Pathogenic microbes are a major source of health and environmental problems, mostly due to their easy proliferation on most surfaces. Currently, new classes of antimicrobial agents are under development to prevent microbial adhesion and biofilm formation. However, they are mostly from synthetic origin and present several disadvantages. The use of natural biopolymers such as cellulose, hemicellulose, and lignin, derived from lignocellulosic materials as antimicrobial agents has a promising potential. Lignocellulosic materials are one of the most abundant natural materials from renewable sources, and they present attractive characteristics, such as low density and biodegradability, are low-cost, high availability, and environmentally friendly.

1. Introduction

The presence of pathogenic microorganisms on the material surfaces can lead to significant healthcare and environmental problems. In recent times, different strategies have been defined to prevent the proliferation and adhesion of microorganisms on medical devices; or materials for food storage, and packaging [1][2]. Moreover, the biofilm formation on the materials surfaces can limit their functionality, leading to critical health related complications [3]. Furthermore, antibiotic-resistant microorganisms have emerged due to the extensive use of antibiotics or biocidal to impair their growth. Thus, it is necessary the development of new drug free materials that could avoid the increase of antibiotic-resistant microorganisms.

The presence of pathogenic microorganisms on the material surfaces can lead to significant healthcare and environmental problems. In recent times, different strategies have been defined to prevent the proliferation and adhesion of microorganisms on medical devices; or materials for food storage, and packaging [1,2]. Moreover, the biofilm formation on the materials surfaces can limit their functionality, leading to critical health related complications [3]. Furthermore, antibiotic-resistant microorganisms have emerged due to the extensive use of antibiotics or biocidal to impair their growth. Thus, it is necessary the development of new drug free materials that could avoid the increase of antibiotic-resistant microorganisms.

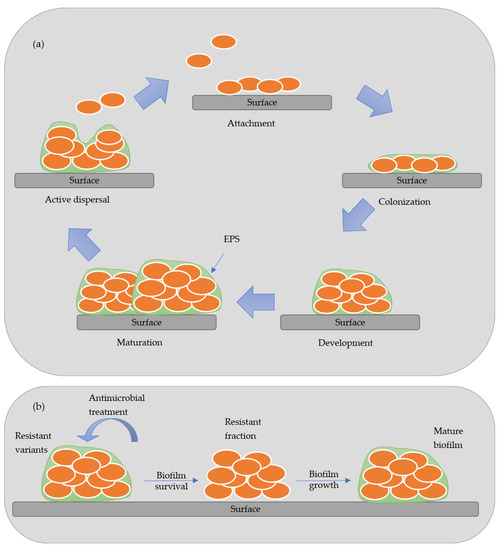

Biofilm is an aggregate of microorganisms that attaches to wet surfaces and multiplies, forming a slimy matrix of extracellular polymeric substances (EPS), thus creating an optimum environment to develop biofilms [4]. The EPS is composed of polysaccharides, proteins, lipids, and nucleic acids, forming a highly hydrated polar mixture that contributes to the three-dimensional structure of the biofilm. The biofilm formation is established in five stages: attachment, colonization, development, maturation, and active dispersal. presents a scheme of the stages of development of biofilm. In the attachment stage, the microorganisms are reversibly absorbed to the biotic or abiotic surface by weak van der Waals forces bonds. In contrast, in the colonization stage, stronger hydrophilic/hydrophobic bonds are established with the surfaces allowing them to proliferated and secret EPS [4][5]. In the maturation stage, a three-dimensional structure contains channels that distribute nutrients and signal molecules in the biofilm. In the last stage, called active dispersion, the cells are detached, either singly or in clumps, and colonize other locations [5]. The formation and development of biofilm depend on many factors, such as the specific bacteria strain, the properties of the material’s surface, the environmental condition (pH, temperature, and nutrients), among others [6]. Biofilms are responsible for biocorrosion, biofouling (accumulating microorganisms in surfaces), and reservoir souring, causing many constraints in different industries [4][7].

presents a scheme of the stages of development of biofilm. In the attachment stage, the microorganisms are reversibly absorbed to the biotic or abiotic surface by weak van der Waals forces bonds. In contrast, in the colonization stage, stronger hydrophilic/hydrophobic bonds are established with the surfaces allowing them to proliferated and secret EPS [4,5]. In the maturation stage, a three-dimensional structure contains channels that distribute nutrients and signal molecules in the biofilm. In the last stage, called active dispersion, the cells are detached, either singly or in clumps, and colonize other locations [5]. The formation and development of biofilm depend on many factors, such as the specific bacteria strain, the properties of the material’s surface, the environmental condition (pH, temperature, and nutrients), among others [6]. Biofilms are responsible for biocorrosion, biofouling (accumulating microorganisms in surfaces), and reservoir souring, causing many constraints in different industries [4,7].

