Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Maria Villen-Guzman.

Electrodialysis is classified as a membrane separation process in which ions are transferred through selective ion-exchange membranes from one solution to another using an electric field as the driving force. Electrodialysis is a mature technology in the field of brackish water desalination, but in recent decades the development of new membranes has made it possible to extend their application in the food, drug, and chemical process industries, including wastewater treatment.

- metal separation

- membrane

- selectivity

1. Introduction

During recent decades, the rising population and industrialization have increased demand for the Earth’s natural resources and the occurrence of subsequent environmental problems. One of these problems is the generation of large amounts of wastewater containing metals that are a risk to the population and ecosystems due to their toxicity [1]. Some metals affect biological function and can accumulate in different organs, causing hazardous effects [2]. The most prevalent metals found in wastewater are Al, As Cd, Cr, Cu, Hg, Pb, Ni, Zn, Co, Fe, and Mn, and their composition in wastewater differs according to the type of industry. The main sectors that contribute to this problem are mining, smelting, foundries, and other chemistries such as textiles and refineries [2].

The negative effect of some metals in wastewater makes it necessary to treat these industrial effluents before discharging to reduce the pollution. The conventional method to remove metals from industrial effluents has been chemical precipitation, adjusting the pH of the effluents, and removing the precipitated particles through sedimentation or filtration [3]. Other chemical-based separation methods include coagulation/flocculation and flotation. These methods can be applied to treat industrial effluents with high metal concentrations. Although these methods are simple and require inexpensive equipment, they involve a large amount of chemicals to reduce metal concentrations and a large-volume sludge formation which requires post-treatment [4]. As an alternative method, adsorption is widely selected to remove metal from aqueous effluents. Several studies have focused on developing cheaper and more efficient adsorbent materials in the last decade, for example, natural materials, industrial by-products, or biological and agricultural waste [5]. However, biosorption (i.e., adsorption with biological materials) has some shortcomings, such as a lack of specificity in metal binding, large amounts of biomass required if the biosorption capacity is low, and a limited reusability of biomass after desorption for real applications in industrial effluents [6]. Another method applied to remove metals from aqueous effluents is ion exchange due to its higher ion selectivity and the reusability of ion-exchange material. The main drawbacks of this technology are high operational costs, which limit application at industrial scale, and the formation of fouling by solids and organic compounds contained in industrial effluents [6]. Electrochemical processes based on passing a direct current through an aqueous solution containing metal between electrodes have also been widely studied. Metal selectivity, no consumption of additional chemicals, high efficiency, and lower amounts of sludge produced are the main advantages of these processes. However, electrochemical technologies possess some drawbacks, such as a high dependence on the pH values of aqueous effluents and high operational costs related to electrical energy requirements and electrode replacement [3].

Some alternative technologies to conventional methods are based on pressure-driven membrane processes, such as ultrafiltration, nanofiltration, and reverse osmosis [7]. Another membrane technology is electrodialysis (ED), which involves the migration of cations and anions through ion-exchange membranes under the effect of an electric field. This technique has been employed industrially to treat saline waters and brines. However, its selective separation of charged species offers excellent advantages, increasing its interest for treating water containing metals. Some advantages related to the selective separation of ions are the high separation efficiency, low operating pressure, small operating footprint, no need for adding chemicals, and reduced sludge formation. Moreover, this technology can treat effluents with low concentrations of metal ions. All these advantages make electrodialysis one of the most effective and promising technologies for treating industrial effluents [8].

