The hydrogel is a hydrophilic scaffold composed of covalent and non-covalent polymeric chains bonds, providing a 3D shape environment similar to the native extra-cellular matrix (ECM).

- advanced polymers

- 4D printing

- tissue engineering

- bioresorbable polymers

1. Printable Hydrogels

The hydrogel is a hydrophilic scaffold composed of covalent and non-covalent polymeric chains bonds, providing a 3D shape environment similar to the native extra-cellular matrix (ECM) [1][2][11,12]. Its cross-linked polymers form a porous 3D structure with a high hydration level (they swell up to 99% (w/w) concerning their dry weight) without dissolving, allowing the network to retain proteins and growing factors, as well as providing an environment for gaseous and nutrients exchange, being essential for cell growth and survival [3][4][5][6][7][13,14,15,16,17]. Furthermore, hydrogel 3D scaffolds are beneficial for cell transplantation and tissue engineering [8][9][18,19].

2. Methods used for fabrication of hydrogel scaffolds

The methods used for fabrication of hydrogel scaffolds include solvent casting/leaching, gas foaming/leaching, photo-lithography, electrospinning, and 3D printing [7][17]. Regarding the development of printable hydrogels, the most challenging approach are the physicochemical and mechanical properties, which allow the hydrogel to hold minimally adequate mechanical properties after printing and quick gelation to ensure fidelity of form of the structure to be rebuilt [1][7][8][11,17,18]. The printed shape maintenance depends on the hydrogel’s rheological properties, which is related to its composition (polymer and crosslinking) [7][10][17,20].

Bioresorbability and biodegradability are required to allow scaffold degradation within the implantation site during tissue regeneration [11][21]. Bioresorbable polymers present four degradation stages in biological systems: hydration, strength decrease, loss of mass integrity, and solubilization via phagocytosis [12][22]. The degradation rate relies on polymeric nature, quantity, pH, and environment temperature [13][23]. The resorption of polymers is desirable for biomedical applications once they perform their function, the polymer chain tend to break into small pieces that will be reabsorbed or eliminated from the body [14][15][24,25]. Additionally, the scaffold’s gradual degradation promotes an increase in pore size, allowing a higher rate of cell proliferation and migration [16][26] for subsequent replacement of newly formed tissue.

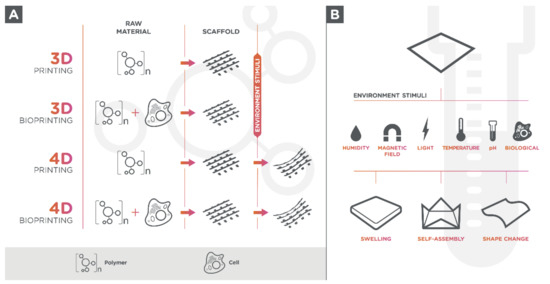

Living cells can be seeded onto 3D-printed hydrogel-scaffold or can be used in a bio ink formulation since hydrogels are biologically active components for 3D printing (bioprinting) (Figure 1A) [17][27]. The use of tissue-specific cells in materials for 3D printing allows the creation of multifaceted and 3D-mimicked tissues, which facilitates cell adhesion due to its cell-containing products, proliferation, and differentiation once they are seeded within the structure [18][19][20][28,29,30].

Bioink selection for 3D bioprinting relies on several requirements, including printability, viscoelasticity, biocompatibility with living cells, tissue regeneration, resorption, shear-thinning, permeability to oxygen, nutrients, and metabolic wastes [21][22][31,32]. Furthermore, other crucial characteristics for bioinks based on hydrogels include the reversibility of gelation (relevant for pre-culture before delivery), fast gelling, and the absence of volume modification during gelling [23][33]. The bioink’s rheological, mechanical, and biological properties will directly impact the functionality of the final printed tissues and organs [24][34].

The most common 3D bioprinting techniques are the inkjet printing, microextrusion, laser-assisted printing (SLS or SLM), and stereolithography (SLA). Inkjet printing (also known as a drop-on-demand printer and direct-writing) is a fast and low-cost method in which drops of bioink liquid are ejected through thermal, electrostatic or piezoelectric actuation onto a substrate to form 3D structures in a discontinuous process [21][25][26][27][31,35,36,37]. In the microextrusion method, the bioink is extruded by a pneumatic or mechanical (piston or screw) dispensing system (needles or nozzle) in a continuous process [28][29][38,39]. In the laser-assisted printing system, a focused laser is pulsed in an absorbing layer (titanium or gold) forcing a drop of the bioink layer to deposit on substrate and form the desired structure [30][31][40,41]. The SLA technique is based on photosensitive polymers (photopolymers), acting as feedstock, which are polymerized through a UV laser light in a layer-by-layer process [32][42].

