In the late twentieth century, the only cost-effective opportunity for waste removal cost at least several thousand dollars, but nowadays, a lot of improvement has occurred. The biomass and waste generation problems attracted concerned authorities to identify and provide environmentally friendly sustainable solutions that possess environmental and economic benefits. The present study emphasises the valorisation of biomass and waste produced by domestic and industrial sectors.

- waste to value

- bio-residues

1. Introduction

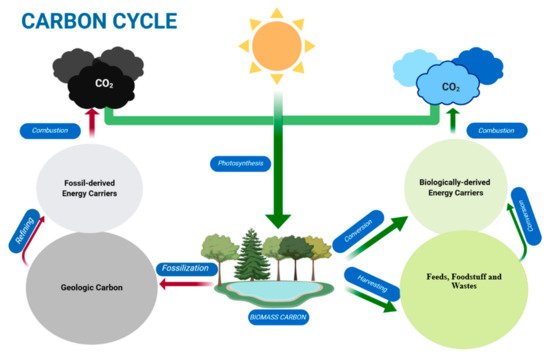

2 emissions are reduced. Biomass is an attractive feedstock due to several reasons. Firstly, it reduces greenhouse gas (GHG) emissions and is a new source, which will be established in the future. Lastly, it has the benefit of providing economic benefits to society. However, biomass possesses an adverse effect when utilised in conventional stoves. It emits polycyclic aromatic hydrocarbons (PAHs). PAHs are composed of more than 100 chemicals that include furans (which are toxic to health either inhaled or ingested), volatile organic compounds, and heavy metals [2][3]. Biomass consists of diverse organic materials which contain chemical energy. Green plants generate this chemical energy by photosynthesis, where sunlight serves as an energy source [4]. Figure 1 illustrates the derived carriers of the resultant energy. These carriers utilise biomass and fix CO

2 (i.e., photosynthesis) with a concurrent transformation of solar energy into chemical energy.

Figure 1. Model of carbon cycle illustrating how energy carriers are derived from biomass. Biomass carbon is generated via photosynthesis upon fixing atmospheric CO

Figure 1. Model of carbon cycle illustrating how energy carriers are derived from biomass. Biomass carbon is generated via photosynthesis upon fixing atmospheric CO

2

2 build-up. Conversely, biomass decomposed over several epochs (geologic carbon) can also be partially recovered and utilised. However, the later process is slow, non-sustainable, and potentially harmful to the natural environment.

Biomass, if not used for alternate energy sources, may lead to severe hazards to the environment in the form of discarded materials like waste, which has become a striking and crucial problem of civilised human societies [5][6]. In the US, people throw away the waste/garbage equivalent to their body weight on a monthly basis where a significant part of discarded material is composted or recycled and/or incinerated or landfilled. Waste production has increased ten-fold because of the affluent and urban population of the world, which will double by 2025. Dealing with waste is one of the most critical issues in developing countries, resulting in increased municipal budgets [7]. Landfills like Laogang (China), Bordo Poniente (Mexico), and Jardim Gramacho (Brazil) are competing for the name of the biggest dump in the world. The urbanisation of the world’s population increases solid-waste generation around the globe. It is hard to predict the expanding socio-economic trends leading towards the 22nd century. We are putting our efforts to avoid the maximum rate of waste production in this century. Our efforts will be in vain until we decrease people’s growth and the rate of consumption material, otherwise, the world will have to bear a growing problem of waste [8].

2. Transformation of Biomass and Waste into Bioproducts

The transformation of biomass into biofuels and chemicals increases worldwide moderate energy sources and reduces global warming [9]. Biomass is a neutral resource of renewable energy and generally burns cleaner than fossil fuels [10][11][12][13]. Different biomass forms are converted into fuels and chemicals, like wood and timber waste, plants in agriculture, industrial waste, sludge, and waste from food processing. In contrast, wood logs can be used directly. Wood waste is easily recycled and used as fertilizer as sawmill residues, slashed from logging and municipal wood waste by most plants and crops [12].

