Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Cheng Zhang and Version 2 by Lindsay Dong.

Photocatalysis, a promising semiconductor-based technology activated by free and eternal solar energy, has great potential for addressing environmental remediation and energy conversion challenges. Concentrated solar power (CSP) technologies, namely parabolic trough reflectors, solar power towers, parabolic dish reflectors and linear Fresnel reflectors, exhibited excellent feasibility for boosting solar-driven photocatalytic processes. Based on the structural characteristics of CSP technologies, the CSP-based photocatalytic reactors could be divided into concentrated types and non/low-concentrated types.

- concentrated solar power (CSP) technology

- photocatalysis

- solar energy

1. Introduction

The sustainable development of the global economy and society is being disrupted by environmental deterioration, energy crises and other aspects [1]. The traditional way of production and life requires a large amount of non-renewable energy to drive, which not only further aggravates the problem of insufficient energy supply but also continues to destroy the ecological environment. Faced with this dilemma, the United Nations put forward the Sustainable Development Goals (SDGs), which emphasize the utilization of renewable energy and new production development modes [2]. Motivated by this, significant effort has been put into searching for new process strategies for energy conservation and emission reduction and studying their utilization patterns.

In the last few decades, photocatalysis has been intensively studied [3][4][5][3,4,5]. Under the illumination of incident light, the photocatalyst, as a semiconductor, could be excited to release electrons and holes, thereby leading to the subsequent generation of free radicals (such as superoxide radicals, hydroxyl radicals, etc.) with strong oxidation–reducing properties [6]. These free radicals could act on the structure of organic molecules and destroy their molecular bonds, resulting in the destruction and degradation of organic particles with no change occurring on the photocatalyst itself. Owing to the non-selectivity, cost-effectiveness, non-toxicity and eco-friendliness, photocatalytic technology exhibited impressive application potential in environment remediation (e.g., wastewater treatment [7][8][7,8], abatement of noxious gases [9], sterilization ([3][10][3,10], etc.), energy conversion (e.g., water splitting for hydrogen generation [11][12][11,12], hydrogen formation via ammonia decomposition [13][14][13,14], microalgae biorefinery [1], etc.) and so on. In order to boost this promising technology further into practical applications, the sources of energy used to drive photocatalytic reactions need to be carefully selected. Solar energy, as a natural source of light, has the following exciting characteristics: (1) permanent supply of energy, (2) wide distribution on earth, (3) easy utilization availability and (4) wide spectral band of wavelengths. Although the proportion of high-energy UV photons is only 3% to 5% of the total solar energy, it does not affect solar light to be the ideal driving force to motivate the photocatalytic processes [1][3][4][7][1,3,4,7].

As a bridge between sources of driving forces (solar energy) and users of driving forces (photocatalysis), photocatalytic reactors have been studied tirelessly in recent decades. The simplest photoreactor was a beaker placed under simulated solar light irradiation, which was filled with a photocatalyst and reactant [15][16][15,16]. Despite initiating the photocatalytic reaction, it was obviously far from practical application. Going one step further, some primitive but systematic prototype photoreactors have been developed and studied, including the classic inclined plate reactor (IPR) [7]. The structure of an IPR is characterized by an inclined plane facing the direction of solar light incidence, and the angle of inclination can be adjusted according to the local latitude. The photocatalyst is immobilized or flows down with wastewater in powder form, and the photocatalytic process is implemented upon the inclined plate. This simple and inexpensive design propelled IPR into widespread use, and an IPR-based wastewater treatment plant was even manufactured for purifying industrial wastewater from textile mills [17]. Nevertheless, one obvious disadvantage of IPR is that it leads to insufficient photocatalytic activity because of the low solar energy collecting efficiency brought on by passive acceptance of solar light [7]. Aiming to promote photocatalytic efficiency under actual sunlight, new photoreactor concepts are required. When it comes to effectively harvesting sunlight, it is natural to think of concentrated solar power (CSP) technology. CSP technology refers to the renewable energy project that concentrates, collects and converts solar energy into heat flux through a photo-thermal conversion process [18]. It has attracted great attention, owing to its unique advantages such as its superior capability for light and thermal collection, wide feasibility for multiple utilization purposes and high technical maturity. Generally, CSP technology can be divided into parabolic trough reflectors (PTRs), solar power towers (SPTs), parabolic dish reflectors (PDRs) and linear Fresnel reflectors (LFRs) according to their system configurations [19]. Since the effective solar energy collection capability of CSP technology matches the demand for solar energy-driven photocatalytic processes, it is not surprising that CSP-based photoreactors are widely developed and studied.

