1. Layout of SOFC/GT Hybrid System

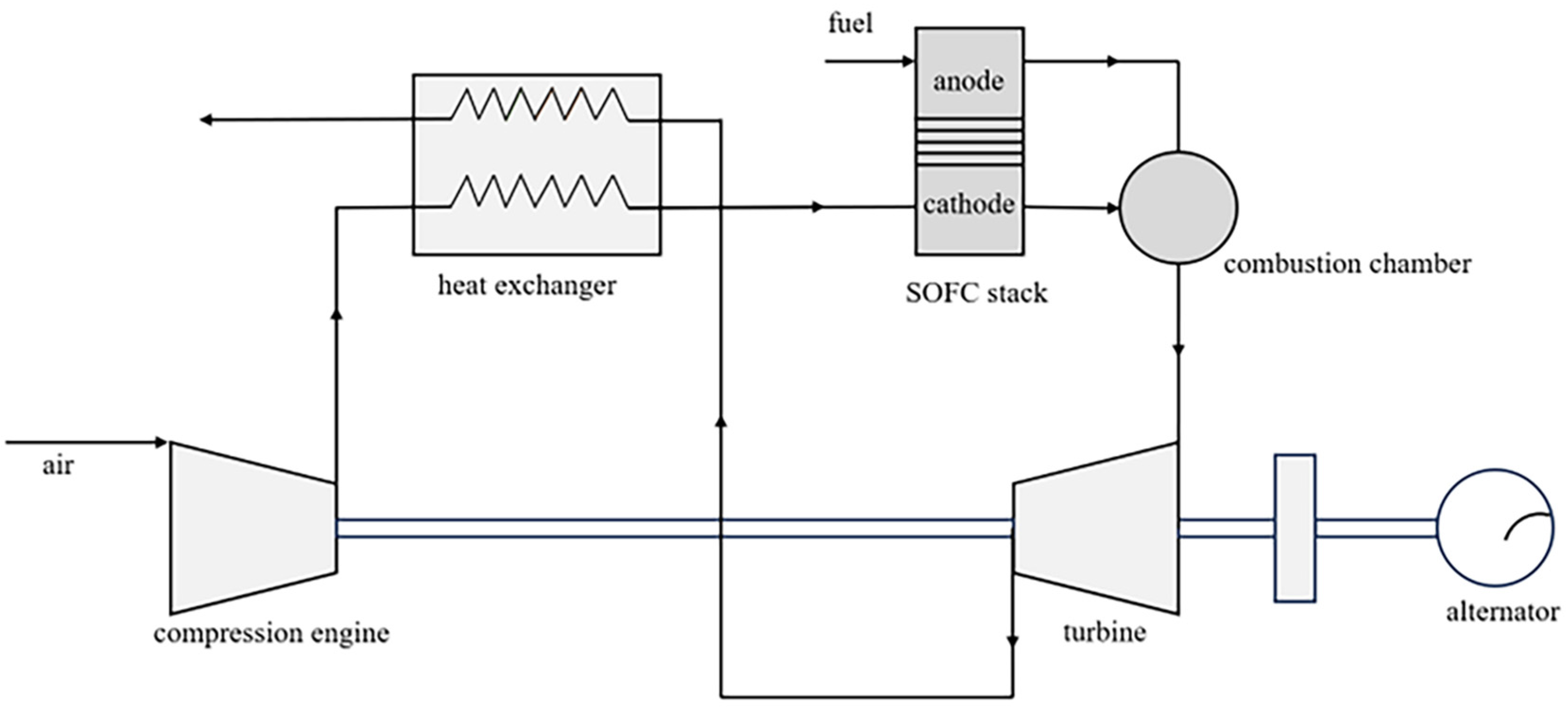

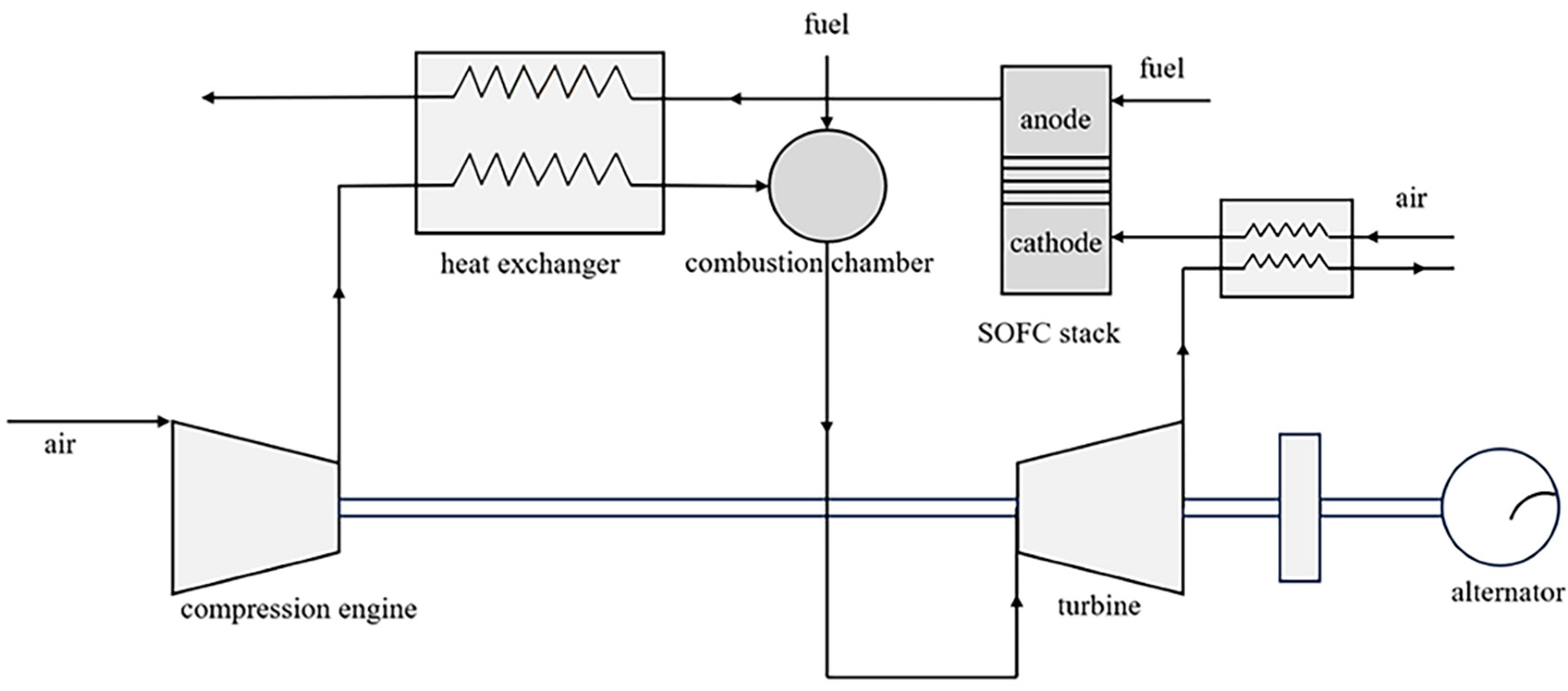

According to the different locations of SOFC and GT, SOFC/GT hybrid systems can be divided into two categories: top cycle and bottom cycle. In the top cycle, the SOFC stack is placed in front of the GT, and the high-temperature gas flow from the SOFC reaction enters the GT combustion chamber to expand, generating electricity externally through a generator. Whereas the bottom cycle is the opposite of the top cycle: the SOFC stack is placed at the back of the GT, and the high-temperature gas released by the GT serves as a source of air for the cathode of the SOFC stack

[55][1].

Due to the different working pressures of fuel cells, the top cycle is also called pressurized SOFC/GT system (Figure 61), and the bottom cycle is also called atmospheric pressure SOFC/GT system (Figure 72). Among them, the efficiency of the bottom cycle is lower than that of the top cycle, and the cost of heat exchanger components of the bottom cycle is higher. Therefore, the top cycle is often used in SOFC/GT hybrid systems.

Figure 61.

Pressurized SOFC/GT hybrid system.

Figure 72.

Non-Pressurized SOFC/GT hybrid system.

In recent years, researchers have been working on different SOFC/GT designs in the effort to improve electrical efficiency and reduce initial investment

[26,56][2][3]. The efficiency and dependability of the system are greatly impacted by the fuel cell’s operating pressure choice. If a fuel cell is to be simple and reliable, it should operate at atmospheric pressure

[57][4]. In this scenario, the SOFC functions autonomously from the GT, with a heat exchanger separating the two subsystems. This configuration ensures the safe operation of SOFC and GT. Specifically, the GT can operate properly with an additional burner that adds heat to the air discharged by the SOFC heat exchanger, thereby stabilizing the gas turbine inlet temperature (TIT) value. In addition, the heat transfer between SOFC exhaust gas and incoming air results in lower TIT values compared to pressurized configurations where SOFC exhaust gas goes directly into a gas turbine. Therefore, in terms of power generation efficiency, pressurized design is the best choice. In this setup, the SOFC chimney generates additional power by acting as a burner in the Brayton cycle