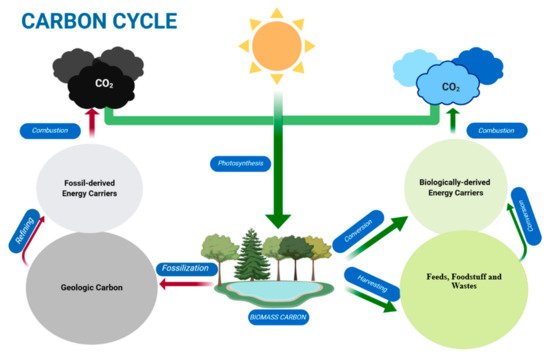

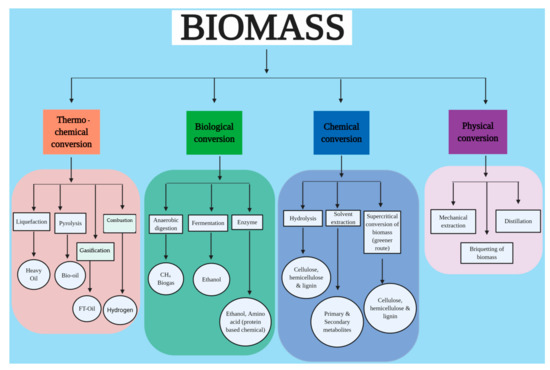

It is possible to use various procedures to transform biomass into energy and other industrially relevant high-interest products (Figure 2) [13][14][15]. Biomass can be converted into fuel, biogas, bioethanol, biodiesel, or changed into syngas [16][17]. Bio-refinery, where several significant processes are integrated and joined with downstream upgrades and cultured separations, will be very attractive to get the most out of feed use and product value [18]. The production of biofuels and chemicals by transforming biomass is becoming popular worldwide to expand energy resources and mitigate global warming. The following characteristics, such as renewable natural sources and carbon-neutral sources, underpin the significance of the biomass. Moreover, resultant fuels acquired from biomass are an important source of sustainable energy because they burn cleanly compared to fossil fuels. Evaluations of the estimated contribution to global energy (i.e., biomass) range from a minimum of 100 EJ/year to a maximum of 400 EJ/year [9]. For example, the total consumption of energy in the USA is around 100 EJ/year and, in 2005, the global commercial consumption of energy was 440 EJ/year. Primary sources of this energy were hydroelectricity, natural gas, oil, coal, and nuclear energy [19]. This means that biomass could contribute between 20% and 90% of world energy demand.

Figure 2. The biomass conversion process and their resulted products of industrial interest.