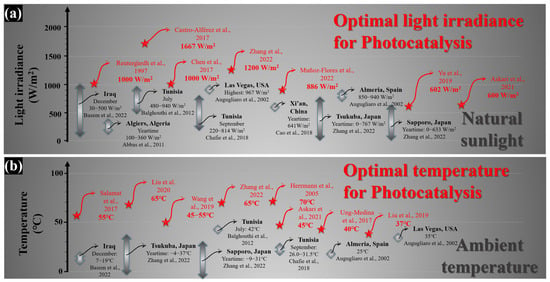

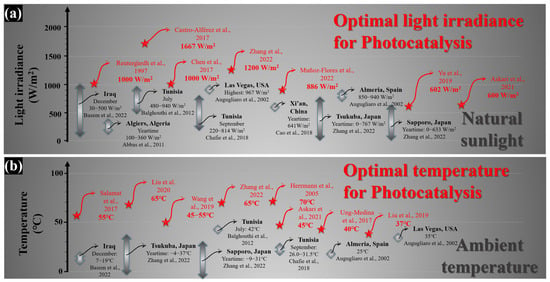

In addition, from a practical point of view, to make photocatalytic technology applicable, efficient photocatalytic processes need to be pursued. Therefore, suitable photocatalytic reaction conditions need to be provided and maintained. Since solar light energy mainly provides light irradiance and the reaction temperature, whether natural sunlight is qualified to meet the appropriate reaction conditions for efficient photocatalysis needs to be investigated. Figure 2a illustrates the optimal light irradiance required for various photocatalytic reactions. It can be observed that for a wide range of photocatalytic reactions, including the removal of organic dyes (rhodamine b, tartrazine, reactive black 5, etc.) [7][38][39][7,38,39], the degradation of harmful antibiotics (metronidazole, tetracycline, cephalexin, etc.) [40][41][40,41], the inactivation of pathogenic bacteria (Escherichia coli, etc.) [42] and the oxidation of organic matters (aerobic oxidation, etc.) [43], the light irradiance in the range of 600–1600 W/m2 is conducive to the implementation of efficient photocatalytic reactions (Figure 2a). However, under real environmental conditions, the solar light irradiance (data from [7][44][45][46][47][48][49][7,44,45,46,47,48,49]) is much lower than the appropriate light irradiance required for efficient photocatalysis (Figure 2a).

In addition, from a practical point of view, to make photocatalytic technology applicable, efficient photocatalytic processes need to be pursued. Therefore, suitable photocatalytic reaction conditions need to be provided and maintained. Since solar light energy mainly provides light irradiance and the reaction temperature, whether natural sunlight is qualified to meet the appropriate reaction conditions for efficient photocatalysis needs to be investigated. Figure 2a illustrates the optimal light irradiance required for various photocatalytic reactions. It can be observed that for a wide range of photocatalytic reactions, including the removal of organic dyes (rhodamine b, tartrazine, reactive black 5, etc.) [7][38][39][7,38,39], the degradation of harmful antibiotics (metronidazole, tetracycline, cephalexin, etc.) [40][41][40,41], the inactivation of pathogenic bacteria (Escherichia coli, etc.) [42] and the oxidation of organic matters (aerobic oxidation, etc.) [43], the light irradiance in the range of 600–1600 W/m2 is conducive to the implementation of efficient photocatalytic reactions (Figure 2a). However, under real environmental conditions, the solar light irradiance (data from [7][44][45][46][47][48][49][7,44,45,46,47,48,49]) is much lower than the appropriate light irradiance required for efficient photocatalysis (Figure 2a).