[58][5]. Additionally, since this configuration does not require an expensive heat exchanger, it is expected to be more cost-effective than the atmospheric one. However, the trial runs have shown how difficult the direct linked (pressurized) SOFC/GT is. This is mostly because of the limited operational range of a traditional GT power plant with regard to mass flow rates and pressures, which results from the unique characteristics of the turbomachinery. Therefore, the generating capacity of SOFC/GT plants is also limited by the SOFC stack rather than the combustor.

Next, it is essential to select the appropriate thermodynamic cycle (e.g., Brayton, IGCC, Rankine, etc.) and the reforming process

[58][5]. Internal Reforming (Direct, DIR or Indirect, IIR) is the preferred option because of its higher overall efficiencies and lower capital cost. However, in this scenario, controlling the methane conversion rate under all operating conditions may prove to be challenging. Additionally, the DIR configuration may result in significant temperature gradients within the cells, as this process is highly endothermic

[30,59,60,61][6][7][8][9].

2. SOFC/GT Systems That Are Powered by Fuels Other Than Natural Gas

Unlike other fuel cell types that are restricted to hydrogen, SOFCs may use a variety of fuels, including hydrogen, methane, carbon monoxide, biogas, and syngas. Because of their adaptability, SOFC/GT systems may be integrated into a wide range of applications, such as the gasification of biomass, landfill gas, and reformed liquid fuels. Because they are readily available and inexpensive, biomass and syngas generated from coal are typically regarded as the most viable alternative fuels for SOFC/GT systems.

2.1. Alternative Fuels: Biomass

Biomass energy is the fourth largest renewable energy source in the world today, and is also an important renewable energy source

[62][10]. Recent studies indicate that biomass and waste collectively account for approximately 10% of global primary energy generation. Crucially, biomass offers a sustainable solution to environmental pollution as it is a carbon-neutral source of fuel. Through partial combustion, biomass can be transformed into producer gas or syngas. The development of power generation systems based on biomass gasification provides a promising and environmentally friendly way to meet the ever-growing demand for electricity.