3. Sources of Waste/Production of Biomass

3.1. Agricultural Aspects

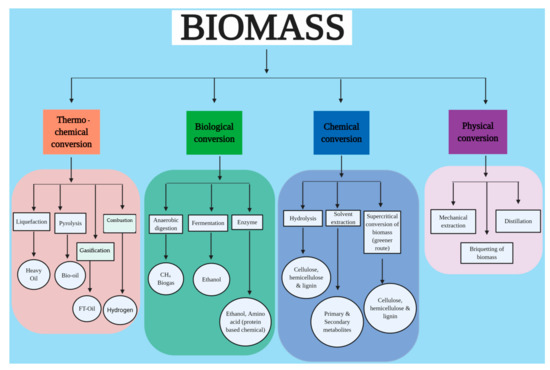

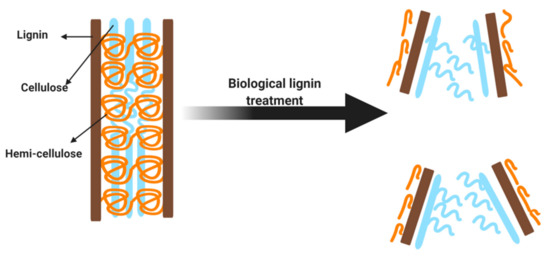

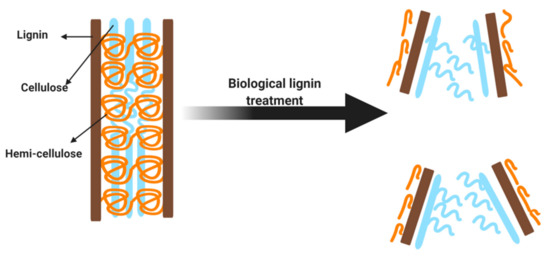

In agricultural production systems, large quantities of harvested crop residues are generated. The cultivation of wheat, rice, vegetables, fruits, and other crops creates substantial amounts of residues essential for the yearly production of biomass. Therefore, biomass produced from agriculture significantly enhances the generation of sustainable energy used in the industry and the domestic processes [15][20][21][22]. Unused biomass from agricultural sources can be split into two categories: (1) parts of the plant kept in the field, (2) loss of plant components owing to harvesting techniques. However, all types of residues could not be used for biomass in the past. Nowadays, such biomass residues can be used for many purposes like biofuels (biogas/bioethanol) or energy production and forage, which contribute significantly to a country’s economic growth [23][24][25]. In horticulture, fruit plants, particularly drupes, have endocarp tissues. A drupe fruit’s endocarp is the hard and uneatable portion of the fruit, whereas the eatable part is mesocarp. The woody biomass of drupe endocarp is the leading lignin source that usually generates 50 percent of the total [26][27][28]. Lignin has a greater energy density than cellulose as a biofuel. Lignin plays an essential role in energy production by using endocarp of fruits in horticulture [29][30][31]. Lignin degradation and the function of the pre-treatment are graphically represented in Figure 3.

Figure 3. Schematic of the role of biological pre-treatment in biomass lignin degradation. The initial step of lignin biodegradation is when the oxidative enzymes induce new functional groups into lignin’s macromolecular structure, making lignin vulnerable to other enzymes’ consequent degradation. The natural form of lignin has numerous different functional groups that could be specifically functionalized.

3.2. Industrial Aspects

Microorganisms can be used for biomass production in industry. Particularly yeast which serves as biocatalysts and used in bakeries, lactic acid (used as starter culture in manufacturing of dairy products), breweries, probiotics, aqua and animal feed production [32][33]. On a large scale, fermentation can be used with economical substrates and products for biomass production. These economical substrates include soya bean meal, sugar cane molasses, and various industries’ wastes [34][35][36]. Solid biomass is preferred to use in the industry. Liquid waste and biogas are also used in industrial applications, but particularly solid biomass is important for the past 7 years. In other countries, 80 percent of the global biomass has significant application in industry. Most of the industry’s biomass is obtained from forests in the United States and mostly black liquor [1]. In Sweden, 41 percent of the industries consumed biomass in 2010. The Finnish timber processing sector accounted for 54 percent of total industrial power consumption in 2010. In particular, wood-based biomass is used by the wood processing sector, which accounted for 45 percent of total industrial power use in 2010.

3.3. Domestic Food Waste and Considerations

Economic growth is facing pivotal problems worldwide due to increased waste products that cause energy loss, damage to the environment and human health, and adversely affect quality of life [37][38]. The European Union’s goal to discover an effective source for the “Recycling Society” can be a better resource to prevent waste generation. Biological waste is the most significant portion of municipal solid waste (MSW), primarily food waste [39][40]. As a result, the rise in the population increased the utilisation of food, and the production of waste (i.e., food waste) is also expected to increase substantially. Food waste is primarily controlled at the EU level by the Waste Framework Directive [41]. Therefore, it is evident that efficient and alternative methods of handling biodegradable waste generated in homes need to be found [36][42][43]. Domestic composting and anaerobic digestion are both familiar, distributed, and compact processes. Still, they fail many times and cause more problems than fixing them, such as odours and greenhouse gas (GHG) emissions [44][45]. Approximately 23% of the 4.8 million tons of municipal solid waste produced yearly are reused (mostly waste from packaging), however, the remaining 77% are disposed of without proper treatment. In the shortage of new innovative projects, the proportion of produced waste is expected to increase continuously with severe environmental issues in the foreseeable future.