2. Fundamentals of Electrodialysis Processes

2.1. Operational Principle

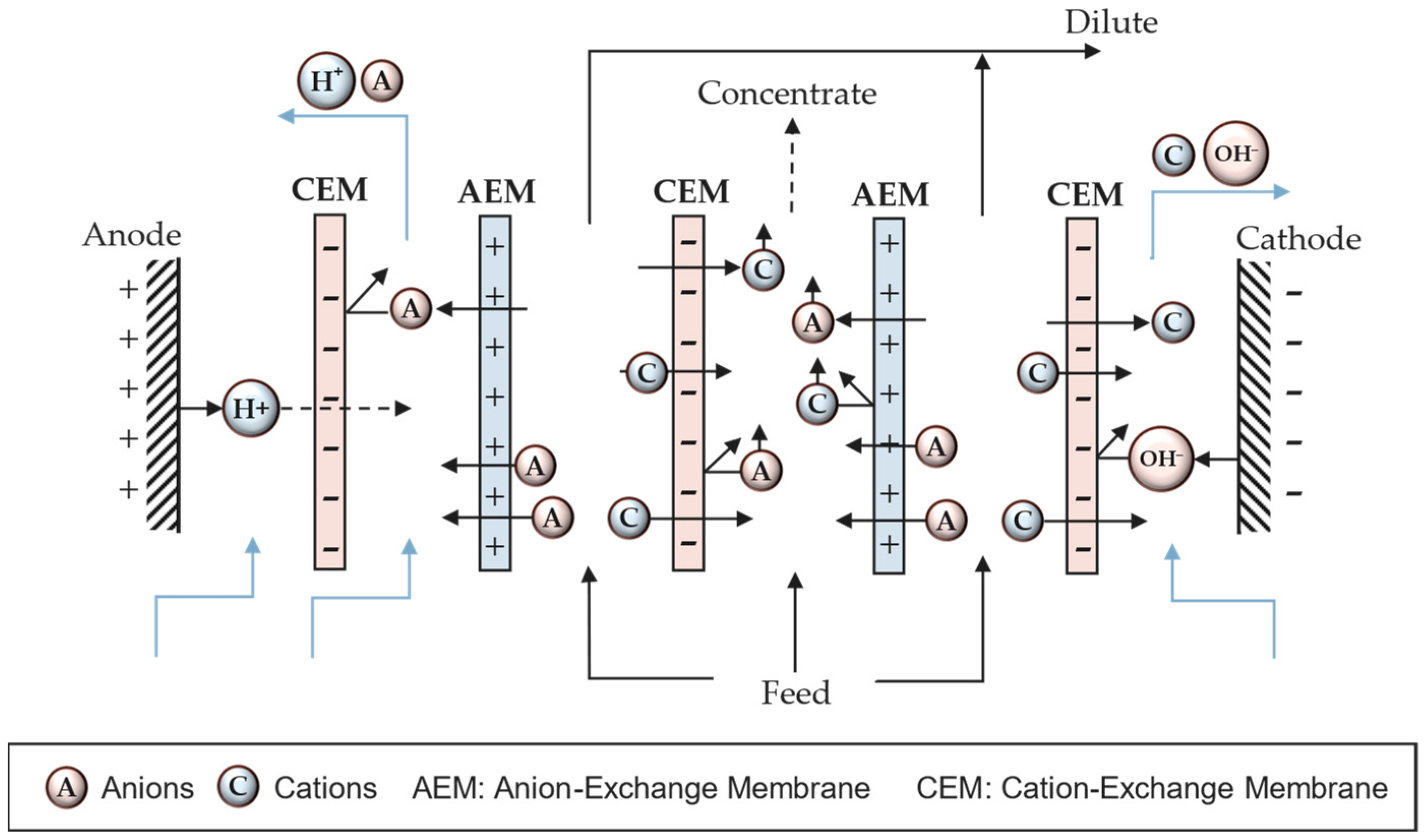

The working principle of ED consists of the migration of cations and anions through cation-exchange membranes (CEMs) and anion-exchange membranes (AEMs), respectively, induced by an applied electric field set between a pair of electrodes. In a simple electrodialysis cell (Figure 1), a pair of membranes is used. Anions migrate towards the anode, and cations towards the cathode, resulting in an overall decrease in the feed stream salt concentration. The membranes are separated by channels ending with the electrode compartments.

Figure 1. Schematic of a simple (two-membrane) electrodialysis cell.

Figure 2. Depiction of a multichannel electrodialysis stack.