Figure 1.

Model of biofilm formation (

a

) and antimicrobial resistant variants (

b

).

The main mechanisms of antimicrobial action by which antimicrobial compounds affect microorganism are protein synthesis inhibition, cell wall disruption, and nucleic acid inhibition. Antimicrobial compounds can act as suppressing protein synthesis targeting the ribosomal subunits or protein folding, thus inhibiting their active role. They can also disrupt cell walls, causing an increase of permeability of the membrane, leading to the leakage of intracellular constituents. In addition, they are able to inhibit nucleic acid mechanism by suppressing the replication of deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) [8]. Currently, there is no deep knowledge on the mechanism of action against pathogenic microorganisms and the way they will act on surfaces.

The conventional methods to disinfect surfaces uses antimicrobial reagents, such as antibiotics, fungicides, antiviral drugs, and nonpharmaceutical chemicals [2]. Antifouling agents are also employed since they prevent the adsorption on the surface and/or kill/inhibit the growth of microbes, preventing the biofilm formation. Antimicrobial or antibacterial agents are classified as a subclass of antifouling agents, and these materials present biocidal activity [9].

The extensive use of these compounds can cause concern due to their environmental pollution potential, and the development of microbial resistance. The use of antimicrobial agents can be limited, and they cannot achieve high and durable local concentrations on the surface and providing lessen disinfection of the materials surfaces [2]. Therefore, it is important to develop new antimicrobial agents able to prevent microbe’s adhesion and proliferation on materials surfaces, and reduce their negative effects.

The antimicrobial agents are classified into two categories, organic and inorganic. The organic antimicrobial agents include natural biopolymers, for instance, the chitosan, cellulose and lignin, phenols, halogenated compounds, and quaternary ammonium salts [10][11][12]. The inorganic antimicrobial agents comprise, for example, metals, or metals bonded with phosphates, and metal oxides. The most common metallic nanoparticles or metal oxides used are silver, copper, titanium oxide, zinc oxide, magnesium, and calcium oxide [10][11][12]. In the literature, several studies explore the use of different antimicrobial agents by incorporation or applied as coatings on materials surfaces. Among them, the antimicrobial potential of natural derived lignocellulosic compounds remains still unexplored.

The antimicrobial agents are classified into two categories, organic and inorganic. The organic antimicrobial agents include natural biopolymers, for instance, the chitosan, cellulose and lignin, phenols, halogenated compounds, and quaternary ammonium salts [10,11,12]. The inorganic antimicrobial agents comprise, for example, metals, or metals bonded with phosphates, and metal oxides. The most common metallic nanoparticles or metal oxides used are silver, copper, titanium oxide, zinc oxide, magnesium, and calcium oxide [10,11,12]. In the literature, several studies explore the use of different antimicrobial agents by incorporation or applied as coatings on materials surfaces. Among them, the antimicrobial potential of natural derived lignocellulosic compounds remains still unexplored.

2. Lignocellulosic Materials and Main Compounds

Lignocellulosic materials are mainly composed of three biopolymers—cellulose, hemicellulose, and lignin—combined with smaller other components. The ratios between these compounds vary depending on the lignocellulosic material origin [13][14][15][16].

Lignocellulosic materials are mainly composed of three biopolymers—cellulose, hemicellulose, and lignin—combined with smaller other components. The ratios between these compounds vary depending on the lignocellulosic material origin [13,14,15,16].

Recently, the antimicrobial activity of lignocellulosic materials has been explored. In , we present examples of the use of lignocellulosic materials main compounds as antimicrobial materials.

Table 1.

Antimicrobial activity of lignocellulosic compounds.

2.1. Cellulose

Cellulose is the most abundant renewable polymer found in nature, and it is the main constituent of the cell wall. It can be biosynthesized by different organisms, such as plants, amoebae, sea animals, bacteria, and fungi [38].

