Achieving lightweight, high-strength, and biocompatible composites is a crucial objective in the field of tissue engineering. Intricate porous metallic structures, such as lattices, scaffolds, or triply periodic minimal surfaces (TPMSs), created via the selective laser melting (SLM) technique, are utilized as load-bearing matrices for filled ceramics. The primary metal alloys in this category are titanium-based Ti6Al4V and iron-based 316L, which can have either a uniform cell or a gradient structure. Well-known ceramics used in biomaterial applications include titanium dioxide (TiO2), zirconium dioxide (ZrO2), aluminum oxide (Al2O3), hydroxyapatite (HA), wollastonite (W), and tricalcium phosphate (TCP). To fill the structures fabricated by SLM, an appropriate ceramic is employed through the spark plasma sintering (SPS) method, making them suitable for in vitro or in vivo applications following minor post-processing. The combined SLM-SPS approach offers advantages, such as rapid design and prototyping, as well as assured densification and consolidation, although challenges persist in terms of large-scale structure and molding design. The individual or combined application of SLM and SPS processes can be implemented based on the specific requirements for fabricated sample size, shape complexity, densification, and mass productivity.

1. Introduction

The objective of tissue engineering is to create advanced biomaterials that are lightweight, possess high strength, and exhibit biocompatibility

[1,2][1][2]. This goal arises from the increasing need for innovative composites to meet the demands of various applications in the biomedical field

[3]. In recent years, intricate porous metallic structures, including lattices, scaffolds, and triply periodic minimal surfaces (TPMSs), fabricated using the selective laser melting (SLM) technique, have gained significant attention as potential load-bearing matrices for filled ceramics

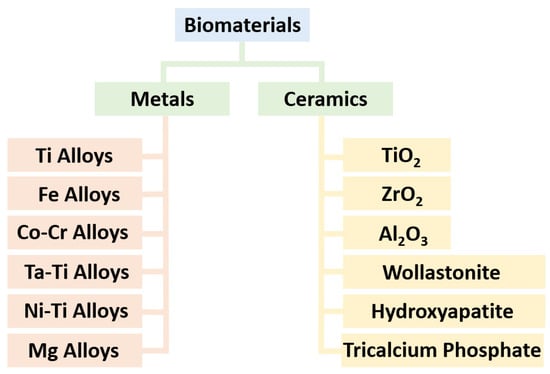

[4,5][4][5]. Within the biomaterial field, metal alloys, such as Ti-, Fe-, Co-Cr, Ta-Ti-, Ni-Ti-, and Mg-based alloys, are utilized in various forms, including porous structures or solid parts

[6,7][6][7]. Additionally, these alloys can be combined with ceramic fillers to enhance their integration with bone tissues

[8]. Conversely, copper-based alloys, when combined with silver, exhibit significant potential for antiviral and virucidal applications beyond live cells

[9].

Among the ceramics commonly utilized in biomaterial applications are titanium dioxide (TiO

2), zirconium dioxide (ZrO

2), aluminum oxide (Al

2O

3), hydroxyapatite (HA), wollastonite (W), and tricalcium phosphate (TCP)

[10,11][10][11]. These ceramics exhibit desirable properties, such as biocompatibility, corrosion resistance, bioactivity, osteoconductivity, strength, hardness, and fracture toughness, that make them suitable for various biological applications. To create metal–ceramic composites, the SLMed structures are filled with a compatible ceramic material using the spark plasma sintering (SPS) process

[12,13][12][13]. This process enhances the mechanical properties and bioactivity of the composites, enabling their utilization both inside and outside living organism applications after undergoing minor post-processing steps

[14].

The novel combined laser powder bed fusion and powder metallurgy (LPBF-PM) approach offers distinct advantages, including rapid prototyping and assured consolidation of the composite materials. However, despite these benefits, challenges persist in terms of optimizing the structure and molding design of the composites to achieve the desired functional characteristics

[15,16][15][16]. Addressing these challenges is essential for advancing the manufacturing processes and enhancing the performance of metal–ceramic composites

[17,18][17][18]. Depending on the specific needs for the sample size of fabrications, shape complexity, densification and porosity level, and number of productions, the SLM—as a LPBF subdivision—and SPS—as a PM prong—processes can be applied individually or in combination to achieve desired outcomes

[19,20][19][20]. For higher technology readiness levels (TRLs) and shifting from Industry 4.0 to 5.0, collaborative synergy between humans and AI-driven machines is emphasized for improved productivity, creativity, and advanced capabilities in additive manufacturing (AM) and LPBF, with evolving precision and compatibility considerations

[21,22][21][22].

2. Materials

Metals and ceramics play the main roles in the realm of biomaterial applications, where their unique properties make them indispensable for various biomedical purposes. Metal alloys, including titanium (CP-Ti and Ti6Al4V), iron (316L), cobalt–chromium (CoCr28Mo6), tantalum–titanium (Ta-Ti), nickel–titanium (Ni-Ti), and magnesium-based (Mg-Zn-Zr and Mg-Al-Zn-Mn) alloys, have garnered significant attention in orthopedics, tissue engineering, and dentistry due to their excellent mechanical strength, biocompatibility, and corrosion resistance

[23,24,25,26][23][24][25][26]. Meanwhile, other metal-based alloys, such as nickel (In625, In718, and In939) and copper (Cu-Ni-Si-Cr, Cu-Cr-Zr, Cu-Sn, and Cu-Ni-Sn), are applied in the chemical industry and antiviral investigations

[27,28,29,30][27][28][29][30]. These materials are often used in implants, prosthetics, and dental fixtures, providing enhanced durability and long-term performance within the human body. On the other hand, ceramics like hydroxyapatite (HA), wollastonite (W), titanium dioxide (TiO

2), and zirconium dioxide (ZrO

2) have found application in bone grafts, dental coatings, and tissue engineering scaffolds

[31,32,33,34,35,36][31][32][33][34][35][36]. These ceramic materials boast exceptional bioactivity, mimicking the mineral composition of bone, promoting osseointegration, and contribute to controlled drug/nutrient delivery and facilitate tissue regeneration. These materials are shown in

Figure 1. Apart from metals and ceramics, synthetic and biodegradable polymers are widely used in biomaterial engineering due to their versatility and biocompatibility. Examples include polyethylene, polyurethane, polylactide, polycaprolactone, and silicone. They are often used in 3D/4D printing of medical devices, drug delivery systems, and tissue engineering scaffolds

[37,38][37][38].