4. Characteristics and Composition of Biomass

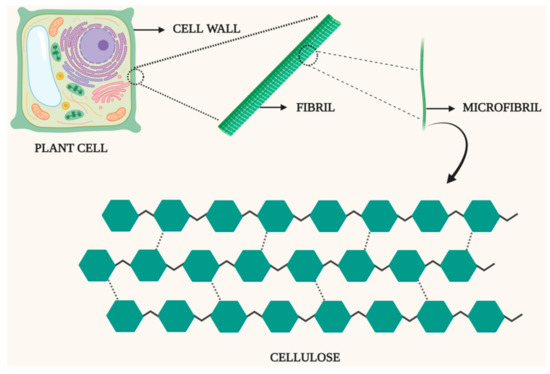

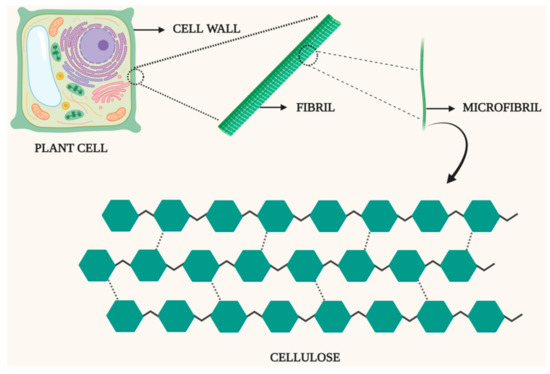

There is a broad range of produced biomass, thereby there are significant variations in the composition of industrial or domestically generated biomass. Cellulose, hemicelluloses, lignin, starch, and proteins are some of the main elements [46][47][48][49]. Cellulose: A polysaccharide where β-glucoside bonds evenly connect

2. Transformation of Biomass and Waste into Bioproducts

3. Sources of Waste/Production of Biomass

3.1. Agricultural Aspects

3.2. Industrial Aspects

3.3. Domestic Food Waste and Considerations

4. Characteristics and Composition of Biomass

D-glucose. Organic compound cellulose is an important component in the primary cell wall of the plants. It supports the structural assembly of the cell wall [50][51]. Cellulose assembles into unbranched and long micro fibrils that provide supports. Several bacterial species secrete cellulose to facilitate biofilm formation [52]. Its molecular formula is (C

