1. Effect of Cryogenic Technologies on Physicochemical and Aroma Compounds of Grape Must and Wine

1.1. Physicochemical Parameters

Total soluble solids (TSSs) of must were shown to be the least affected by freezing, as no difference was observed for storage periods less than six months

[1][2][3][4][5][25,35,42,50,51]. However, in a study conducted by the authors of

[6][32], different freezing techniques, i.e., involving liquid nitrogen as opposed to ultra-fast mechanical freezing, resulted in significant differences in TSS values. Total acidity (TA) of grape must was lower in cryogenic-treated samples, which validated the earlier findings of Olarte Mantilla et al.

[4][50], Santesteban et al.

[3][42], and Zhang et al.

[1][25]. This was related to the precipitation of potassium (K

+) salts during the freezing process and the lower solubility of acidic salts during defrosting of the grapes. Additionally, higher pH levels observed in must obtained after freezing and defrosting complemented previous studies

[1][2][3][5][6][25,32,35,42,51]. Moreover, the chemical parameter most affected by freeze storage was found to be titratable acidity

[2][35].

Research conducted by Naviglio et al.

[5][51] and Naranjo et al.

[7][52] involved the rapid cooling of Bianchello del Metauro grapes by sparging the grapes with liquid CO

2 before crushing and destemming. The white wines produced from these treated grapes were not statistically different from the control wines in terms of alcohol, pH, titratable acidity, and volatile acidity

[8][9][55,56]. This was similar to findings observed in earlier research. However, significant differences were observed for malic acid

[3][5][42,51]. Previous research showed that the physicochemical parameters of wine produced from fresh and frozen grapes as well as grape juice had significant differences in tartaric acid, but not alcohol content

[3][5][42,51].

Moreover, studies conducted by Zhang et al.

[1][25] and Pedrosa-López et al.

[10][34] found differences in alcohol levels in final wines produced from previously frozen whole grapes and macerated grapes. These differences were attributed to the extraction of compounds, which affected the fermentation process. Zhang et al.

[1][25] further found that wines produced from cold-macerated grapes had higher pH and glycerol levels compared to the control and skin-macerated treatments. This is similar to previous findings

[3][5][42,51], although it differed from the findings of Carillo et al.

[11][36] and other research, which showed that wines produced from grapes subjected to cold maceration did not show significant differences in chemical parameters when compared to the control

[2][5][6][12][32,35,38,51].

It should, however, be noted that these effects were not necessarily only due to the freezing treatment but resulted from the storage time, duration of skin contact, and grape cultivar

[1][3][6][25,32,42]. Furthermore, the type of cryomaceration treatment applied as well as type of berries used, i.e., whole berries or macerated grapes or juice, influence must and wine physicochemical parameters as conflicting results were observed between studies

[1][6][25,32].

Furthermore, this was not the focus of this review and will not be further discussed.1.2. Effect of Cryogenic Technologies on Grape Aroma Compounds

Aroma compounds or odourants can be classified according to the different stages of wine grape and/or juice processing that they originated from (

Table 12), namely varietal (cultivar), pre-fermentative (processing), fermentation (yeast and bacteria during alcoholic and malo-lactic fermentation), and post-fermentation (aging and maturation in wood, wine bottle storage, and preservation) aromas

[13][14][15][6,7,57]. These compounds are often present in the grape as odourless or non-volatile precursors and are released during winemaking, specifically during the alcoholic fermentation process

[15][16][57,58].

The three major classes of odourants that contribute significantly to varietal characteristics in wines are monoterpenes, methoxypyrazines, and volatile thiols

[17][18][28,59]. Volatile thiol compounds, also considered impact odourants, can either have a positive (tropical-, passionfruit-, guava-like) or negative influence (rotten egg, cooked vegetables, onion, cabbage) depending on their concentration in wines

[19][60]. Other compounds also present in wine and found to play a significant role in its aroma are esters, fatty acids, higher alcohols, and aldehydes

[15][17][20][28,57,61].