2. Feasibility of Solar Energy for Photocatalytic Applications

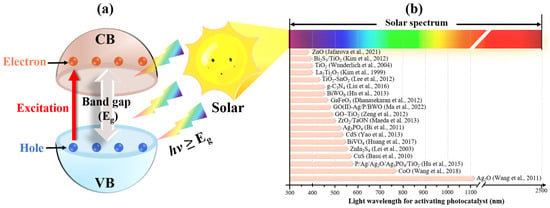

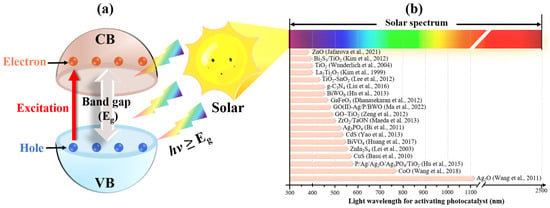

The formation of electrons and holes in photocatalysts requires photon excitation with sufficient energy. In order to excite electrons from the valence band (VB) of the photocatalyst to the conduction band (CB), the photon energy carried by the incident light needs to overcome the band gap between the VB and CB (as shown in Figure 1a). After decades of development, a large family of photocatalysts has been formed. According to the element composition, synthesis conditions and defect location, different photocatalysts have different band gaps. Figure 1b shows the light wavelength required for activating some typical photocatalysts (data from [8][20][21][22][23][24][25][26][27][28][29][30][31][32][33][34][35][36][37][8,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37]). It can be seen that although the sun emits light over a wide range of wavelengths, traditional photocatalysts such as TiO2 can only be excited by UV light with wavelengths less than 380 nm [28]. Since UV energy only accounts for a small proportion of solar energy, this results in low UV radiation intensity and low photocatalytic efficiency. In recent years, newly developed photocatalysts such as P/Ag/Ag2O/Ag3PO4/TiO2 composites [31] have expanded the utilizable solar radiation band, enabling it to be excited by both visible light and UV, significantly improving the photocatalytic efficiency compared to TiO2 alone. Since solar energy is an infinite and widely distributed light source possessing a broad spectrum wavelength ranging from 300 to 2500 nm [7], it could excite the photocatalyst with any band gap, thus implementing the photocatalytic reaction process.

Figure 2. Comparison of optimum photocatalytic reaction conditions with natural conditions. (a) Light irradiance [7][38][39][40][41][42][43][44][45][46][47][48][49][7,38,39,40,41,42,43,44,45,46,47,48,49]; (b) temperature [7][10][40][45][46][47][49][50][51][52][53][54][7,10,40,45,46,47,49,50,51,52,53,54].