6

10

5

n

D

D

D-mannose. Hemicellulose possesses a lower molecular weight than cellulose and has a less specialised structure than cellulose [53][54][55]. Hemicellulose is known as a second main component of the biomass from the plant. The industrial use of hemicellulose has expanded with time and the integration of modern techniques into the existing methods. Lignin: A compound whose constituent units, phenyl-propane, and its derivatives are 3-dimensionally linked. Cellulose, hemicelluloses, and lignin are widely discovered in many types of biomass [55]. A network of irregular polymers that consists of cellulose and hemicellulose fibres is recognised as lignin. The said network provides structural support to the plants. The irregular formation and complex structural identity make its exploitation challenging in the industry sector. The complex structure is impervious to most of the chemical and hydrolysis treatment methods. Plant biomass chemical composition differs between species. Generally, crops are comprised of about 25 percent lignin and 75 percent carbohydrates. The percentage of carbohydrates is composed of many sugar molecules in the form of polymers. There are two distinctive categories: cellulose and hemicellulose. The moisture content is considered the most significant property of biomass feedstock. The moisture content negatively affects the fuel’s energy when used for incineration and other processes (e.g., thermo-chemical) [13][14]. Dry biomass has a higher heating value because it utilises little energy to evaporate any moisture. There is a direct association between the energy ratio and humidity, an increase in humidity entails less energy [14][56][57]. Biomass materials contain a certain amount of humidity, from 10% for a dried straw to over 50% for new cut timber [58]. Figure 4. Schematic illustration of plant cellulose.Carbon: Biomass carbon content is around 45%, while coal has 60% or higher. A greater carbon content results in a higher heating value [58]. Hydrogen: Biomass hydrogen content is about 6% [59]. A greater content of hydrogen results in a greater value of heating. Nitrogen: Biomass nitrogen content ranges from 0.2 percent to over 1 percent [59]. Fuel-bound nitrogen is responsible for most emissions from the biomass combustion of nitrogen oxide (NOx). Lower nitrogen content should result in reduced emissions of NOx in the fuel (e.g., diesel). Sulphur: Biomass fuels have a sulphur content of less than 0.2 percent, with a few exceptions as elevated as 0.5–0.7 percent. Coals range from 0.5 percent to 0.75 percent [58]. Chloride: Biomass combustion with elevated levels of chloride may result in enhanced fouling of ash. The boiler tubes’ high chloride content results in hydrochloric acid formation, leading to corrosion resulting in pipe failure and water leakage in the boiler.

Figure 4. Schematic illustration of plant cellulose.Carbon: Biomass carbon content is around 45%, while coal has 60% or higher. A greater carbon content results in a higher heating value [58]. Hydrogen: Biomass hydrogen content is about 6% [59]. A greater content of hydrogen results in a greater value of heating. Nitrogen: Biomass nitrogen content ranges from 0.2 percent to over 1 percent [59]. Fuel-bound nitrogen is responsible for most emissions from the biomass combustion of nitrogen oxide (NOx). Lower nitrogen content should result in reduced emissions of NOx in the fuel (e.g., diesel). Sulphur: Biomass fuels have a sulphur content of less than 0.2 percent, with a few exceptions as elevated as 0.5–0.7 percent. Coals range from 0.5 percent to 0.75 percent [58]. Chloride: Biomass combustion with elevated levels of chloride may result in enhanced fouling of ash. The boiler tubes’ high chloride content results in hydrochloric acid formation, leading to corrosion resulting in pipe failure and water leakage in the boiler.

