Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Kotohiro Nomura and Version 2 by Rita Xu.

The recent developments of the synthesis of bio-based long-chain aliphatic polyesters by the acyclic diene metathesis (ADMET) polymerization of α,ω-dienes, derived from plant oils and bio-based chemicals, like bis(10-undecenoate) with isosorbide, using ruthenium-carbene catalysts. The development of subsequent (one-pot) tandem hydrogenation produced saturated polyesters under mild conditions.

- bio-based

- polyester

- metathesis polymerization

- plant oil

- circular economy

- chemical recycling

- aliphatic polyester

- bio-based polyester

1. Introduction

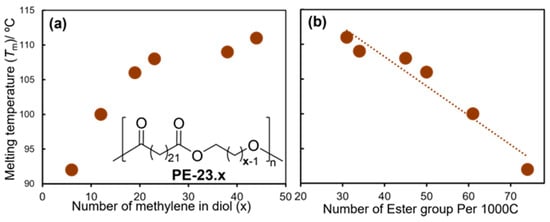

The development of sustainable polymers from renewable feedstocks attracts considerable attention from the viewpoints of the circular economy as well as green sustainable chemistry. Hydrocarbon-rich molecular biomasses, such as vegetable oils (castor, coconut, linseed, olive, palm, soybean, sunflower, etc.) presented as triglycerides with fatty acids, or fatty acid esters (FAEs) are naturally abundant and are recognized as low-cost molecular biomass products [1][2][3][4][5][6][7][8][9][10][11][1,2,3,4,5,6,7,8,9,10,11]. A study on bio-based advanced polyesters (exhibiting tunable mechanical properties and biodegradability), in particular, long-chain aliphatic polyesters (LCAPEs), are semicrystalline materials considered as a promising alternative of polyethylene [6][8][6,8]. The melting temperatures (Tm values) of polyesters are generally influenced by the methylene length (and the direction of dipoles called the odd–even effect) [6][12][13][14][6,12,13,14]; the placement of longer methylene units should be effective for the obtainment of polyesters without softening them at elevated temperatures. It has been considered that the precise polymerization technique provides a new strategy and methodology for the design of macromolecular architectures.

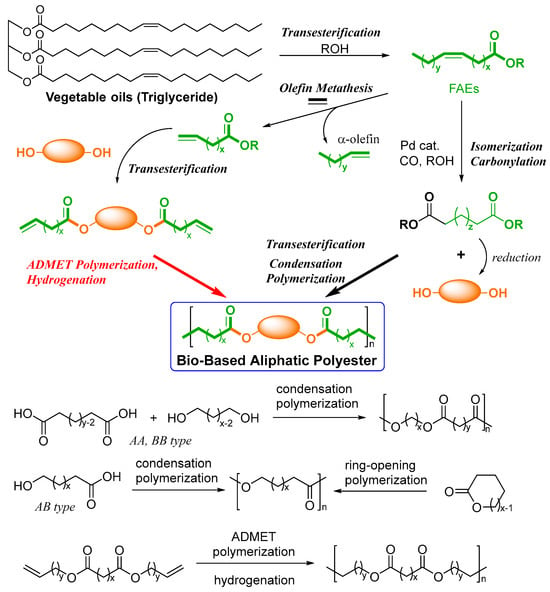

Two condensation polymerization approaches—(i) condensation polymerization by transesterification (dicarboxylic acid and diol, etc.) and (ii) acyclic diene metathesis (ADMET) polymerization (nonconjugated α,ω-dienes)—and subsequent hydrogenation (Scheme 1) are considered for the synthesis from FAEs [6][8][6,8]. The ring-opening polymerization (ROP) approach from cyclic monomers can also be considered, but the method has a limited monomer scope; the method also faces the difficulty of catalysts enabling the synthesis of high molar mass polymers [15][16][15,16]. Studies on alternative approaches to polymers are also under investigation [17][18][19][20][17,18,19,20]. Moreover, the recent progress in the development of olefin metathesis catalysts for the conversion of plant oils (FAEs) is well known [21][22][23][24][21,22,23,24].

Scheme 1. Synthesis of bio-based polyesters from plant oil (triglycerides).

