The avocado (Persea americana Mill.) is a tree native to Mexico and Guatemala, and currently it is cultivated in more than 70 countries. Avocado consumption, fresh or in the form of processed products, is growing everywhere and it has caused a large number of countries to invest heavily in avocado production. The industrialization of avocado gives as a result a huge amount of waste: peel, stone, tree pruning, and oil extraction wastes. Although the industrial application of these biomasses is still limited, numerous studies suggest that they can serve as raw materials to obtain bioenergy and different types of bioproducts. To take full advantage of them, it would particularly interesting to develop biorefinery models.

- avocado biomass,bioenergy,bioproducts,biorefinery,natural antioxidants,valorization

Please note: Below is an entry draft based on your previous paper, which is wrirren tightly around the entry title. Since it may not be very comprehensive, we kindly invite you to modify it (both title and content can be replaced) according to your extensive expertise. We believe this entry would be beneficial to generate more views for your work. In addition, no worry about the entry format, we will correct it and add references after the entry is online (you can also send a word file to us, and we will help you with submitting).

1. Introduction

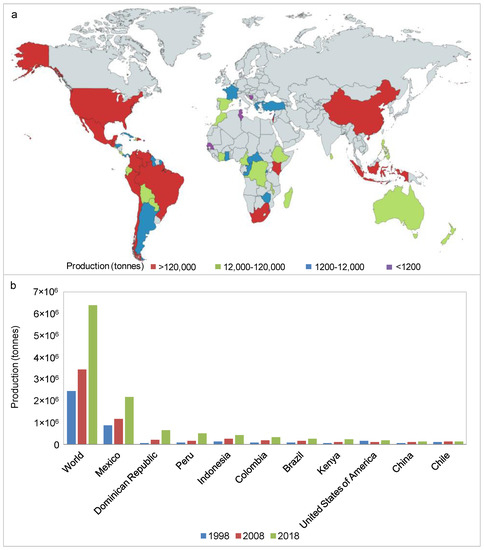

The avocado (Persea americana Mill.) is a tree native to Mesoamerica. The name of the avocado comes from Nahuatl (Ahuacatl), a word that means "“tree testicles"”. Avocado belongs to the family Lauraceae, which is one of the oldest among the flowering plants; particularly, avocado is the most important and only edible fruit of this family and has a high commercial value.[1][2][3] Production areas were concentrated in Central and South America, but it is currently cultivated in more than 70 countries. Avocado consumption is growing everywhere, and it has caused a large number of countries to invest heavily in avocado production. Figure 1a shows the world map of distribution of avocado. Figure 1b shows the production of avocados in the top 10 countries in 1998, 2008, and 2018 based on FAOSTAT data.[1][4] In 2018, the world’s avocado production was around 6.4 million tons, of which these countries produced 77.4%.

Figure 1. Production quantities of avocados by country in 2018 (created with mapchart.net) (a) and by the top 10 producers in 1998, 2008, and 2018 (b). Based on FAOSTAT data.[1][4]

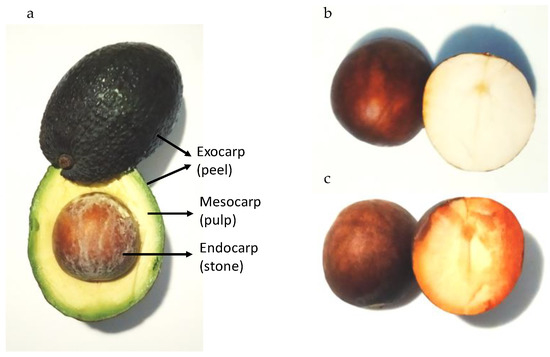

Avocado fruit consists of a dark green peel (7–15%), a yellow-green pulp rich in oil (65–73%), and stone (including the seed) (14–24%) (Figure 2)[5][6][7][8][9] (Figure 2). Avocado has a characteristic texture, pleasant organoleptic characteristics and a high nutritional value. The reported health-benefit of avocado is another main driver for buying this fruit.[10] The pulp of the avocado is consumed fresh or in the form of halves and frozen cubes. Other processed products are also obtained from avocado, such as guacamole, oil, jams, candy juice, ice cream, or as a sauce like dips, chutney, sandwich spreads, mayonnaise, etc. In addition, research has been done on the conservation of avocado fruit by dehydration, freezing, and canning.[11][12]