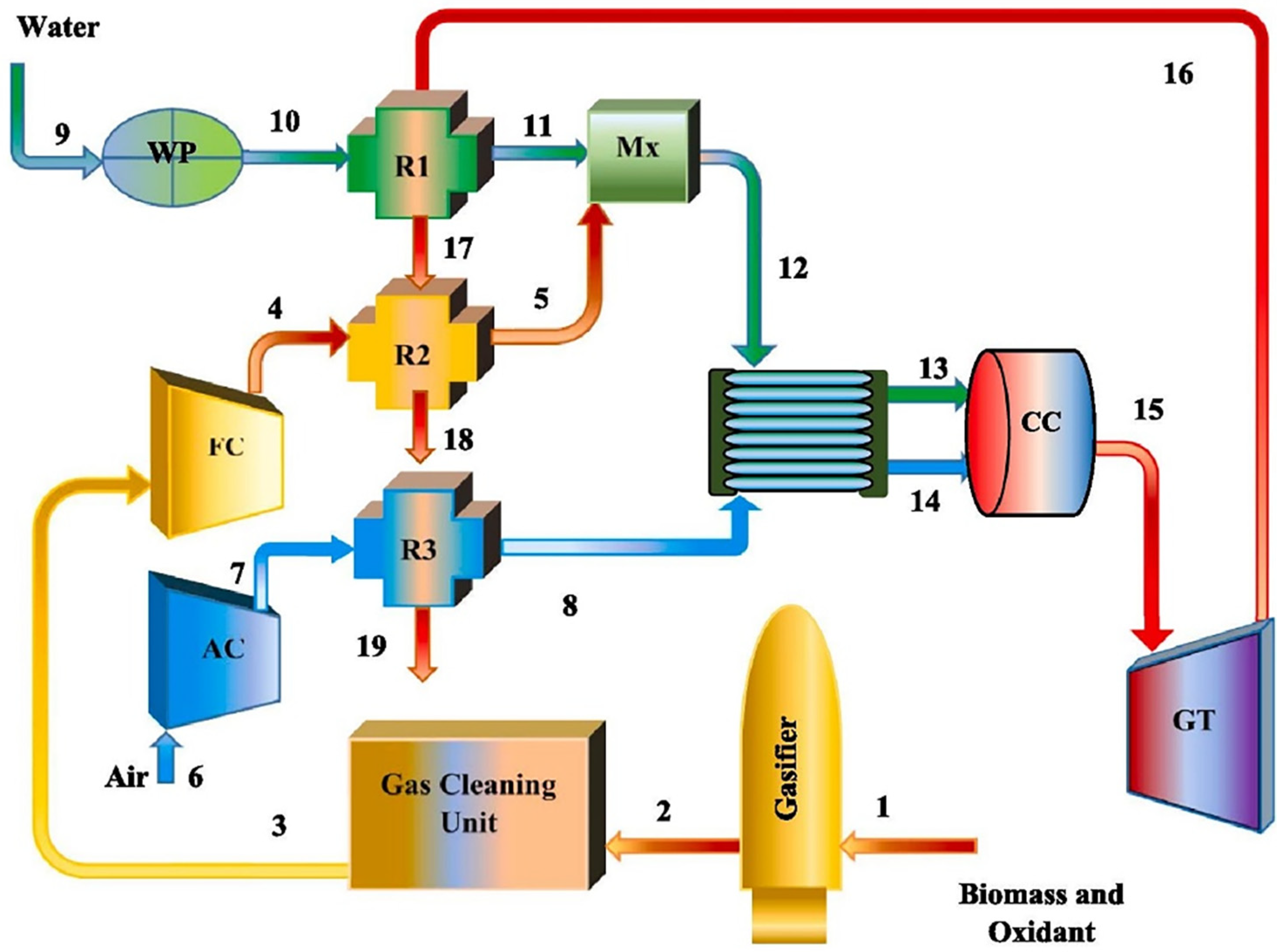

An analysis of the energy-exergy and sustainability of a new biomass-fueled SOFC/GT hybrid configuration published by A.A. Sinha et al.

[63][11] is compared. A schematic of the proposed hybrid arrangement cycle is shown in

Figure 83. Three different biomass fuel types—pine sawdust, aspen sawdust, and apricot shells—are suggested by the research to power this cutting-edge hybrid system. MATLAB-based simulations were used in the study to evaluate the fuel cell hybrid cycle’s performance. To assess the system’s performance, three important performance metrics were examined: pressure ratio, turbine input temperature, and current density. Each cycle component, as well as the entire system, was assessed using the energy-(exergy) method and the first and second laws of thermodynamics. It was determined that the SOFC/GT hybrid system could achieve maximum efficiency using all three biomass fuels at a pressure ratio of 6 and a turbine input temperature of 1250 K. Pine sawdust demonstrated the highest exergy damage (2653.14 kW), environmental impact (0.91), and the lowest sustainability index (2.09), while also boasting the highest thermal efficiency (63.12%)

[64,65][12][13]. The findings suggest that biomass fuels have the potential to become an important source of energy for solving the energy crisis and mitigating climate change.

Figure 83. Schematic diagram of the hybrid system design with three different biomass fuels [63]. Schematic diagram of the hybrid system design with three different biomass fuels [11].

Fuel suitability analysis of an intermediate temperature solid oxide fuel cell (IT-SOFC) and GT hybrid system fueled by biomass gas is discussed by Ding et al.

[66][14].

Figure 94 shows the schematic diagram of the IT-SOFC/GT hybrid system, which mainly consists of IT-SOFC, single-axis GT, external reformer, catalytic combustor, fuel compressor, water needle pump, and generator. This study presents the design of an IT-SOFC/GT hybrid system for small-scale distributed generation, with an intended output power scale of around 180 kW. After being heated, the biomass gas is sent into the reformer, where it is reformed and sent onto the SOFC’s anode side to participate in the electrochemical process. To deliver O

2 to the electrochemical process, the compressed air is first heated to high temperature and pressure by heat exchangers 1 and 2, which then introduce it to the cathode side of the SOFC. The catalytic combustion combustor receives the exhaust gas from the SOFC reaction and burns it entirely. The gas turbine then receives the high-temperature, high-pressure outlet gas, which produces output power.

Figure 94. Diagram of an IT-SOFC/GT hybrid system with different biomass fuels expected power scales of 180 kW [66]. Diagram of an IT-SOFC/GT hybrid system with different biomass fuels expected power scales of 180 kW [14].

The study conducted a thermodynamic analysis of systems using different types of biomass gases as fuel, taking into account component fluctuations. The study compares the system’s performance and safety evaluations when dealing with variations in the composition of wood chip gas and farm biogas. Findings indicate that the system can achieve high efficiency using wood chip gas, but its efficiency decreases with farm biogas due to composition fluctuations. The study emphasizes the significant impact of fuel composition variations on system performance and safety and discusses the potential for the use of biomass fuels in hybrid systems

[67][15]. In addition, the literature review emphasizes the limited research that has been conducted on the analysis of system suitability and safety in response to fluctuations in the composition of a wide range of biomass fuels. Regional factors affecting biomass fuel quality are also mentioned.

