Large-scale land-use change (LUC) to expand bioenergy crops, such as sugarcane, raises concerns about the potential negative environmental and socioeconomic side effects. However, such effects are context-specific, and depending on the LUC scenario and management practices, several co-benefits can be attained. In that context, sugarcane-derived bioenergy becomes an important, feasible and sustainable option for mitigating global warming and climate change.

- soil carbon sequestration

- soil health

- ecosystem services

- ethanol

- bioelectricity

- RenovaBio

- land-use change

- Brazil

- climate change

1. CoIntextualization of sugarcane-derived bioenergy proroduction

Most climate change mitigation pathways that limit global warming to 1.5 °C or 2 °C rely on bioenergy production to reduce greenhouse gas (GHG) emissions and also store carbon (C) in the soil [1,2]. Among the bioenergy crops, sugarcane (Saccharum spp.) stands out due to its proven potential to produce high yields of food (sugar and by-products) and bioenergy (first- and second-generation ethanol, and bioelectricity). Sugarcane-derived bioethanol is a well-established renewable energy alternative to fossil fuels[1] [3] recognized for the low C emissions in its life cycle that, if properly done, can avoid negative impacts on food security and biodiversity[2] [4]. Global projections have indicated that annual ethanol production will expand from about 100 billion L to nearly 134.5 billion L by 2028[3] [5]. Two-thirds of this increase is expected to originate from Brazilian sugarcane.

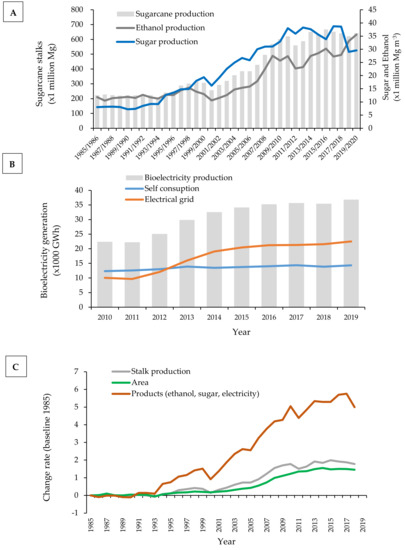

Brazil is the world’s largest sugarcane producer, responsible for 40% of global production [6]. Due to sugarcane, Brazil became the second largest producer of bioethanol (28 billion L) in the world[4] [7], and stands out with the largest fleet of flex-fuel vehicles (~ 30 million)[5] [8]. In the past decades, Brazil has been increasing not only the area under sugarcane cultivation (Figure 1A), but also the production of sugar (Figure 1A), ethanol (Figure 1A), and bioelectricity (Figure 1B). In 2019, cogeneration power plants fed with [sugarcane] bagasse and straw generated about 36.8 TWh, supplying the mills’ needs of steam and power, and delivered a surplus of 22.6 TWh to the national grid (Figure 1B), which represented 5.9% of total electricity production in Brazil this year[6] [9]. The sugarcane sector has become increasingly more efficient (Figure 1C), since the cultivated area has grown at a lower rate (+1.5 times since 1985) than the stalk production (+1.8 times), and especially at a much lower rate than the production of derived products, such as sugar, ethanol, and bioelectricity (+5.0 times), thanks not only to improved crop yield and juice quality, but also to substantial increases in industrial efficiency in the last decades. Moreover, the sugarcane area likely will keep increasing in near future, in response to growing domestic and international market demand and support provided by national public policies (e.g., RenovaBio–[7][10]) and international commitments to achieve the Nationally Determined Contributions (NDC) of the 2015 Paris Agreement[8] [11]. However, it must do so in sustainable ways through both enhanced field and industrial productivity. A recent example of intensification is the growing industry’s interest in producing bioenergy (second-generation ethanol and bioelectricity) by using sugarcane crop residue (named straw) [9][12].

Figure 1. Sugarcane-derived bioenergy production in Brazil. (A) Sugarcane stalk, ethanol, and sugar production. (B) Bioelectricity generation. (C) Change rate of the area, stalk production, and sugarcane products (sugar + ethanol + bioelectricity) using 1985 as a baseline. Source: UNICA[10] [22].