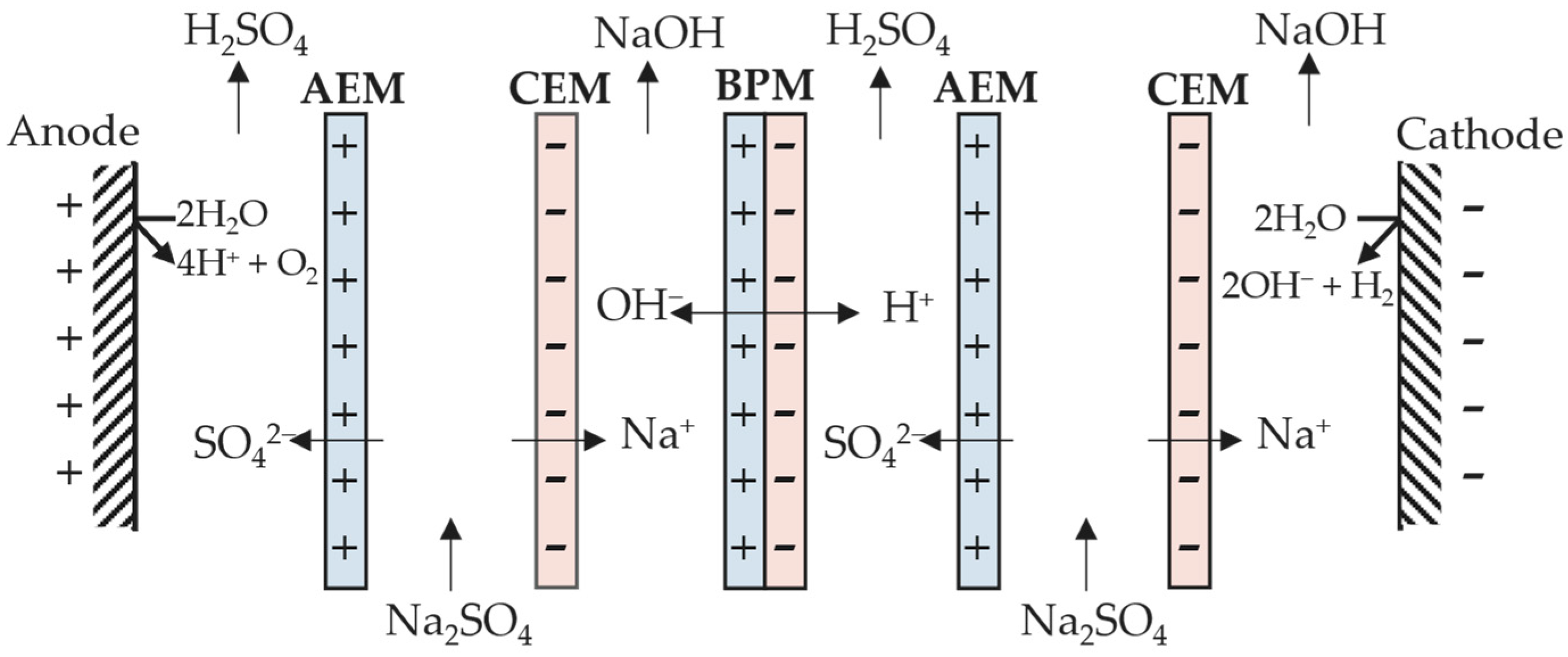

Figure 3. Depiction of a three-compartment electrodialytic cell with a bipolar membrane.