Table 12. Aroma development stage, compounds, and their origin.

| Aroma Development Stage |

Compound |

Origin |

| Varietal |

Precursors (free or bound) |

Grape berry (skin and pulp) |

| Pre-fermentative |

C6 compounds |

Enzymatic/catalytic reactions due to processing (crushing of berries) |

| Fermentation |

Ethyl esters, fusel alcohols, fatty acids, thiols |

Microorganism metabolism (yeast and bacterial) |

| Post-fermentation |

Oxidation of volatile aroma compounds; increase in fatty acids, esters, aldehydes, ketones, and polyphenols |

Wine aging (bottle, barrel, storage, aging on lees) |

Over the past three decades, there has been considerable interest and research into the volatile thiol aroma compounds and their precursors

[15][19][21][57,60,62]. Grape aroma compounds are predominantly located in the grape skin and require an extraction process to be released. The extraction of a compound is dependent on the nature of the compound, the concentration in the berry, the location within the berry, and the method used during processing

[22][23][24][63,64,65]. Winemakers usually achieve this by using a maceration step whereby the compounds are transferred from the solid components to the juice. Pre-fermentative cold maceration is another technique that has gained popularity during the white wine production process and was shown to enhance the varietal character of the wines produced

[10][25][26][29,31,34].

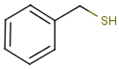

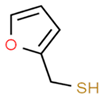

1.3. Effect of Cryogenic Technologies on Varietal Thiols

Varietal thiols are sulphur compounds found in grapes in a bound form that originate from fatty acids

[13][27][6,19]. These sulphur-containing compounds are originally associated with off-odours resulting from hydrogen sulphide (H

2S), methylmercaptan (methanethiol), ethanethiol, and methionol

[16][58]. They are considered the main compounds involved in the aroma of wine and responsible for its archetypal flavour

[28][30]. These volatile sulphur compounds are typically divided into two categories, i.e., highly volatile compounds, most of which are associated with aroma defects (carbon sulphide, ethanethiol, methanethiol, hydrogen sulphide), and low-volatile compounds, including the main desirable sulphur compounds that contribute to the enhancement of the sensorial quality of wines. Thiols are “bound” with glutathione or cysteine and released by the yeast during the fermentation process via the carbon–sulphur lyase (C-S) enzyme. Therefore, the quantification of their natural precursors in the must is important and can help the wine producer determine the aromatic potential of the grapes. An accurate quantification of these natural and deuterated compounds, i.e., 4-sulfanyl-4-methylpentan-2-one precursors (S-4-(4-methylpentan-2-one)-L-cysteine and S-4-(4-methylpentan-2-one)-glutathione), is achieved using SIDA (stable isotope dilution assay) that involves labelled analogues

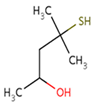

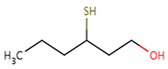

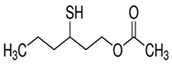

[13][23][6,64]. Key thiols present in Sauvignon blanc and responsible for its varietal aromas are 4-methyl-4-sulfanylpentan-2-one (4-MSP), 3-sulfanylhexan-1-ol (3-SH), and 3-sulfanylhexyl acetate (3-SHA) with perception thresholds of 0.8 ng L

−1, 60 ng L

−1, and 4 ng L

−1, respectively (

Table 23). They are predominantly responsible for the “tropical” (gooseberry, grapefruit, and passion fruit) characteristics associated with Sauvignon blanc

[9][56]. However, it is interesting to note that when present in excessive concentrations, they often impart less desirable strong, sweaty aromas resembling “cat urine”

[9][29][54,56]. Furthermore, research conducted on South African (SA) Chenin blanc revealed the presence of the varietal thiols 3-SH and 3-SHA in concentrations above their aroma thresholds, indicating that these two compounds also contribute significantly to the aroma of Chenin blanc wines

[24][30][31][65,66,67].

