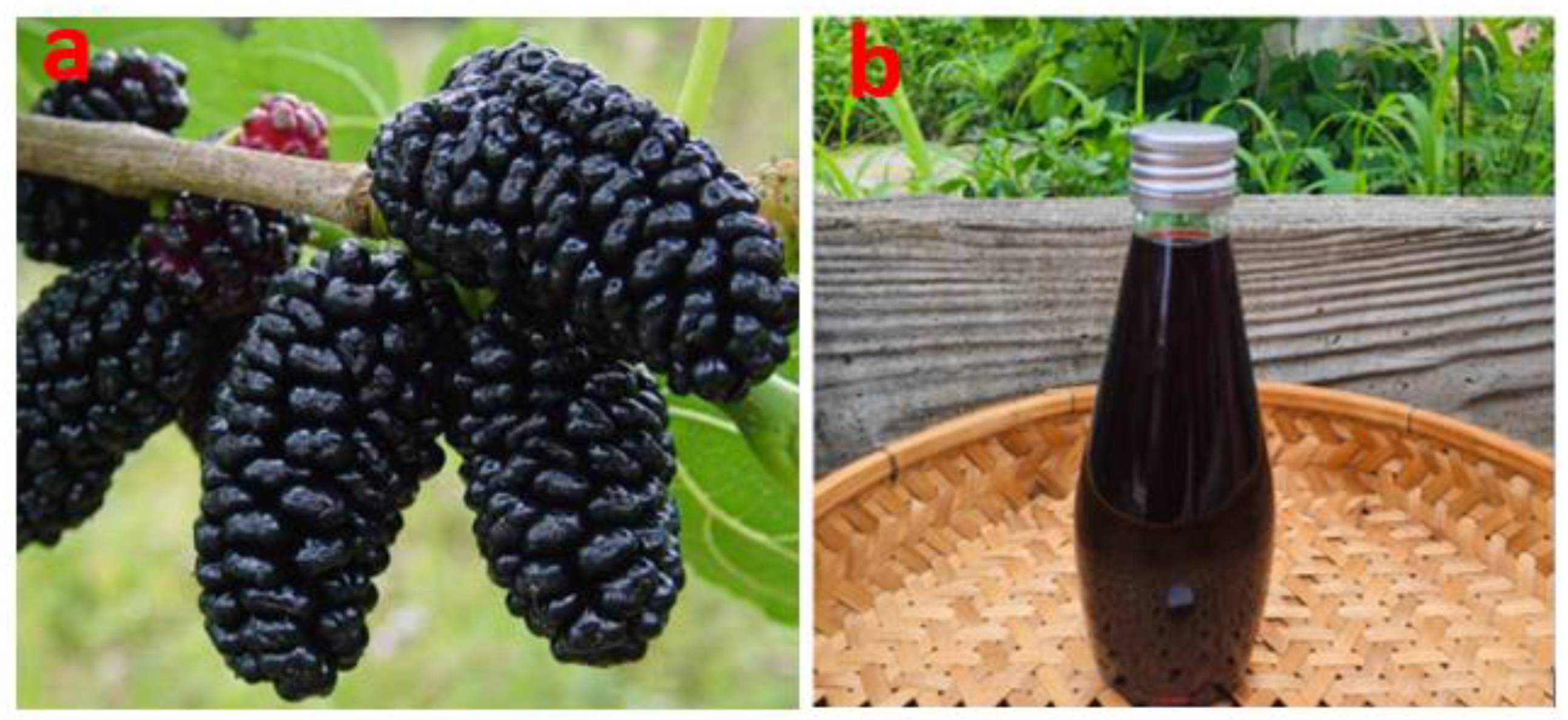

Mulberry is renowned for its medicinal properties and bioactive compounds, yet its high moisture content renders it highly perishable and challenging to transport over long distances. This inherent limitation to its shelf life poses sustainability challenges due to potential food waste and the increased carbon footprint associated with transportation. To address this issue sustainably, mulberry vinegar emerges as a biotechnological solution. Utilizing a fermented mixture of crushed mulberries, sugar, and mixed acid, transforms the highly perishable raw material into a more stable product. However, conventional methods of mulberry vinegar production often involve heat-intensive processing, which poses environmental concerns and energy inefficiencies.

