Rice (Oryza sativa) bran is the main commercial by-product of rice grain milling. It is a multilayer fraction composed by the most external tissues of the rice caryopsis. It is produced in large quantities worldwide and its composition is mainly related to insoluble dietary fibres, lipids and other nutrients and bioactive compounds with significant health-related properties.

- rice bran

- by-products

- bioactive compounds

- dietary fibres

- circular economy

1. Introduction, rice bran composition and application

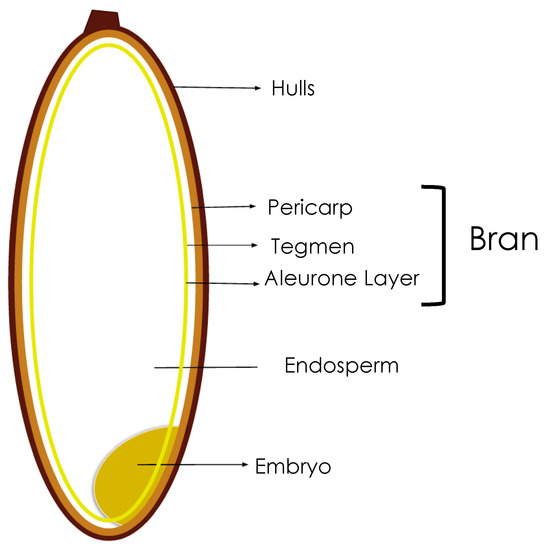

Food processing is a set of operations that permit to transform raw materials into valuable food ingredients. Cereal crops, for example, are rarely consumed as whole grains and during their transformation process a large amount of residue is produced. Rice bran (RB) is a by-product that derives from the milling of rice grain, the third most consumed cereal overworld [1]. It represents around 12% of the total kernel weight and it is composed by the external layer of the seed (i.e., pericarp, tegmen, and aleurone layer (Figure 1)), translatable in almost 68 million tons of hardly unmanageable material per year, worldwide [2].

Figure 1. Schematic representation of rice grain, highlighting the multilayer bran fraction.

Schematic representation of rice grain, highlighting the multilayer bran fraction.

2. Others

Similarly to other cereal species, the kernel surrounding layers are richer in bioactive compounds, minerals, vitamins, dietary fibers, proteins and lipids than the core endosperm, which is characterized by simple carbohydrates and starch granules [3,4] (Table 1). In particular, rice bran has a not-negligible amount of lipids (15–20 g/100 g of RB), where some of the most important bioactive compounds, such as γ-oryzanol, ferulic acid, tocopherol and polyunsaturated fatty acids could be found; thus, for this reason, RB has been used for oil extraction [5]. Despite that, RB is highly sensitive to lipid oxidation due to the rapid activity of lipolytic endogenous enzymes, which means that a thermal stabilization step usually required [6]. However, the first fate of rice bran is the feed formulation industry, losing the opportunity for the recovery of its potential and to building of a strong circular economy based on agri-food waste reintegration.

Table 1. Mean proximate composition of rice bran and the content of its main bioactive compounds.

| Compound | mg/100 g | References | ||||||||||||

| Carbohydrates | 33–42 | [ | 7 | , | 8 | , | 9 | , | 10 | , | 11 | , | 12 | ] |

| Proteins | 11–16 | |||||||||||||

| Fats | 12–20 | |||||||||||||

| Saturated fats | 15–20 | |||||||||||||

| Unsaturated fats | 75–80 | |||||||||||||

| Dietary fibres (DF) | 15–30 | |||||||||||||

| Insoluble DF | 13–26 | |||||||||||||

| Soluble DF | 1–2.25 | |||||||||||||

| Ash | 8–12 | |||||||||||||

| Bioactive Compounds | mg/g | |||||||||||||

| Phenolic acids * | 800–1243 | |||||||||||||

| Tocopherols | 0.35–0.77 | |||||||||||||

| γ-oryzanol | 0.56–1.08 |

* as total ferulic acid, the most abundant phenolic acid found in cereal grains (soluble and insoluble forms).

Despite the poor organoleptic quality of rice bran, its treatment and manipulation through fermentation, extrusion and air classification seems to be emerging technologies for obtaining a valuable food ingredient with a pleasant sensory profile, good nutritional properties and excellent functionalities, for the further development of new food products and the concomitant exploitation of cereal industry side-streams.

* as total ferulic acid, the most abundant phenolic acid found in cereal grains (soluble and insoluble forms).

Despite the poor organoleptic quality of rice bran, its treatment and manipulation through fermentation, extrusion and air classification seems to be emerging technologies for obtaining a valuable food ingredient with a pleasant sensory profile, good nutritional properties and excellent functionalities, for the further development of new food products and the concomitant exploitation of cereal industry side-streams.