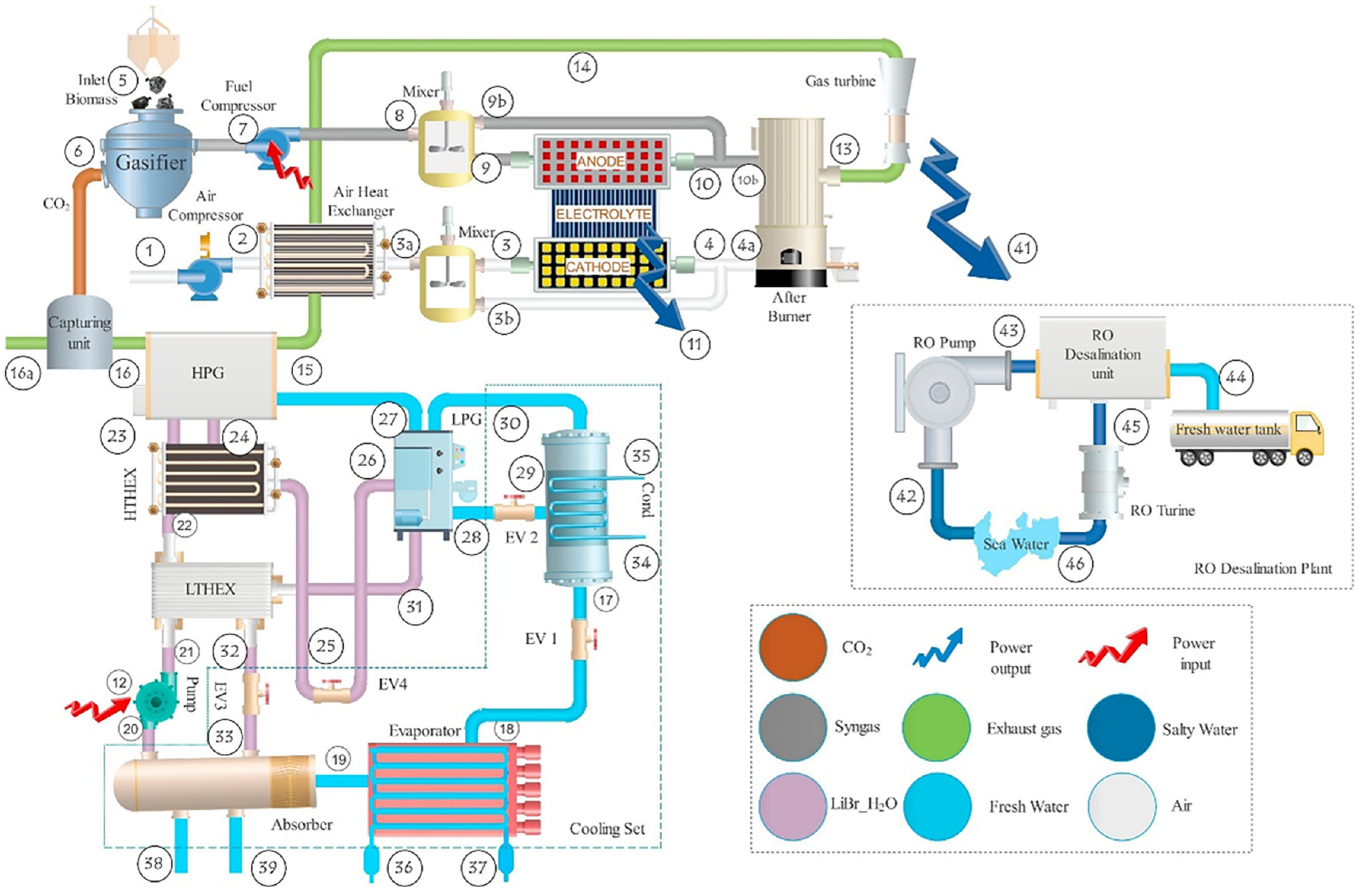

A parametric study of a recently suggested biomass-based SOFC integrated with GT was carried out by Behzadi et al.

[27][16], The model consists of three primary components: a dual-effect LiBr-H

2O absorption chiller, a reverse osmosis (RO) unit, and SOFC/GT hybrid system (

Figure 105). To enhance overall energy efficiency, surplus heat from the SOFC/GT is utilized in a dual-effect cooling system. Additionally, the RO unit utilizes the excess power generated by the GT to produce clean water.

Figure 105.

Schematic structure of biomass-based SOFC/GT/double-effect absorption cooler/RO hybrid desalination system with CO

To reduce environmental pollution, the system incorporates a reverse osmosis desalination unit, GT, SOFC, double-effect absorption chiller, and CO

2 recycling. To find the ideal operating conditions, the study uses multi-objective optimization and parametric analysis

[68][17]. The findings demonstrate that, under ideal operating conditions, the suggested system achieves an exergy efficiency of 38.16% and a total product unit cost of 69.47 $/GJ.

2.2. Alternative Fuels: Coal

Numerous research works in the body of the current literature investigate the potential use of coal syngas in SOC/GT hybrid systems. Zhao et al.

[69][18] explored this option. For the effective integration of a syngas-fueled SOFC and GT in a hybrid power plant, the author has described the construction of a thermodynamic modeling and optimization framework (

Figure 116). Using an optimization technique, this method links an irreversible GT model with a syngas-fed SOFC model to analyze operating circumstances. The system as a whole is analyzed in terms of energy and entropy balance in order to see how irreversibility is distributed and what role each component plays. In addition, parameter sensitivity analyses were performed to examine the optimal behavior of the system and to predict the sensitivity of system performance to changes in key design and operating parameters

[70][19]. This approach provides a new perspective for the optimal integration of fuel cells, GTs, and other system components in an atmospheric SOFC/GT hybrid cycle.

Figure 116. Schematic diagram of the integrated atmospheric syngas-fueled SOFC-GT hybrid system structure [69]. Schematic diagram of the integrated atmospheric syngas-fueled SOFC-GT hybrid system structure [18].