3. Others

The biopolymers (alginate, hyaluronic acid, collagen, fibrin, fibroin, gelatin, and chitosan), are the most used polymers for the production of printable hydrogels and hydrogel-based bioinks in addition to the synthetic polymers, which include the polyethylene glycol (PEG), the polylactide acid (PLA), the poly(lactic-co-glycolic acid) (PLGA), the polycaprolactone (PCL), and the poloxamers.

Agarose is a linear polysaccharide polymer derived from red algae, and its gelation arises through the formation of intermolecular hydrogen bonds upon cooling [33][34][43,44]. Agarose hydrogels’ viscoelastic properties depend on the source, the purification method employed, the molecular weight, and in the solution concentration [35][45]. These hydrogels can elicit unfavored in vivo reactions [36][46] and are usually used as a fugitive ink or sacrificial material in tissue engineering [37][38][47,48].

Alginate is a water-soluble polysaccharide and consists of a linear (1–4)-linked β-d-mannuronic acid (M blocks) and its C5-epimer α-l-guluronic acid (G blocks) residues [39][49]. The gel’s viscosity and elasticity depend on the alginate source, concentration, and the G block content [40][41][42][50,51,52]. It can be extracted from a brown seaweed or can be synthesized using bacterial Pseudomonas or Azotobacter [43][53]. This polyanionic hydrophilic polysaccharide presents a relatively short cross-linking time and is compatible with several cell types [44][45][54,55]. The hydrogel is formed when multivalent cations (usually Ca2+) are added to an aqueous alginate solution. Although it is mechanically unstable for a prolonged culture, alginate hydrogels present low degradation rates and cannot be used alone [46][56]. Alginate-based hydrogels can be applied for vascular and cartilage tissues and are extensively studied in the area of tissue engineering. [47][48][49][57,58,59].

Chitosan is a deacetylated form of chitin derived from shells of crustaceans [50][51][60,61]. This natural cationic polysaccharide is insoluble in water and needs to be solubilized in acid solutions [52][62]. The hydrogel presents relatively good mechanical stability and may be easily mixed with other hydrogels. Due to its acidity, it needs to be neutralized and can reduce cell viability. In addition, presents a limited printability due to its low mechanical strength and low gelation speed and for that reason cannot be printed alone. There are only few studies of chitosan-based hydrogels for tissue engineering [53][63].

Collagen, the most abundant protein in the mammalian species and marine organisms, is the primary studied natural polymer for biomaterials [54][64]. Collagen hydrogels are considered a suitable cell carrier that may be easily mixed with other hydrogel materials; therefore, it presents low mechanical stability and a prolonged cross-linking time (slow gelation). Likewise, it is not indicated to be used alone, and it better performs when used in polymeric composites. Type I collagen (Col-I) can self-assemble to form fibrous hydrogels at 37 °C [55][65]. These hydrogels have been reported in various tissue engineering applications, but mainly have been mainly utilized in cartilage and skin tissues [56][57][58][66,67,68].

Gelatin is a partially hydrolyzed polypeptide and is considered a form of collagen. Its gelling property depends on its source. Gelatin hydrogels present a good cell viability, a low mechanical stability, and a high solubility at a physiological temperature [59][69]. The thermo-responsive property functions as a cell carrier and fugitive ink, making it a good choice to be used in tissue engineering. Gelatin methacryloyl (GelMA) is a modified gelatin with a low mechanical stability [60][70]. Although, GelMA is compatible to many cell types, cell viability in GelMA hydrogels depends on the photocrosslinking time, which is the intensity of light and photoinitiator used to induce polymerization [61][71]. There are several studies of vascular, cartilage, and liver tissue engineering using gelatin and GelMA based-hydrogels [62][63][64][65][66][67][68][72,73,74,75,76,77,78].

The hyaluronic acid is a linear non-sulfated glycosaminoglycan (GAG) polysaccharide that requires association to other polymers as a consequence of its low mechanical stability [69][79]. It is commonly used to increase cell viability through cell proliferation enhancement. Due to their properties, hyaluronic acid-based hydrogels have been studied for cardiovascular and cartilage tissue engineering [70][71][80,81].

