y | - | Y | - | - | - | |||||||||||||||||||

8 | Dippenaar [53] | [44] |

Y | - | Y | Y | - | Y | - | Y | |||||||||||||||||||

9 | Combrinck and Boshoff [37] | [45] |

- | Y | - | - | - | - | - | - | |||||||||||||||||||

10 | Kwak and Ha [108] | [46] |

- | - | - | - | Y | Y | - | - | |||||||||||||||||||

11 | Ah-Sha, Sanders, and Saiidi [36] | [47] |

- | - | - | - | Y | - | - | - | |||||||||||||||||||

Legends: A: Concrete constituent materials, B: Concrete mix design, C: Structural design, D: Curing, E: Placing sequence and environment conditions, F: Vibration, G: Cooling method, and H: Formwork.

References

- ACPA. Concrete Crack and Partial-Depth Spall Repair Manual for Airfields; American Concrete Pavement Association: Rosemont, IL, USA, 2003.

- Bentz, D.P. A Review of Early-Age Properties of Cement-Based Materials. Cem. Concr. Res. 2008, 38, 196–204.

- Stark, J. Recent Advances in the Field of Cement Hydration and Microstructure Analysis. Cem. Concr. Res. 2011, 41, 666–678.

- Kim, J.H.; Ferron, R.P.; Shah, S.P. Fresh Concrete and Its Significance for Sustainability. J. Sustain. Cem.-Based Mater. 2012, 1, 16–23.

- Kovler, K.; Roussel, N. Properties of Fresh and Hardened Concrete. Cem. Concr. Res. 2011, 41, 775–792.

- Nehdi, M.; Soliman, A. Early-age Properties of Concrete: Overview of Fundamental Concepts and State-of-the Art Research. Proc. Inst. Civ. Eng. Constr. Mater. 2011, 164, 57–77.

- Reinhardt, H.W. Characterization of Fresh and Early Age Concrete Using NDT. In Nondestructive Testing of Materials and Structures; Büyüköztürk, O., Taşdemir, M.A., Güneş, O., Akkaya, Y., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 2013; pp. 407–421. ISBN 978-94-007-0723-8.

- Mihashi, H.; Leite, J.P.D.B. State-of-the-Art Report on Control of Cracking in Early Age Concrete. J. Adv. Concr. Technol. 2004, 2, 141–154.

- Emborg, M.; Bernander, S. Assessment of Risk of Thermal Cracking in Hardening Concrete. J. Struct. Eng. 1994, 120, 2893–2912.

- Klemczak, B.; Knoppik-Wróbel, A. Early Age Thermal and Shrinkage Cracks in Concrete Structures–Description of The Problem. Archit.-Civ. Eng.-Environ. 2011, 4, 35–48.

- Holt, E.E. Early Age Autogenous Shrinkage of Concrete; Technical Research Centre of Finland: Espoo, Finland, 2001; Volume 446, ISBN 951-38-5870-7.

- Holt, E.; Leivo, M. Cracking Risks Associated with Early Age Shrinkage. Cem. Conc. Compos. 2004, 26, 521–530.

- ACI Committee 224. Causes, Evaluation, and Repair of Cracks in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2007; ISBN 9995899051.

- Issa, M.A. Investigation of Cracking in Concrete Bridge Decks at Early Ages. J. Bridge Eng. 1999, 4, 116–124.

- Hiller, J.E.; Roesler, J.R. Determination of Critical Concrete Pavement Fatigue Damage Locations Using Influence Lines. J. Transp. Eng. 2005, 131, 599–607.

- Bamforth, P.B. Early-Age Thermal Crack Control in Concrete; Construction Industry Research and Information Association: London, UK, 2007; p. 112. ISBN 978-0860176602.

- Sule, M.; van Breugel, K. The Effect of Reinforcement on Early-Age Cracking due to Autogenous Shrinkage and Thermal Effects. Cem. Concr. Compos. 2004, 26, 581–587.

- Jensen, O.M.; Hansen, P.F. Influence of Temperature on Autogenous Deformation and Relative Humidity Change in Hardening Cement Paste. Cem. Concr. Res. 1999, 29, 567–575.

- Meagher, T.; Shanahan, N.; Buidens, D.; Riding, K.A.; Zayed, A. Effects of Chloride and Chloride-Free Accelerators Combined with Typical Admixtures on the Early-Age Cracking Risk of Concrete Repair Slabs. Constr. Build. Mater. 2015, 94, 270–279.

- Perumal, V. Early-Age Thermal Stress Analysis of Concrete. Master’s Thesis, National University of Singapore, Singapore, 2009.

- Harrison, T. Early-Age Thermal Crack Control in Concrete; CIRIA: London, UK, 1981; ISBN 0860171663.

- Khan, A.A. Concrete Properties and Thermal Stress Analysis of Members at Early Ages. Ph.D. Thesis, McGill University Canada, Montreal, QC, Canada, 1995.

