You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Jose Aguilar and Version 2 by Jessie Wu.

One of the great current challenges of Micro, Small and Medium Enterprises (MSMEs) is to dynamically innovate to improve their supply of goods, products, and services in order to respond to the changing needs of the market. In particular, several studies have concluded that investment in innovation has a high impact on the competitiveness of organizations, which can lead to the introduction of new products and processes. Thus, innovation is a means for companies to adapt to remain in the market, considering available resources.

- production-chain

- agroindustry

- autonomous computing

- artificial intelligence

1. Application of Methodology for the Specification of IData Analytics TasksANO to the Agroindustrial Production Chain of Small and Medium EnterpriMSMEses

Table 1 summarizes the use of the methodology for the specification of data analytics tasks (MIDANO) to analyze the agroindustrial production chain of Small and Medium Enterprises (MSMEs)MSMEs.

Table 1.

Use of MIDANO phases for Industrial Automation Processes.

| Phase | Use |

|---|---|

| Phase 1 | Analysis of the production chain in the agroindustrial to improve their competitiveness. To this end, this research proposes ACODAT to improve industrial production. |

| Phase 2 | Identification of data sources (e.g., quantity, quality, time, and cost). |

| Phase 3 | Implementation of autonomic cycles for the automation of the production chains in agroindustry. |

2. Agroindustrial Production Chain of MSmall and Medium EnterpriseMEs

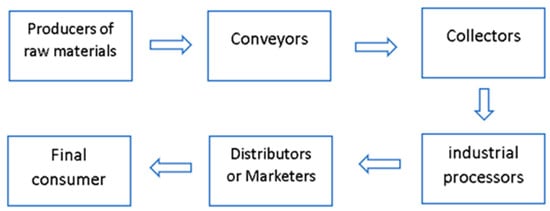

Based on an analysis of agribusiness, it is possible to establish the macro conditions under which the production chains operate. In general, there is a wide range of activities and, therefore, actors that are part of a chain. It is, therefore, necessary to clearly establish the limits of the production chain and define its operating structure by establishing a model. The work [1][29] proposes a production chain model (see Figure 12), the basis of reseaourchers' proposal.

Figure 12.

Production chain links (source: United Nations Industrial Development Organization).

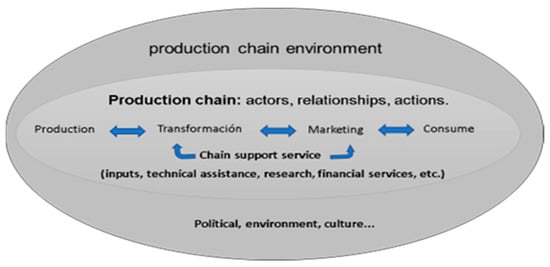

In this context, Nonaka [2][30] has defined a scheme of the production chain and its main actors (see Figure 23).

As a starting point from such a model, it is necessary to understand the framework of production chains and establish how they are conceived, what their constituent elements are, and what characteristics they should have. The steps to follow to properly model a production chain are summarized below [3][4][31,32].

| 3 | ||||||||||||||||

| 4 | ||||||||||||||||

| 2 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 2 | 3 | 4 | ||||||

| 4 | Production, service and support processes are identified. | 2 | 4 | 3 | 4 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 2 | 3 | 4 |

| 4 | Environmental responsibility, good use and conservation of biodiversity. | 3 | 4 | 4 | 4 | 2 | 4 | 4 | 3 | 4 | 4 | 4 | 4 | 2 | 3 | 3 |

| 4 | Machinery capacity | 2 | 3 | 4 | 4 | 2 | 3 | 3 | 3 | 4 | 4 | 3 | 4 | 3 | 3 |

| ACDM |

).

Table 4.

Evaluation metrics.