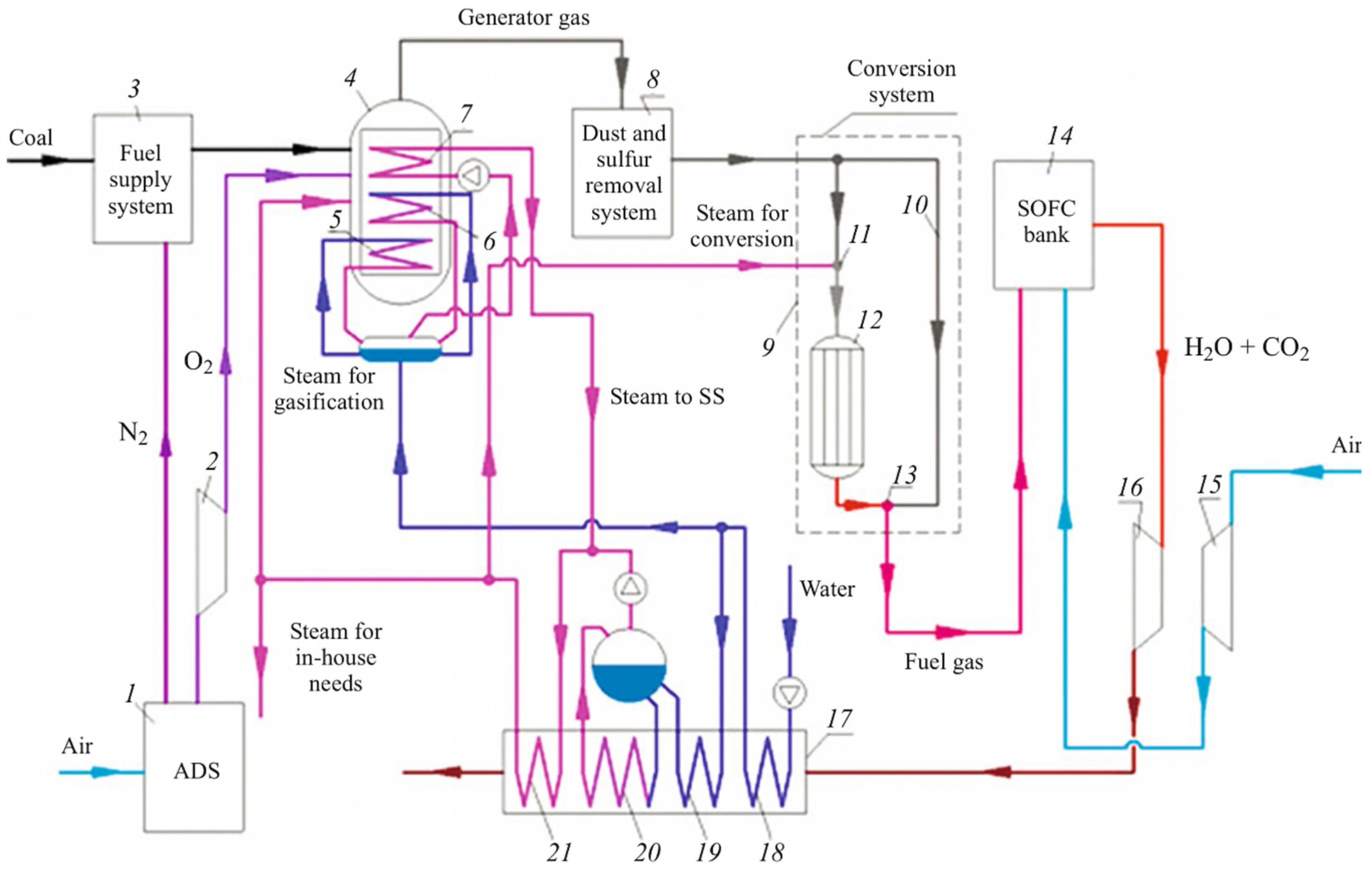

Grigoruk and Kasilova

[71][20] discussed a study of the thermal configuration parameters of a SOFC hybrid system using coal gasification products. The study focused on the efficiency of the system and the effect of different parameters on its performance (

Figure 127). The study indicates that the gasification setup with dry particulates has a higher electrical efficiency compared to a water-coal mixture, resulting in a 3–5% decrease due to the reduced calorific value of the fuel gas. In addition, pressurized SOFCs are more electrically efficient, and when the operating pressure of the SOFC stack drops to atmospheric pressure, the electrical efficiency decreases by 5–10%, resulting in a decrease in power output

[72][21]. Furthermore, an increase in efficiency is achieved with a regenerative air preheater, which minimizes heat loss from the SOFC exhaust gases and raises the temperature of the gas supplied to the GT.

Figure 127.

An illustration of a hybrid system’s thermal configuration using fuel cells and coal gasification products without CO

2.3. Alternative Fuels: Ammonia

Ammonia, with the chemical formula NH

3, functions as a hydrogen storage medium. There are a number of ways to use the stored energy, including quick combustion and ammonia dissociation and separation for the recovery of H

2. A fuel cell can then be powered by the hydrogen that has been collected. Ammonia can also be blended with diesel fuel to reduce emissions by 8 tons of CO

2-equivalent and provide a more affordable fuel option for hybrid systems. In addition, ammonia is more economical compared to diesel fuel, and there are several other advantages of ammonia

[73,74][22][23]:

-

Energy Storage: Ammonia serves as a method for storing and transporting hydrogen, which can be extracted from the ammonia to produce power in fuel cells, positioning it as a potential energy carrier.

-

Scalability: Compared to hydrogen, ammonia can be produced in large quantities, making it a scalable energy storage and transportation option.

-

Versatility: Ammonia has a variety of uses, including as a fuel for internal combustion engines, fuel cells, and as a feedstock for the production of various chemicals.

-

Safety: Ammonia boasts a high energy density and can be stored and transported with relative safety, making it a feasible option for energy storage and distribution.