- sustainable

- mulberry vinegar

- non-thermal technologies

- ultrasonication

- ultra-high-pressure homogenization

- pulsed light treatment

- membrane filtration

1. Introduction

2. Mulberry Vinegar Production: An Overview

3. Current Thermal Procedures in Mulberry Vinegar Production

4. Non-Thermal Pre-Processing Techniques in Mulberry Vinegar Production

References

- Zhang, H.; Ma, Z.F.; Luo, X.; Li, X. Effects of Mulberry Fruit (Morus alba L.) Consumption on Health Outcomes: A Mini-Review. Antioxidants 2018, 7, 69.

- Jiang, Y.; Nie, W. Chemical properties in fruits of mulberry species from the Xinjiang province of China. Food Chem. 2015, 174, 460–466.

- Can, A.; Kazankaya, A.; Orman, E.; Gundogdu, M.; Ercisli, S.; Choudhary, R.; Karunakaran, R. Sustainable Mulberry (Morus nigra L., Morus alba L. and Morus rubra L.) Production in Eastern Turkey. Sustainability 2021, 13, 13507.

- Jan, B.; Parveen, R.; Zahiruddin, S.; Khan, M.C.; Mohapatra, S.; Ahmad, S. Nutritional constituents of mulberry and their potential applications in food and pharmaceuticals: A review. Saudi J. Biol. Sci. 2021, 28, 3909–3921.

- Ramappa, V.K.; Srivastava, D.; Singh, P.; Kumar, U.; Kumar, D.; Gosipatala, S.B.; Saha, S.; Kumar, D.; Raj, R. Mulberries: A Promising Fruit for Phytochemicals, Nutraceuticals, and Biological Activities. Int. J. Fruit Sci. 2020, 20, S1254–S1279.

- Zhang, L.; Wang, H.; Luo, H. Uncovering the inactivation kinetics of Escherichia coli in saline by atmospheric DBD plasma using ATR FT-IR. Plasma Process. Polym. 2020, 17, 1900197.

- Song, S.; Shi, J.; Duan, Y.; Wang, J.; Gao, H.; Liu, B. Distribution Characteristics and Industrialization Development of Mulberry in Mu Us Desert. Agric. For. Econ. Manag. 2022, 5, 55–62.

- Samami, R.; Seidavi, A.; Eila, N.; Moarefi, M.; Ziaja, D.J.; Lis, J.A.; Rubiu, N.G.; Cappai, M.G. Production performance and economic traits of silkworms (Bombyx mori L., 1758) fed with mulberry tree leaves (Morus alba, var. Ichinose) significantly differ according to hybrid lines. Livest. Sci. 2019, 226, 133–137.

- Wang, B.; Luo, H. Effects of mulberry leaf silage on antioxidant and immunomodulatory activity and rumen bacterial community of lambs. BMC Microbiol. 2021, 21, 250.

- Alipanah, M.; Abedian, Z.; Nasiri, A.; Sarjamei, F. Nutritional Effects of Three Mulberry Varieties on Silkworms in Torbat Heydarieh. J. Entomol. 2020, 2020, 6483427.

- Choosung, P.; Wasusri, T.; Utto, W.; Boonyaritthongchai, P.; Wongs-Aree, C. The supply chain and its development concept of fresh mulberry fruit in Thailand: Observations in Nan Province, the largest production area. Open Agric. 2022, 7, 401–419.

- Kobus-Cisowska, J.; Dziedzinski, M.; Szymanowska, D.; Szczepaniak, O.; Byczkiewicz, S.; Telichowska, A.; Szulc, P. The Effects of Morus alba L. Fortification on the Quality, Functional Properties and Sensory Attributes of Bread Stored under Refrigerated Conditions. Sustainability 2020, 12, 6691.

- Rohela, G.K.; Shukla, P.; Kallur, M.; Kumar, R.; Chowdhury, S.R. Mulberry (Morus spp.): An ideal plant for sustainable development. Trees For. People 2020, 2, 100011.

