Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Md Tota Miah and Version 2 by Mona Zou.

The Fourth Industrial Revolution (Industry 4.0 or I4.0) has gained increasing attention both in the academic and non-academic domains. Industry 4.0 was a term coined in 2011 in Germany. Since then, the academic literature describing and analyzing I4.0 technologies has grown considerably. While so-called Industry 3.0 introduced computers, Industry 4.0 is characterized by advancements in computing technology including expanded digitalization in logistics, cognitive and connected machines in various industrial processes, and data analytics.

- Industry 4.0

- South Asia

- workforce employability

- artificial intelligence

- data analytics

- digital skills

- labor market

1. Introduction

The Fourth Industrial Revolution (Industry 4.0 or I4.0) has gained increasing attention both in the academic and non-academic domains. Industry 4.0 was a term coined in 2011 in Germany. Since then, the academic literature describing and analyzing I4.0 technologies has grown considerably (Cannavacciuolo et al. 2023; Rad et al. 2022; Pereira et al. 2018). While so-called Industry 3.0 introduced computers, Industry 4.0 is characterized by advancements in computing technology including expanded digitalization in logistics, cognitive and connected machines in various industrial processes, and data analytics (Rahman et al. 2022). Leong et al. (2020) refer to I4.0 as having nine technological pillars: the Internet of Things, cloud computing, robots and autonomous systems, big data analytics, augmented reality, cybersecurity, simulation, system integration, and additive manufacturing. This new technological frontier is transforming the way businesses create value, how individuals perform their work, and the manner in which people connect and communicate with each other. I4.0 has significantly transformed job roles and the skill profiles required of workers (Ghislieri et al. 2018). These technologies are the cornerstones of changing industrial processes to substantially enhance productivity.

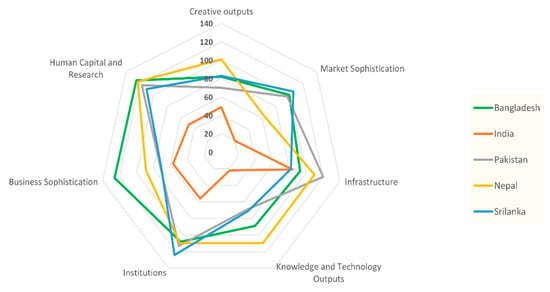

However, the rapid shift in robotization and digitalization are also a growing concern. Particularly in South Asian countries (e.g., Bangladesh, India, Pakistan, Nepal, Bhutan, Sri Lanka, Maldives, and Afghanistan), unemployment resulting from replacing jobs with robots is feared. Yet, employers and employees can adopt to technological changes in a timely way for the better of the future labor market (Bajaj et al. 2018). Researchers from engineering to management have increasingly concentrated their academic research on enabling Industry 4.0 technologies (Weerasekara et al. 2022; Perez Perales et al. 2018). Several studies particularly focused on the success factors and benefits of Industry 4.0 technologies while bypassing their downsides (Kadir et al. 2019; Bolbot et al. 2022; Echchakoui and Barka 2020). Studies are lacking that examine the effects of Industry 4.0 technologies on employment and skills.

2. Concept of Industry 4.0

Since the industrial trade fair Hannover Messe, Germany in 2011, the term “Industrie 4.0” has ignited a vision of a new industrial revolution and has been inspiring a lively, ongoing debate about the future of work (Dregger et al. 2016). The Fourth Industrial Revolution refers to the transformation of technology in the 21st century. It is creating a radical shift for employees, organizations, and society as a whole, given the impact of included and emerging technologies such as artificial intelligence and Internet of Things (Ross and Maynard 2021; Kowalikova et al. 2020). Savytska and Salabai (2021) consider I4.0 a trend within the Fourth Industrial Revolution. They found that businesses could benefit from new opportunities, expand operations, and increase efficiencies by integrating digital processes. Industry 4.0 covers a wide range of topics, such as production methods, productivity, data management, consumer relationships, and competitiveness. (Piccarozzi et al. 2018). According to Culot et al. (2020), I4.0 has evolved significantly, leading to similar concepts often referred to as “smart manufacturing”, “digital transformation”, and “fourth industrial revolution”. However, Erboz (2017) identified that the development of highly automated industries through human–machine interaction is one of the main aspects of Industry 4.0. Freund and Al-Majeed (2021) highlighted the effect of Industry 4.0 on both the micro and macro levels, including the financial, political, and socio-cultural spheres.3. Historical Overview of the Industrial Revolution

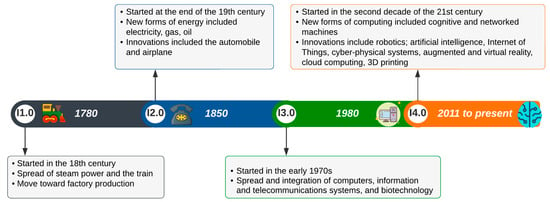

Technological trends have a historical perspective. Figure 1 utilizes two sources to illustrate the history of industrial revolutions. The first industrial revolution, which started at the end of the 18th century, shifted production from labor-intensive to more capital-intensive production. The biggest changes came in the form of mechanization. The invention of steam-powered machines combined with the division of labor changed production technology from piece-to-piece production to mass production. The second industrial revolution started at the end of the 19th century, and by the middle of the 19th century, there were technological advancements helped the emergence of new sources of energy. This era saw the spread of electrification across the world, and radical transformation in transportation including the development of the automobile and the airplane. The third wave of industrialization started in the early 1970s with the development of the computer. This third industrial revolution led directly into the fourth because of how those computing technologies advanced. By the beginning of the 21st century, huge developments in communication and information technologies and software-based production technologies enabled the development of smart systems. Davies (2015) reported that the Europe Union was at the beginning of a new industrial revolution—Industry 4.0—in 2015. Member states began sponsoring national initiatives, such as “Industrie 4.0” in Germany, “the Factory of the Future” in France and Italy, and the Catapult centers in the United Kingdom. In the few short years since then, Industry 4.0 has spread everywhere and changed the production paradigm through a shift from work previously done by humans to work that is now automated (Klingenberg et al. 2022). Today, managers cannot ignore the technological revolution in the field of robotics, artificial intelligence, the Internet of Things, cyber-physical systems, augmented reality, virtual reality, biotechnology, nanotechnology, autonomous vehicles, cloud computing, and 3D printing (Sharma et al. 2021).

Figure 1. Timeline of the Industrial Revolutions based on: (Kagermann et al. 2013; Vaidya et al. 2018).