A range extender is an auxiliary power unit that provides an electric vehicle with additional energy to complement the primary battery in propelling the vehicle.

- electric vehicles

- range extenders

- zinc-air batteries

1. Introduction

A promising alternative to ICE vehicles (ICEVs) is electric vehicles (EVs) [5,6][1][2]. In the past, there was resistance toward electrification of vehicles since ICE vehicles had been optimized in performance and costs while EVs had not. However, as time passes by, and with more research and development effort being put into EVs, vehicle electrification is currently considered an inevitable part of the future. EVs use a motor, powered by a lithium-ion (Li-ion) battery pack, to propel the vehicle [7][3]. Li-ion battery is used due to their long lifespan, high energy density, high power density, and environmental benefits [8,9][4][5]. EVs have lower environmental and health impacts compared to ICEVs because they do not directly release any emissions or pollutants [10][6]. NOx and particulate matters (PMs) are major contributing factors in tail-pipe emissions. From a well-to-wheel standpoint, utilizing a battery EV can reduce PMs by 4 times and NOx by 20 times [11][7]. Therefore, EVs can help prevent climate change and protect public health [12][8]. EVs also play an important role in the development of smart cities in the future [13][9]. However, due to the lack of available charging infrastructure, the long charge time, the high cost of long-ranged EVs, and the limited range on affordable EVs, there exists a range anxiety issue that hinders the expansion of EVs. Range-extended EVs (REEVs) are seen as a potential solution to the limited range and high cost of EVs.

A range extender is an auxiliary power unit (APU) that provides the vehicle with additional energy to complement the primary battery in propelling the vehicle [14][10]. According to the 2012 Amendments to the Zero Emission Vehicle Regulations, a range-extended battery EV should comply, among others, with the following criteria [15][11]:

- The vehicle must have a rated all-electric range of at least 120 km.

- The APU must provide a range less than or equal to the main battery range.

- The APU must not be switched on until the main battery charge has been depleted.

- The vehicle must meet the super ultra-low emission vehicle (SULEV) requirements.

- The APU and its associated fuel must meet the zero evaporative emissions requirements.

Aside from the commonly known range extenders such as internal combustion engines, free-piston linear generators, fuel cells, and micro gas turbines, another type of range extender, zinc-air batteries, has been recently studied with promising results.

2. Zinc-Air Battery as a Range Extender

2.1. Definitions, Mechanisms, and Pros and Cons

Zn-air is a type of metal-air battery that consists of an air cathode and a zinc anode. Zn-air batteries can work as a range extender because they possess high specific energy and good resistance to degradation from aging, allowing them to be an efficient energy storage source for a REEV [64]. A full battery EV requires a large Li-ion battery pack which can be expensive. In a REEV, with a Zn-air battery pack serving as a range extender for longer trips, the Li-ion battery pack can be significantly smaller and only used for daily commutes [64]. The concept of Zn-air batteries was first discovered in 1840, with the first commercial Zn-air battery arriving in the market in 1932 [65]. However, Zn-air batteries are not currently used commercially in EVs [66]. In the Zn-air battery cell, oxygen enters the gas diffusing electrode and is reduced by electrons coming from the anode where zinc is oxidized [67]. Oxygen then reacts with the water and the catalyst, becoming OH

Zn-air is a type of metal-air battery that consists of an air cathode and a zinc anode. Zn-air batteries can work as a range extender because they possess high specific energy and good resistance to degradation from aging, allowing them to be an efficient energy storage source for a REEV [12]. A full battery EV requires a large Li-ion battery pack which can be expensive. In a REEV, with a Zn-air battery pack serving as a range extender for longer trips, the Li-ion battery pack can be significantly smaller and only used for daily commutes [12]. The concept of Zn-air batteries was first discovered in 1840, with the first commercial Zn-air battery arriving in the market in 1932 [13]. However, Zn-air batteries are not currently used commercially in EVs [14]. In the Zn-air battery cell, oxygen enters the gas diffusing electrode and is reduced by electrons coming from the anode where zinc is oxidized [15]. Oxygen then reacts with the water and the catalyst, becoming OH

−

ions. The OH

−

ions travel to the anode and react with zinc to form zincate Zn(OH)

42−

and two electrons which are the electrical energy released by the battery. Finally, the zincate decomposes to recycle all of the chemicals, except for oxygen which is supplied by the environment.