Globally, the expansion of the area dedicated to the production of bioenergy is a cause of concern. The production and use of biomass for bioenergy can have co-benefits, adverse side-effects, and risks, including land degradation, water scarcity, food insecurity, GHG emissions, and impinging on sustainable development goals[11] [2,13]. These impacts are context-specific and depend on the scale of deployment, previous land use, bioenergy crop, soil health, regional climate, and management practices [2]. For example, limiting bioenergy expansion to marginal or degraded lands, such as extensive and low-productivity pastures in Brazil, would benefit the environment[2][12] [4,14] and have interesting synergies with food security with little or no negative impact on food availability, including food export [2][13][4,15]. In addition, several co-benefits can be achieved, such as enhanced soil fertility[14][15] [16,17], biodiversity[16][17] [18,19], and soil C sequestration[18][19] [20,21], when land conversion for bioenergy production is associated with best management practices and implementation at appropriate scales [2].

2. Best Management Practices towards Sustainable Sugarcane-Derived Bioenergy Production

Minimizing the negative effects of the cultivation of bioenergy crops or even bringing benefits to soils and the environment depends on the adoption of adequate management practices, including conservation tillage and crop rotation, management of crop residues and fertilization, and recycling sugarcane by-products for soil C sequestration and the promotion of a circular economy.

2.1. Conservation Tillage and Crop Rotation

In the last decades, the sugarcane production system has undergone profound changes, chiefly the gradual conversion of manual harvesting of burned sugarcane to a green mechanized harvesting system. The adoption of the green harvesting system is recognized as a win–win strategy because of its benefits involving agronomic and environmental aspects[20] [68]. However, the heavy and intense machinery traffic, especially during mechanized harvesting and transportation operations[21][22] [49,55], that occurs in this new system, leads to high levels of soil compaction, which has been recognized as central issue in sugarcane cropping systems.

Historically, soil tillage is performed before sugarcane planting to reduce soil compaction. Tillage disrupts soil aggregates and exposes the soil organic matter to microbial respiration, and consequently increases soil C losses by CO2 emissions to the atmosphere[23][24][25] [59,60,61]. However, recent studies indicate that the benefits of soil tillage are of little persistence and are no longer detected after one or two years of sugarcane cultivation[22] [55]. Conversely, the adoption of conservation tillage (e.g., reduced tillage) in substitution to conventional tillage preserves soil physical quality in annual crops[26] [69] because soil disturbance is confined only in the planting row and most of the soil surface remains covered with crop residues. Several studies worldwide have indicated that the adoption of conservation tillage results in greater nutrient cycling and soil C sequestration[27][28][29][30][31] [70,71,72,73,74], soil biological activity[32] [75], soil protection against erosion[33] [76], and crop yield gains[29][31] [72,74]. However, the magnitude of these effects, particularly soil C sequestration and crop yield, depend on climate and soil conditions, as well as adoption of other best management practices (e.g., crop residue retention, cover crops, crop rotation)[30][31] [73,74].

Despite the recognized benefits of conservation tillage systems, conventional tillage operations (i.e., plowing, harrowing, and subsoiling) are still predominantly used in Brazilian sugarcane fields[29] [72]. The main challenge for adopting conservation tillage in sugarcane is to overcome the problems caused by soil compaction, subsoil acidity, and specific soil pests (e.g., Sphenophorus levis) and weeds (e.g., Cynodon spp). Under Brazilian conditions, recent studies have indicated that most soil C accumulated during the sugarcane cycle in green cane areas is lost after tillage operations in the replanting period[23] [59,71,72,77]. For instance, Silva-Olaya et al.[26] [59] reported that 3.5 Mg CO2 ha−1 was lost after soil tillage for reforming sugarcane fields. Conversely, the adoption of conservation tillage practices resulted in a soil C accumulation rate of 0.96 Mg ha−1 year−1, indicating that this practice can be a feasible strategy to increase C sequestration in sugarcane soils [71]. However, conservation tillage in sugarcane fields is a type of reduced tillage because around 13% of the soil layer (until 40 cm) is disturbed by the planting furrow made once every five years [72]. In the future, with the adoption of new technologies, such as controlled traffic systems and transplanting pre-sprouted seedlings, the soil disturbance in sugarcane planting should be considerably reduced, improving the potential for soil C accumulation and contributing to mitigate GHG emissions. Additionally, the elimination of tillage practices in sugarcane planting reduces fossil fuel consumption and indirectly mitigates GHG emissions[34] [78].