3. Brief Overview of Concentrated Solar Power Technologies

3.1. Parabolic Trough Reflectors

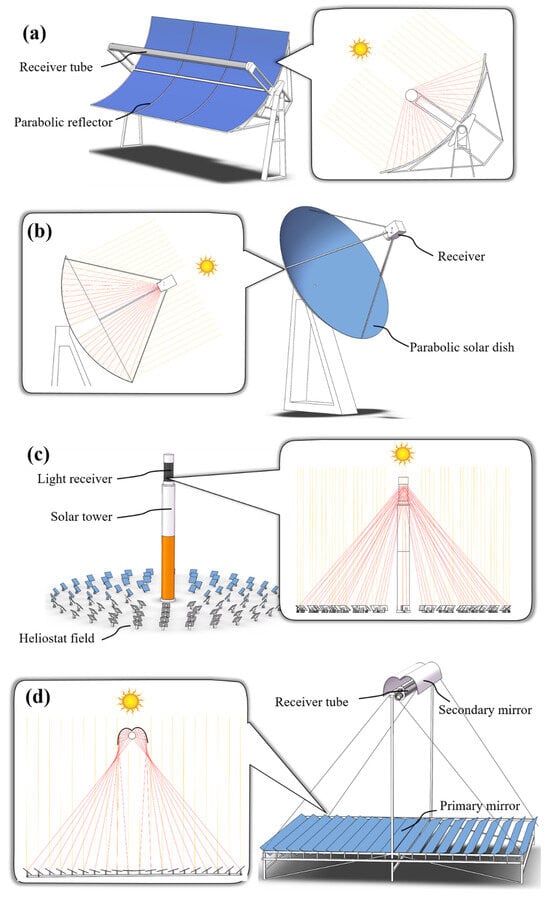

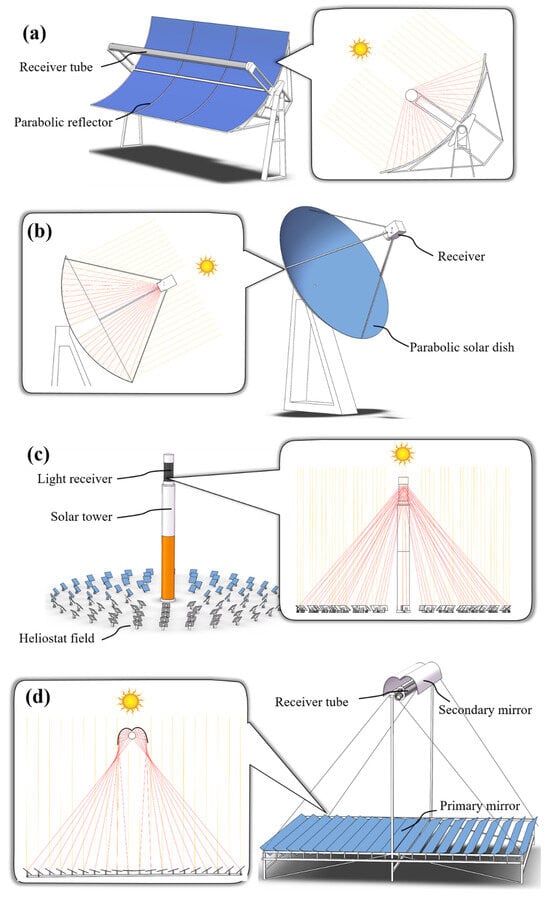

The PTR might be the most common and widely deployed CSP technology. As shown in Figure 3a, the most important technical feature of the PTR is that it is equipped with a parabolic-shaped concentrator mirror and a receiver tube located at the focal line of the parabola [45]. Owing to the optical properties of the paraboloid, it can efficiently focus incident parallel sunlight onto its focal line. This capability allows the receiver to harness a substantial amount of light energy, subsequently converting it into a concentrated heat flux. In order for the parabolic mirror to accurately converge parallel solar rays, the aperture of the parabola must always face the incidence direction of sunlight accurately. Therefore, parabolic mirrors are usually equipped with a controlling system to track solar motion. Due to its simpler structure compared with other CSP technologies, PTR has been successfully applied in various application scenarios. The most interesting application of PTR might be in the field of solar thermal power generation [55]. By concentrating a large amount of light and heat energy, the thermal medium (such as thermal oil and molten salts) in the receiver tube is heated, thus heating the water into high-temperature steam, which drives the turbine to generate electricity. Additionally, the solar cooking system also consists of an aluminum reflector with a vacuum tube, which provides a suitable cooking temperature of over 200 °C under actual solar conditions [56].

Figure 3. Schematic diagram of major concentrated solar power (CSP) technologies. (a) Parabolic trough reflector (PTR); (b) parabolic dish reflector (PDR); (c) solar power tower (SPT) and (d) linear Fresnel reflector (LFR).