Figure 1.

Integration of metals and ceramics in tissue engineering for the fabrication of artificial biomaterials.

3. Methods

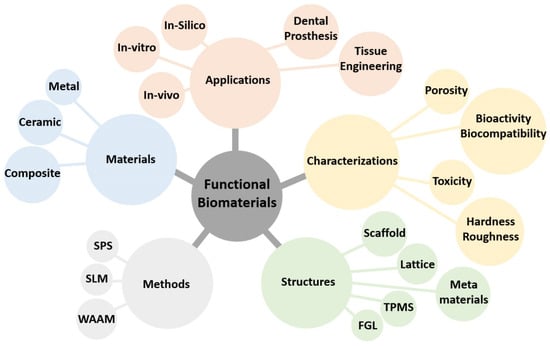

Nowadays, functional biomaterials (FBMs) play a crucial role in advancing tissue engineering and regenerative medicine. The present study focuses on the fabrication of functionally graded lattice (FGL) structures and scaffolds using SLM and SPS methods. The integration of SLM and SPS techniques with these materials offers promising avenues for designing and producing highly tailored biomaterials with enhanced structural integrity and bioactive properties, paving the way for innovative applications in biomedical research, as shown in

Figure 2. These FBM structures employ FGL metal alloys and bioceramic powders as the base materials, known for their biocompatibility and mechanical properties, showcasing their potential for combination and applications in tissue engineering.

Figure 2. Schematic of functional biomaterial fabrication and applications using additive manufacturing.

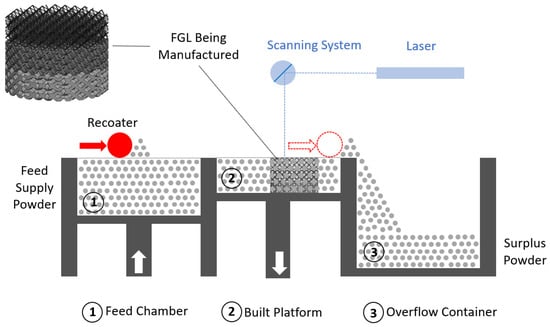

3.1. Selective Laser Melting Process

SLM is an AM technique used to create 3D objects by selectively melting layers of metal powder using a high-powered laser. The SLM process offers several advantages, including the ability to produce complex geometries, intricate internal structures, and parts with high accuracy. It allows for the direct manufacturing of metal parts without the need for traditional machining (subtractive manufacturing (SM)) or casting processes (e.g., metal injection molding (MIM)), reducing material waste and enabling faster production times. It is a form of 3D printing that enables the production of complex and intricate metal parts with high precision and involves the following steps. The SLM process is schematically illustrated in

Figure 3.

Figure 3. Schematic of the selective laser melting process.

Design—The first step is to create a digital 3D model of the desired object using CAD software. The model is sliced into thin layers, typically ranging from 20 to 100 µm in thickness. These sliced layers serve as instructions for the SLM machine during the manufacturing process.

Powder preparation—Metal powders are selected based on the desired material properties and characteristics of the final object. The powder particles are typically gas atomized and spherical in shape and have a specific size distribution, mostly ranging from 10 to 60 µm, to ensure proper flowability and packing. The metal powder is then spread in a thin layer over the build platform.

Layer-by-layer melting—The build platform is lowered by the thickness of one layer, and a high-powered laser beam is directed onto the metal powder layer based on the instructions from the sliced 3D model. The laser selectively melts and fuses the metal powder particles together according to the cross-section of the current layer. The laser energy causes the powder to rapidly reach its melting point, allowing for fusion and solidification [80].Layer-by-layer melting—The build platform is lowered by the thickness of one layer, and a high-powered laser beam is directed onto the metal powder layer based on the instructions from the sliced 3D model. The laser selectively melts and fuses the metal powder particles together according to the cross-section of the current layer. The laser energy causes the powder to rapidly reach its melting point, allowing for fusion and solidification [39].

Cooling and solidification—Once a layer is melted and fused, the build platform is lowered, and a new layer of metal powder is spread on top. The process is repeated, layer by layer, until the entire object is created. As each layer cools, the molten metal solidifies, forming a solid part. The build platform is gradually lowered as new layers are added to compensate for the growing height of the object.

Post-processing—After the printing process is complete, the object is typically removed from the build platform and undergoes post-processing steps. This may involve removing support structures if they were used during printing, cleaning the object to remove excess powder, and performing any necessary heat treatment or surface finishing processes to achieve the desired final properties.