Crop rotation is another agricultural practice to reduce GHG emissions, break the monoculture cycle, and improve soil health[35][36][37] [79,80,81]. Since sugarcane is a semi perennial crop, annual crop rotation cannot be easily implemented, but, at least, different crops can be cultivated during the sugarcane replanting time every five years. Green manure legumes (e.g., sunn hemp—Crotalaria sp.) are preferred due to their well-known abilities to establish a symbiotic association with N-fixing bacteria. Legume cover crops enhance other components of soil health[38] [82] and provide relevant soil-related ES, including a reduction in pest infestation, control of soil erosion, and the supply of N through biological N fixation, which reduces the N-fertilizer demand for the subsequent crop[39][40] [83,84], decreasing the associated nitrous oxide (N2O) emissions and nitrate leaching.

Sugarcane is responsive to legumes cultivated in rotation, resulting in yield gains ranging from 15% to 25% in Australia[41] [85] and around 30% in Brazil[39] [83]. In combination with the adoption of conservation tillage and maintenance of soil covered with crop residues during the sugarcane cycle, the use of a cover crop is an important step to improve the sustainability of the soil–plant system.

2.2. Rational Crop Residue Management

Currently, 94% of the sugarcane areas in central-southern Brazil make use of the green sugarcane system[6] [7], in which large amounts of harvest straw residues (ranging from 10 to 20 Mg ha−1) are maintained in the fields[42] [86]. The thick layer of straw has influenced the dynamics of soil–plant–atmosphere system in several ways, including benefits such as: increasing crop yields[43][44][45] [87,88,89], soil C stocks[46][47] [90,91], nutrient recycling[15] [16], regulation of soil temperature and moisture[48][49] [92,93], soil structure quality[50] [94], soil erosion control[51] [95], soil biodiversity[52][53] [96,97], and weed control[54] [98]; however, negative effects have also been found, such as higher pest infestation[55] [99] and GHG emissions[56][57] [100,101]. However, despite the agronomic and environmental effects of maintaining straw in the field[24][58] [68,102], this residue contains one-third of the energy potential of the sugarcane crop[59] [103]. Therefore, sugarcane straw is a valuable feedstock for bioenergy production (cellulosic ethanol, electricity, and other bioproducts), enabling new opportunities for the sugarcane industry. Based on this dual purpose, several studies were performed to estimate the amounts of straw that could be removed from the field without jeopardizing soil health and sugarcane yield and maximizing economic gains[11] [12].

The benefits of straw maintenance to soil health indicators are not proportional to the amounts of straw left over the soil. Such benefits tend to level off with 7 to 10 Mg ha−1 of straw [49][50][52][93,94,96,101,[57][60]104] and no extra gains are observed at higher rates of straw. Indeed, Silva et al.[60] [104] reported that full soil coverage is reached when at least 7 Mg ha−1 of straw is retained on the field. Considering the average of 14 Mg ha−1 of straw produced annually[42] [86], removing part of the straw (ranging from 4 to 7 Mg ha−1) should increase the availability of biomass for bioenergy production without negative impacts on soil health indicators.

Sugarcane straw is the main C input in sugarcane soils[61] [105] and indiscriminate removal of this crop residue for industrial purposes tends to reduce soil C stocks[46][47][62] [90,91,106]. Tenelli et al. [72] concluded that 55 and 95 kg C ha−1 was retained for each megagram of sugarcane straw returned to sandy and clayey soils, respectively, in the short-term basis. These findings are in line with modeling studies, which reported that long-term straw inputs on soil surface positively effect soil C stocks[61][64] [41,105,107]. However, soil C increments are decreasing over time as the amount of straw left on the soil surface increases[29][62] [72,105].