Cellulose is the most abundant renewable polymer found in nature, and it is the main constituent of the cell wall. It can be biosynthesized by different organisms, such as plants, amoebae, sea animals, bacteria, and fungi [17].

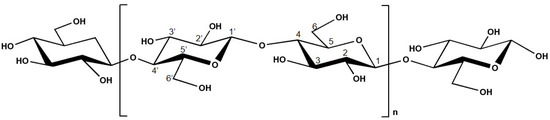

Cellulose is a linear homopolysaccharide with the molecular formula (C6

H10

O5

)n, and it is composed of ß-D-glucopyranose (glucose) moieties linked by β-(1,4) glycosidic bonds [13][14][39][40]. The chemical structure of cellulose is presented in

and it is composed of ß-D-glucopyranose (glucose) moieties linked by β-(1,4) glycosidic bonds [13,14,18,19]. The chemical structure of cellulose is presented in . This compound possesses both well-ordered (crystalline) and disordered (amorphous) regions [13][14][39][41]. The presence of polar oxygen and hydrogen atoms in cellulose allows the formation of intermolecular and intra-molecular bonding [42].

. This compound possesses both well-ordered (crystalline) and disordered (amorphous) regions [13,14,18,20]. The presence of polar oxygen and hydrogen atoms in cellulose allows the formation of intermolecular and intra-molecular bonding [21].

Figure 2.

Chemical structure of cellulose.

The structure of this material is organized as microfibrils, with a diameter between 2 and 20 nm, connect together to form cellulose fibers [38][43].

The structure of this material is organized as microfibrils, with a diameter between 2 and 20 nm, connect together to form cellulose fibers [17,22].

Cellulose is commonly used as a raw material in different industries, such as textile, plastic, wood, cosmetics, and pharmaceutical. Cellulose presents high biocompatibility, biodegradability, non-toxicity, and high hydrophilicity. It also reveals good mechanical properties, thermal and chemical stability, chirality and allows chemical modification [44][45][46]. Cellulose can be applied in a wide range of applications, such as packaging [47][17], biomedical [22][48][49], tissue engineering [19], wound dressing [19][50][23], marine coatings [51], among others. For instance, Onofrei et al. [48], developed films composed of cellulose acetate blended with hydroxypropylcellulose. The film with a higher concentration of cellulose acetate inhibited the growth of

Cellulose is commonly used as a raw material in different industries, such as textile, plastic, wood, cosmetics, and pharmaceutical. Cellulose presents high biocompatibility, biodegradability, non-toxicity, and high hydrophilicity. It also reveals good mechanical properties, thermal and chemical stability, chirality and allows chemical modification [23,24,25]. Cellulose can be applied in a wide range of applications, such as packaging [26,27], biomedical [28,29,30], tissue engineering [31], wound dressing [31,32,33], marine coatings [34], among others. For instance, Onofrei et al. [29], developed films composed of cellulose acetate blended with hydroxypropylcellulose. The film with a higher concentration of cellulose acetate inhibited the growth of Escherichia coli

(E. coli

) and Staphylococcus aureus

(S. aureus

).

In work by Sun et al. [17], cellulose-based membranes were produced with cellulose fibers modified by azidation, followed by epoxidation and grafted with poly(hexamethylene guanidine) (PHMB). The antibacterial activity of the membranes against

In work by Sun et al. [27], cellulose-based membranes were produced with cellulose fibers modified by azidation, followed by epoxidation and grafted with poly(hexamethylene guanidine) (PHMB). The antibacterial activity of the membranes against E. coli

and S. aureus

was investigated after each modification step. Here, membranes with PHMB grafting showed higher antibacterial activity. Furthermore, the antibacterial effect lasted up to 60 days, possibly due to the covalent connection between cellulose and PHMB. It is proposed that the membranes can be used for packaging applications.