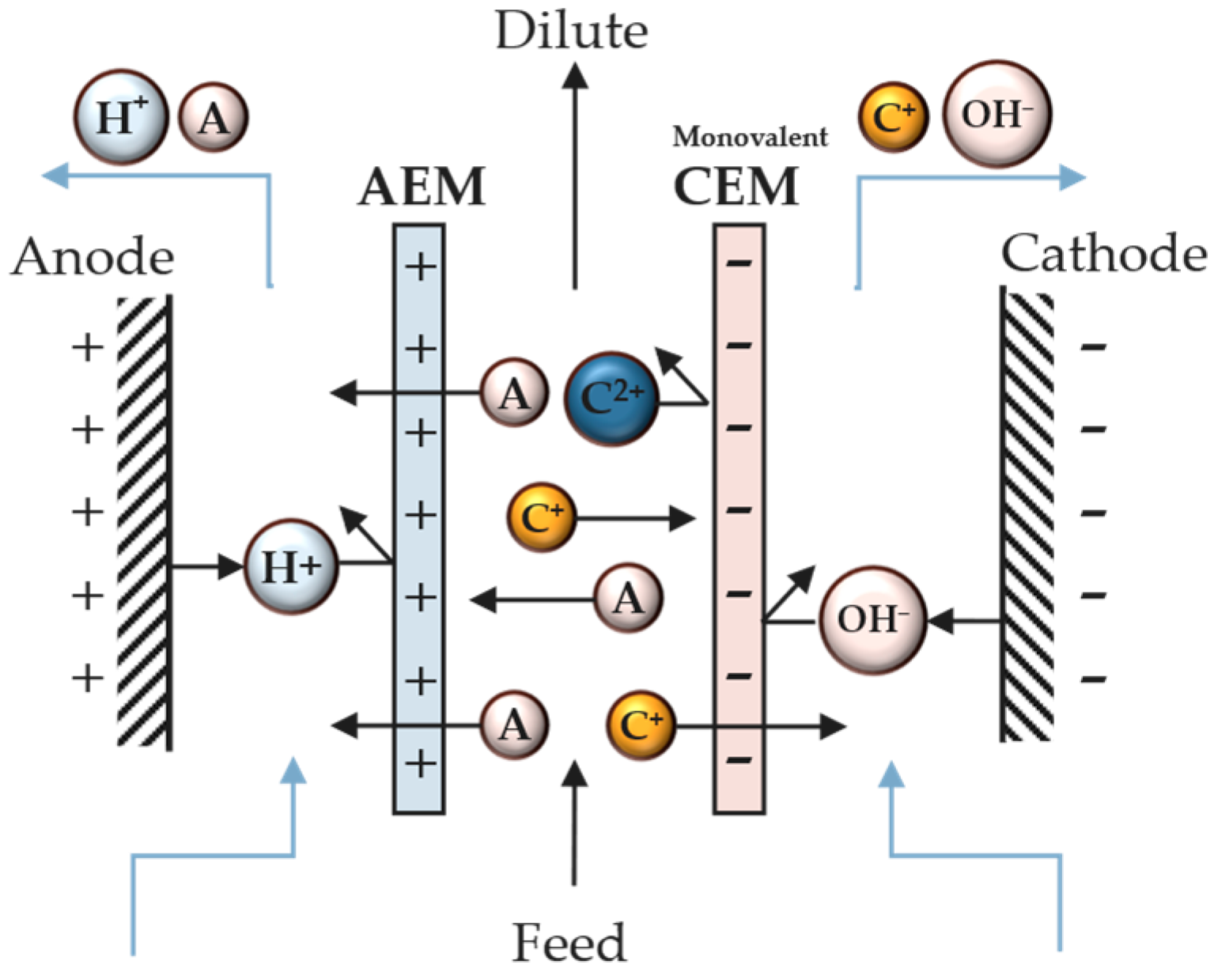

Figure 4. Scheme of a unit cell with a monovalent cation-exchange membrane.

2.2. Mass Transport Mechanism

Mass and charge transport in electrolyte solutions and ion-exchange membranes is described with the same set of equations. Under an electric field, ions are mainly transported by electromigration. Diffusion transport becomes significant at the boundary layers, near the membranes and the electrodes, due to high concentration gradients. The coupling of these transport mechanisms is known as electrodiffusion and can be described by the Nernst–Plank transport equation, which considers the diffusive, electromigration, and convective flux to calculate the total flux of ions, (mol/m2/s):References

- Ahmed, J.; Thakur, A.; Goyal, A. Chapter 1: Industrial Wastewater and Its Toxic Effects. In Biological Treatment of Industrial Wastewater; The Royal Society of Chemistry: London, UK, 2021; pp. 1–14.

- Briffa, J.; Sinagra, E.; Blundell, R. Heavy Metal Pollution in the Environment and Their Toxicological Effects on Humans. Heliyon 2020, 6, e04691.

- Shrestha, R.; Ban, S.; Devkota, S.; Sharma, S.; Joshi, R.; Tiwari, A.P.; Kim, H.Y.; Joshi, M.K. Technological Trends in Heavy Metals Removal from Industrial Wastewater: A Review. J. Environ. Chem. Eng. 2021, 9, 105688.

- Barakat, M.A. New Trends in Removing Heavy Metals from Industrial Wastewater. Arab. J. Chem. 2011, 4, 361–377.