Straw mulching increases N2O emissions in sugarcane soils[57][65][66] [100,108,109], and consequently, the removal of this crop residue could be a mitigation strategy. Straw preservation recycles several nutrients in the soil[16] [16] and acts as a physical barrier to preserve soil moisture[49] [92], and thus, favors soil microbiota activity and N2O emissions. Gonzaga et al.[57] [100] synthesized the literature data on the effect of sugarcane straw removal on N2O emissions and derived regional N2O-N emission factors of 0.28%, 0.44%, 0.70%, and 0.56%, respectively for total, high, low, and no removal scenarios. Despite the higher N2O emissions observed when more straw was left on soil, it is important to highlight that in all cases, the N2O emission factors obtained under Brazilian conditions were lower than the 1%, used as a default for Tier 1 by the Intergovernmental Panel on Climate Change (IPCC)[67] [110].

The effects of straw removal on soil indicators are clear, but the same pattern has not always been observed for sugarcane yield. A comprehensive study by Carvalho et al.[46] [89], encompassing 28 field experiments, concluded that the effect of straw removal depends on regional climate conditions, soil texture, harvesting season, and crop age. This study showed that the higher yield losses induced by straw removal occur in regions where sugarcane undergoes longer periods of water deficit throughout the year, such as in important areas of sugarcane expansion in southern Goiás and western São Paulo. Therefore, straw removal recommendations should not be based on isolated factors but rather on holistic and integrated knowledge to ensure that enough straw is left to sustain crop yield and other multiple soil-related ecossystem services.

2.3. Fertilization Management and GHG Emissions in Sugarcane Fields

Fertilizers, especially N, have a relevant impact on the energy and GHG emissions balance of bioenergy crops because of the embedded energy in the manufacturing of the fertilizers and the GHG emissions arising from their application in the fields, mostly as N2O[68] [111]. Nitrogen fertilizers may account for up to 40% to 50% of the GHG emitted to produce ethanol from sugarcane[4][69] [4,112] and approximately 25% of the energy spent to grow sugarcane in the field [70][113].

The IPCC uses an N2O-N fertilizer emission factor of 1% as a default for Tier 1[67] [110], expressed as the proportion of the N fertilizers applied that is emitted as N2O. The default value has been employed to estimate the GHG emitted for bioenergy from sugarcane in Brazil[4][67] [4,110] as regional emission factors were scarce. However, recent data indicate that N2O emissions from N fertilizers applied to sugarcane are lower than the IPCC values. Analyzing the data of 44 independent field observations conducted in Brazil with several fertilizer sources, we estimated an average N2O-N fertilizer emission factor of 0.60. Low emission factors have been reported for other crops, being attributed to the good drainage of the deep Oxisols that predominate in most agricultural areas in Brazil [70][113], which does not favor anaerobic conditions that stimulate N2O emissions via denitrification. In fact, nitrification, which prevails in well-aerated soils, seems to be the dominant pathway for N2O formation in sugarcane soils[71] [114].

The relatively low N2O emissions from N fertilizer in sugarcane soil are partially reverted when the sugarcane industry by-products, such as vinasse, are recycled in the fields. Vinasse is a liquid residue of the must distillation to produce ethanol and is generated in large quantities (i.e., 10 to 13 L/L−1 of ethanol). It is applied in amounts that vary from 50 to 150 m3/ha−1 and is a source of K and other nutrients[72] [115]. While the N2O emission factor of the N contained in vinasse is close to or below the IPPC default value, when vinasse is applied with N fertilizers or shortly after or before fertilization, the emission factor of N fertilizers may double[73][74] [116,117]. Good management practices, such as the separation of vinasse and fertilizer application in space or time, or the use of nitrification inhibitors can reduce such emissions[73][75][76] [116,118,119], which is desired to maintain a favorable GHG balance in the production of biofuels.