Varietal thiols are present in grape juice in the form of aroma-inactive, non-volatile precursors and are released by yeast enzymes during the fermentation process

[9][12][32][33][34][35][12,38,56,68,69,70]. Pinu et al.

[16][58] showed that the production of varietal thiols and other aroma compounds in Sauvignon blanc wines is not necessarily only dependent on nitrogenous and sulphur compounds but is also influenced by other juice metabolites such as carboxylic and fatty acids. Their research demonstrated that concentrations of wine aroma compounds can be modified using pre-fermentative treatments to produce different wine styles from the same grape varietal based on the metabolic profile of the juice, thus altering the metabolite levels. In addition, juice modulation through new winemaking practices, i.e., metabolite supplementation or blending, could be seen as a useful tool to create new wine styles

[16][58].

Pre-fermentative cold maceration has gained popularity in white wine production as it was shown to enhance the varietal characteristic of the wines

[10][28][29][30,34,54]. Two volatile precursors of 3-SH (3-S-cysteinylhexan-1-ol (Cys-3-SH) and 3-S-glutathionylhexan-1-ol (Glut-3-SH) were significantly higher in frozen thawed berries than in the juice of fresh berries as well as in the frozen juice of fresh berries

[10][28][30,34]. Glut-3-SH was fourfold higher in frozen grapes stored at −20 °C for two months compared to that found in frozen or fresh juices

[10][28][30,34]. Capone et al.

[36][37][71,72] made similar observations where a fivefold difference was found in precursor concentrations between freezing whole grapes and freezing juice, especially for the Glut-3-SH precursor, whilst no significant difference was found in the concentrations of the Cys-3-SH precursor. These results revealed that berry damage was the primary cause of the differences, and the major contributor was the glutathione conjugate formation rather than the extraction process resulting from the freezing and thawing processes

[36][37][71,72]. The results suggested that the Cys-3-SH precursor was already present in the grape berry whereas the Glut-3-SH precursor was formed because of berry damage

[36][37][71,72]. Although numerous studies have been conducted using cryogenic pre-treatment techniques on whole grapes and grape juice, their focus was on the overall aroma compounds and precursor formation in the grape juice. However, the effect of such treatments shows no direct relationship between the levels of precursors in the grape juice and the levels of varietal thiols in the wine. Therefore, this warrants further investigation and understanding

[10][28][36][37][38][39][30,34,53,71,72,73].

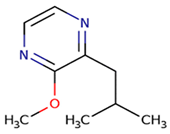

1.4. Effect of Cryogenic Technologies on Methoxypyrazines

Methoxypyrazines (MPs) are volatile nitrogen-containing heterocyclic compounds found in plants, insects, fungi, and bacteria

[40][41][74,75]. They are primarily responsible for the vegetative, grassy, green pepper, capsicum, and asparagus aromas present in Sauvignon blanc

[13][17][41][42][6,28,75,76]. The perception of green attributes is seen as positive and adds complexity to Sauvignon blanc

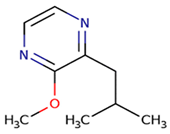

[17][42][43][28,76,77]. The most essential MP found in grapes and wines is 2-methoxy-3-

isobutylpyrazine (ibMP), the main contributor to the vegetative, grassy, green pepper, capsicum, and asparagus aromas in Sauvignon blanc

[17][40][41][42][43][28,74,75,76,77]. It is typically present in wine as free volatile compounds in concentrations ranging from 2 to 30 ng L

−1 (

Table 34).