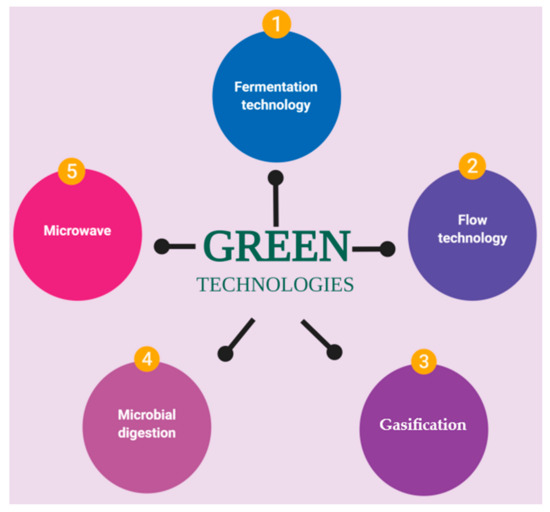

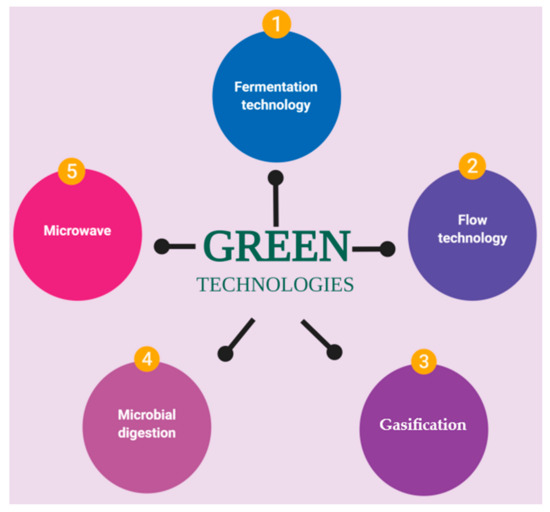

5. Green Technologies for Biomass and Waste Valorisation

Waste valorisation is a process that converts waste materials into valuable products like chemicals, fuels, and materials. The waste valorisation concept relies on the thought; the waste products contain unused polymeric products that can convert into energy and different forms of chemicals [60][61]. These types of products make the waste residues a valuable source that could not be left unharnessed. This idea can be applied to artificial waste or bio-waste, and it will become the basis of the waste-to-energy approach. Waste valorisation is not magnificent because of the deletion of natural resources, but it is much-needed technology for waste management and renewable energy production and also produces high values of nano-bioplastic products and ethanol, which are cost-effective and sustainable [62]. Figure 5 illustrates a graphical representation of green technologies applied for biomass and waste valorisation. Figure 5. Green technologies applied for biomass and waste valorisation.In this context, waste-to-value (WtV) and, more specifically, waste-to-energy (WtE) have noteworthy potential that should be considered in future considerations prior to the development and implementation of tools like Life Cycle Assessment (LCA), Ecological Indicators (EI), and/or Ecological Footprint Analysis (EFA) [63][64]. Using WtV and/or WtE thematic concepts with a zero-waste approach, fine chemicals and/or valuable energy are produced from waste residues using processes, such as green processing technologies, using organic and inorganic chemicals, genetically engineered organisms, and others. Other technological WtE solutions, such as anaerobic digestion, incineration, gasification, pyrolysis, landfill waste, and agro-industrial waste biomass residues to bioenergy, are considered valuable drivers to optimise the waste supply chain management to strengthens the modern WtE facilities [64]. Some of the technological and in practice strategies are taken as model examples and thus are discussed in the following subsections.

Figure 5. Green technologies applied for biomass and waste valorisation.In this context, waste-to-value (WtV) and, more specifically, waste-to-energy (WtE) have noteworthy potential that should be considered in future considerations prior to the development and implementation of tools like Life Cycle Assessment (LCA), Ecological Indicators (EI), and/or Ecological Footprint Analysis (EFA) [63][64]. Using WtV and/or WtE thematic concepts with a zero-waste approach, fine chemicals and/or valuable energy are produced from waste residues using processes, such as green processing technologies, using organic and inorganic chemicals, genetically engineered organisms, and others. Other technological WtE solutions, such as anaerobic digestion, incineration, gasification, pyrolysis, landfill waste, and agro-industrial waste biomass residues to bioenergy, are considered valuable drivers to optimise the waste supply chain management to strengthens the modern WtE facilities [64]. Some of the technological and in practice strategies are taken as model examples and thus are discussed in the following subsections.

5.1. Fermentation Technology

On a commercial scale, fermentation is used in different countries to make ethanol. The synthesis of ethanol is performed using sugar crops (i.e., sugar beet) and starch crops (i.e., wheat). Starch combines with enzymes to convert sugars, sugars are transformed with yeast into ethanol [65][66]. Distillation of the ethanol is an energy-intensive phase and produces approximately 450 mL of ethanol per ton of dry maize. The strong residues used as a bovine feed form the fermentation method. For boilers or gasification, it can be used as a bagasse fuel. The more complex biomass is converting lingo-cellulosic biomass because long-chain polysaccharide molecules are present and require acid before the sugars are fermented to ethanol [14][67].