Polyethylene glycol (PEG) is the most used synthetic polymer to produce biomedical hydrogels [72][82]. This hydrophilic polymer can be transformed into a gel by photopolymerization [73][83]. PEG hydrogels present good mechanical stability and their properties may be easily manipulated using chemical modification techniques, however, they do not provide biological cues for cell proliferation [74][84]. The photocrosslinking time, the intensity of the light, and the photoinitiator have a great influence on cell viability. PEG-based hydrogels can be applied in different approaches to tissue regeneration, such as vascular, bone, and cartilage tissues [38][75][76][77][78][48,85,86,87,88].

Poly(lactic acid) (PLA) is a biocompatible synthetic hydrophobic aliphatic polyester [79][89] commonly used in bone tissue engineering [76][77][78][79][86,87,88,89]. The stereoisomers distribution within the polymers chains (L/D ratios) and molecular weights determines the thermal stability and the degradation properties [80][90].

Poly(lactic-co-glycolic acid) (PLGA) is a synthetic copolymer composed of lactic acid (LA) and glycolic acid (GA), which polymerizes through the ester linkage of their monomers [81][82][91,92]. This copolymer can be degraded by hydrolysis and the degradation time is determined by the monomer’s ratio. Considering its good mechanical strengths and structural versatility, it is often used as support structures for cartilaginous and osteochondral tissue regeneration [83][84][85][86][87][93,94,95,96,97]. Nonetheless, it is commonly associated with other polymers (polymeric composites) [88][89][90][91][92][98,99,100,101,102] since it presents poor bioactivity characteristics.

Polycaprolactone (PCL) is a thermoplastic polyester obtained by ring-opening polymerization of ε-caprolactone monomers via anionic, cationic, coordination, or radical polymerization mechanism [93][103]. It is a bioresorbable polymer that degrades by hydrolysis of their ester linkages. PCL may be produced with different molecular weights and shape, impacting on the degradation rate and mechanical strength [94][104]. PCL hydrogels present good rheological and viscoelastic properties, regulable resorption, and controllable mechanical properties; nevertheless, PCL does not have biofunctional groups to promote better surface chemistry and favor a better cell adhesion in comparison to other bioactive polymers; hence, the PCL present a low biocompatibility [95][96][105,106]. It is consequently an excellent choice of use as a supporting device, especially for hard tissues. There are several reports of its use in cardiac, bone, and cartilage engineering [96][97][98][99][100][101][102][103][106,107,108,109,110,111,112,113].

Pluronic acid (or polaxamer) is a tri-block thermoplastic copolymer consisting of a hydrophobic poly(propylene oxide) (PPO) portion and two hydrophilic poly(ethylene oxide) (PEO) portions arranged in a PEO-PPO-PEO configuration. The non-ionic surfactant gelation temperature is dependent on its concentration and structure [104][114]. The main characteristics of this gel form are good biocompatibility, low cytotoxicity, weak mechanical properties, quick degradation rates, rapid dissolution in aqueous solutions, and poor cell viabilities [105][106][115,116]. In the area of tissue engineering, polaxamer hydrogels have been studied for diverse approaches in tissue regeneration [104][107][108][109][110][114,117,118,119,120].

Biocompatible and bioresorbable polymers can also be used to produce bio-based aerogels. Aerogels are materials synthesized from gels by replacement of the solvent with a gas [111][121]. This replacement is carried out, after gelation step, during a supercritical fluid drying process [112][122]. The result is a material with a high porosity (90–99%), comprising meso and micropores (50 nm), which provides a high internal surface area and low densities [113][114][115][116][117][118][123,124,125,126,127,128]. These scaffolds can be used for tissue engineering applications due to its nanofibrous structure that are suitable for cell adhesion, proliferation and migration [119][129]. However the traditional technologies for aerogel production lack reproducible customization of the 3D structures and do not allow the fabrication of complex structures [111][121]. 3D printing of aerogel can overcome the above-mentioned shortcomings, but it requires printable sol or gel with suitable viscosity and mechanical strength. Only a few studies have been reported using 3D printing techniques [111][120][121][122][123][124][125][121,130,131,132,133,134,135]. Maleki et al. [125][135] formulated a hybrid silica–silk fibroin aerogel with an excellent printability in the wet state using a micro-extrusion based 3D printing approach. Cheng et al. [111][121] described a new technique that integrates direct ink writing and freeze-casting with non-toxic solvent-based inks followed by special drying techniques. Taken together, these polymers, biopolymers, or synthetic polymers, could be divided into conventional and advanced (smart) polymers according to their response to environmental [126][3].