Gogoi et al. [51], also modified nanofibrillar cellulose from

Gogoi et al. [34], also modified nanofibrillar cellulose from Colocasia esculenta

with triethanolamine and silver (Ag) nanoparticles to produce epoxy resin composites. The combination of nanofibrillar cellulose with Ag nanoparticles presented improved antibacterial activity against S. aureus

and antifungal activity against Candida albicans

(C. albicans). Guna et al. [22], prepared cellulose fibers from the tulsi stalk and tested the antimicrobial activity against

). Guna et al. [28], prepared cellulose fibers from the tulsi stalk and tested the antimicrobial activity against S. aureus

, E. coli

, Ser. marcescens

, and B. cereus. The work shows a bacteria reduction between 55% and 62% for the nanofibrillar cellulose, and a higher reduction of 90% to 98% for the tulsi stalk fiber. The same trend was also observed by Ilangovan et al. [50], where fibers made from cellulose extracted from

. The work shows a bacteria reduction between 55% and 62% for the nanofibrillar cellulose, and a higher reduction of 90% to 98% for the tulsi stalk fiber. The same trend was also observed by Ilangovan et al. [32], where fibers made from cellulose extracted from Curcuma Longa L. residues. Gabov et al. [18], showed that beads prepared from the combination of cellulose and lignin obtained from birch wood chips presented antimicrobial activity against

. residues. Gabov et al. [35], showed that beads prepared from the combination of cellulose and lignin obtained from birch wood chips presented antimicrobial activity against S. aureus. However, the beads had a high concentration of lignin in the matrix, which could have influenced the antibacterial activity. Yadav et al. [19], prepared bio-sponges from a composite of sodium alginate and cellulose extracted from mango wood scrap combined with bio-extracts from rice water and Giloy extract. The bio-sponges demonstrated good antibacterial activity against Gram-positive,

. However, the beads had a high concentration of lignin in the matrix, which could have influenced the antibacterial activity. Yadav et al. [31], prepared bio-sponges from a composite of sodium alginate and cellulose extracted from mango wood scrap combined with bio-extracts from rice water and Giloy extract. The bio-sponges demonstrated good antibacterial activity against Gram-positive, B. subtilis

, and Gram-negative bacteria, E. coli

, and P. aeruginosa. Oliva et al. [47], isolated the cellulose from paper with concentrated sulfuric acid to produce films that were then treated with zinc oxide and carvacrol essential oil. The films made with cellulose extract showed good antibacterial activity against

. Oliva et al. [26], isolated the cellulose from paper with concentrated sulfuric acid to produce films that were then treated with zinc oxide and carvacrol essential oil. The films made with cellulose extract showed good antibacterial activity against E. coli

and S. aureus

, but the ones made with the essential oil only presented a considerable reduction of the bacteria at higher concentrations (2 wt.%). On the other hand, hydrogels made with cellulose obtained from sugarcane bagasse and combined with zinc oxide nanoparticles present good antimicrobial activity against S. aureus

(bacteria) and T. rubrum (fungi). It was verified that the zinc nanoparticles enhanced the already existing antimicrobial properties of the cellulose. Furthermore, Anagha et al. [21], suggested that the good antimicrobial properties allied with their excellent biocompatibility and low cytotoxic, making these hydrogels good for biomedical applications. Likewise, films made with nanocellulose obtained from oil palm or empty fruit bunches via alkaline treatment and acid hydrolysis combined with zinc oxide showed good antibacterial activity against

(fungi). It was verified that the zinc nanoparticles enhanced the already existing antimicrobial properties of the cellulose. Furthermore, Anagha et al. [37], suggested that the good antimicrobial properties allied with their excellent biocompatibility and low cytotoxic, making these hydrogels good for biomedical applications. Likewise, films made with nanocellulose obtained from oil palm or empty fruit bunches via alkaline treatment and acid hydrolysis combined with zinc oxide showed good antibacterial activity against E. coli

and S. aureus

higher than the activity observed for the zinc oxide particles [52]. Overall, these studies indicate that cellulose derived from different sources demonstrates good antimicrobial activity, thus inferring to the potential of these materials.

The antimicrobial activity of cellulose can be enhanced by the inclusion of inorganic nanoparticles. Li et al. [49], prepared composites by combining titanium dioxide and cellulose that presented higher inhibitory activity against

The antimicrobial activity of cellulose can be enhanced by the inclusion of inorganic nanoparticles. Li et al. [30], prepared composites by combining titanium dioxide and cellulose that presented higher inhibitory activity against E. coli

than S. aureus

. On the other hand, Li et al. [53] also prepared composites with silver chloride and cellulose that demonstrated good antibacterial activity against both E

. coli

and S. aureus

. Furthermore, other studies developed composites made with cellulose, silver nanoparticles, and other commercial polymers such as Polyvinyl alcohol (PVA) [54] and polyurethane (PU) [55], also exhibit good antibacterial properties, suggesting that the addition of commercial polymers have no additional effect on the antibacterial properties of cellulose-based composite.