- Wen, P.; Hu, T.-G.; Linhardt, R.J.; Liao, S.-T.; Wu, H.; Zou, Y.-X. Mulberry: A review of bioactive compounds and advanced processing technology. Trends Food Sci. Technol. 2019, 83, 138–158.

- Oktay, Y. Physicochemical and sensory properties of mulberry products: Gümüşhane pestil and köme. Turk. J. Agric. For. 2013, 37, 762–771.

- Yuan, Q.; Zhao, L. The Mulberry (Morus alba L.) Fruit—A Review of Characteristic Components and Health Benefits. J. Agric. Food Chem. 2017, 65, 10383–10394.

- Dzah, C.S.; Duan, Y.; Zhang, H.; Boateng, N.A.S.; Ma, H. Latest developments in polyphenol recovery and purification from plant by-products: A review. Trends Food Sci. Technol. 2020, 99, 375–388.

- Gialos, A.; Zeimpekis, V.; Madas, M.; Papageorgiou, K. Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study. Sustainability 2022, 14, 10724.

- Mahboubi, M. Morus alba (mulberry), a natural potent compound in management of obesity. Pharmacol. Res. 2019, 146, 104341.

- Feng, Y.; Liu, M.; Ouyang, Y.; Zhao, X.; Ju, Y.; Fang, Y. Comparative study of aromatic compounds in fruit wines from raspberry, strawberry, and mulberry in central Shaanxi area. Food Nutr. Res. 2015, 59, 29290.

- Oza, A.D.; Dave, R.B.; Rathi, M.G.; Mane, D.V.; Shankar, P.; Boopathi, R.; Prabu, M.; Singh, H.; Copper, G.V.S.; Copper, B.; et al. Republic of Korea Intellectual Property Office (Kr) Public Patent Publication. In Proceedings of the World Congress on Engineering 2012 Vol III WCE 2012, London, UK, 4–6 July 2012; Volume 19, pp. 1–17.

- Ochando, T.; Mouret, J.R.; Humbert-Goffard, A.; Aguera, E.; Sablayrolles, J.M.; Farines, V. Comprehensive study of the dynamic interaction between SO2 and acetaldehyde during alcoholic fermentation. Food Res. Int. 2020, 136, 109607.

- Sedjoah, R.A.; Ma, Y.; Xiong, M.; Yan, H. Fast monitoring total acids and total polyphenol contents in fermentation broth of mulberry vinegar using MEMS and optical fiber near-infrared spectrometers. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 260, 119938.

- Ekonomou, S.I.; Boziaris, I.S. Non-Thermal Methods for Ensuring the Microbiological Quality and Safety of Seafood. Appl. Sci. 2021, 11, 833.

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45.

- Darvishi, H.; Salami, P.; Fadavi, A.; Saba, M.K. Processing kinetics, quality and thermodynamic evaluation of mulberry juice concentration process using Ohmic heating. Food Bioprod. Process. 2020, 123, 102–110.

- Hardinasinta, G.; Salengke, S.; Mursalim; Muhidong, J. Evaluation of ohmic heating for sterilization of berry-like fruit juice of mulberry (Morus nigra), bignay (Antidesma bunius), and jambolana (Syzygium cumini). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1034.

- Fazaeli, M.; Hojjatpanah, G.; Emam-Djomeh, Z. Effects of heating method and conditions on the evaporation rate and quality attributes of black mulberry (Morus nigra) juice concentrate. J. Food Sci. Technol. 2013, 50, 35–43.

- Hojjatpanah, G.; Emam-Djomeh, Z.; Ashtari, A.K.; Mirsaeedghazi, H.; Omid, M. Evaluation of the fouling phenomenon in the membrane clarification of black mulberry juice. Int. J. Food Sci. Technol. 2011, 46, 1538–1544.

- Hojjatpanah, G.; Fazaeli, M.; Emam-Djomeh, Z. Effects of heating method and conditions on the quality attributes of black mulberry (Morus nigra) juice concentrate. Int. J. Food Sci. Technol. 2011, 46, 956–962.

- Fazaeli, M.; Yousefi, S.; Emam-Djomeh, Z. Investigation on the effects of microwave and conventional heating methods on the phytochemicals of pomegranate (Punica granatum L.) and black mulberry juices. Food Res. Int. 2013, 50, 568–573.