5.2. Flow Technology

When considering fresh procedures, the elevated amount of biomass’s physical and chemical complexity is a major problem. One prospective key to overcoming the difficulty of biomass includes converting it into simpler fractions that are easier to handle in downstream procedures. In a single petroleum industry facility, bio-refinery is the source of chemicals, energy, and fuel production [20][68][69]. These significant biomass derivatives (so-called platform molecules or construction blocks) are comparatively easy compounds with various functionalities in their structures that are appropriate for a range of useful chemical compound transformations [70]. Continuous flow processing enables the response conditions to be better controlled. This is beneficial when dealing with extremely reactive feedstock such as biomass-derived feedstock. Flow processing also promotes scaling up, considering that many biomass procedures are still on the laboratory scale, which is a significant point. Therefore, the development of flow technologies in the near future will contribute to the marketing of biomass technologies [71][72]. Since the chemical structure of biomass feedstock is usually very distinct from that of the final products, various processing steps are typically needed in such transformations, negatively influencing the process economy. Using stream processing techniques enables chemical processes to be intensified, thereby contributing considerably to technology simplification [73].

5.3. Gasification

The gasification process is the partial oxidation of organic/natural products producing syngas at a constant temperature (i.e., 500–1800 °C). The gasification method appears as a char that responds to hydrogen and carbon monoxide with water vapour and CO

5. Green Technologies for Biomass and Waste Valorisation

5.1. Fermentation Technology

5.2. Flow Technology

5.3. Gasification

2

2, hydrogen, and carbon monoxide become stable very fast at the given temperature in a gasifier [74][75], to produce heat or electricity, which is used as fuel through syngas. The gasification agents, which are the combination of carbon dioxide, oxygen, and steam, are used in a gasifier. The gasification process can be used as a cleaner and is a more logical technology than combustion [76]. Before its commercial organisation, biomass gasification must control some barriers. The main application of gasification is to remove tars, problems related to the production and pre-treatment of biomass feedstock, and the effect of biomass properties must be clearly understood [77]. Supercritical gasification of water in wet biomass is an advanced technology nowadays and seeks the attention of all big countries like the USA, Germany, Netherlands, and Japan [78]. Super Critical Water Gasification (SCWG) has the advantage that this technique does not require any dry method for the wet biomass before subjecting to gasification [79].

5.4. Microbial Digestion

Microbial digestion of organic matter through metabolic pathways leads to CO

5.4. Microbial Digestion

2 and methane formation [80][81]. Biogas is called a combination of coal dioxide and methane [82][83][84]. Anaerobic digestion gives renewable energy production possibilities and a higher quality of agro-residue-waste treatment. Recently, this technology became an appealing technique for biodegrading strong municipal waste organic fractions in Europe [85]. The method takes place in well-designed ships called the anaerobic bioreactor/anaerobic digester. A biogas plant includes the entire feedstock, digester, biogas holder, and digestive tank system.

5.5. Microwave Technology

Biomass feedstock is traditionally heated with pressure (i.e., ~60–100 bar). The heating activity is carried out between 180 and 200 °C in the closed vessel where oxygen (O

5.5. Microwave Technology

2) is not present for at least 12 h [86][87][88]. Through conduction and convection, heat transfer is accomplished through temperature gradients. Potential disadvantages of standard heating techniques include extended periods of residence and surface heating [89]. The microwave hydrothermal carbonization method was suggested to solve these disadvantages. Over the years, microwave technology has been used to substitute standard heating with carbohydrate [90][91] digestion, sterilisation [92], synthesis [93], and recently the dry pyrolysis method of the biomass feedstock to produce char and gas [56][94][95]. Besides the benefit of shorter periods of residence, microwave heating provides fast, selective, and volumetric heating, promoting fresh response paths and appropriate conditions for new products [96][97].In conclusion, the operational considerations are met by the accurate and well-regulated nature of microwave technology and its prospective portable processing capability (owing to the comparatively small size of a reactor) [98]. The suitability of microwave heating to process human bio-wastes arises from their comparatively elevated water molecule, which is easily coupled with electromagnetic fields that cause “microwave dielectric heating” [99][100][101].