Zn-air batteries have several promising upsides. They have a greater specific energy and energy density than Li-ion batteries, theoretically making them a great solution to the range anxiety issue [64]. They are also easier to manufacture and made from more common, less expensive materials, making them more cost-effective. Zn-air batteries prove to be a safer option compared to other batteries used in EVs [68]. Furthermore, they have high energy efficiency and a long lifespan [67]. In comparison to gasoline engines, the Zn-air range extender has lower tailpipe emissions [69]. However, there are some problems that need to be addressed before Zn-air can be used commercially in EVs. CO

Zn-air batteries have several promising upsides. They have a greater specific energy and energy density than Li-ion batteries, theoretically making them a great solution to the range anxiety issue [12]. They are also easier to manufacture and made from more common, less expensive materials, making them more cost-effective. Zn-air batteries prove to be a safer option compared to other batteries used in EVs [16]. Furthermore, they have high energy efficiency and a long lifespan [15]. In comparison to gasoline engines, the Zn-air range extender has lower tailpipe emissions [17]. However, there are some problems that need to be addressed before Zn-air can be used commercially in EVs. CO

2 can alter the pH of the cell’s electrolyte, harming the electrolyte conductivity. The cell can also be dried out if the incoming air does not have the appropriate humidity level [66]. Zn-air batteries suffer heavily from cycle degradation, limiting their cycle life [64]. Some other issues with the Zn-air range extender include the dendrite formation at the zinc anode, further advancements of air cathode materials for commercialization, and the slow process of converting the energy in the cell [65,67].

can alter the pH of the cell’s electrolyte, harming the electrolyte conductivity. The cell can also be dried out if the incoming air does not have the appropriate humidity level [14]. Zn-air batteries suffer heavily from cycle degradation, limiting their cycle life [12]. Some other issues with the Zn-air range extender include the dendrite formation at the zinc anode, further advancements of air cathode materials for commercialization, and the slow process of converting the energy in the cell [13][15].

2.2. Recent Research Developments

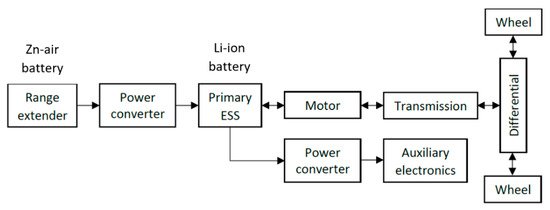

Even though Zn-air batteries are not widely researched for use in EVs, there have been some studies that investigated the feasibility of Zn-air as a range extender. Eckl et al. [70] stated that a range of 100 km per day is suitable for 90% of the daily trips in a year in Germany. The authors used a Zn-air range extender with a peak power of 4 kW and an energy content of 4 kWh to produce some promising results. Cano et al. [68] stated that Zn-air batteries could be the future of EVs. The authors claimed that the potential is greater when combining a Zn-air battery with a Li-ion battery in a dual battery configuration. Catton et al. [69] modeled and compared various powertrains including a REEV with Zn-air, a conventional gasoline-powered vehicle, a fuel cell vehicle, and a REEV with ICE. The comparison criteria included energy consumption, range, life cycle and tailpipe emissions, cost, and consumer acceptance. The results for the Zn-air REEV showed lower tailpipe and greenhouse gas emissions compared to the ICE REEV while being able to maintain a similar driving range. Sherman et al. [66] designed a powertrain consisting of a Li-ion battery supported by a Zn-air battery as a range extender. In the simulation, the vehicle performance compared favorably to a full battery EV with a single Li-ion battery, traveling up to 75 km further in total while having a significantly lower cost. The simulation also demonstrated that the Zn-air battery could reach a ten-year lifespan under certain conditions. Tran et al. [64] expanded on the same powertrain concept and further analyzed the environmental and economic benefits of the Zn-air REEV. Their powertrain architecture proposal is shown in

Even though Zn-air batteries are not widely researched for use in EVs, there have been some studies that investigated the feasibility of Zn-air as a range extender. Eckl et al. [18] stated that a range of 100 km per day is suitable for 90% of the daily trips in a year in Germany. The authors used a Zn-air range extender with a peak power of 4 kW and an energy content of 4 kWh to produce some promising results. Cano et al. [16] stated that Zn-air batteries could be the future of EVs. The authors claimed that the potential is greater when combining a Zn-air battery with a Li-ion battery in a dual battery configuration. Catton et al. [17] modeled and compared various powertrains including a REEV with Zn-air, a conventional gasoline-powered vehicle, a fuel cell vehicle, and a REEV with ICE. The comparison criteria included energy consumption, range, life cycle and tailpipe emissions, cost, and consumer acceptance. The results for the Zn-air REEV showed lower tailpipe and greenhouse gas emissions compared to the ICE REEV while being able to maintain a similar driving range. Sherman et al. [14] designed a powertrain consisting of a Li-ion battery supported by a Zn-air battery as a range extender. In the simulation, the vehicle performance compared favorably to a full battery EV with a single Li-ion battery, traveling up to 75 km further in total while having a significantly lower cost. The simulation also demonstrated that the Zn-air battery could reach a ten-year lifespan under certain conditions. Tran et al. [12] expanded on the same powertrain concept and further analyzed the environmental and economic benefits of the Zn-air REEV. Their powertrain architecture proposal is shown in

Figure 6. It was found that the cost of Zn-air REEVs was 15% lower than that of full battery EVs. Furthermore, the costs associated with air pollution would decrease by 44.8% with the mass rollout of REEVs.