- Dincer, C.; Tontul, I.; Topuz, A. A comparative study of black mulberry juice concentrates by thermal evaporation and osmotic distillation as influenced by storage. Innov. Food Sci. Emerg. Technol. 2016, 38, 57–64.

- Chottamom, P.; Kongmanee, R.; Manklang, C.; Soponronnarit, S. Effect of Osmotic Treatment on Drying Kinetics and Antioxidant Properties of Dried Mulberry. Dry. Technol. 2012, 30, 80–87.

- Ongaratto, R.S.; Menezes, L.; Borges, C.P.; Laranjeira da Cunha Lage, P. Osmotic distillation applying potassium pyrophosphate as brine. J. Food Eng. 2018, 228, 69–78.

- Hii, C.L.; Tan, C.H.; Woo, M.W. Special Issue “Recent Advances in Thermal Food Processing Technologies”. Processes 2023, 11, 288.

- Allai, F.M.; Azad, Z.R.A.A.; Mir, N.A.; Gul, K. Recent advances in non-thermal processing technologies for enhancing shelf life and improving food safety. Appl. Food Res. 2023, 3, 100258.

- Chacha, J.S.; Zhang, L.; Ofoedu, C.E.; Suleiman, R.A.; Dotto, J.M.; Roobab, U.; Agunbiade, A.O.; Duguma, H.T.; Mkojera, B.T.; Hossaini, S.M.; et al. Revisiting Non-Thermal Food Processing and Preservation Methods-Action Mechanisms, Pros and Cons: A Technological Update (2016–2021). Foods 2021, 10, 1430.

- Jadhav, H.B.; Annapure, U.S.; Deshmukh, R.R. Non-thermal Technologies for Food Processing. Front. Nutr. 2021, 8, 657090.

- Arshad, R.N.; Abdul-Malek, Z.; Munir, A.; Buntat, Z.; Ahmad, M.H.; Jusoh, Y.M.M.; Bekhit, A.E.; Roobab, U.; Manzoor, M.F.; Aadil, R.M. Electrical systems for pulsed electric field applications in the food industry: An engineering perspective. Trends Food Sci. Technol. 2020, 104, 1–13.

- Ranjha, M.M.A.N.; Kanwal, R.; Shafique, B.; Arshad, R.N.; Irfan, S.; Kieliszek, M.; Kowalczewski, P.L.; Irfan, M.; Khalid, M.Z.; Roobab, U.; et al. A Critical Review on Pulsed Electric Field: A Novel Technology for the Extraction of Phytoconstituents. Molecules 2021, 26, 4893.

- Arshad, R.N.; Abdul-Malek, Z.; Roobab, U.; Munir, M.A.; Naderipour, A.; Qureshi, M.I.; Bekhit, A.E.; Liu, Z.; Aadil, R.M. Pulsed electric field: A potential alternative towards a sustainable food processing. Trends Food Sci. Technol. 2021, 111, 43–54.

- Pan, Y.; Cheng, J.; Sun, D. Cold Plasma-Mediated Treatments for Shelf Life Extension of Fresh Produce: A Review of Recent Research Developments. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1312–1326.

- Yang, N.; Huang, K.; Lyu, C.; Wang, J. Pulsed electric field technology in the manufacturing processes of wine, beer, and rice wine: A review. Food Control 2016, 61, 28–38.

- Artíguez, M.L.; de Marañón, I.M. Inactivation of spores and vegetative cells of Bacillus subtilis and Geobacillus stearothermophilus by pulsed light. Innov. Food Sci. Emerg. Technol. 2015, 28, 52–58.

- Liu, Y.; Li, Y.; Xiao, Y.; Peng, Y.; He, J.; Chen, C.; Xiao, D.; Yin, Y.; Li, F. Mulberry leaf powder regulates antioxidative capacity and lipid metabolism in finishing pigs. Anim. Nutr. 2021, 7, 421–429.

- Huang, X.; Sun, L.; Dong, K.; Wang, G.; Luo, P.; Tang, D.; Huang, Q. Mulberry fruit powder enhanced the antioxidant capacity and gel properties of hammered minced beef: Oxidation degree, rheological, and structure. LWT 2022, 154, 112648.