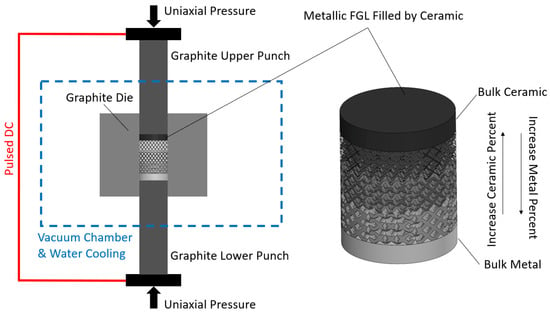

3.2. Spark Plasma Sintering Process

SPS is a relatively new and specialized powder metallurgy technique used for consolidating or sintering materials, typically ceramics, metals, and composites, into dense and high-quality components. It is a relatively rapid and energy-efficient process that offers advantages over traditional sintering methods [90,91,92]. The key advantages of SPS include its ability to achieve high densification levels, reduce sintering time, and retain the properties of the starting materials. It is particularly useful for materials that are difficult to sinter using conventional methods, such as those with high melting points or low diffusivity. The SPS process involves the following steps.SPS is a relatively new and specialized powder metallurgy technique used for consolidating or sintering materials, typically ceramics, metals, and composites, into dense and high-quality components. It is a relatively rapid and energy-efficient process that offers advantages over traditional sintering methods [40][41][42]. The key advantages of SPS include its ability to achieve high densification levels, reduce sintering time, and retain the properties of the starting materials. It is particularly useful for materials that are difficult to sinter using conventional methods, such as those with high melting points or low diffusivity. The SPS process involves the following steps.

Powder preparation—The starting materials are typically in the form of fine powders. These powders can be pure metals, metal alloys, ceramics, composite mixtures, or powder filled/embedded into a structure. The powders’ size and shape are effective in the final product.

Mold assembly—The powders are placed in a die cavity or mold, which is made of a conductive material, such as graphite, or refractory metals, like tungsten or molybdenum. The mold is designed to accommodate the desired shape and size of the final component.

Pressure application—Pressure is applied to the powder compact using a hydraulic or mechanical press. The pressure helps to remove trapped gases, improve particle rearrangement, and enhance the density of the final product. The pressure can vary depending on the materials being sintered but is typically in the range of 10–200 MPa. For certain applications, this can manifest as a pressureless procedure or involve a rapid and pronounced fluctuation in pressure application. Furthermore, the SPS process commonly takes place within a vacuum chamber.

Heating and spark plasma—Once the pressure is applied (preliminary or program-based), the assembly is subjected to intense pulsed electric currents. The electric current is passed through the mold, which acts as a resistive heating element. This causes the temperature of the powder compact to rise rapidly. During the heating process, electric sparks occur between adjacent powder particles due to the high electrical current passing through the mold. These sparks generate localized heating and facilitate the sintering process. The spark plasma phenomenon promotes rapid atomic diffusion and enhanced material transport, resulting in accelerated densification.

Sintering and cooling—The combination of pressure, heating, and spark plasma promotes the densification of the powder particles through plastic deformation, diffusion, and recrystallization. The material reaches a high temperature, typically below its melting point, allowing for particle bonding. Once the desired sintering temperature is achieved, the assembly is rapidly cooled, solidifying the component into its final form.

Figure 4 illustrates the schematic representation of the SPS process applied to FGL and FBM structures. These structures are intended to be filled with a specified ceramic ratio. The ceramic volume that is filled increases from the bottom to the top, while the lattice volume fraction is established throughout the SLM process.

Figure 4. Schematic of the spark plasma sintering process.

3.3. Effect of Powder in SLM and SPS

The use of gas-atomized and pre-alloyed powders in sphere-shaped form significantly influences the effectiveness of AM, specifically in approaches like LPBF and SLM [102]. As-received powders often undergo vacuum or air drying to eliminate moisture, which can lead to issues related to flowability, porosity formation, and increased oxidation, particularly in alloys like AlSi10Mg containing substances such as MgO, AlThe use of gas-atomized and pre-alloyed powders in sphere-shaped form significantly influences the effectiveness of AM, specifically in approaches like LPBF and SLM [43]. As-received powders often undergo vacuum or air drying to eliminate moisture, which can lead to issues related to flowability, porosity formation, and increased oxidation, particularly in alloys like AlSi10Mg containing substances such as MgO, Al 2O

3, and SiO

2. Compared to Ti6Al4V and Inconel 718, AlSi10Mg is more susceptible to moisture and oxygen absorption, resulting in reduced spreadability and relative density on the build platform [103]. Conversely, when combining commercial metals, such as CP-Ti or Ti6Al4V, with hard ceramics, like TiB. Compared to Ti6Al4V and Inconel 718, AlSi10Mg is more susceptible to moisture and oxygen absorption, resulting in reduced spreadability and relative density on the build platform [44]. Conversely, when combining commercial metals, such as CP-Ti or Ti6Al4V, with hard ceramics, like TiB 2 or coated diamonds, it is essential to mill them for an optimal duration before employing the SLM process. For instance, a mixture of pure Ti powder and 5 wt.% TiB

2 composite exhibits more spherical particles after 2 h of milling, resulting in a 5% higher fabrication density following the SLM approach compared to a 4 h powder milling duration [104]. It is important to note that increasing the milling time has a negative impact on the porosity level, as revealed by this investigation. composite exhibits more spherical particles after 2 h of milling, resulting in a 5% higher fabrication density following the SLM approach compared to a 4 h powder milling duration [45]. It is important to note that increasing the milling time has a negative impact on the porosity level, as revealed by this investigation.