- Branch, J.; Hannant, D.; Mulheron, M. Factors Affecting the Plastic Shrinkage Cracking of High-Strength Concrete. Mag. Concr. Res. 2002, 54, 347–354.

- Holt, E. Contribution of Mixture Design to Chemical and Autogenous Shrinkage of Concrete at Early Ages. Cem. Concr. Res. 2005, 35, 464–472.

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006; ISBN 978-0071797870.

- Abel, J.; Hover, K. Effect of Water/Cement Ratio on the Early Age Tensile Strength of Concrete. J. Transp. Res. Board 1998, 1610, 33–38.

- Nguyen, D.; Dao, V. Tensile Properties of Early-Age Concrete. In Proceedings of the 27th Biennial National Conference of the Concrete Institute of Australia in conjunction with the 69th RILEM Week, Melbourne, Australia, 31 August–2 September 2015; pp. 1314–1324.

- Krauss, P.D.; Rogalla, E.A. Transverse Cracking in Newly Constructed Bridge Decks; National Academy Press: Washington, DC, USA, 1996; ISBN 0309057167.

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S.; Ulm, F.-J. Microprestress-Solidification Theory for Concrete Creep. I: Aging and Drying Effects. J. Eng. Mech. 1997, 123, 1188–1194.

- Bažant, Z.P.; Cusatis, G.; Cedolin, L. Temperature Effect on Concrete Creep Modeled by Microprestress-Solidification Theory. J. Eng. Mech. 2004, 130, 691–699.

- Pickett, G. The Effect of Change in Moisture-Content on the Creep of Concrete under a Sustained Load. J. Proc. 1942, 333–356.

- Bažant, Z.P.; Xi, Y. Drying Creep of Concrete: Constitutive Model and New Experiments Separating Its Mechanisms. Mater. Struct. 1994, 27, 3–14.

- De Schutter, G.; Taerwe, L. Specific Heat and Thermal Diffusivity of Hardening Concrete. Mag. Concr. Res. 1995, 47, 203–208.

- Van Breugel, K. Self-Healing Material Concepts as Solution for Aging Infrastructure. In Proceedings of the 37th Conference on Our World in Concrete & Structures, Singapore, 29–31 August 2012; pp. 1051–1057.

- Silfwerbrand, J. The Influence of Traffic-Induced Vibrations on the Bond between Old and New Concrete; Department of Structural Mechanics and Engineering, Royal Institute of Technology: Stockholm, Sweden, 1992.

- De Schutter, G. Durability of Marine Concrete Structures Damaged by Early Age Thermal Cracking. In Proceedings of the International RILEM Workshop on Life Prediction and Aging Management of Concrete Structures, Cannes, France, 16–17 October 2000; pp. 185–194.

- Ba, H.; Su, A.; Gao, X.; Tao, Q. Cracking Tendency of Restrained Concrete at Early Ages. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2008, 23, 263–267.

- Huang, H.; Ye, G.; Qian, C.; Schlangen, E. Self-healing in Cementitious Materials: Materials, Methods and Service Conditions. Mater. Des. 2016, 92, 499–511.

- Kumar, S.V.; GangaRao, H.V. Fatigue Response of Concrete Decks Reinforced with FRP Rebars. J. Struct. Eng. 1998, 124, 11–16.

- De Borst, R.; Van den Boogaard, A. Finite-Element Modeling of Deformation and Cracking in Early-Age Concrete. J. Eng. Mech. 1994, 120, 2519–2534.

- Shing, P.B.; Abu-Hejleh, N. Cracking in Bridge Decks: Causes and Mitigation; Colorado Department of Transportation: Denver, CO, USA, 1999.

- Babaei, K.; Purvis, R.L. Prevention of Cracks in Concrete Bridge Decks; Pennsylvania Department of Transportation: Harrisburg, PA, USA, 1995.

- French, C.E.; Eppers, L.; Le, Q.; Hajjar, J. Transverse Cracking in Bridge Decks: Field Study; Minnesota Department of Transportation: Saint Paul, MN, USA, 1999.

- Dippenaar, J.D. The Tensile Properties of Early Age Concrete and The Experimental Apparatus Required for Its Determination. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2015.

- Combrinck, R.; Boshoff, W. Influence of Restraint on the Early Age Cracking of Concrete with and without Fibres. In Proceedings of the 8th RILEM International Symposium on Fiber Reinforced Concrete: Challenges and Opportunities (BEFIB 2012), Guimarães, Portugal, 19–21 September 2012; Barros, J.A.O., Ed.; RILEM Publications SARL: Guimarães, Portugal, 2012; pp. 86–99.

- Kwak, H.-G.; Ha, S.-J. Plastic Shrinkage Cracking in Concrete Slabs. Part II: Numerical Experiment and Prediction of Occurrence. Mag. Concr. Res. 2006, 58, 517–532.

- Ah-Sha, H.H.; Sanders, D.H.; Saiidi, M.S. Early Age Shrinkage and Cracking of Nevada Concrete Bridge Decks; National Technical Information Service: Springfield, VA, USA, 2001.