Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Tigist Tadesse Shonte and Version 2 by Lindsay Dong.

Desirable techno-functional properties of packaging materials such as permeability and mechanical and thermal properties play a key role in maintaining quality by preventing off-flavour development, contamination, browning, and softening, thereby extending the shelf life of mushrooms. Regardless of the type of packaging system, they all play an important role in maintaining or improving the quality of mushrooms and extending their shelf life. Each packaging system has unique performance characteristics defining their strengths/benefits in terms of preserving edible mushrooms, safety, and circular economy impact.

- mushrooms

- nanopackaging

- biodegradable packaging

- edible coatings

1. Introduction

Agaricus bisporus, Lentinus edodes, Pleurotus ostreatus, Flammulina velutipes, and Pleurotus eryngii are common edible mushroom species found in mainstream foods [1]. Because of its great flavor and nutritional value, Agaricus bisporus, commonly referred to as “white button mushroom”, is the most widely grown and consumed edible mushroom in the world, making up 30% of all mushroom production [2]. It is a rich source of nutrients including protein, amino acids, and dietary fiber [3][4][5][3,4,5], antioxidants [5][6][5,6], terpenoids [7], lectins [8], phenolic compounds [5][9][5,9], polysaccharides [5][10][5,10], and ergosterols [11][12][11,12].

Edible mushroom production and trade are expanding globally, with a significant positive impact on human living standards [13]. According to the Global Mushroom Market (2023–2030) research report, the compound annual growth rate (CAGR) of the mushroom market increased globally by 9.2% from USD 57.18 billion in 2022 to USD 62.44 billion in 2023. At a CAGR of 9.8%, the mushroom market is projected to reach USD 90.88 billion in 2027. Teagasc Fact sheet Horticulture reported that around 68,000 tonnes of Agaricus bisporus are produced annually in Ireland, nearly all of which are exported to the UK, with 20% used to supply the domestic market [14]. The fact sheet states that the mushroom industry contributes to the Irish economy with a production value of approximately EUR 130 million in 2022. However, exporting to continental Europe is not feasible due to the short shelf life of mushrooms, as they typically only last three days at ambient conditions and five to eight days in a cold storage system [15], as well as to the narrow margins that the industry faces.

The main contributing factors to the short shelf life of mushrooms are their high moisture content and enzyme activity coupled with their lack of a cuticle [16], which aggravates the respiratory and metabolic rates of the seeds’ tender tissues. Additionally, these factors make mushrooms more vulnerable to mechanical damage and microbial contamination, which can result in browning and a decline in quality [17][18][19][17,18,19]. These effects involve physicochemical quality degradation, including cap opening, loss of essential phenolic compounds, proteins, and vitamins, water loss, cell membrane deterioration, loss of firmness, and increased microbial activity in the process of storage and transportation [20][21][20,21], in turn leading to loss of nutritional value, flavor, market acceptability value, and shelf life. Recent findings have reported a wide range of preservation techniques for fresh mushrooms, including irradiation [22], ultrasonication [22], pulsed eclectic field treatment [23][24][23,24], [25][26][25,26], 1-methylcyclopropene treatment [27], modified atmosphere packaging, active packaging, edible coatings and nanopackaging [1][15][28][29][30][31][1,15,28,29,30,31], and biodegradable packaging made from materials such as dextran/chitosan [32].

More specifically, edible coatings and biodegradable packaging are safe and environmentally friendly packaging systems; they are made from natural substances such as pectin, chitosan, or sodium alginate to maintain quality and extend the shelf life of mushrooms [32][33][34][35][36][32,33,34,35,36], and are mostly composed of active ingredients with antibacterial and antioxidant activities [37][38][37,38]. Studies have shown that the incorporation of essential oils, active ingredients, and nanoparticles in edible coatings and biodegradable film packaging can improve the techno-functional properties of the packaging materials [39]. Furthermore, tyrosine inhibitors such as plant extracts, fungus and bacterial extracts, and synthetic and natural phenolic compounds are utilized to control mushroom browning [40][41][42][43][40,41,42,43].