1. It was found that the cost of Zn-air REEVs was 15% lower than that of full battery EVs. Furthermore, the costs associated with air pollution would decrease by 44.8% with the mass rollout of REEVs.

References

- Panchal, S.; Gudlanarva, K.; Tran, M.-K.; Fraser, R.; Fowler, M. High Reynold’s number turbulent model for micro-channel cold plate using reverse engineering approach for water-cooled battery in electric vehicles. Energies 2020, 13, 1638.

- Tran, M.-K.; Mevawala, A.; Panchal, S.; Raahemifar, K.; Fowler, M.; Fraser, R. Effect of integrating the hysteresis component to the equivalent circuit model of Lithium-ion battery for dynamic and non-dynamic applications. J. Energy Storage 2020, 32, 101785.

- Tran, M.-K.; Fowler, M. Sensor fault detection and isolation for degrading lithium-ion batteries in electric vehicles using parameter estimation with recursive least squares. Batteries 2019, 6, 1.

- Mevawalla, A.; Panchal, S.; Tran, M.-K.; Fowler, M.; Fraser, R. Mathematical heat transfer modeling and experimental validation of lithium-ion battery considering: Tab and surface temperature, separator, electrolyte resistance, anode-cathode irreversible and reversible heat. Batteries 2020, 6, 61.

- Mevawalla, A.; Panchal, S.; Tran, M.-K.; Fowler, M.; Fraser, R. One dimensional fast computational partial differential model for heat transfer in lithium-ion batteries. J. Energy Storage 2021, 37, 102471.

- Tran, M.-K.; Fowler, M. A review of Lithium-Ion battery fault diagnostic algorithms: Current progress and future challenges. Algorithms 2020, 13, 62.

- Van Mierlo, J. The World Electric Vehicle Journal, The Open Access Journal for the e-Mobility Scene. World Electr. Veh. J. 2018, 9, 1.

- Tran, M.-K.; Akinsanya, M.; Panchal, S.; Fraser, R.; Fowler, M. Design of a hybrid electric vehicle powertrain for performance optimization considering various powertrain components and configurations. Vehicles 2021, 3, 20–32.

- Lai, C.S.; Jia, Y.; Dong, Z.; Wang, D.; Tao, Y.; Lai, Q.H.; Wong, R.T.K.; Zobaa, A.F.; Wu, R.; Lai, L.L. A review of technical standards for smart cities. Clean Technol. 2020, 2, 290–310.

- Husain, I. Electric and Hybrid Vehicles Design Fundamentals, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011.

- 2014 BMW I3 Electric Car: Why California Set Range Requirements Engine Limits. Available online: (accessed on 22 June 2020).

- Tran, M.-K.; Sherman, S.; Samadani, E.; Vrolyk, R.; Wong, D.; Lowery, M.; Fowler, M. Environmental and economic benefits of a battery electric vehicle powertrain with a zinc-air range extender in the transition to electric vehicles. Vehicles 2020, 2, 398–412.

- Zhang, J.; Zhou, Q.; Tang, Y.; Zhang, L.; Li, Y. Zinc–air batteries: Are they ready for prime time? Chem. Sci. 2019, 10, 8924–8929.

- Sherman, S.B.; Cano, Z.P.; Fowler, M.; Chen, Z. Range-extending Zinc-air battery for electric vehicle. AIMS Energy 2018, 6, 121–145.

- Gilligan, G.E.; Qu, D. Advances for Medium and Large-Scale Energy Storage; Woodhead Publishing: Cambridge, UK, 2015; pp. 441–461.

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279.

- Catton, J.; Wang, C.; Sherman, S.; Fowler, M.; Fraser, R. Extended range electric vehicle powertrain simulation, and comparison with consideration of fuel cell and metal-air battery. SAE Tech. Pap. Ser. 2017, 1.

- Eckl, R.; Burda, P.; Foerg, A.; Finke, H.; Lienkamp, M. Alternative range extender for electric cars—Zinc air batteries. In Conference on Future Automotive Technology; Springer: Fachmedien Wiesbaden, Germany, 2013; pp. 3–18.