Figure 2. (a) Parts of the avocado fruit; stone split in half before (b) and after (c) partial oxidation, in the latter appearing the orange color.[1]

The consumption and the industrialization of avocado gives as a result a huge amount of waste, not only the peel and stone but also the waste generated by the pruning practices and oil extraction. As Figure 1b highlights, avocado production has a tendency to grow and thus this waste is going to generate more environmental pressure. However, these biomasses could be the source of new bioenergy, biofuels, and new bioproducts. In particular, in order to take full advantage of them, the integration of several valorization ways to produce a portfolio of bioproducts (energy, biofuels, and/or bio-based products)—in a single installation—is attractive; i.e., a biorefinery.

2. Avocado Processing and By-Products

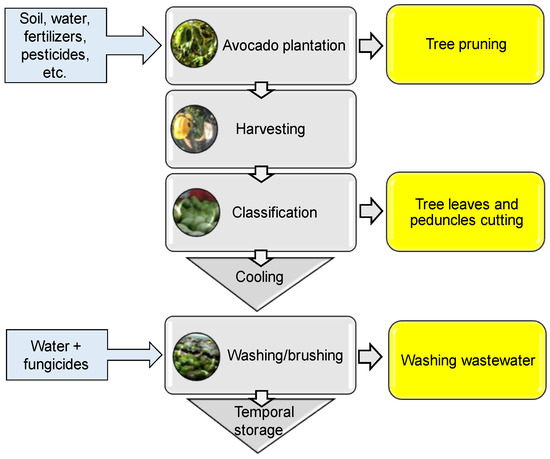

Throughout the avocado value chain, from tree planting to avocado processing, there are stages where different types of biomass are generated. The activities prior to industrialization are planting, harvesting, selection, cooling, washing/brushing, packing, and temporary storage (Figure 3).[13] In the traditional plantation system, the density is around 117 trees per hectare; trees are planted with distances of around 10 × 10 m between them and the tree grows up to 8 or 10 m. In the new orchards, the tree grows up to a maximum height of around 3 m to facilitate the practices of phytosanitary control, harvesting, foliar fertilization, and cutting. This enables a density increase to 300 and up to 1000 trees per hectare with plantation distances of 6 × 3 m or up to 3 × 3 m.[13][14] Thus, the maintenance pruning practices results in a big amount of branches and leaves that must be removed from the fields to avoid propagation of plant diseases. One sustainable alternative is to use it for compost, although in most occasions this waste is burned.

Figure 3. Activities prior to commercialization of avocado and by-products/waste generated in the field (yellow squares).[1]

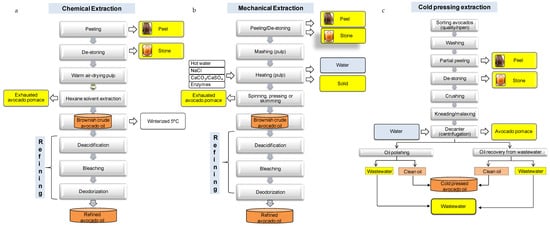

In addition to the market of avocado fruit as a fresh food product, avocado is processed into several types of processed foods, as commented before, that generates other type of waste. Among them, avocado oil is other conventional processed product. In order to extract avocado pulp oil, several processes have been suggested, some industrially consolidated (Figure 4): (i) chemical extraction by organic solvents, which is the most widespread, using mainly hexane; and (ii) physical methods like mechanical extraction (the traditional method) and centrifugation, also known as cold-pressing. Other techniques have been applied on a laboratory scale (see review [7]).