2. Mechanisms of Action and Preservation Effects

2.1. Changes in Quality of Fresh Mushrooms

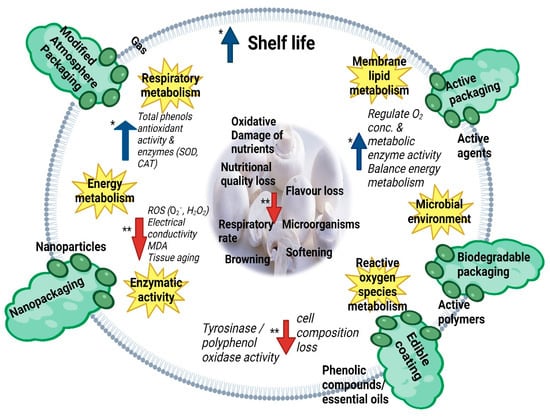

Fresh mushrooms are flavorful, have a moisture content ranging from 81.8% to 94.8%, and are rich sources of nutrients such as carbohydrates (50%–65%), protein (19%–35%), fat (2%–6%), minerals, dietary fiber, phenolic compounds, and vitamins [44][46]. A wide range of studies have shown change in quality of fresh mushrooms during storage, including texture [45][46][47][47,48,49], color [16][48][49][50][16,50,51,52], nutrients, and flavor [17][45][47][51][52][53][17,47,49,53,54,55]. These quality changes in mushrooms are attributed to the cumulative effects of respiratory, energy, membrane lipids, and reactive oxygen species metabolic reactions due to changes in enzymatic activity and microbial activity in response to intrinsic factors and the atmosphere surrounding the product. For example, the transport of electrons in mitochondria cells results in excessive reactive oxygen species accumulation such as H2O2 and O2− in mushroom [54][56]. These processes can lead to oxidative damage to nutrients such as membrane lipids, nucleic acids, and proteins as well as enzyme activity inhibition, leakage of electrolytes, and increased electrical conductivity, ultimately causing tissue aging, nutritional quality loss, and reduced shelf life of mushrooms [46][55][48,57]. Figure 12 provides an overview of changes in mushroom quality along with the mechanisms of action and preservation effects of five major packaging systems for the preservation of fresh edible mushrooms: edible coatings, modified atmosphere packaging, active packaging, biodegradable packaging, and nanopackaging. For instance, edible coatings and biodegradable packaging made with active ingredients can successfully delay or minimize browning reactions by inhibiting tyrosinase and polyphenol oxidase activities in fresh mushrooms [56][57][58][59][58,59,60,61].

Figure 12. Mechanisms of action and preservation effects of active packaging, edible coating, biodegradable packaging, modified atmosphere packaging, and nanopackaging for the preservation of fresh edible mushrooms. CAT—catalase, H2O2—hydrogen peroxide, MDA—malondialdehyde, O2−—superoxide radical, ROS—reactive oxygen species, SOD—superoxide dismutase, * an increase, ** a decrease.

2.2. Edible Coatings, Essential Oils, and Tyrosinase Inhibitors

Edible coatings have moderate to excellent barrier, preservative, cosmetic, and aesthetic qualities, are biocompatible and environmentally friendly, and can usually be consumed with food [17]. Edible coatings combined with active ingredients can supply bioactive compounds to enhance the quality of edible mushrooms or prolong their shelf life, in addition to superior qualities of high air permeability and moisture permeability [64][65]. Chitosan, guar gum, sodium alginate, aloe vera, leek powder, pectin, carboxymethyl, and cellulose are commonly used as edible coating materials for edible mushrooms; they are based on natural biopolymers with essential oils, nanoparticles, and active ingredients such as cinnamon (Table 1). For example, the mixture of chitosan with guar gum can significantly increase antimicrobial activity, reduce cell wall and membrane destructive symptoms, and maintain higher firmness, protein, and ascorbic acid while increasing total soluble solids and reducing sugars of Lentinus edodes mushrooms [65][66]. Edible coatings made from a cinnamon nanoemulsion active ingredient in polymeric matrixes of alginate and glycerol significantly decreased the respiration rate, PPO activity, pseudomonas count, and weight loss while increasing antioxidant activity and maintaining firmness, color, and total polyphenols of Agaricus bisporus mushrooms [66][67].Table 1.

Mechanism of actions and preservation effects of edible coatings of fresh edible mushrooms.

| Edible Coating | Applicable | Mechanism of Actions a | Preservation Effects b | Reference |

|---|---|---|---|---|

| Chitosan-guar gum | Lentinus edodes | Significantly reduced cell wall and membrane destructive symptoms Increased antimicrobial activity |

Maintained higher firmness, protein, and ascorbic acid Increased total soluble solids and reducing sugars |

[65][66] |

| Alginate-glycerol-cinnamon nanoemulsions | Agaricus bisporus | Decreased respiration rate Reduced polyphenol oxidase activity Reduced Pseudomonas counts Increased antioxidant activity |

Decreased weight loss Maintained firmness Maintained colour and total polyphenols |

[66][67] |

| Pectin-chitosan-sodium alginate- carboxymethyl | ||||

| Reduced weight loss | Maintained colour | [ | 69][70] | |

| Alginate-nanoAg-Silver nitrate-sodium Borohydride-polyvinylpyrrolidone |

Lentinus edodes | Reduced the rate of respiration and physiological activity | Extended shelf life Reduced weight loss softening, browning, and microbial counts. Increased total soluble solids |

[70][71] |

a respiration and energy metabolism, antimicrobial activity, antioxidant activity; b nutritional value, shelf life, and sensory quality.