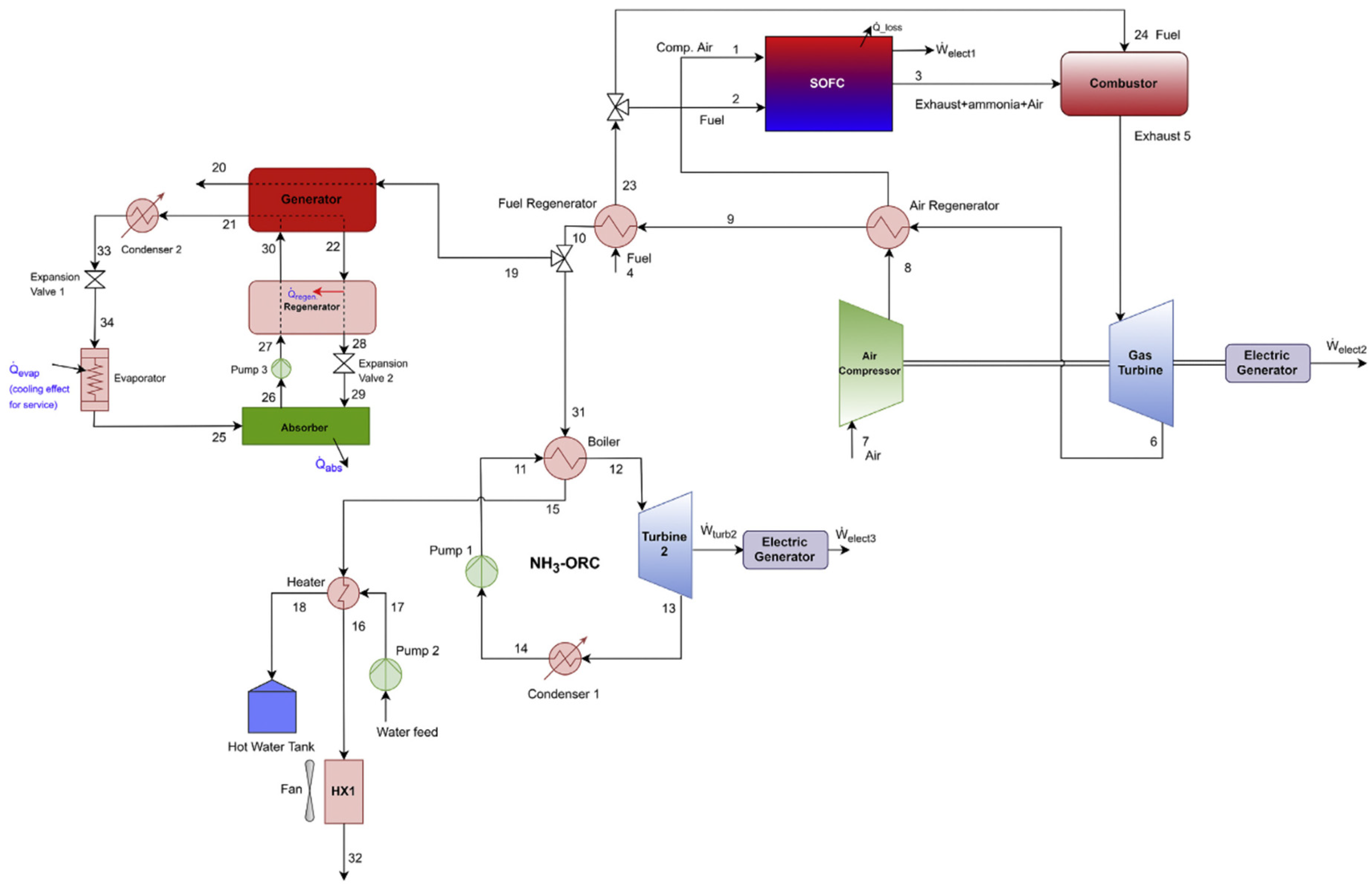

Al-Hamed et al.

[75][24] presented a new integrated system for clean railway electric transport using direct ammonia SOFCs and GTs (

Figure 138). The article examines the energy and exergy efficiency of the system and conducts parametric studies to enhance its performance. The utilization of a supercritical ammonia-organic Rankine cycle enhances efficiency in comparison to ammonia-based systems. The article highlights the advantages of using ammonia as a fuel, such as cost-effectiveness, environmental friendliness, and high energy density. The article also discusses the potential for lowering SOFC operating temperatures and the feasibility of using ammonia as a direct fuel.

Figure 138. A diagram illustrating the complete ammonia-based SOFC-GT-ORC system with an absorption chiller [75]. A diagram illustrating the complete ammonia-based SOFC-GT-ORC system with an absorption chiller [24].

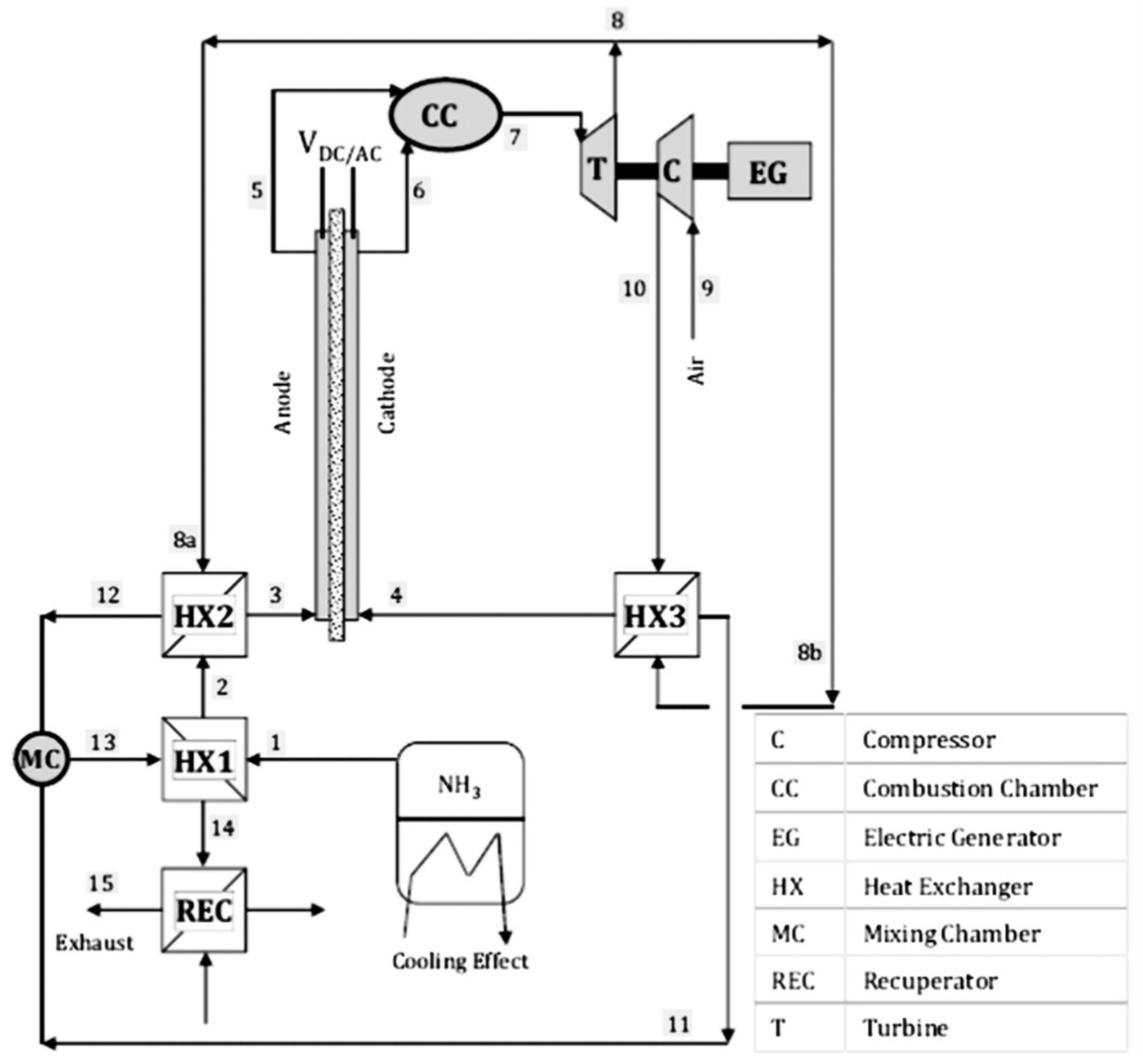

F. Ishak et al.

[76][25] presented the integration of a direct ammonia SOFC with a GT in a combined cooling, heating, and power cycle (

Figure 149). The comparative analysis is conducted between the integration strategies of oxygen ion-conducting solid oxide fuel cells (O-SOFC) and hydrogen proton-conducting solid oxide fuel cells (H-SOFC or PCFC). The system is aimed at utilizing the cooling properties of ammonia to minimize complexity and cost. A comprehensive study was carried out to evaluate the impact of different operational conditions on energy and exergy efficiencies. The findings indicate that the integrated H-SOFC system outperforms the O-SOFC option. The study also elaborates on the operation of the DA-SOFC and the integrated DA-SOFC/GT systems. The system employs pressurized ammonia for immediate delivery and integrates a closed-loop heat exchanger for thermal exchange. The ammonia extracted is preheated prior to entering the fuel cell stacks, and the heat generated during the electrochemical reaction is utilized. The research offers a comprehensive analysis of the integrated system and its performance under different conditions.