Figure 4. Chemical (a), mechanical (b), and cold-pressing extraction (c) of avocado oil and the by-products/waste obtained (yellow squares).[1]

During chemical extraction (Figure 4a), the shell and bone are totally removed to obtain the pulp that is dried with hot air, and then the oil is extracted with an organic solvent, such as hexane; an up to 95% extracted oil content is obtained.[15][16] The mechanical extraction of avocado oil (Figure 4b) is obtained by peeling and destoning the fruit, crushing the pulp, and finally drying it. Then, the paste is heated with hot water with CaCO3/CaSO4 or NaCl, and rotated, pressed or skimmed (by natural decantation) to obtain the oil phase. In both methods, the oil is refined for most applications. Considering the oil content of avocado, the generated residual pulp fraction can be around 46% of the avocado weight.[16]

Avocado oil can be also extracted by cold pressing, i.e. cold pressing avocado oil (CPAO). For this process, the cultivar ‘Hass’ was chosen as the raw material since it is the main cultivar commercialized worldwide and also due to its characteristics: thick skin to protect the fruit during transport and oil yield (around 31%).[16] If CPAO is extracted from high-quality fruits, the avocado oil is defined as extra virgin avocado oil[16] since it is going to present a high quality. CPAO is characterized for a high content in the monounsaturated fatty acid oleic acid. Compared to the aformentioned methods, CPAO does not require refining (Figure 4c), presenting the advantage that oil maintains the organoleptic characteristics of the fruit pulp. However, the CPAO yield is lower than using the aforementioned methods, up to 85%.[15][16]

Currently, the use of this method has become more popular and it is also used in several countries, such as New Zealand, Chile, South Africa, Kenya, Israel, etc. In general, this process begins with washing, draining, and destoning of the avocado, where the stones and around 90% of skin are separated from the pulp. Skin separation can be calibrated according to the desired quality, since the proportion of skin into the processed mash may affect the pigment composition of the avocado oil. The pulp goes through a grinder where it is simultaneously sliced and crushed. Subsequently, the avocado paste is continuously stirred, and the oil separated by centrifugation using a horizontal three-phase decanter, along with the pomace (exhausted pulp and residual skin), and a liquid phase (wastewater). In some cases, where a vertical two-phase decanter is used, the liquid phase can be further processed in a centrifuge to remove the remaining CPAO from the wastewater. The estimated amounts of waste per avocado fruit processed can be around 15% pomace, 45% wastewater, 27% skin + stones, and 5% residual water, while the CPAO is around 8% (or 8.5 L), depending on the avocado type.[15][16]

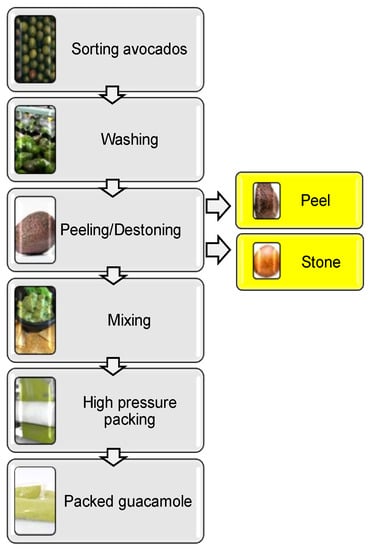

Another star product of the avocado is guacamole, as commented before. Its production process (Figure 5) consists of the selection of ripe avocados, washing, and, as for the extraction of oil, removing the peel and stone to recover the pulp. Then, it is mixed with others elements (onion, tomato, and salt, basically) to finally obtain the guacamole, which is packaged.[17] The percentage of this waste depends on the cultivar of the fruit and even some differences can be found in the same cultivar; for example, the proportion of avocado waste (peel and stone) in the cultivar ‘Fuerte’ was higher than in ‘Hass’, i.e., 31% vs. 24%-27%, respectively.[8][9]

Figure 5. The guacamole process and by-products/waste generated (yellow squares).[1]

Regardless of the type of production method, the stone, peel, and/or exhausted pulp are discarded as waste, which results in a large amount of solid residues that can represent 21–76% of the fruit weight, with some exceptions in some varieties,[18][19] and also the wastewater.

3. Chemical Composition of Avocado Waste

The valorization of avocado waste deserves further attention due to the high amounts generated worldwide and considering its mositure and chemical composition, including the major and minor constituents (but relevant).