The conventional condensation polymerization approach through transesterification (ester bond exchange) requires high temperatures with the efficient removal of by-products (such as alcohols and water) to obtain high molar mass polymers with a high degree of polymerization (DPn). For example, the synthesis of poly(ethylene terephthalate) from terephthalic acid (which must be purified) with excess ethylene glycol requires high temperatures up to 290 °C under a reduced pressure [25]. This method, however, seems to be difficult to apply for the synthesis of LCAPEs due to the difficulty of removing diols with high boiling points (e.g., 1,12-dodecanediol, 189 °C/12 Torr; 1,16-hexadecane diol 197–199 °C/3 mmHg). Moreover, precise stoichiometric control (hydroxy and carboxylic groups) is needed for this purpose [6][26][27][28][6,26,27,28]; polymerization with the precise stoichiometric ratios of diols (algae oil) and diesters (C17 and C19) is required to create high molar mass polymers (Mn = 4.0 × 104) possessing a Tm value of 99 °C [28].

2. Synthesis of Aliphatic Polyesters by ADMET Polymerization and Hydrogenation

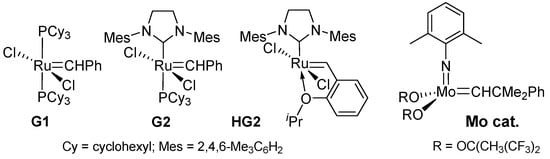

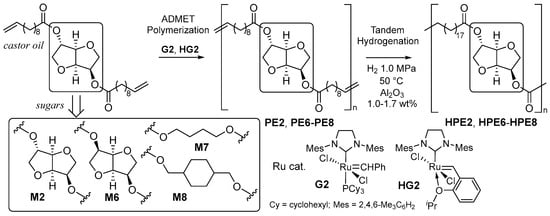

Reports on the synthesis of bio-based polyesters by ADMET polymerization, especially using commercially available (Grubbs-type) ruthenium carbene catalysts RuCl2(PCy3)2(CHPh) (G1; Cy = cyclohexyl), RuCl2(PCy3)(IMesH2)(CHPh) (G2; IMesH2 = 1,3-bis(2,4,6-trimethylphenyl)imidazolin-2-ylidene), and RuCl2(IMesH2)(CH-2-OiPr-C6H4) (HG2), shown in Scheme 2, are well known. These ruthenium catalysts have been employed [8] because these complexes can be readily available and do not require treatment with the strict Schlenk technique due to their insensitivities toward water and oxygen (better functional group tolerance) [29][30][31][32][32,33,34,35]. More recently, the example using a molybdenum-alkylidene catalyst (Mo cat.) [33][34][35][36,37,38], shown below, also demonstrates the synthesis of high molar mass polymers that exhibit good tensile properties [36][39].

Scheme 2. Ruthenium-carbene and molybdenum-alkylidene catalysts for the synthesis of aliphatic polyesters by ADMET polymerization.

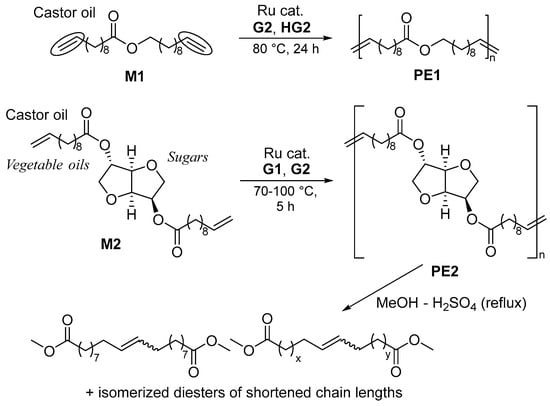

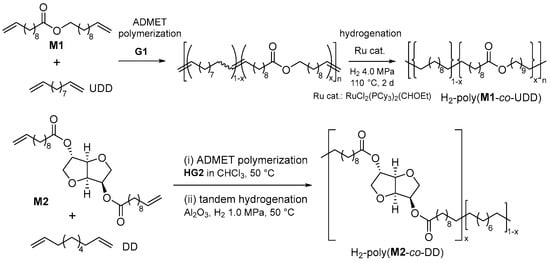

Scheme 3. ADMET polymerization of castor oil-derived monomers (M1, M2).