3.2. Parabolic Dish Reflectors

The main components of a PDR system (shown in Figure 3b) include a parabolic dish concentrator mirror and a thermal receiver mounted at the focus point of the parabolic dish [57][63]. Similar to PTR technology, PDR also requires the incident direction of the parallel sunlight to be perpendicular to the aperture of the parabolic dish, thus enabling effective solar energy harvesting. Therefore, a two-axis sun tracking system is also indispensable for PDR. Generally, PDR systems are characterized by a high efficiency, autonomous operation and excellent modularity [57][63]. Many PDR-based power plants have been manufactured worldwide, which exhibit high solar-to-electric conversion efficiency and have the potential to become one of the most effective renewable energy utilization approaches [44][49][57][44,49,63].3.3. Solar Power Towers

In recent decades, as a representative of high-temperature concentration engineering, SPT has been a popular topic in CSP engineering applications [58][68]. As shown in Figure 3c, in the SPT system, a large number of heliostats are arranged in an oval shape around the heat collecting tower. The heliostat could automatically track the movement of the sun and focus sunlight to the receiver located above the tower, thereby converting light energy into heat flux. The solar concentration ratio of a SPT can reach the equivalent of hundreds to thousands of suns, thereby achieving ultra-high operating temperatures. In recent years, to achieve the goal of saving energy and reducing emissions, SPT-based photo-thermal power plants employing the Rankine or Brayton cycle have been intensively studied and deployed [59][69].3.4. Linear Fresnel Reflectors

In the past few decades, LFRs have also been studied and developed, and they have been widely used in photo-thermal power generation projects [60][61][70,71]. As shown in Figure 3d, the main structure of an LFR includes segmented flat mirrors which are mounted in parallel (as a primary mirror) and a secondary mirror located above the primary mirror array. The light receiver is mounted at the focus position of the secondary mirror. Each row of primary mirrors has a rotation axis, and all the primary mirrors track the position of the sun in the sky under the control of the driving mechanism, focusing the sunlight on the secondary mirror [7]. The shape of the secondary mirror is a compound parabolic collector (CPC) that can capture and reflect incoming sunlight in all directions to its focal point [62][72]. CPC, as a supporting CSP technology for LFR, plays a crucial role in improving the efficiency and heat flow uniformity of LFR systems. CPC is usually formed by a variety of shape combinations (such as involute, parabola, etc.), thus endowing it with the unique capability to collect beam radiation and diffuse radiation within a specific acceptable half-angle and without the utilization of a complex solar tracking system [63][73].4. CSP Technologies Applied in Photocatalysis

4.1. Solar Concentrated Type

4.1.1. Parabolic Trough Reflector-Based Photoreactors

At present, solar-concentrated types of photoreactors mainly apply three technologies, including PTR, PDR and LFR. As a compact and efficient configuration for harvesting solar energy, it is not surprising that PTRs have been widely adopted as the basis for the construction of photocatalytic reactors [64][65][66][67][68][69][70][71][72][74,75,76,77,78,79,80,81,101]. As early as 1991, Anderson et al. reported a PTR-based photocatalytic reactor for groundwater remediation, which was widely considered to be the first on-site application project [72][101]. This project was built at the Lawrence Livermore Laboratory in the United States. The system structure consisted of rows of parabola troughs arranged in a field to form a trough array, which could reflect solar rays onto the reaction tube filled with photocatalyst particles. Subsequently, from 1993, a series of PTR-based photoreactors employing TiO2 as a photocatalyst for the degradation of various organic pollutants was tested and evaluated at the Plataforma Solar de Almeria (PSA), Spain. For example, Minero et al. established a large solar plant for the photocatalytic degradation of pentachlorophenol, which achieved a water treatment capacity of cubic meters per hour [68][78]. The system consisted of a total of twelve heliostat modules that could track solar motion, and every heliostat module was equipped with four PTRs. The nominal aperture area of each heliostat module was 32 m2, thus providing sufficient light energy for the reaction tube. They also carried out the photocatalytic degradation of atrazine by employing one of the heliostat modules in the above solar plant, which exhibited an atrazine removal ratio of 98% in 2 h. Other photocatalytic experiments using PTR-based photoreactors include the inactivation of Escherichia coli [65][75], the elimination of methylene blue and rhodamine b [70][80] and the removal of oxalic acid [71][81].4.1.2. Parabolic Dish Reflector-Based Photoreactors