The moisture content and the chemical characterization of the aforementioned by-products are shown in Table 1. One limitation is the high moisture content since dried samples are required for some technologies before processing. If it cannot be used as fresh biomass or there is a shortage in time to process, a drying step can transform this waste into storable commodities, but the energy cost will depend not only on the technology but also on the moisture content, as well as on the type of avocado by-product. Some authors have applied air-drying, convective-, freeze- and microwave-drying before further application of the stone, peel, and avocado pomace,[1][15][20][21] and freeze- and spray-drying for wastewater.[15] Alternatively, to be used as a biofuel for heating, Perea-Moreno et al.[22] suggested to apply a cheap drying system to reach a moisture around 10%, such as that used in the wood chip industry.

Table 1. Moisture (%, fresh weight) and chemical composition of some avocado residues (%, dry weight).[1][15][20][22][23][24][25][26]

|

By-product |

Moisture |

Ash |

Lipids |

CP |

Ext |

Hem 3 |

Cel/Glu 4 |

Lignin |

Table 2. Elemental analysis of some avocado residues.[1][22][27]

|

Element |

Avocado Peel (%) |

Avocado Stone (%) |

|||||||||

|

Exhausted pulp/pomace |

81.4–82.8 |

4.5–7.0 |

9.3 |

14.7–12.8 |

|||||||

|

C |

49.8 |

42.1–48.0 | 18.2 | 1 |

8.5 |

29.8 |

26.9 |

||||

|

Peel |

|||||||||||

|

H | 70.9–75.3 |

5.7 |

1.0–8.7 |

5.6–5.8 |

6.3–10.4 |

6.0–9.3 |

43.7 1/20.5–34.4 2 |

11.5–25.3 |

12.1–27.6 |

4.4–35.3 |

|

|

Stone |

35.2–57.0 |

0.9–2.9 |

2.3–6.0 |

3.7–5.3 |

21.0–35.9 2 |

6.5–40.9 |

1.8–15.8 |

||||

|

N |

1.0 |

0.5–0.7 | 3.0–47.9 |

Wastewater |

88.3 |

||||||

|

O |

42.2 |

17.9 |

53.8 |

10.3 |

ND |

ND |

ND |

ND |

CP, crude protein; Cel/Glu, cellulose/glucans; Ext, extractives; Hem, hemicellulose; ND, not determined; PC, phenolic content. 1 Ether extract. 2 Aqueous-ethanolic extractives, which refer to non-structural material determined using the standard method reported by the National Renewable Energy Laboratory (NREL). 3 As xylan, arabinan, galactan, and/or mannan. 4 In some studies, cellulose was determined on the basis of the glucose content as glucans, and so starch can contribute to this value. Other studies determined the available carbohydrate content (free sugars, dextrins, and starch), which was pomace (0.6%), peel (1.2%), stone (69.1%), and wastewater (0.9%).

In all cases, the higher components are the sugar fraction (glucans + hemicellulosic sugars), the extractives fraction (non-structural components), and lignin, but a high variability exists (Table 1). The variety/cultivar, ripeness, pedoclimatic conditions, etc. may affect the chemical composition of these residues, as well the methodology applied.[1] Moreover, among the avocado waste, a large part of the carbohydrates from the stone are available (69%), making it an underexploited starch source.[15]

Moreover, the elemental analysis (%, dry weight) of some of these by-products is shown in Table 2.

43.0–50.8 | ||

|

S |

ND |

ND–0.1 |

ND, not detected.

4. Valorization Technologies of Avocado-Derived Biomass

Avocado-derived biomass can be used as a raw material to obtain bioenergy and bioproducts, taking advantage of their heat capacity and chemical composition, which can be used in different industries, such as the energy, food, cosmetic, and pharmaceutical sectors.