The impact of powder morphology in the SPS process is not as significant as in the SLM process, unless specific physical properties, such as structural anisotropy, are explicitly required [105]. SPS commonly employs wide-shaped, e.g., nano-sized, flake-like, and gas-atomized, particles. When dealing with irregular shapes, large or elongated samples, or when combining SLMed porous structures with ceramic fillings inside lattices, the design of SPS molds for complex structures becomes crucial. The primary goals are achieving fully dense samples and controlled interface deformation [106]. In general, areas with greater thickness variations in the shape of a sample lead to more pronounced densification inhomogeneity during the SPS process. Design challenges often involve managing thermal gradients, differences in metal–ceramic melting points, unmolten powders from the SLM process, and mold–sample separation. Additionally, the simultaneous fabrication of multiple complex parts can pose a further challenge in ultrarapid sintering processes [107]. This capability, however, proves valuable for creating customized implants, prosthetics, or parts embedded within each other, where separation is facilitated using graphite sheets/foils. These graphite sheets serve as membranes/discriminants between the mold wall and samples, as well as between multiple parts. Innovations in molding design and the optimization of SPS parameters, including time, pressure, temperature, and heating rate, are of the utmost importance, especially when considering biomedical applications [108]. A ceramic composite mixture of CaSiOThe impact of powder morphology in the SPS process is not as significant as in the SLM process, unless specific physical properties, such as structural anisotropy, are explicitly required [46]. SPS commonly employs wide-shaped, e.g., nano-sized, flake-like, and gas-atomized, particles. When dealing with irregular shapes, large or elongated samples, or when combining SLMed porous structures with ceramic fillings inside lattices, the design of SPS molds for complex structures becomes crucial. The primary goals are achieving fully dense samples and controlled interface deformation [47]. In general, areas with greater thickness variations in the shape of a sample lead to more pronounced densification inhomogeneity during the SPS process. Design challenges often involve managing thermal gradients, differences in metal–ceramic melting points, unmolten powders from the SLM process, and mold–sample separation. Additionally, the simultaneous fabrication of multiple complex parts can pose a further challenge in ultrarapid sintering processes [48]. This capability, however, proves valuable for creating customized implants, prosthetics, or parts embedded within each other, where separation is facilitated using graphite sheets/foils. These graphite sheets serve as membranes/discriminants between the mold wall and samples, as well as between multiple parts. Innovations in molding design and the optimization of SPS parameters, including time, pressure, temperature, and heating rate, are of the utmost importance, especially when considering biomedical applications [49]. A ceramic composite mixture of CaSiO 3/TiO

2/HA exhibits higher hardness and compressive strength when sintered at 1250 °C compared to 1150 °C. To prevent damage to lattice/scaffold structures in metallic–ceramic composites, it is recommended to use a pressureless approach with a high heating rate. A successful example of this is the rapid-heated pressureless SPSing of ZrO

2, utilizing a heating rate of 500 °C/min, a dwell time of 2 min, and sintering at 1600 °C, resulting in crack-free, homogeneous, and efficiently processed ceramics [109].

, utilizing a heating rate of 500 °C/min, a dwell time of 2 min, and sintering at 1600 °C, resulting in crack-free, homogeneous, and efficiently processed ceramics [50].

4. Functionally Graded Lattice

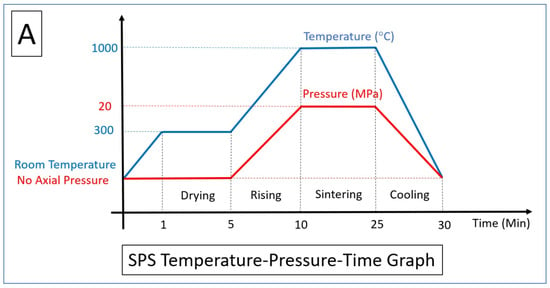

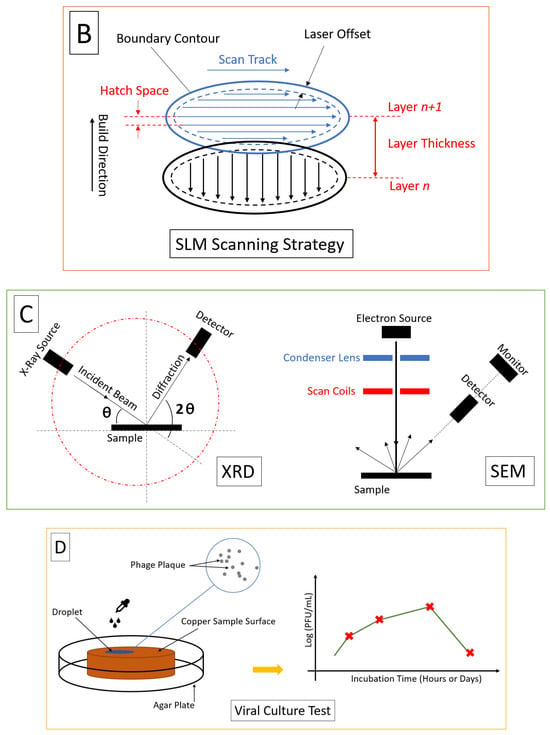

The initial heating, temperature elevation, dwell time during holding, and swift cooling stages in the SPS process are illustrated in

Figure 5A. Additionally,

Figure 5B delineates the scanning strategy (laser current, exposure time, and point distance) and defines the hatch spacing (including overlapping and the boundary counter). The scan strategy defines the pattern in which the laser scans the powder bed. Common strategies include raster scanning, parallel scanning, and contour scanning. The choice of scan strategy can influence the thermal gradients, residual stresses, and microstructure of the fabricated part. It is typically determined based on the part geometry, orientation, and desired properties

[110][51]. In addition, the layer thickness determines the height of each deposited layer. It affects the resolution, surface roughness, and build time of the part. Thinner layers provide higher resolution but increase processing time, while thicker layers can reduce resolution but expedite the process. The layer thickness should be optimized based on the specific requirements of the application, powder characters, and metal conductivity

[111,112][52][53].

Figure 5. Key parameters for SPS–SLM processing and measurements: (

A) SPS parameters, (

B) SLM parameters, (

C) Micrograph and characterization, and (

D) Viral tests.

SEM (scanning electron microscopy), TEM (transmission electron microscopy), XRD (X-ray diffraction), and EDS (energy-dispersive spectroscopy) represent the most-recognized microscopy techniques for characterizing composite structures. Typically, this stage occurs after processing (such as LPBF or PM) and post-processing (including procedures like polishing, powder jet cleaning, subtractive manufacturing, etc.) and precedes virucidal, biocompatibility, and mechanical testing. The schematic of this phase is displayed in

Figure 5C.