Despite the important contribution of N fertilizer to the overall GHG emissions for biofuels from sugarcane, recent studies outlined here indicate that emissions in sugarcane production are generally lower than the default values used in many life cycle analysis assessments. In addition, there are practical solutions for situations where emissions may be high. The fact that the amounts of N fertilizer applied to sugarcane in Brazil are usually 20% to 30% lower than in most important producing countries[77] [120] also contributes to the favorable GHG balance of bioenergy from sugarcane. This is further evidence of the good environmental performance of ethanol from sugarcane produced in Brazil.

2.4. Recycling Sugarcane by-Products: Nutrient Savings and Promotion of the Circular Economy

The exported material by the sugarcane industry—mostly sugar and ethanol—is composed of C, O, and H; therefore, mineral nutrients can be recycled. Most mills in Brazil crush 2 million megagrams of sugarcane or more per year. Thus, large amounts of biomass are transported to the mills where they are processed in centralized facilities, making it easy to organize the recycling of by-products. Each megagram of sugarcane stalk generates approximately 125 kg of bagasse dry matter (i.e., the residue after the juice is removed by crushing). There are several uses for bagasse, but the most common is to produce steam and electricity to supply energy for the mill. Burning bagasse results in the production of approximately 6 kg of ashes Mg−1 of sugarcane[78] [121]. Ashes, with high contents of silicate and oxides of K, Ca, Mg and other metals[79] [122], return to the sugarcane fields usually mixed with other by-products such as filter cake.

The filter cake, or press mud, comprises small pieces of bagasse and sludge retained during vacuum filtration of sugarcane juice clarification to produce sugar. Nowadays, many ethanol distilleries also clarify the juice; therefore, filter cake can be generated from both sugar and ethanol processes[78] [121]. The filter cake yield (70% moisture) is approximately 35 kg/Mg−1 sugarcane. In addition to organic matter, filter cake contains small amounts of mineral nutrients present in the sugarcane biomass and those added to help juice clarification, including phosphate, making phosphorus the nutrient in the highest concentration in this by-product (i.e., 5.7 to 9.2 kg P Mg−1)[78] [121]. Filter cake is recycled in sugarcane fields fresh or composted with other by-products of sugarcane processing, such as ash, vinasse, and, eventually, bagasse.

A typical mill produces both sugar and ethanol, in proportions that vary from 40% to 60% of each. If the sugarcane is processed for sugar, the resulting molasses are fermented to produce ethanol at a rate of 13 L Mg−1 of sugarcane. When the sugarcane syrup is directly fermented, the ethanol yield is approximately 85 L Mg−1 of stalk[72][78] [115,121]. The primary use of vinasse is as fertilizer, distributed in the fields through special channels or trucks. The allowed application rates are regulated by environmental legislation to prevent excess salts in soils[80] [123]. Whenever vinasse is used, K fertilization is unnecessary, and the rates of other nutrients are also adjusted.

The recycling of nutrients by the by-products in the sugarcane industry is part of a circular economy. It brings agronomic, environmental, and economic advantages, as sizeable amounts of nutrients return to the fields (

Table 1). The organic matter and the nutrients in these by-products provide well-documented benefits for both soil fertility and crop yields[77][78] and promising effects on soil C stocks[81][82]. Considering the average annual fertilization of 50, 65, 120 kg ha

). The organic matter and the nutrients in these by-products provide well-documented benefits for both soil fertility and crop yields [120,121] and promising effects on soil C stocks [42,124,125]. Considering the average annual fertilization of 50, 65, 120 kg ha

−1

of N, P, and K, respectively, in plant cane and 100, 13, 100 kg ha

−1 of N, P, and K, respectively, in the ratoon cycles[83], and that 20% of the sugarcane fields are plant cane and 80% are ratoon crops, the annual consumption of fertilizers for a 25,000 ha plantation would be 2250 Mg N, 585 Mg P, and 2600 Mg K. Therefore, the potential amounts of nutrients recycled with by-products (data of

of N, P, and K, respectively, in the ratoon cycles [126], and that 20% of the sugarcane fields are plant cane and 80% are ratoon crops, the annual consumption of fertilizers for a 25,000 ha plantation would be 2250 Mg N, 585 Mg P, and 2600 Mg K. Therefore, the potential amounts of nutrients recycled with by-products (data of

Table 1) represent 23%, 40%, and 87% of the necessary fertilization for N, P, and K, respectively. Despite that, not all nutrients will be available for the crop in the short term due to slow straw decomposition and eventual nutrient losses in the system. The need for external sources of nutrients may be further reduced with other practices such as straw preservation, which also allows for nutrient cycling and better fertilizer management [84].