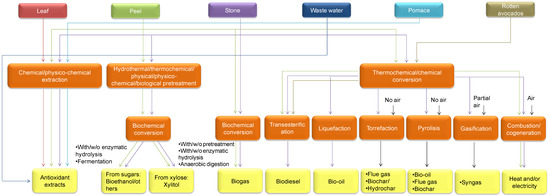

In general, the conversion of biomass into biofuel is accomplished by means of mechanical transformations, chemical transesterification, thermochemical transformations, and biological transformations (fermentation, anaerobic digestion, etc.). In general, for energy purposes, the initial humidity of the biomass must be considered, as commented on before. In this sense, in the energy production process from the dry biomass, the methods of direct combustion, pyrolysis, gasification, and transesterification to biodiesel can be used. Alternatively, when the generation of energy is from wet biomass, hydrothermal treatments, enzymatic hydrolysis, fermentation to bioethanol/biohydrogen/biobutanol, and anaerobic digestion can be used.[28] The potential that avocado biomass has to obtain bioenergy and biofuels is highlighted in Figure 6. These technologies applied to avocado waste make it an alternative energy source to fossil fuels; also, greenhouse gas emissions can be reduced while, compared to other renewable resources, they do not compete with food production. Besides these valorization ways, other studies have been focused on the obtention of antioxidant extracts from the different biomasses,[1][8][29][26][30] with potential to be used as food ingredients, for example, as inhibitors of lipid and protein oxidation and color deterioration in meat products.[8] Also, avocado stones are a source of starch,[6][31] with potential applicability in different sectors, and other uses have also been published for avocado waste (e.g. as biosorbent, colorant, etc.).[32][33][34][35]

Figure 6. Overview of the valorization ways applied to the avocado-based waste/by-products.[1]

References

- Minerva C. García-Vargas; María Del Mar Contreras; Eulogio Castro; Avocado-Derived Biomass as a Source of Bioenergy and Bioproducts. Applied Sciences 2020, 10, 8195, 10.3390/app10228195.

- Zhengke Zhang; Donald J. Huber; Jingping Rao; Antioxidant systems of ripening avocado (Persea americana Mill.) fruit following treatment at the preclimacteric stage with aqueous 1-methylcyclopropene. Postharvest Biology and Technology 2013, 76, 58-64, 10.1016/j.postharvbio.2012.09.003.

- Haiming Ding; Young-Won Chin; A. Douglas Kinghorn; Steven M. D'ambrosio; Chemopreventive characteristics of avocado fruit. Seminars in Cancer Biology 2007, 17, 386-394, 10.1016/j.semcancer.2007.04.003.

- Crops . FAOSTAT. Retrieved 2020-12-24

- João Jaime Giffoni Leite; Érika Helena Salles Brito; Rossana Aguiar Cordeiro; Raimunda Sâmia Nogueira Brilhante; José Júlio Costa Sidrim; Luciana Medeiros Bertini; Selene Maia De Morais; Marcos Fábio Gadelha Rocha; Chemical composition, toxicity and larvicidal and antifungal activities of Persea americana (avocado) seed extracts. Revista da Sociedade Brasileira de Medicina Tropical 2009, 42, 110-113, 10.1590/s0037-86822009000200003.

- Camila Delinski Bet; Lucas Henrique Waiga; Cristina Soltovski De Oliveira; Luiz Gustavo Lacerda; Egon Schnitzler; Morphological and Thermoanalytical Study of Modified Avocado Seeds Starch with Lactic Acid. Chemistry Journal of Moldova 2017, 12, 13-18, 10.19261/cjm.2017.438.

- Fernanda D. Krumreich; Caroline D. Borges; Carla Rosane B. Mendonça; Cristina Jansen-Alves; Rui Carlos Zambiazi; Bioactive compounds and quality parameters of avocado oil obtained by different processes. Food Chemistry 2018, 257, 376-381, 10.1016/j.foodchem.2018.03.048.

- J.G. Rodríguez-Carpena; D. Morcuende; M. Estévez; Avocado by-products as inhibitors of color deterioration and lipid and protein oxidation in raw porcine patties subjected to chilled storage. Meat Science 2011, 89, 166-173, 10.1016/j.meatsci.2011.04.013.

- García-Vargas, M.C.; del Contreras, M.; Gómez-Cruz, I.; Romero-García, J.M.; Castro, E. Avocado-derived biomass: Chemical composition and antioxidant potential. Proceedings. 2020. Available online: https://sciforum.net/paper/view/7750

- U.S. consumers' main drivers for buying avocados 2019 Published by M. Shahbandeh, Mar 2, 2020 The statistic shows the results of an annual survey conducted by the Hass Avocado Board from May 8 to May 22, 2019. Grocery shoppers were asked about their main drivers for purchasing avocados. Some 74 percent of U.S. grocery shoppers reported that they believe that avocados are healthy. Consumers' main drivers for buying avocados in the United States in 2019 . Statista. Retrieved 2020-12-24

- Luis Chel-Guerrero; Enrique Barbosa-Martín; Agustino Martínez-Antonio; Edith González-Mondragón; David Betancur-Ancona; Some physicochemical and rheological properties of starch isolated from avocado seeds. International Journal of Biological Macromolecules 2016, 86, 302-308, 10.1016/j.ijbiomac.2016.01.052.