For the construction of the prioritization table, 15 experts in the MSME Agroindustrial sector, and 10 research professors rated each of the criteria. In the result, each of the answers provided by them was averaged. The results are shown in Table 5, where the columns with the numbers in red represent the subprocesses with the highest priority (they represent the highest scores), for which the ACODATs are proposed in this woresearchk.

Table 5.

Prioritized subprocesses by experts.

| Weight | Evaluation Criteria | Processes | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input Suppliers | Producers and/or Growers | Industrial Transformer | Wholesaler/Retailer | |||||||||||||

| SCS | AOEI | EPST | AAPF | MOEP | SAAF | APAC | NTAP | TIAT | NTAT | ACDM | NEDN | ACOP | NIVE | DIST | ||

| Relevance to Production Management | ||||||||||||||||

| 4 | the factors that intervene in the process are characterized. | 4 | 3 | 2 | 4 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 4 |

| 4 | the uses and functions of the materials and tools used are distinguished | 3 | 4 | 3 | 4 | 2 | 2 | 4 | 4 | 4 | 4 | 4 | 3 | 2 | 3 | 3 |

| 4 | information and knowledge management is identified | 2 | 3 | |||||||||||||

| 2 | ||||||||||||||||

| 4 | Accessibility to technology. | 3 | 3 | 4 | 2 | 2 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 4 |

| 4 | Skilled Labor (Requirement and Availability) | 4 | 3 | 3 | 2 | 4 | 2 | 3 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 4 |

| 4 | Identification of suppliers of raw materials and inputs (domestic, international origin) | 4 | 4 | 4 | 3 | 2 | 3 | 3 | 2 | 4 | 4 | 4 | 4 | |||

-

Establish the links in the production chain (defined by the blue arrows in Figure 23).

-

Determine the segments that make up each of the links in the production chain by using segmentation instruments and their corresponding variables.

-

Represent the material and capital flows that take place in the chain.

-

Establish the institutional and organizational environment of the chain.

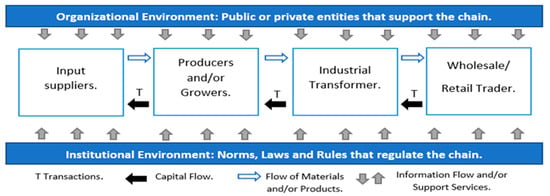

The above activities must be accompanied by a validation by the chain actors. For the construction of the proposal, 15 experts from the MSME agribusiness sector validated each of the links in the production chain. Figure 34 shows ouresearchers' proposal of an Agroindustrial Production Chain for MSMEs.

Figure 34. Researchers' Proposal of an Agroindustrial Production Chain for MSMEs.

Our Proposal of an Agroindustrial Production Chain for MSMEs.

ReseaOurchers' proposal has four processes (see Table 2): Input Suppliers, Producers and/or Growers, Industrial Transformer and Marketing.

Table 2. Processes in researchers' agroindustrial production chain.

Processes in our agroindustrial production chain.

| 4 | ||||||||||||||||

| 3 | ||||||||||||||||

| 4 | ||||||||||||||||

| Relevance for performing data analysis tasks | ||||||||||||||||

| 4 | ||||||||||||||||

| How many internal or external sources of information exist: databases, Excel sheets, reports, etc. | 3 | 3 | 4 | 3 | 3 | 3 | 3 | 4 | 3 | 4 | 4 | 4 | 4 | 3 | 4 | |

| 4 | What level of access do you have to the information | 4 | 3 | 3 | 4 | 3 | 2 | 4 | 4 | 3 | 4 | 4 | 4 | |||

| Process | Examples | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Suppliers of Input Materials | Irrigation systems, organic and inorganic fertilizers, certified seeds. | |||||||||||||||

| Producers and/or Growers | Land tenure, area, labor force, technological level, degree of specialization, market share, working capital, forestry support services, agricultural support activities, post-harvest activities, seed processing. | |||||||||||||||

| Industrial Transformer | Size of the property, labor force, type of input to be processed, quality parameters, technological level, the added value of the product, market scope and coverage, level of specialization of the business. | |||||||||||||||

| Wholesaler/Retailer | Stockpiling and Distribution. Storage, Classification, Standardization, Packaging and Transportation. | |||||||||||||||

-

Input Suppliers: the entities that provide or supply certain products or services to companies for their use, for example, agrochemicals and packaging.