Plaques are clearings in a layer of cells caused by the infection and replication of viruses. Plaque-forming units (PFU) are a unit of measurement used in virology to quantify the number of viral particles capable of forming plaques in a viral culture or assay

[113][54]. In virological studies, a PFU assay is commonly used to assess the infectivity and viral replication capacity of a virus and determine the viral titer in a sample. Colony-forming units (CFU) are used to quantify viable microorganisms, such as bacteria or fungi, in a sample. The CFU assay involves plating a diluted sample onto a solid agar medium, allowing individual viable cells to grow and form visible colonies

[114][55]. CFU is commonly used in microbiology for environmental monitoring and food safety. Generally, CFU is used to measure viable bacteria by counting the number of visible colonies on solid agar in microbiology, while PFU is used to measure viable viral particles by counting the number of plaques formed during viral infection in virology. Viral culture is a laboratory test to find viruses that able to infect, which is shown in

Figure 5D. Viral titer is determined by the number of plaques formed, to determine the strength of a virus against the host cells.

The future of lattice, scaffold, TPMS, and 3D-printed porous structures is promising, with several potential developments on the horizon.

Improved resolution and accuracy—LPBF, and more specifically SLM technology, is constantly improving, with advances in laser and material technology allowing for the fabrication of structures with higher resolution and accuracy. This could lead to the creation of lattice structures with even greater complexity and specificity, allowing for more precise control over properties, such as porosity, cell design, compressive strength, and mechanical strength

[117][56].

Development of new materials—The range of materials that can be used in SLM is expanding, with the development of new biocompatible and bioresorbable materials that could be used to fabricate lattice structures. These new materials could offer improved biocompatibility and better integration with surrounding tissues, leading to improved patient outcomes.

Integration with other technologies—SLM could be combined with other technologies, such as bioprinting or tissue engineering, to create even more complex structures. For example, lattice structures could be combined with living cells or tissues to create hybrid structures that have the potential to regenerate damaged or diseased tissues; or, they can be involved in PM processes to create bio-metal–ceramics. These composites are made by biocompatible ceramics to fill scaffold structures created through powder metallurgy for tissue engineering applications due to their excellent biocompatibility, bioactivity, osteoconductive properties, and innovative treatments for a variety of tissue defects and injuries.

Biocompatibility and biomechanical strength—The material used to create the lattice or scaffold structure should be biocompatible and non-toxic, with no potential for adverse reactions when implanted in the body. In addition, it needs to have favorable strength. For example, a scaffold designed for bone regeneration should be able to withstand compressive forces, while a scaffold designed for cartilage regeneration should be able to withstand shear forces.

Porosity and geometry complexity—The porosity of the structure should be carefully controlled to ensure that it is suitable for the intended application. A scaffold with high porosity may be suitable for tissue engineering applications, while a scaffold with lower porosity may be better suited for load-bearing applications

[118][57]. The geometry of the structure should be carefully designed to ensure that it is stable and can support the intended load. The design should also consider any potential stress concentrations that could lead to material failure, in addition to stress shielding, due to its crucial role in promoting optimal healing and growth

[119][58].

In AM technology, the terms “lattice” and “scaffold” are often used to describe two different types of structures used to optimize the design and functionality of 3D-printed objects. Lattice structures refer to a type of internal or external geometric pattern that is repeated throughout the object. These patterns (also known as cells) consist of a network of interconnected struts forming a porous or honeycomb-like structure. Lattices are designed to provide specific mechanical properties, such as lightweight, high strength-to-weight ratios, and enhanced energy absorption capabilities. They are commonly used to reduce the weight of 3D-printed parts without compromising structural integrity. The porous nature of lattices can facilitate better airflow, heat dissipation, and fluid flow through the object, making them suitable for applications in aerospace, automotive, and biomedical industries. Scaffold structures, on the other hand, are primarily used in the context of bioprinting or tissue engineering. In this field, scaffold structures are designed to mimic the extracellular matrix found in living tissues. The scaffold acts as a temporary support structure that provides a framework for cells to grow and organize into FBMs. Scaffold structures in bioprinting are typically created using biocompatible materials, such as hydrogels or polymers, that can be safely implanted into the body.

There is a third type of structure, TPMS, which is not typically considered a scaffold in the context of AM or bioprinting. TPMS refers to a specific type of surface that has a minimal surface area among all surfaces that can be periodically repeated in three dimensions. These surfaces have unique mathematical properties and are often characterized by complex, interconnected patterns. TPMS structures have various applications in different fields, but they are not primarily used as scaffolds for tissue engineering or bioprinting. Instead, TPMS structures find applications in areas such as materials science, surface coating, architectural design, metamaterials, and mathematical research.

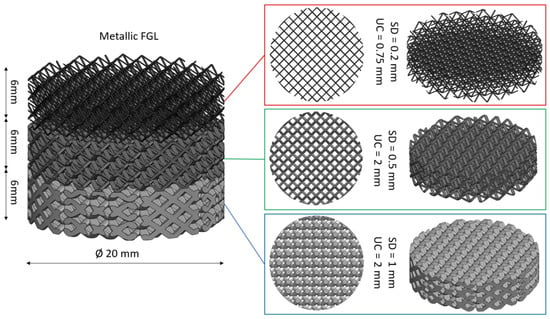

FGLs made by AM are structures that exhibit a gradual variation in their properties and geometries. They are designed to have different characteristics, such as varying porosity, mechanical properties, or thermal conductivity, across different regions of the lattice. This gradient allows for customized performance and functionality in specific applications. The FGL structure is characterized by a seamless transition starting from pure metal at the base, progressing through a gradient of a metal–ceramic lattice with varying ratios (e.g., SLMed), and culminating in a 100% dense ceramic oxide in the top (e.g., SPSed) for intense reinforcement in a single direction. An advantageous feature is its adaptability for radial, axial, or mixed designs, allowing the customization of bioceramic and biometal proportions according to specific applications

[122,123][59][60]. This definition is shown in

Figure 6.