- Gutierrez-Contreras, M.; Lara-Chavez, M.B.N.; Guillen-Andrade, H.C.-B. Agroecoloy of the avocado-producing belt area in Michoacan, Mexico/Agroecologia de la Franja Aguacatera en Michoacan, Mexico/Agroecologia da Faixa de Abacateiros em Michoacan, Mexico. Interciencia 2010, 35, 647–653.

- Subsecretaría de Fomento a los Agronegocios. Monografía de Cultivos; SAGARPA Mexico DF: Mexico City, Mexico, 2011.

- Macías, A.M. México en el mercado internacional de aguacate. Rev. Cienc. Soc. 2011, 17, 517–532.

- Rahul Permal; Wee Leong Chang; Brent Seale; Nazimah Hamid; Rothman Kam; Converting industrial organic waste from the cold-pressed avocado oil production line into a potential food preservative. Food Chemistry 2020, 306, 125635, 10.1016/j.foodchem.2019.125635.

- Giacomo Costagli; Matteo Betti; Avocado oil extraction processes: method for cold-pressed high-quality edible oil production versus traditional production. Journal of Agricultural Engineering 2015, 46, 115, 10.4081/jae.2015.467.

- Giselle A Ramtahal; John O Akingbala; Gail Sh Baccus-Taylor; Laboratory preparation and evaluation of Pollock variety avocado (Persea americana Mill) guacamole. Journal of the Science of Food and Agriculture 2007, 87, 2068-2074, 10.1002/jsfa.2965.

- Ana López-Cobo; Ana María Gómez-Caravaca; Federica Pasini; María Fiorenza Caboni; Antonio Segura-Carretero; Alberto Fernández-Gutiérrez; HPLC-DAD-ESI-QTOF-MS and HPLC-FLD-MS as valuable tools for the determination of phenolic and other polar compounds in the edible part and by-products of avocado. LWT - Food Science and Technology 2016, 73, 505-513, 10.1016/j.lwt.2016.06.049.

- Rafael G. Araújo; Rosa M. Rodriguez-Jasso; Héctor A. Ruiz; Maria Manuela Estevez Pintado; Cristóbal N. Aguilar; Avocado by-products: Nutritional and functional properties. Trends in Food Science & Technology 2018, 80, 51-60, 10.1016/j.tifs.2018.07.027.

- Jorge Saavedra; Andrés Córdova; Rosa Navarro; Paulo Díaz-Calderón; Claudia Fuentealba; Carolina Astudillo-Castro; L.N. Toledo; Javier Enrione; Lena Galvez; Industrial avocado waste: Functional compounds preservation by convective drying process. Journal of Food Engineering 2017, 198, 81-90, 10.1016/j.jfoodeng.2016.11.018.

- Pratywi, C.D.; Marantika, S.; Dwijananti, P. Masturi Characterization of starch degradation during simple heating for bioethanol production from the avocado seed. IOP Conf. Ser. Mater. Sci. Eng. 2018, 432, 10–15.

- Alberto-Jesús Perea-Moreno; María-Jesús Aguilera-Ureña; Francisco Manzano-Agugliaro; Fuel properties of avocado stone. Fuel 2016, 186, 358-364, 10.1016/j.fuel.2016.08.101.

- D. Eliyahu; E. Yosef; Z.G. Weinberg; Y. Hen; M. Nikbachat; R. Solomon; S. J. Mabjeesh; J. Mirón; Composition, preservation and digestibility by sheep of wet by-products from the food industry. Animal Feed Science and Technology 2015, 207, 1-9, 10.1016/j.anifeedsci.2015.05.005.