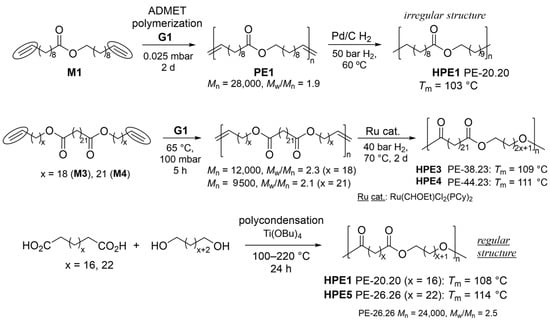

Scheme 4. Synthesis of linear polyesters (LCAPEs).

Figure 1. Plots of melting temperature (Tm) vs. number of (a) methylene units (x) in diol and (b) ester groups per 1000 C (methylene) in PE-23.x.

Scheme 5. One-pot synthesis of bio-based polyesters by Ru-catalyzed ADMET polymerization and hydrogenation.

Scheme 6. ADMET copolymerization of undec-10-en-1-yl undec-10-enoate (M1) or bis(undec-10-enoate) with isosorbide (M2) with nonconjugated dienes, and subsequent hydrogenation.

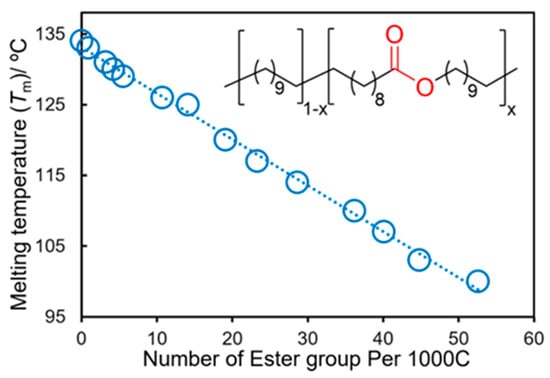

Figure 2. Plots of melting temperature (Tm) vs. number of ester groups per 1000 C (methylene units) in the hydrogenated copolymers, H2-poly(M1-co-UDD)s.

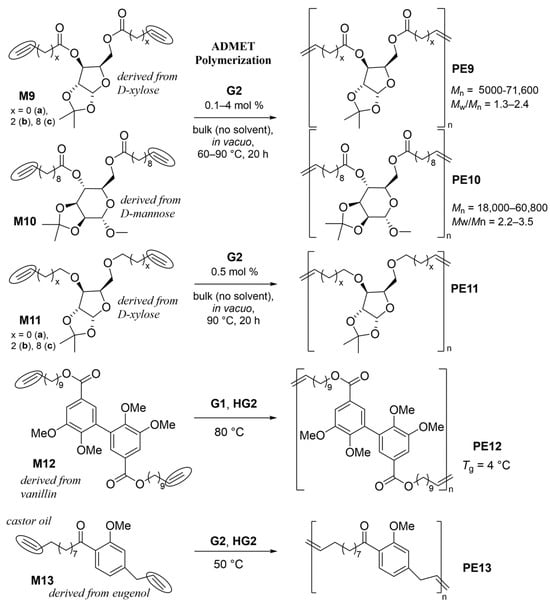

Scheme 7. ADMET polymerization of α,ω-dienes containing D-xylose, D-mannose, vanillin, and eugenol as the monomer units.

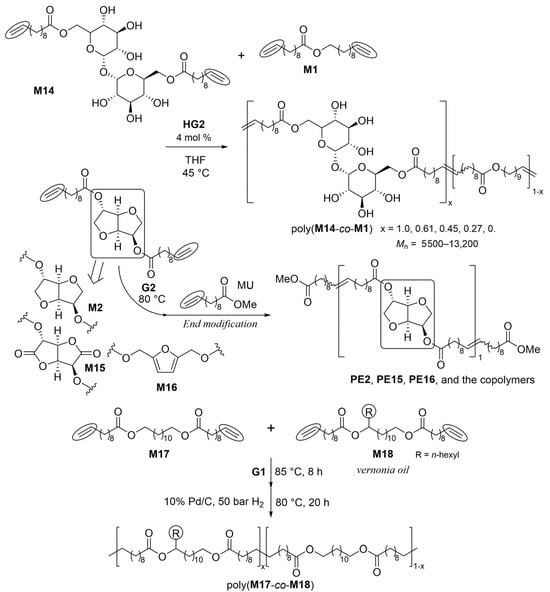

Scheme 8. Synthesis of bio-based copolyesters with different molar ratios.