2.2. Hemicellulose

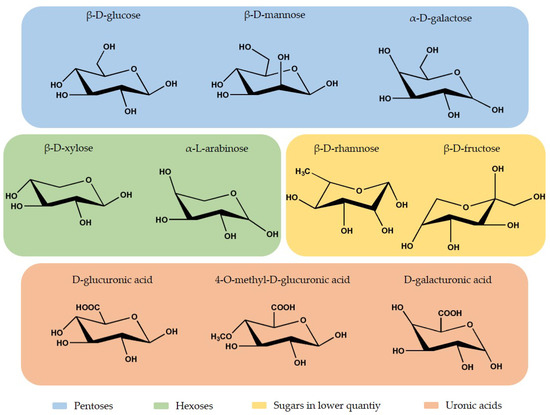

Hemicellulose is a short-chain heteropolysaccharide present in the cell wall, and it corresponds to 15% to 35% of the plant composition, depending on the plant species [56][57][58]. The heteropolymer presents an amorphous branched structure and a lower polymerization degree than cellulose, approximately 200 [58]. Hemicellulose is constituted by different monosaccharide units, hexoses (β-D-glucose, β-D-mannose, and β-D-galactose) and pentoses (β-D-xylose and α-L-arabinose) in higher quantities, and other sugars (fructose and rhamnose) in lower quantities. It also presents uronic acids, like 4-O-methyl-D-glucuronic acid, D-glucuronic acid, D-galacturonic acid, and acetyl groups [40][56][58][59][60]. In

Hemicellulose is a short-chain heteropolysaccharide present in the cell wall, and it corresponds to 15% to 35% of the plant composition, depending on the plant species [56,57,58]. The heteropolymer presents an amorphous branched structure and a lower polymerization degree than cellulose, approximately 200 [58]. Hemicellulose is constituted by different monosaccharide units, hexoses (β-D-glucose, β-D-mannose, and β-D-galactose) and pentoses (β-D-xylose and α-L-arabinose) in higher quantities, and other sugars (fructose and rhamnose) in lower quantities. It also presents uronic acids, like 4-O-methyl-D-glucuronic acid, D-glucuronic acid, D-galacturonic acid, and acetyl groups [19,56,58,59,60]. In , is possible to observe the chemical structure of the monosaccharides units present in hemicellulose.

Figure 3.

Chemical structure of hemicellulose monosaccharides units. Adapted from Wang [58], with permission. Copyrigth 2017, Elsevier.

Thus far, the antimicrobial properties of hemicellulose are less explored when compared to cellulose and lignin. Nevertheless, these polymers offer great antimicrobial potential due to their components. Ahmad et al. [24], the hemicellulose films inhibited the growth of the bacteria

Thus far, the antimicrobial properties of hemicellulose are less explored when compared to cellulose and lignin. Nevertheless, these polymers offer great antimicrobial potential due to their components. Ahmad et al. [38], the hemicellulose films inhibited the growth of the bacteria S. aureus

, E. coli

, and P. aeruginosa. Bouaziz et al. [25], the authors assessed the antibacterial activity of hemicellulose extracted from almond gum against different strains of Gram-positive (

. Bouaziz et al. [39], the authors assessed the antibacterial activity of hemicellulose extracted from almond gum against different strains of Gram-positive (B. subtilis

, B. thuringiensis

, Actinomyces

sp., L. monocytogenes

, and S. aureus

) and Gram-negative bacteria (P. aeruginosa

, Sal. enterica

, Salmonella typhimurium

, and K. pneumoniae

). Here, the hemicellulose presented higher inhibitory activity against B. thuringiensis

, S. enterica

, and P. aeruginosa

and moderated inhibition against Actinomyces

sp., Sal

. thyphimirium

, K. pneumonia

, L. monocytogenes

, and B. subtilis

. However, the hemicellulose antibacterial activity was lower when compared to the positive control. Nevertheless, the work suggests that hemicellulose has a bacteriostatic behavior against the tested bacterial, showing that these materials could be used for food or non-food applications.