- Javier A. Dávila; Moshe Rosenberg; Eulogio Castro; Carlos A. Cardona; A model biorefinery for avocado (Persea americana mill.) processing. Bioresource Technology 2017, 243, 17-29, 10.1016/j.biortech.2017.06.063.

- Enrique Barbosa-Martín; Luis Chel-Guerrero; Edith González-Mondragón; David Betancur-Ancona; Chemical and technological properties of avocado ( Persea americana Mill.) seed fibrous residues. Food and Bioproducts Processing 2016, 100, 457-463, 10.1016/j.fbp.2016.09.006.

- Damila R. De Morais; Eliza M. Rotta; Sheisa Cyleia Sargi; Eduardo Morgado Schmidt; Elton Guntendorfer Bonafe; Marcos N. Eberlin; Alexandra Christine Helena Frankland Sawaya; Jesui Vergilio Visentainer; Antioxidant activity, phenolics and UPLC–ESI(–)–MS of extracts from different tropical fruits parts and processed peels. Food Research International 2015, 77, 392-399, 10.1016/j.foodres.2015.08.036.

- Consuelo Pizarro García; Consuelo Pizarro; Antonio Gutiérrez Lavín; Julio L. Bueno; Characterization of Spanish biomass wastes for energy use. Bioresource Technology 2012, 103, 249-258, 10.1016/j.biortech.2011.10.004.

- N. Gaurav; S. Sivasankari; Gs Kiran; A. Ninawe; J. Selvin; Utilization of bioresources for sustainable biofuels: A Review. Renewable and Sustainable Energy Reviews 2017, 73, 205-214, 10.1016/j.rser.2017.01.070.

- Francisco J. Segovia; Gádor Indra Hidalgo; Juliana Villasante; Xavier Ramis; María Pilar Almajano; Avocado Seed: A Comparative Study of Antioxidant Content and Capacity in Protecting Oil Models from Oxidation. Molecules 2018, 23, 2421, 10.3390/molecules23102421.

- Bruno Melgar; Maria Inês Dias; Ana Ciric; Marina Sokovic; Esperanza M. Garcia-Castello; Antonio D. Rodriguez-Lopez; Lillian Barros; Isabel C.R.F. Ferreira; Bioactive characterization of Persea americana Mill. by-products: A rich source of inherent antioxidants. Industrial Crops and Products 2018, 111, 212-218, 10.1016/j.indcrop.2017.10.024.

- Rafael G. Araújo; Rosa M. Rodríguez-Jasso; Héctor A. Ruiz; Mayela Govea-Salas; Walfred Rosas-Flores; Miguel A. Aguilar-González; Maria Manuela Estevez Pintado; Claudia Magdalena López-Badillo; Cynthia Luevanos; Cristóbal N. Aguilar; et al. Hydrothermal–Microwave Processing for Starch Extraction from Mexican Avocado Seeds: Operational Conditions and Characterization. Processes 2020, 8, 759, 10.3390/pr8070759.

- C. Palma; Lucia Lloret; Antonio Puen; Maira Tobar; Elsa Contreras; Production of carbonaceous material from avocado peel for its application as alternative adsorbent for dyes removal. Chinese Journal of Chemical Engineering 2016, 24, 521-528, 10.1016/j.cjche.2015.11.029.

- L.L. Díaz-Muñoz; Adrián Bonilla-Petriciolet; H.E. Reynel-Ávila; D.I. Mendoza-Castillo; Sorption of heavy metal ions from aqueous solution using acid-treated avocado kernel seeds and its FTIR spectroscopy characterization. Journal of Molecular Liquids 2016, 215, 555-564, 10.1016/j.molliq.2016.01.022.

- Deepti Dabas; Ryan J. Elias; Joshua D. Lambert; Gregory R. Ziegler; A Colored Avocado Seed Extract as a Potential Natural Colorant. Journal of Food Science 2011, 76, C1335-C1341, 10.1111/j.1750-3841.2011.02415.x.

- A. Ariestya Arlene; K. Anastasia Prima; Lidya Utama; S. Airin Anggraini; The Preliminary Study of the Dye Extraction from the Avocado Seed Using Ultrasonic Assisted Extraction. Procedia Chemistry 2015, 16, 334-340, 10.1016/j.proche.2015.12.061.