Due to the high efficiency and compactness of PDR technology in concentrating solar energy, unique PDR-based photoreactors have also been explored. Oyama et al. presented a batch-mode photoreactor system aiming to achieve the photocatalytic degradation of commercial detergent under real sunlight [73][82]. The system consisted of a round concave mirror (parabolic dish reflector) with an aperture diameter of 1.0 m and a flask-type reaction vessel. The parabolic dish reflector employed could achieve a geometric concentration ratio of 70 suns. The reaction vessel was mounted at the focal point of the parabolic dish for adsorbing the incident solar energy. TiO2, as the photocatalyst, was used in suspension and flowed inside the system circulation loop. The photocatalytic degradation of the refractory detergent driven by concentrated sunlight exhibited a much higher treatment efficiency than conventional biodegradation.4.1.3. Fresnel Condenser-Based Photoreactors

Linear Fresnel reflectors, due to their excellent solar energy harvesting capabilities and widely acknowledged low costs, have also shown strengths in the structural exploration of photocatalytic systems. Zhang et al. developed an LFR-based photoreactor for the photocatalytic treatment of various organic contaminants including organic dye, antibiotics and pathogenic microorganisms [7]. In this system, six flat primary mirrors were mounted on the pedestal of the reactor and driven by stepper motors. The system was located in the north–south direction, with the primary continuously tracking and reflecting solar rays to the reaction tubes. The quartz glass reaction tubes were located above the primary mirror array, which could be moved in a north–south direction to accommodate the solar altitude angle in different seasons. Different from previous studies employing TiO2 particles, this LFR-based photoreactor utilized TiO2-coated silicone beads as the photocatalyst, which filled the inside of the reaction tubes. Rhodamine b, amoxicillin and Escherichia coli were successfully eliminated under actual weather conditions including a sunny day, cloudy day and rainy day, which demonstrated the feasibility of the LFR configuration for providing solar energy to photocatalysis.4.1.4. Problems in Solar-Concentrated Photoreactors