) represent 23%, 40%, and 87% of the necessary fertilization for N, P, and K, respectively. Despite that, not all nutrients will be available for the crop in the short term due to slow straw decomposition and eventual nutrient losses in the system. The need for external sources of nutrients may be further reduced with other practices such as straw preservation, which also allows for nutrient cycling and better fertilizer management [127].

Table 1. Nutrients and organic matter recycled in a mill processing 2 million Mg of sugarcane per year (approximately 25,000 ha).

| By-Product (*) | Amount Recycled | Recycled Nutrients and Organic Matter (**) | |||

|---|---|---|---|---|---|

| N | P | K | Organic Matter | ||

| Mg or m3 | Mg year−1 | ||||

| Filter cake | 10,500 | 15 | 89 | 4 | 3150 |

| Ash | 12,000 | 0 | 36 | 132 | 0 |

| Vinasse | 1,274,000 | 510 | 111 | 2123 | 35,672 |

| Total | - | 524 | 235 | 2259 | 38,822 |

(*) Filter cake: 35 kg Mg−1 sugarcane stalk (70% moisture), assuming that only the sugarcane used for sugar generates filter cake; Ash: 6 kg Mg−1 sugarcane stalk; Vinasse (m3): 13 L L−1 of ethanol produced. Ethanol yield: 85 L Mg−1 (ethanol from juice) and 13 L Mg−1 (ethanol from molasses). It was assumed that half of the sugarcane is used for ethanol and half for sugar. (**) Data of composition of filter cake, ash, and vinasse were compiled from Mutton, Rossetto, and Mutton[72] [115]; Câmara et al.[79] [122]; and Rossetto et al.[78] [121].

In terms of soil C, if the 38,822 Mg of high-quality organic matter is evenly distributed in the 25,000 ha of sugarcane fields that supply feedstock to the mill (data of Table 1), the C input will be of approximately 0.9 Mg ha−1 year−1. Soil C gains induced by vinasse and filter cake were predicted by Silva-Olaya et al. [42] using the Century model. Simulations suggested that changes from burning to green harvesting would increase soil C stocks by an average of 0.21 Mg ha−1 year−1, but soil C gain can be higher, an average of 0.37 Mg ha−1 year−1 when vinasse and filter cake are added to the soil. Similar soil C gains were also reported in simulations performed by Brandani et al. [81][124] and Zani et al. [82][125].

However, because of economics and logistics, the application of sugarcane by-products (especially vinasse) in many sugarcane companies occurs mostly in areas closer to the mill. In this scenario, nutrients are recycled only in a portion of the cultivated area, resulting in excess nutrients in some areas and, consequently, environmental drawbacks, such as the intensification of GHG emissions and nutrient leaching. More recently, to expand the area where vinasse can be economically applied, new technologies, such as vinasse concentration and the production of liquid biofertilizer, have been adopted. In addition, the amounts of vinasse that can be added to a field are regulated to prevent nutrient overload and leaching losses[80] [123].

More recently, the use of biochar from sugarcane residues has been considered a feasible strategy to improve the circular economy[84] [127]. Biochar is the product of biomass pyrolysis and has been applied to the soil to improve soil health, increase soil C stocks, and reduce N2O emissions[85][86][87][88] [128,129,130,131]. Several studies worldwide have shown the benefits of biochar application on soil attributes and crop yields. However, although the high potential of biochar use, little information is available on the effects of sugarcane-based biochar on soil GHG emissions in Brazil (e.g., [89][132]). It is relevant to mention that biochar produced from different feedstocks may have distinct characteristics and should result in different effects on agricultural soils. More studies are needed to understand the pros and cons of using sugarcane biochar as a strategy to increase soil C stocks and mitigate N2O emissions.

Nonetheless, the proper management of sugarcane by-products can positively impact the sustainability of bioenergy from sugarcane.