Table 2 shows the effects incorporation of different sources of essential oils in edible coatings on the shelf life of fresh mushroom. A recent study showed that an edible coating with cajuput (Melaleuca cajuputi Powell.) essential oil extract minimized weight loss and respiration rate while maintaining firmness, color, and fungal antioxidant metabolites, and had a shelf life of 12 days [28]. Furthermore, edible coatings of mushroom with Citrus aurantium essential oil provided 20 days of shelf life [71][72], and Eucalyptus leaf essential oil provided 12 days of shelf life [61][72][63,73].

Steroids, alkaloids, and phenolic compounds make up the majority of the diverse range of tyrosinase inhibitors isolated from plant sources and fungi, and are frequently incorporated in polymeric matrixes of edible coatings. Phenolic compounds, which can range in size from simple to large and complex tannins and derived polyphenols, display strong tyrosinase inhibition because of their molecular weight and quantity of aromatic rings [42][56][59][42,58,61]. To identify new sources of anti-tyrosinase compounds, research has been performed on the tyrosinase inhibitory activity of several plant extracts [59][78][61,79], and all significantly inhibited tyrosinase activity.

A smaller class of alkaloids and polyphenols found in fungi, including Aspergillus sp., Paecilomyces sp., Trichoderma sp., Phellinus linteus, Daedalea dickinsii, and Dictyophora indusiata, have been reported to selectively block the enzyme and are a source of novel tyrosinase inhibitors [40][41][40,41]. Studies have shown that four distinct strains of lactic acid bacteria isolated from cow faeces exhibit tyrosinase inhibitory activity [79][80]. For instance, the most active compounds within the group of natural flavones, flavanols, isoflavones, and flavanones inhibited mushroom tyrosinase with an IC50 of 44–500 μM, while natural anthocyanidins, aurones, and chalcones had an IC50 ranging from 18 to 106.7 μM, which was in comparison to kojic acid (a potent inhibitor of tyrosinase) with a tyrosinase inhibitory activity of IC50 of 59–318 μM (Table 3).

Table 2.

The effects of different sources of essential oils in edible coatings on the shelf life of fresh mushrooms.

| Essential Oils | Shelf Life | References |

|---|

Natural and synthetic phenolic compounds at half-maximal inhibitory concentration (IC50) values against white button mushroom tyrosinase.

| Compound Name | Tyrosinase Inhibition (IC50 Values (mM)) |

References | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Eucalyptus leaf | 12 | [61][72] | |||||||

| Natural anthocyanidins | 18–78 | [63,73] | |||||||

| [ | 80 | ][81][81,82] | Lemon | ||||||

| Natural aurones | 12 | [45][ | 31.7–98.547] | cellulose- N-acetyl cysteine | |||||

| [ | 81 | ][82] | Agaricus bisporus | Controlled lipid peroxidation Increased antioxidant activity |

Delayed weight loss and cap opening | [ | Cinnamon | 5 | [73][ |

| Synthetic aurones | 31–100 | 74][74,75 | 67 | ][68] | |||||

| ] | |||||||||

| [ | 82 | ][83] | Aloe vera-basil essential oil | Agaricus bisporus | Reduced polyphenol oxidase, respiration, and electrolyte leakage rate Increased phenylalanine ammonia-lyase and antioxidant activity |

Tocopherol with zein | 12 | [75][76]Reduced weight loss and softening Increased total phenolic contents Delayed browning and colour change |

[68][69] |

| Natural chalcones | 23–106.7 | [58][60] | Leek powder sunflower oil-guar gum | CinnamaldehydeAgaricus bisporus | 12Reduced the rate of respiration | ||||

| Synthetic chalcones | [ | 66][67] | |||||||

| 29.3–114.4 | [ | 56][83][58,84] | Satureja khuzistanica | 16 | [76][77] | ||||

| Citrus aurantium peel | 20 | [77][78] | |||||||

| Cumin seed | 20 | [77][78] | |||||||

| Cuminum cyminum | 20 | [77][78] | |||||||

| Citrus aurantium | 20 | [71][72] | |||||||

| Melaleuca cajuputi Powell. | 12 | [28] |

Table 3.

| Natural flavones | ||

| 110 | ||

| [ | 56 | ][57][58][59][58,59,60,61] |

| Natural flavanols | 55–300 | [56][57][58,59] |

| Natural isoflavones | 52–500 | [59][61] |

| Natural flavanones | 44–500 | [80][81][81,82] |

| Synthetic flavonols | 53–182 | [81][82] |

| Kojic acid | 59–318 | [56][57][58]59][84][58,59,60[,61,85] |