Figure 6. CAD design of a functionally graded lattice (FGL). All samples have a diameter of 20 mm and a height of 6 mm. Strut diameter (SD) and unit cell (UC) size, from top to bottom, are, respectively, (0.2, 0.75), (0.5, 2.0), and (1.0, 2.0) mm.

5. In Vivo, In Vitro, and In Silico Studies

The utilization of subtractive manufacturing allows the precise shaping, solidification, densification, and refining of cermet structures, while additive manufacturing enables the creation of intricate designs with enhanced complexity and customization. This synergistic approach promises to revolutionize the biomedical field by enabling the production of advanced cermet components that exhibit superior innovative solutions, performance, and biocompatibility.

It is worth mentioning that the preferred structure is a perpetual implant designed to remain permanently inside the body (as the in vivo goal). This implant consists of two main components: a functionally graded porous metallic structure and a ceramic part filled with a specified volume fraction in each desired section. This unique design serves various purposes, like drug delivery release, bone regeneration, and gradient reinforcement, longitudinally or radially. The next generation of bone regeneration holds great promise as it can be achieved through a combination of bioceramics, such as HA-W-TCP, along with materials possessing high strength-to-weight ratios and excellent impact damping capacity, such as Mg-Zn-Zr, Mg-Al-Zn-Mn, Mg-Nd-Zn-Zr, Mg-Nd-Zr-Y-Gd, Al-Si-Mg, and Al-Mg-Sc

[134][61].

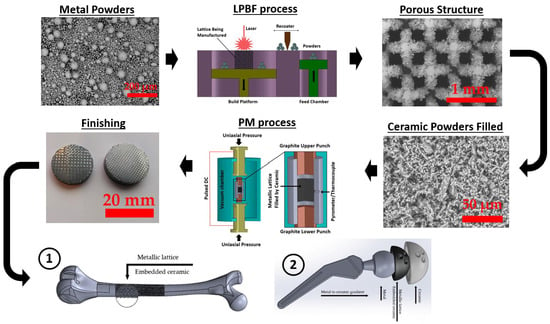

When it comes to manufacturing metal–ceramic composites, the choice of additive manufacturing techniques plays a significant role. For porous samples, SLM proves to be favorable, while SPS is preferred for solid/bulk samples. However, the combination of LPBF-PM, referring to the merging of SLM and SPS, becomes inevitable when dealing with ceramic-embedded metals. Currently, ceramic 3D printing using LPBF methods is progressing based on different heat treatments, but concerns remain regarding compression strength, crack formation, and brittleness

[138][62]. On the other hand, SM excels in creating solid metallic parts, but its limitations in achieving lightness and reducing stress shielding reduction drive us towards AM techniques. In this context, the LPBF-PM approach proves beneficial as it allows the deliberate incorporation of pores in the ceramic phase through SPS parameters and precise control of the volume fraction in the metal matrix via SLM parameters. Metal matrix composites (MMCs) find extensive use across various applications and are produced using a variety of techniques

[139,140][63][64]. This enables us to evaluate the final production’s brittleness, ductility, lightness, porosity level, and proportion of components. These factors are essential for designing effective metal–ceramic composites, ensuring the correct volume fraction of each component.

The significance of cermet composites lies in the fact that ceramics are generally more brittle than metals, meaning that they tend to fracture or break easily under stress without significant plastic deformation. On the other hand, metals are typically more ductile, allowing them to undergo plastic deformation before failure, making them better suited for applications requiring toughness and elongation, and offer good strength-to-weight ratios. Ceramics generally have a higher specific strength and stiffness, making them lighter per unit volume compared to most metals.

Figure 7 illustrates the integration of ceramics within a metallic framework, encompassing a variety of materials. This involves the utilization of the SLM technique for antiviral or biomaterial metals, like Cu or Mg, followed by the SPS process for incorporating ceramics with virucidal and biocompatible properties, such as TiO

2-Ag or W-HA

[115,141][65][66].

Figure 7. Fabrication of ceramic-doped metal through the LPBF-PM combined procedure. Note that the figure is not a representation of a certain process but rather a depiction of possible options for materials and methods. The figure shows copper-based Cu15Ni8Sn alloy, a schematic of the SLM process, a 316L lattice structure, wollastonite irregular-shaped powder, a schematic of the SPS process, and a Ti6Al4V lattice filled by a TiO

2 oxide ceramic, respectively.

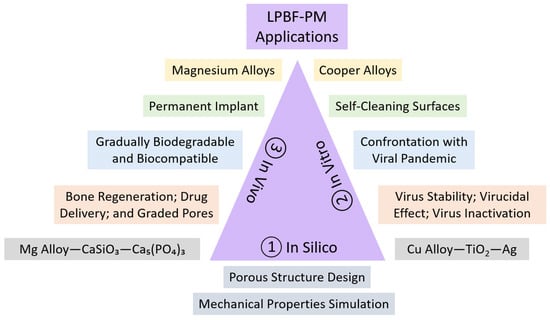

The terms in vivo, in vitro, and in silico refer to experiments which, respectively, are performed in living organisms, inside laboratories, and as computer simulations. Combining computer-aided design (CAD) software, like SolidWorks, and finite-element method (FEM) software, like ANSYS, enables us to assess the complicated shaped gradient and uniform lattice structures before fabrication and in the in silico stage

[122,124,147][59][67][68]. Testing virus stability, virucidal effect, virus inactivation, and bacteriophage infectivity in contact with metals, ceramics, and cermet composites can be performed under in vitro conditions to assess the contamination of a specimen’s surface and the virucidal potential of a composite. The delivery and release of antibiotics, vitamins, oxygen, or liquids depend on longitudinally, latitudinally, and radially graded pores. During consideration for an in vivo application, applying the FGL/FBM structure avoids the stress shielding phenomenon and enables us to fill the metallic lattice with the desired ceramic too

[148,149][69][70].