Figure 149. Schematic diagram of integrated DA-SOFC/GT system [76]. Schematic diagram of integrated DA-SOFC/GT system [25].

In general, SOFC-GT hybrid systems can use a variety of alternative fuels, and there is no doubt that hydrogen, as a clean energy source with water vapor as a by-product, is one of the most suitable fuels, but there are many problems with its manufacture, storage and transportation. In recent years, many researchers have done a lot of research on biomass fuel, coal and ammonia.

The above analysis shows that the use of biomass fuel can reduce the dependence on fossil fuels and reduce greenhouse gas emissions. At the same time, it faces challenges such as high production cost, unstable supply, and low energy density. In the future, as biomass energy technology continues to advance, it is expected to become a more sustainable energy option. As for coal energy, despite its abundant resources and low cost, problems such as its high carbon emissions and serious air pollution make it an unsustainable energy choice, and improving combustion efficiency and carbon dioxide capture capacity is one of the major challenges for future development. Ammonia, as a clean, high-energy-density fuel, has the potential to be the fuel of choice for SOFC-GT systems. However, challenges in terms of its safety, production cost, and supporting facilities need to be addressed to realize the wide application of ammonia in the energy sector. With continued technological advances and cost reductions, ammonia may play an important role in the energy transition.

3. Performance Analysis of the SOFC/MGT Hybrid System

In the energy sector, GTs and micro gas turbines (MGTs) are two different types of gas turbines. The dividing line between them is usually based on power levels and application areas. Typically, GTs are more powerful and are used for large-scale energy production and industrial applications, while MGTs are less powerful and are mainly used for micro-energy systems, distributed energy sources, and portable energy devices.

As distributed power generation systems rapidly develop, MGT systems have also progressed. Due to their unique features, MGT can seamlessly integrate with SOFC systems. At present, SOFC/MGT hybrid systems are crucial in the field of distributed power generation. It can improve efficiency and reduce environmental impact, promising to meet the growing demand for distributed energy systems.

L. Fryda et al.

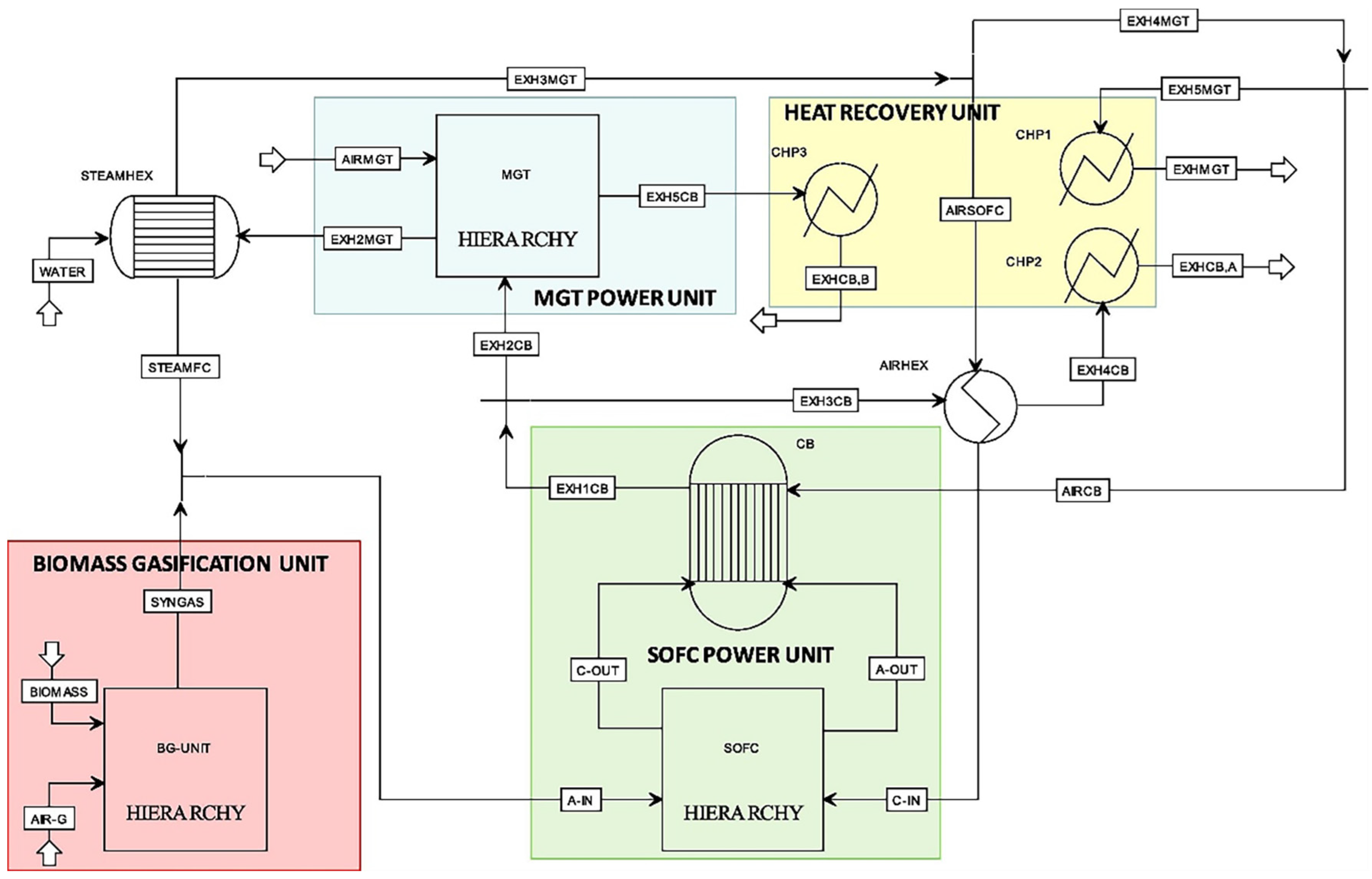

[77][26] investigated the integration of autothermal biomass gasification with SOFC and MGT in small-scale combined heat and power (CHP) systems (

Figure 150). Three configurations are compared: gasification at different pressures with SOFC, MGT, or both. The study uses process simulation software to model the system components and conducts an exergy analysis to evaluate system performance. The results show that the electrical efficiency of SOFC/MGT configuration is the highest, reaching 35.6%. The research aims to develop more efficient biomass fuel energy systems and explore the potential of biomass gasification and SOFC technologies for small-scale CHP applications.