- Villen-Guzman, M.; Cerrillo-Gonzalez, M.M.; Paz-Garcia, J.M.; Rodriguez-Maroto, J.M.; Arhoun, B. Valorization of Lemon Peel Waste as Biosorbent for the Simultaneous Removal of Nickel and Cadmium from Industrial Effluents. Environ. Technol. Innov. 2021, 21, 101380.

- Doble, M.; Kumar, A. Treatment of Waste from Metal Processing and Electrochemical Industries. In Biotreatment of Industrial Effluents; Butterworth-Heinemann: Oxford, UK, 2005; pp. 145–155.

- Goh, P.S.; Wong, K.C.; Ismail, A.F. Membrane Technology: A Versatile Tool for Saline Wastewater Treatment and Resource Recovery. Desalination 2022, 521, 115377.

- Arana Juve, J.M.; Christensen, F.M.S.; Wang, Y.; Wei, Z. Electrodialysis for Metal Removal and Recovery: A Review. Chem. Eng. J. 2022, 435, 134857.

- Gurreri, L.; Cipollina, A.; Tamburini, A.; Micale, G. Electrodialysis for Wastewater Treatment—Part I: Fundamentals and Municipal Effluents. In Current Trends and Future Developments on (Bio-) Membranes: Membrane Technology for Water and Wastewater Treatment—Advances and Emerging Processes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 141–192. ISBN 9780128168240.

- Van der Bruggen, B. Ion-Exchange Membrane Systems—Electrodialysis and Other Electromembrane Processes. In Fundamental Modeling of Membrane Systems: Membrane and Process Performance; Elsevier: Amsterdam, The Netherlands, 2018; pp. 251–300.

- Pärnamäe, R.; Mareev, S.; Nikonenko, V.; Melnikov, S.; Sheldeshov, N.; Zabolotskii, V.; Hamelers, H.V.M.; Tedesco, M. Bipolar Membranes: A Review on Principles, Latest Developments, and Applications. J. Membr. Sci. 2021, 617, 118538.

- Kitchenham, B. Procedures for Performing Systematic Reviews; Keele University: Keele, UK, 2004; Volume 33.

- Hansima, M.A.C.K.; Makehelwala, M.; Jinadasa, K.B.S.N.; Wei, Y.; Nanayakkara, K.G.N.; Herath, A.C.; Weerasooriya, R. Fouling of Ion Exchange Membranes Used in the Electrodialysis Reversal Advanced Water Treatment: A Review. Chemosphere 2021, 263, 127951.

- Tanaka, Y. Chapter 2: Electrodialysis Reversal. In Membrane Science and Technology; Elsevier: Amsterdam, The Netherlands, 2007; Volume 12, pp. 383–404.

- Güler, E.; Elizen, R.; Vermaas, D.A.; Saakes, M.; Nijmeijer, K. Performance-Determining Membrane Properties in Reverse Electrodialysis. J. Membr. Sci. 2013, 446, 266–276.

- Luo, T.; Abdu, S.; Wessling, M. Selectivity of Ion Exchange Membranes: A Review. J. Membr. Sci. 2018, 555, 429–454.

- Tekinalp, Ö.; Zimmermann, P.; Holdcroft, S.; Burheim, O.S.; Deng, L. Cation Exchange Membranes and Process Optimizations in Electrodialysis for Selective Metal Separation: A Review. Membranes 2023, 13, 566.

- Moura Bernardes, A.; Zoppas Ferreira, J.; Siqueira Rodrigues, M.A. Electrodialysis and Water Reuse: Novel Approaches; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9783642402494.

- Ebbers, B.; Ottosen, L.M.; Jensen, P.E. Electrodialytic Treatment of Municipal Wastewater and Sludge for the Removal of Heavy Metals and Recovery of Phosphorus. Electrochim. Acta 2015, 181, 90–99.

- Abou-Shady, A.; Peng, C.; Almeria, O.J.; Xu, H. Effect of PH on Separation of Pb (II) and NO3- from Aqueous Solutions Using Electrodialysis. Desalination 2012, 285, 46–53.

- Dean, J.A. Lange’s Handbook of Chemistry, 15th ed.; McGraw-Hill Professional Publishing: New York, NY, USA, 1999; ISBN 0-07-016384-7.

More