Table 34. Methoxypyrazines present in Sauvignon blanc wines: aroma description, perception, and range in wine.

| Compound & Chemical Structure |

Aroma Description |

Aroma Perception in Water

(ng L–1) |

Aroma Perception in Wine

(ng L–1) |

Range in

Wine

(ng L–1) |

2–methoxy–3–isobutylpyrazine (ibMP)

|

vegetative, green pepper |

1–2 |

2–163 |

2–30 |

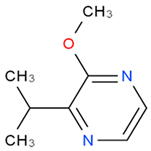

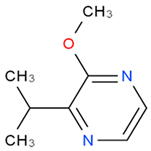

2–methoxy–3–isopropylpyrazine (ipMP)

|

earthy, mushroom, cooked, or canned asparagus, green beans |

1–2 |

2–16 |

<10 |

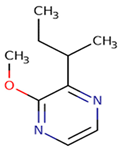

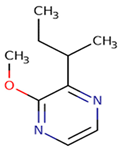

2–methoxy–3–sec–butylpyrazine (sbMP)

|

green (peas, bell pepper, galbanum), ivy leaves, bell pepper |

1–2 |

2–16 |

<10 |

Moreover, two additional MPs present in must and wine at lower concentrations are 2-methoxy-3-

isopropylpyrazine (ipMP) and 2-methoxy-3-

sec-butylpyrazine (sbMP), which contribute to the earthy, asparagus aromas

[17][40][41][28,74,75]. Sensory detection thresholds for ibMP, ipMP, and sbMP are typically very low, i.e., 1–2 ng L

−1 in water and 2–16 ng L

−1 in wine

[17][40][41][28,74,75]. Interestingly, during literature searches, the authors noted no publications investigating the effect of cryogenic treatments on MPs, which warrants further investigation and understanding as MPs are major contributors to the aroma profile of Sauvignon blanc wines. Previous research incorporating cryogenic practices focused mainly on their effect on major aroma compounds, i.e., polyphenols, terpenes, esters, higher alcohols, fatty acids, as well as the varietal thiols, i.e., 3-SH, 3-SHA, and 4-MSP

[17][18][26][43][44][28,31,59,77,78].

2. Effect of Cryogenic Technologies on Sensory Properties of Wine

Wine quality and consumer acceptance of wine are frequently determined by organoleptic properties (aroma, colour, and taste), particularly the aroma profile

[17][44][45][46][47][48][26,28,78,79,80,81]. In most cases, wines produced from grapes subjected to pre-fermentative cryomaceration treatments had a higher aroma intensity, improved mouthfeel, improved colour, oxygen stability, as well as enhanced aroma characteristics related to the cultivar

[2][6][9][10][25][48][49][29,32,33,34,35,56,81]. This is due to an increase in the extraction of the aroma and flavour compounds, i.e., terpenes, thiols, esters, phenols, etc., present in the grape skin

[2][6][10][11][25][44][50][29,32,34,35,36,37,78]. Alti Palacious et al.

[25][29] demonstrated that cold pre-fermentation maceration treatments prior to vinification were capable of modifying the nutrient composition of the grape must, therefore enhancing the formation of aroma compounds, resulting in wines with an enhanced final quality.

In addition to the discussion on how cryogenic pre-treatment techniques affect the sensory profiles of the final wines

[11][36], it was shown that wines produced from whole grape bunches sprayed with liquid CO

2 (inertized wine (IW)) whilst passing through a cooling tunnel had a better colour than the untreated wine. This was confirmed by analysing the total phenol concentration and the lowest value of gallic acid. Moreover, non-trained judges (preference test) preferred the IW wines. Inertized wines were found to achieve a good quality standard, capable of satisfying consumer preferences

[11][36]. Furthermore, the research conducted by Alti Palacious et al.

[25][29] further found that treating grape must with dry ice (solid CO

2) assisted in modulating the aroma compounds, therefore enhancing the aromatic quality and complexity of the final wines. Overall, the general trend observed from the literature shows that freezing techniques produced wines of a more intense aroma when compared to wines obtained using traditional methods. Moreover, the cryogenic method affected the overall quality of the wines

[26][31].