The antimicrobial activity of xylan is one of the most studied polymers derived from hemicellulose extract. Fu et al. [61], showed that gels using xylan, gelatin glycerol, and Nicotinamide had good antimicrobial activity against Yeast but lower activity against B. subtilis

and S. aureus.

Moreover, the gels displayed good cytocompatibility to be applied in cosmetic industries. Arellano-Sandoval et al. [62], also produced hydrogels with xylan extracted from bagasse and Poly(N-vinylcaprolactam) that inhibited the bacterial growth of E. coli

, S. aureus

, and P. aeruginosa

.

2.3. Lignin

Since 1977, when Adler [63] described lignin as a highly branched polymer with different functional groups: aliphatic and phenolic hydroxyls, carboxylic, carbonyl, and methoxyl groups, the structure of lignin has significantly been studied and explored. Lignin is one of the most abundant polymers in nature, and it is an amorphous heterogeneous polymer network of phenylpropane units linked together by different, non-regular sequence bonds [13][14][64].

Since 1977, when Adler [63] described lignin as a highly branched polymer with different functional groups: aliphatic and phenolic hydroxyls, carboxylic, carbonyl, and methoxyl groups, the structure of lignin has significantly been studied and explored. Lignin is one of the most abundant polymers in nature, and it is an amorphous heterogeneous polymer network of phenylpropane units linked together by different, non-regular sequence bonds [13,14,64].

The phenylpropane units are originated from three aromatic alcohol precursors, monolignols, p-coumaryl (H-lignin), coniferyl (G-lignin), and sinapyl (S-lignin) alcohols. During the polymerization process, the monolignols units are linked by radical coupling reactions to form the three-dimensional molecular architecture with different bonds, and typically around half of these bonds are β-4-O ether connections [65][66][67][68][69].

The phenylpropane units are originated from three aromatic alcohol precursors, monolignols, p-coumaryl (H-lignin), coniferyl (G-lignin), and sinapyl (S-lignin) alcohols. During the polymerization process, the monolignols units are linked by radical coupling reactions to form the three-dimensional molecular architecture with different bonds, and typically around half of these bonds are β-4-O ether connections [65,66,67,68,69]. presents the chemical structure of lignin with the highlighted bonds between the monolignols.

Lignin behavior is similar to a thermoplastic, presenting decomposition temperature and glass transition temperature that varies with the isolation method, absorbed water, molecular weight, and thermal history [65].

This compound is responsible for binding the lignocellulosic materials’ components, acting as a glue, making it insoluble in water. Lignin presents an essential role in woody plants; it is the major component of the vascular plant’s cell wall and confers rigidity, impermeability, resistance to microbial attack, and oxidative stress. Lignin is mainly used to generate heat and energy but is also used as a food and concrete additive, dispersants, resin, and binding material [13][14][39][64][70].

This compound is responsible for binding the lignocellulosic materials’ components, acting as a glue, making it insoluble in water. Lignin presents an essential role in woody plants; it is the major component of the vascular plant’s cell wall and confers rigidity, impermeability, resistance to microbial attack, and oxidative stress. Lignin is mainly used to generate heat and energy but is also used as a food and concrete additive, dispersants, resin, and binding material [13,14,18,64,70].

The lignin’s antimicrobial activity is influenced by different factors, such as the origin or the extraction method. Several lignin’s extracted with different methods are described in the literature, such as kraft lignin, hydrolysis lignin, organosolv lignin [71]. In the kraft process, the lignocellulosic materials are treated with a solution of sodium hydroxide (NaOH) and sodium hydrosulphide (NaHS) in a temperature range of 150 to 170 °C. After the treatment, the lignin ether bonds are cleaved, and lignin is converted to small fragments, also known as alkali-soluble lignin. For the organosolv method, lignin is dissolved in organic solvents (acetic acid, ketone, and ester), and the organosolv lignin is highly pure, sulphuric-free, and has less modification.

To understand the effect of the origin and the extraction method and how the lignin origin influence in antimicrobial properties, Gordobil et al. [27], used lignin obtained from eucalyptus and spruce by two different methods, kraft, and organosolv. The author used solutions with different lignin concentrations to evaluate antifungal activity against

To understand the effect of the origin and the extraction method and how the lignin origin influence in antimicrobial properties, Gordobil et al. [41], used lignin obtained from eucalyptus and spruce by two different methods, kraft, and organosolv. The author used solutions with different lignin concentrations to evaluate antifungal activity against