-

Producers and/or Growers: this process is in charge of the harvest and post-harvest preparation. It must consider, among other things, the workmanship, the forestry support services and post-harvest activities.

| 4 | ||||

| 3 | ||||

| 4 | ||||

| 4 | ||||

| Level of use of computer tools (Words, excel, power point, etc.). | ||||

| 2 | ||||

| 3 | 3 | 3 | 3 | 2 |

- Industrial Transformer:

- this process transforms or adapts the inputs for the materialization of the intended products or services. It must consider, among other things, The type of input to be transformed, the technology required for the transformation, etc.

-

Wholesaler/Retailer Commercialization: this process is the distribution of products or services to the market. It must consider, among other things, stockpiling and marketing.

Each process of the Agroindustrial Production Chain of MSMEs has different subprocesses, which should be prioritized according to whether data analysis tasks can be used and what its relevance is to improve the competitiveness of an MSME in the agroindustrial sector. RWesearchers identify 15 subprocesses, listed in Table 3.

Table 3.

Subprocesses in the Agroindustrial Production Chain of MSMEs.

| 3 | ||||||||||||||||

| 4 | ||||||||||||||||

| 3 | ||||||||||||||||

| 3 | ||||||||||||||||

| 4 | ||||||||||||||||

| 3 | ||||||||||||||||

| 4 | ||||||||||||||||

| 3 | 4 | |||||||||||||||

| 4 | Frequency of information gathering at this stage of the process | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 4 | 4 | 3 | 4 |

| Total unweighted | 39 | 43 | 43 | 44 | 34 | 37 | 44 | 48 | 48 | 50 | 51 | 49 | 40 | 39 | 48 | |

| Weighted total | 36 | 36 | 37 | 39 | 37 | 33 | 38 | 39 | 42 | 41 | 38 | 41 | 37 | 36 | 38 | |

| Process | Subprocess | ACRONYM | Meaning | Weight | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input suppliers |

Certified seeds | SCS | ||||||||||||||

| Subprocess is not important | 1 | |||||||||||||||

| Organic and inorganic fertilizers | AOEI | |||||||||||||||

| Primary, secondary and tertiary packaging | EPST | |||||||||||||||

| Applications of agrochemicals in particular and fertilizers. | AAPF | |||||||||||||||

| Subprocess is slightly important | Producers and/or growers |

Workmanship | MOEP | |||||||||||||

| Forestry support services | SAAF | |||||||||||||||

| 2 | Post-harvest activities | APAC | ||||||||||||||

| Technological level | NTAP | |||||||||||||||

| Industrial transformer |

Type of input to be processed | TIAT | ||||||||||||||

| Level of business specialization. | ||||||||||||||||

| NEDN | ||||||||||||||||

| Wholesaler/retailer | ||||||||||||||||

| Subprocess is important | 3 | |||||||||||||||

| Subprocess is very important | 4 | Transformer technology level | NTAT | |||||||||||||

| Market reach and coverage. | commercialization |

Stockpiling | ACOP | |||||||||||||

| Leveling | NIVE | |||||||||||||||

| Distribution | DIST |

3. Prioritization of Subprocesses of the Agroindustrial Production Chain of MSMEs

A prioritization table has been used to select the subprocesses. The criteria to evaluate the relevance of the subprocesses were defined according to the importance of each subprocess in the MSME Agroindustrial Production Chain, and the possibility of performing data analysis tasks. Thus, these values determine the level of importance of each subprocess (see Table 4

From the above table, the subprocesses “Type of Input to Transform”, “Transforming Technological Level” and “Business Specialization Level” were the highest prioritized.