Figure 8 depicts the context of these experiments, with a particular emphasis on bone regeneration and the reduction in viral contamination using the LPBF-PM approach. This illustration outlines a vertical sequence within a rectangle, presenting appropriate metal alloys, objectives, traits, domains of application, and desirable ceramic compositions, arranged from the upper section to the lower section.

Figure 8. LPBF-PM solution for the regeneration of bone and reducing viral contamination.

6. Mechanical Tests and Properties

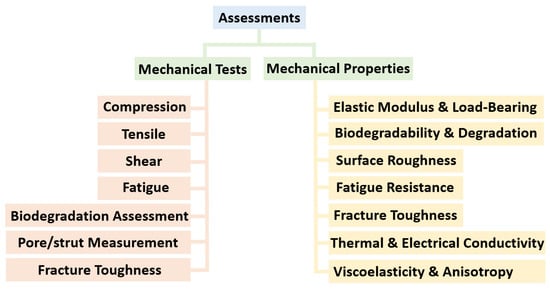

Mechanical testing of porous structures for biomedical applications is crucial to ensure that these structures possess the required mechanical properties to support tissue growth, withstand physiological loads, and maintain structural integrity. The primary mechanical tests and properties are illustrated in

Figure 9. The choice of mechanical tests will depend on the specific application and the intended tissue or organ being engineered. Several mechanical tests can be performed on these structures.

Figure 9. Mechanical tests and properties of porous structures for biomedical applications.

Compression test—Compression tests involve applying axial loads to the scaffold/lattice structure to evaluate its compressive strength, stiffness, and deformation behavior. Sing et al. [169] conducted a study to examine how process parameters affect dimensional accuracy and compressive behavior. They observed that as laser power or laser scan speed increased, the thickness of powder adhesion on the struts decreased. Additionally, they found that an increase in relative density led to a higher elastic constant in compression for the lattice structures. This is important for applications where the scaffold will experience compressive forces, such as in the femur, humerus, and other long bones.

Tensile test—Tensile tests assess the scaffold’s ability to withstand tensile forces. Tensile strength, elastic modulus, and strain-to-failure ratio are important parameters to determine. This test is particularly relevant for scaffolds used in soft tissue engineering. Scaffolds displayed a deformation behavior primarily characterized by stretching when subjected to tensile loads, and their stiffness and strength were influenced by the level of porosity [170]. Adjustments in laser parameters led to enhanced fatigue resistance in tensile loading, with a notable improvement observed, especially in the gyroid microarchitectural design.

Shear test—Shear testing evaluates the resistance of the scaffold to shear forces. It is important for scaffolds used in applications where shear loads are significant, such as cartilage or meniscus tissue engineering. Due to the inability of the body to naturally heal substantial bone defects, persistent endeavors are dedicated to advancing the field of 3D scaffolds for bone tissue engineering [171]. Zero-shear viscosity is a property of a material’s viscosity when it is unaffected by shear stress and holds significance in tissue engineering and rheology studies. It can be relevant when studying the flow behavior of biomaterials, such as hydrogels or other materials used for creating tissue scaffolds or drug delivery systems.

Biodegradation assessment—In some cases, mechanical testing may be combined with degradation studies to assess how the mechanical properties of the scaffold change over time as it degrades in the body. This is particularly relevant for biodegradable scaffolds [172].

Pore size (porosity) and strut diameter (accuracy)—While not a traditional mechanical test, analyzing the pore size distribution and porosity of the scaffold is essential for understanding its permeability and ability to facilitate nutrient and waste exchange within the tissue. Qui et al. [173] demonstrated that the laser scanning speed primarily affected strut thickness when operated at slower rates, with the highest porosity observed at intermediate speeds. Furthermore, high-speed imaging revealed that increasing laser power resulted in a larger melt pool.

Fatigue test—Fatigue tests are conducted by subjecting the scaffold to repeated cyclic loading to assess its resistance to fatigue failure. This is particularly important for scaffolds that will be subjected to repetitive loading in vivo, such as those used in joint tissue engineering. Clearly, the key factors influencing fatigue behavior are cell size and strut diameter. In a study conducted by Zhao et al. [174], various unit cell types (tetrahedron and octahedron) and pore sizes (500 µm and 1000 µm) were fabricated using the SLM process. The results revealed that octahedron scaffolds exhibited superior static mechanical properties, longer fatigue lives, and higher fatigue strength when compared to their tetrahedron counterparts. As anticipated, scaffolds with 1000 µm pores exhibited lower compressive properties and shorter fatigue lives when contrasted with those featuring 500 µm pores.

Fracture toughness test—This test assesses the scaffold’s resistance to crack propagation. This is relevant in situations where the structure may be exposed to potential sources of damage, e.g., HA, W, BCP, and TCP. An essential factor affecting fracture toughness is the building direction of metallic lattices during the SLM process. Alsalla et al. [175] discovered that the density of lattice structure samples remained consistent, regardless of whether they were built vertically or horizontally. However, it was observed that the samples built in the vertical direction exhibited superior tensile and fracture toughness properties when compared to those constructed in the horizontal direction.

Mechanical properties of lattice and scaffold structures should be tailored to match the specific requirements of the target tissue and the intended application. The structures used in biomedical applications should possess specific mechanical properties to fulfill their intended functions and support tissue regeneration. The desired mechanical properties can vary depending on the target tissue, organ, and application [176]. Some key mechanical properties that lattice and scaffold structures can have for biomedical applications are detailed here.

