Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Federico Danzi and Version 2 by Karina Chen.

Structural power composites are a new class of materials/structural configurations capable of storing electric energy and, at the same time, carrying mechanical loads.

They stand out as a possible solution to the demands of the modern transportation system of more efficient and eco-friendly vehicles.

- structural batteries

- solid electrolyte

- Composite materials

- Multifunctional materials

Lithium-ion based batteries have already demonstrated an unparalleled combination of high energy and power density, quick charge and long-life that made this technology the present choice for electric vehicles, portable electronic devices, and many other applications. In recent years, the research in this field moved companies and governments to invest an extensive amount of money for developing more and more efficient and safer types of batteries. Yet looking at the future, advanced and green energy storage components are nowadays the main drivers for all modern transportation systems. From electric vehicles (EVs) to unmanned aerial vehicles (UAVs), from high altitude satellites to electric airplanes, the target for the next years is the development of lighter, greener, and more sustainable vehicles. A great opportunity to achieve all of these goals at the same time is offered by the use of multifunctional systems and materials

. As described by Thomas et al.

[5]

, multifunctional systems and materials correspond to all the structural configurations and materials that are capable of fulfilling more than one primary function simultaneously. In this perspective, the idea of manufacturing structural composite batteries capable of storing electric energy and, at the same time, carrying mechanical loads is one of the most appealing applications of multifunctionality.

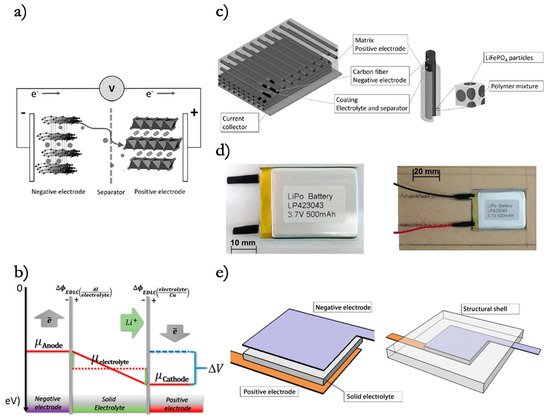

Two main approaches have already been investigated. The first one focuses on adding functionalities to structures by embedding off-the-shelf thin batteries into composite laminates or sandwich panels

. The other one aims to realize multifunctional composite materials where the reinforcement elements act as the electrodes while the polymeric matrix works as the electrolyte and as a structural binder for the fibers

. An alternative path could come from the use of all-solid-state electrolytes.

shows the basic conceptualization of these alternatives, while a schematic representation of the physical principles and the constructive solutions described in this paper is shown in

.

Figure 1. Structural power composites as an alternative to battery pack dead weight.

Figure 2. Structural power composite principles: (a) Lithium-ion battery [20] and (b) Solid state battery [21]. Structural power composite applications: (c) Multifunctional material with structural battery electrolyte [20], (d) Multifunctional systems with market available lithium-ion batteries embedding [10] and(e) All-solid-state structural battery.

The embedded cell idea emerged from the necessity of optimizing the volume, more than the weight, of a composite structure by embedding electrical power elements without compromising their mechanical performance. The bonding process, anyway, does not result in a remarkable overall improvement due to the fact that the battery elements, as they are, are bearing no load, hence their mass is not contributing at all to the structural performance of the final product. The other concept of monolithic multifunctional materials, instead, comes from the consideration that high-performance composites and modern lithium-ion batteries have several features in common. First, the fact that carbon fibers, commonly used in high-performance composites for their high specific stiffness and strength, also exhibit remarkable electrochemical properties such as good electrical conductivity and high lithium-ion intercalation in the case of the graphite carbon allotrope. In a second development, the layered configuration that characterizes both modern composites and state-of-the-art lithium-ion batteries could be exploited for a synergistic design. Moreover, the well-known wide range of composites processing techniques enables great freedom in the design of innovative configurations suitable also for the structural batteries.

References

- Ferreira, A.D.B.; Nóvoa, P.R.; Marques, A.T. Multifunctional Material Systems: A state-of-the-art review. Compos. Struct. 2016, 151, 3–35.

- González, C.; Vilatela, J.; Molina-Aldareguía, J.; Lopes, C.; Llorca, J. Structural composites for multifunctional applications: Current challenges and future trends. Prog. Mater. Sci. 2017, 89, 194–251.