Figure 150. A diagram of the biomass gasification CHP with SOFC and/or MGT [77]. A diagram of the biomass gasification CHP with SOFC and/or MGT [26].

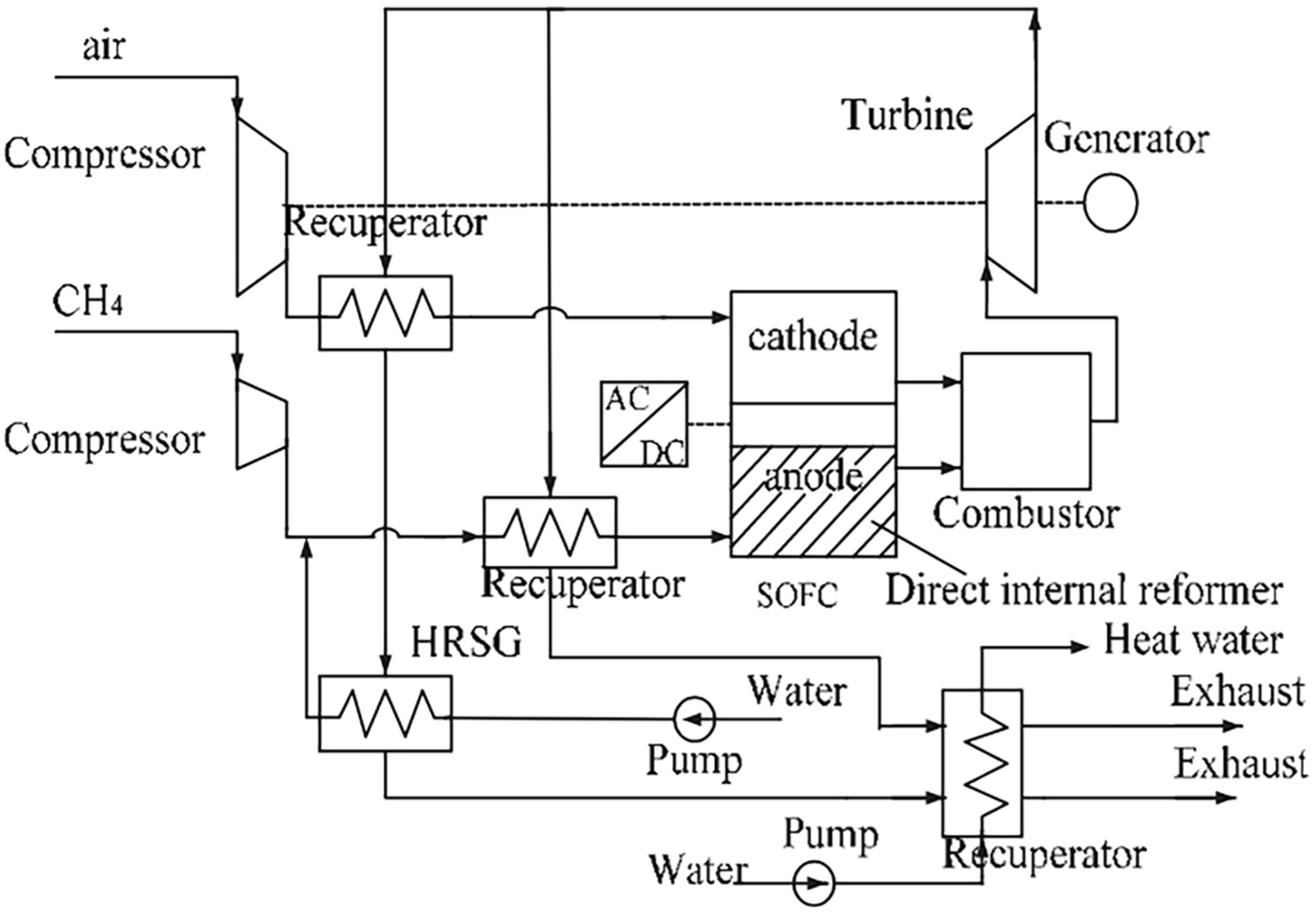

Duan et al.

[78][27] focused on a SOFC/MGT hybrid power system (

Figure 161). The study aims to explore and optimize important parameters that significantly affect the overall system performance. It looks into the thermodynamic potential for improving the hybrid system by integrating the SOFC with an advanced thermal cycle system. It also describes how to optimize the main SOFC/MGT hybrid system parameters, with the MGT inlet temperature acting as a constraint. The results indicate that the Turbine Inlet Temperature (TIT) is the primary parameter constraining the electrical efficiency of the hybrid system. In a hybrid system with a fixed number of batteries, increasing the operating temperature of the SOFC can achieve higher power efficiency, but higher operating temperatures can also lead to an increase in TIT. Improving fuel efficiency is seen as an effective method for enhancing the performance of the hybrid system. Additionally, research has shown that as the gas-carbon ratio increases, the electrical efficiency and TIT of the hybrid system will decrease. These findings offer valuable reference points for future research on efficient SOFC/MGT hybrid systems.

Figure 116. Schematic diagram of the SOFC-MGT hybrid power system [78]. Schematic diagram of the SOFC-MGT hybrid power system [27].

Alessandra Perna et al.

[79][28] examined the performance evaluation of a small-scale hybrid power plant that combines an MGT and a SOFC powered with syngas from a biomass downdraft gasifier (

Figure 172). The plant is specifically designed to maximize the production of electric and thermal power, with a focus on decentralized combined heat and power (CHP) plants. The performance evaluation is conducted using a numerical model and validation with experimental data. The research assesses the influence of operational parameters on cogeneration performance, and emphasizes the potential for achieving high electric and cogeneration efficiencies.

Figure 172. A diagram of the hybrid BG-SOFC/MGT cogeneration plant [79]. A diagram of the hybrid BG-SOFC/MGT cogeneration plant [28].

Overall, the SOFC-MGT combined cycle system is a highly efficient energy conversion technology with the potential to achieve high power generation and cogeneration efficiencies. However, the high manufacturing and maintenance costs of SOFC-MGT combined-cycle systems make them challenging for commercial applications. Therefore, the development of SOFC-MGT has a long way to go in terms of energy and environmental benefits.