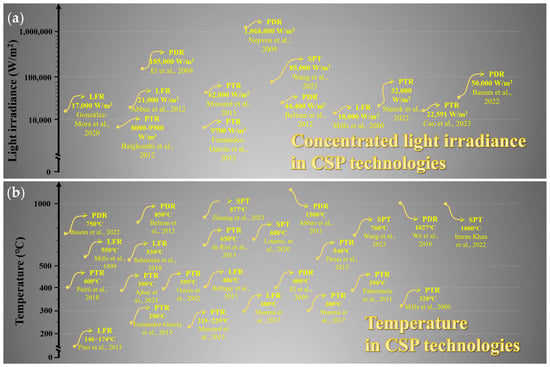

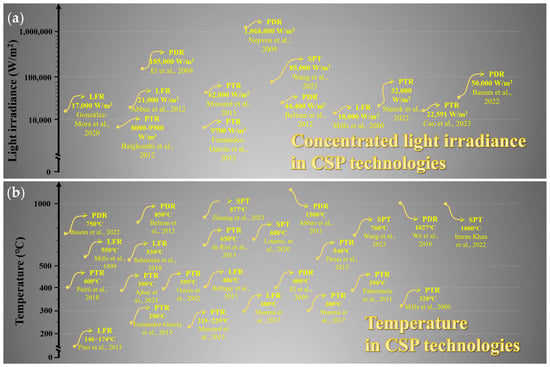

Although solar energy-concentrated photocatalytic reactors have demonstrated the capability of improving photocatalytic efficiency, their inherent disadvantages appeared with further research. First, solar-concentrated photoreactors may provide excessively high light irradiance and reaction temperatures for photocatalytic reactions [17][74][17,102]. Figure 47a shows the ability of some typical PTRs [45][75][76][77][78][45,62,103,104,105], PDRs [49][79][80][81][49,106,107,108], SPTs [59][69] and LFRs [60][62][82][70,72,109] to concentrate solar energy. Usually, these solar concentrators are used to concentrate solar energy efficiently to produce high temperatures which can be employed in thermal engineering processes such as in photo-thermal power plants. A solar concentration ratio equivalent to hundreds or thousands of suns was achieved, resulting in ultra-high light irradiance (Figure 47a).

Figure 47. Solar thermal energy provided by typical CSP technologies. (a) Concentrated light irradiance [45][49][59][60][62][75][76][77][78][79][80][81][82][45,49,62,69,70,72,103,104,105,106,107,108,109]; (b) temperature [18][19][44][49][57][58][59][61][62][75][77][79][81][83][84][85][86][87][88][89][90][91][92][18,19,44,49,62,63,68,69,71,72,104,106,108,110,111,112,113,114,115,116,117,118,119].

Figure 47b illustrates the temperature in some typical CSP projects, including PTR [18][19][62][75][77][83][84][85][86][87][18,19,62,72,104,110,111,112,113,114], PDR [44][49][57][79][81][44,49,63,106,108], SPT [58][59][88][89][68,69,115,116] and LFR [61][84][90][91][92][71,111,117,118,119]. For example, de Risi et al. optimized a PTR-based solar collector, which achieved a nanofluid outlet temperature of 650 °C [87][114]. Khan et al. introduced a next-generation SPT system with a temperature of more than 1000 °C [58][68]. Additionally, a dish Stirling system was developed by Abbas et al., who demonstrated its ability to achieve a temperature in excess of 1500 °C [44].

Secondly, although PTR, PDR, SPT and LFR can achieve effective solar energy convergence under sunny conditions with sufficient direct light, their photothermal harvesting capability will plummet on cloudy days, thus greatly limiting the efficiency of the photocatalytic reaction [1][7][1,7]. Thirdly, for these solar concentrator configurations, complex mechanisms for driving these structures are unavoidable due to the need to actively track the incidence angle of the solar rays [17]. This would increase the overall design difficulty, construction investment, operation and maintenance costs of photocatalytic reactors. Due to the above issues, traditional CSP-based photoreactors, mainly PTRs, are widely considered to be an outdated technology. In order to find photoreactors that can achieve appropriate enhancement of natural solar energy for achieving promoted photocatalytic efficiency, non/low-concentrated photoreactors began to be developed.

4.2. Non/Low-Concentrated Photoreactors

4.2.1. V-Groove-Based Photoreactors

The V-groove, as a variant of the PTR, simplifies the profile of the parabola into two flat mirrors, thereby dramatically reducing the solar concentrating ratio. V-groove-based photoreactors were mainly studied in 2004 by McLoughlin et al. and Bandala et al. to explore the advantages and disadvantages of PTR, V-groove and CPC technologies in photocatalytic applications [65][71][75,81]. TiO2 was adopted as the photocatalyst for the degradation of various organic targets including oxalic acid and Escherichia coli under real sunlight. Due to the low concentration of sunlight, the reaction temperature of the V-groove-based photoreactor never exceeded 38 °C. In comparison experiments, the CPC-based photoreactor clearly demonstrated a higher photocatalytic efficiency compared to the V-groove-based photoreactor. This may be due to the fact that the V-groove has no optical focus; therefore, the flat mirror cannot effectively provide the reflected light to the reaction tube, thereby resulting in its low efficiency. As a transitional photocatalytic reactor technology, the V-groove-based photoreactor was quickly eliminated by CPC-based photoreactors.