- Yang, H. A Review of Structural Batteries Implementations and Applications. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; pp. 223–228.

- Asp, L.E.; Greenhalgh, E.S. Multifunctional Structural Battery and Supercapacitor Composites. In Multifunctionality of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 619–661.

- Thomas, J.; Qidwai, S.; Pogue, W.; Pham, G. Multifunctional structure-battery composites for marine systems. J. Compos. Mater. 2012, 47, 5–26.

- Pereira, T.; Guo, Z.; Nieh, S.; Arias, J.L.; Hahn, H.T. Energy Storage Structural Composites: A Review. J. Compos. Mater. 2009, 43, 549–560.

- Roberts, S.C.; Aglietti, G.S. Structural performance of a multifunctional spacecraft structure based on plastic lithium-ion batteries. Acta Astronaut. 2010, 67, 424–439.

- Galos, J.; Khatibi, A.A.; Mouritz, A.P. Vibration and acoustic properties of composites with embedded lithium-ion polymer batteries. Compos. Struct. 2019, 220, 677–686.

- Attar, P.; Galos, J.; Best, A.; Mouritz, A. Compression properties of multifunctional composite structures with embedded lithi-um-ion polymer batteries. Compos. Struct. 2020, 237, 111937.

- Galos, J.; Best, A.; Mouritz, A. Multifunctional sandwich composites containing embedded lithium-ion polymer batteries under bending loads. Mater. Des. 2020, 185, 108228.

- Galos, J.; Fredriksson, C.; Das, R. Multifunctional sandwich panel design with lithium-ion polymer batteries. J. Sandw. Struct. Mater. 2020, 1099636220946554.

- Pattarakunnan, K.; Galos, J.; Das, R.; Mouritz, A. Tensile properties of multifunctional composites embedded with lithium-ion polymer batteries. Compos. Appl. Sci. Manuf. 2020, 136, 105966.

- Asp, L.E.; Greenhalgh, E.S. Structural power composites. Compos. Sci. Technol. 2014, 101, 41–61.

- Asp, L.E.; Johansson, M.K.; Lindbergh, G.; Xu, J.; Zenkert, D. Structural battery composites: A review. Funct. Compos. Struct. 2019, 1, 42001.

- Ekstedt, S.; Wysocki, M.; Asp, L.E. Structural batteries made from fibre reinforced composites. Plast. Rubber Compos. 2010, 39, 148–150.

- Shirshova, N.; Qian, H.; Shaffer, M.S.; Steinke, J.H.; Greenhalgh, E.S.; Curtis, P.T.; Kucernak, A.; Bismarck, A. Structural composite supercapacitors. Compos. Appl. Sci. Manuf. 2013, 46, 96–107.

- Greenhalgh, E.; Ankersen, J.; Asp, L.; Bismarck, A.; Fontana, Q.; Houllé, M.; Kalinka, G.; Kucernak, A.; Mistry, M.; Nguyen, S.; et al. Mechanical, electrical and microstructural characterisation of multifunctional structural power composites. J. Compos. Mater. 2014, 49, 1823–1834.

- Johannisson, W.; Ihrner, N.; Zenkert, D.; Johansson, M.; Carlstedt, D.; Asp, L.E.; Sieland, F. Multifunctional performance of a carbon fiber UD lamina electrode for structural batteries. Compos. Sci. Technol. 2018, 168, 81–87.

- Schneider, L.M.; Ihrner, N.; Zenkert, D.; Johansson, M. Bicontinuous Electrolytes via Thermally Initiated Polymerization for Structural Lithium Ion Batteries. ACS Appl. Energy Mater. 2019, 2, 4362–4369.

- Xu, J.; Varna, J. Matrix and interface cracking in cross-ply composite structural battery under combined electrochemical and me-chanical loading. Compos. Sci. Technol. 2020, 186, 107891.

- Braga, M.H.; Oliveira, J.E.; Kai, T.; Murchison, A.J.; Bard, A.J.; Goodenough, J.B. Extraordinary Dielectric Properties at Het-erojunctions of Amorphous Ferroelectrics. J. Am. Chem. Soc. 2018, 140, 17968–17976.

More