Load bearing strength—The scaffold should have sufficient strength to withstand the mechanical loads it will encounter in the body. The required strength varies widely depending on the tissue being replaced, with load-bearing tissues like bone requiring higher strength than soft tissues. Carluccio et al. [177] assessed the current state of biodegradable metal processing through SLM for load-bearing bone scaffold applications and conducted a meta-analysis to understand the impact of processing parameters on relative density. Synthetic bone scaffolds are gaining in popularity for treating critical bone defects, and SLM offers a means to create customized scaffolds with complex architectures. While the SLM process for biodegradable metal is still emerging, it is evident that future research should focus on broader guidelines for SLM machines to optimize the manufacturing efficiently.

Elastic modulus—The scaffold’s elastic modulus (stiffness) should match that of the surrounding tissue as closely as possible to avoid stress shielding or mechanical mismatch. This property is especially critical for orthopedic and musculoskeletal applications. Kadirgama et al. [178] conducted a study to investigate the correlation between various factors and the Young’s modulus of structures with values ranging from 0.01 to 1.84 GPa. Their findings highlighted the substantial influence of porosity in this relationship.

Porosity and pore size—Controlling the porosity and pore size of the scaffold is essential to promote cell infiltration, nutrient diffusion, and waste removal. The specific values depend on the tissue type and the desired level of porosity [179,180].

Biodegradability and degradation rate—Some scaffolds need to be biodegradable, gradually breaking down as new tissue forms. The rate of degradation should be tailored to match tissue regeneration rates [181]. Zinc exhibits low melting and boiling points, leading to increased porosity in the fabricated components during the SLM process. Demir et al. [182] explored the possibility of achieving greater porosity by manufacturing under varying atmospheric conditions. They introduced an innovative approach involving an open chamber setup with an inert gas jet flowing over the powder bed.

Interconnectivity—Interconnected pores and channels within the scaffold facilitate cell migration, nutrient exchange, and tissue integration. Proper interconnectivity is particularly crucial in complex tissues like vascular or neural tissue [183].

Surface roughness—Surface roughness can influence cell adhesion and proliferation. Controlled roughness can be beneficial for promoting cell–scaffold interactions [184].

Fracture toughness—For tissues subjected to potential impact or crack propagation, a high fracture toughness is essential to resist fracture or damage. In a research investigation focused on Ti6Al4V, Cain et al. [185] examined a comparison between heat-treated (post-processing) and as-built structures concerning fracture toughness and crack growth rate. The most significant enhancement in properties through heat treatment was notably observed when the fracture plane was perpendicular to the SLM build direction. This alteration during heat treatment plays a crucial role in achieving rapid densification and enhancing mechanical properties.

Thermal and electrical conductivity—In some specialized applications, thermal properties may be important, such as in scaffolds used for thermal ablation or hyperthermia treatments. Scaffolds with electrical conductivity may be required for applications involving electrical stimulation or integration with electronic devices, such as cardiac tissue engineering or neural interfaces. As demonstrated in a study conducted by Butler et al. [186], the processing parameters and scanning strategies employed in SLM process exert a substantial influence on both porosity and thermal conductivity. While there is a strong inclination toward additively manufactured components with minimal porosity, this research highlights the potential to significantly lower laser energy density requirements, by roughly one order of magnitude, while still achieving acceptable levels of thermal conductivity.

Viscoelasticity and anisotropy—In some applications, especially soft tissue engineering, viscoelastic properties become important as the scaffold must mimic the behavior of natural tissue under dynamic loads. In cases where tissue has anisotropic properties (e.g., muscle or tendons), scaffolds can be designed to exhibit anisotropic behavior by aligning the structural elements in specific directions [187].

In short, the mechanical properties of lattice structures in the SLM process are vital for tailoring them to specific tissue and application requirements. Load-bearing strength, elastic modulus, and fracture toughness are crucial considerations, with ongoing research exploring methods to optimize these properties [188,189,190]. Controlling porosity, pore size, interconnectivity, and surface roughness is essential for promoting cell integration and functionality. Additionally, biodegradability and degradation rates must align with tissue regeneration rates.

Compression test—Compression tests involve applying axial loads to the scaffold/lattice structure to evaluate its compressive strength, stiffness, and deformation behavior. Sing et al. [71] conducted a study to examine how process parameters affect dimensional accuracy and compressive behavior. They observed that as laser power or laser scan speed increased, the thickness of powder adhesion on the struts decreased. Additionally, they found that an increase in relative density led to a higher elastic constant in compression for the lattice structures. This is important for applications where the scaffold will experience compressive forces, such as in the femur, humerus, and other long bones.

Tensile test—Tensile tests assess the scaffold’s ability to withstand tensile forces. Tensile strength, elastic modulus, and strain-to-failure ratio are important parameters to determine. This test is particularly relevant for scaffolds used in soft tissue engineering. Scaffolds displayed a deformation behavior primarily characterized by stretching when subjected to tensile loads, and their stiffness and strength were influenced by the level of porosity [72]. Adjustments in laser parameters led to enhanced fatigue resistance in tensile loading, with a notable improvement observed, especially in the gyroid microarchitectural design.

Shear test—Shear testing evaluates the resistance of the scaffold to shear forces. It is important for scaffolds used in applications where shear loads are significant, such as cartilage or meniscus tissue engineering. Due to the inability of the body to naturally heal substantial bone defects, persistent endeavors are dedicated to advancing the field of 3D scaffolds for bone tissue engineering [73]. Zero-shear viscosity is a property of a material’s viscosity when it is unaffected by shear stress and holds significance in tissue engineering and rheology studies. It can be relevant when studying the flow behavior of biomaterials, such as hydrogels or other materials used for creating tissue scaffolds or drug delivery systems.