1. Energy Consumption Problems in Autonomous Vehicles

The major ambition of the automotive industry is the marketing of autonomous vehicle (AV) technology. Consequently, research in this area is swiftly expanding across the world. However, despite this high level of research effort, literature addressing straightforward and efficient energy approaches to developing an autonomous vehicle research platform is sparse

[1][18]. This

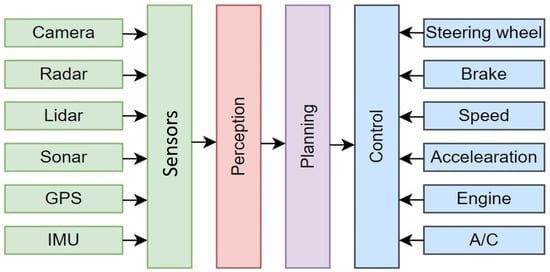

review section highlights the main problems and optimization regarding energy in automated vehicles in the scope of both standard autonomous vehicles (AVs) and Electrified Autonomous Vehicles (EAVs). Autonomous vehicles are emerging embedded systems, and of course, energy may be considered one of the most important related issues. The biggest challenge facing AV energy consumption is the requirements for attached sensors, control systems, computer processing units, remote data transfer protocols, and networking hardware as demonstrated in

Figure 12. These systems are needed to perceive surrounding real-world circumstances and respond to real-time decisions

[2][19]. Additionally, vehicle weight and probably higher drag may raise the energy consumption of AVs compared to human-driven vehicles

[3][20]. These extra loads dilate the auxiliary load profile, consequently decreasing the range of an automated vehicle. Furthermore, additional electrical loads can be appended on fully autonomous vehicles due to fail-safe requirements from the sensor to vehicle control

[2][19]. Thus, increasing energy efficiency has been the subject of numerous studies for decades.

Figure 12.

Autonomous vehicles components.

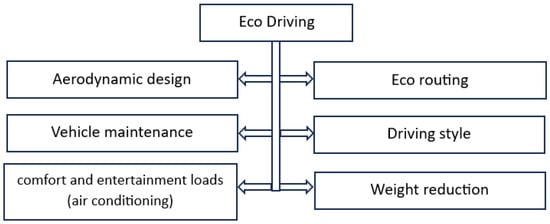

Eco-driving is an effective technology for realizing significant energy efficiency and achieving sustainable transportation

[4][5][21,22]. Eco-driving refers to adopting a driving approach to conserve energy and minimize harmful emissions.

Figure 23 shows the general notation of the eco-driving system. A more energy-efficient drive cycle can be achieved for the same route by adopting a heuristic set of goals, such as eliminating stops, preserving a constant speed, limiting acceleration, and smoothing the velocity profile. In this way, energy economy improvements of 10% can be achieved for modern vehicles and 30% for fully autonomous vehicles

[6][7][23,24]. Furthermore, applying eco-driving can result in longer battery life and slower battery degradation. The formulation of maximizing energy efficiency improvement problem as an optimal control problem can be accomplished by predicting the driving circumstances along the route through eco-driving. These predictions can be sensed by the technology of vehicle sensors, vehicle to vehicle (V2V), and vehicle to infrastructure (V2I). Many studies have shown that exploiting these factors can improve power efficiency, and that predictions of traffic light signal phase and timing (V2I technology) can raise the improvement to 27%

[3][8][20,25].

Figure 23.

General notation of eco-driving system.

Using V2I (enabling traffic light prediction) can decrease power consumption in eco-driving

[9][26]. Other methods are proposed using information from the leading vehicle and the data from traffic lights for red light avoidance, putting constraints on vehicles in green light queues, and optimizing the speed and power distribution between the motor and engine under A/C load

[10][27]. Furthermore, implementing Model Predictive Control (MPC) and Dynamic Programming (DP) has been considered in a leading vehicle-following scenario. Leading vehicle-following driving is a type of cooperative driving strategy used in autonomous vehicles to improve safety, power efficiency, and comfort. In AVs, the leading vehicle-following scenario can be implemented using sensors and cameras to monitor the leading vehicle’s movements and adjust the following vehicle’s speed and acceleration accordingly. By maintaining a safe distance and matching the leading vehicle’s speed and acceleration, the following vehicle can take full advantage of the aerodynamic drafting effect, resulting in improved fuel efficiency and reduced energy consumption

[11][12][28,29].

Vehicle velocity prediction is an essential technique for realizing improvements in the energy economy and determines the constraints of the energy optimization problem

[13][14][30,31]. Energy saving in AVs can be degraded due to inaccurate velocity prediction, resulting in reduced fuel efficiency and increased energy consumption

[15][32]. Many researchers have recognized self-driving vehicle possibilities for adapting Artificial Neural Network (ANN) prediction models in which their outputs can improve the power economy through control strategy derivation

[16][33]. Other approaches have shown remarkable performance using artificial intelligence (AI) techniques

[15][16][17][18][32,33,34,35].

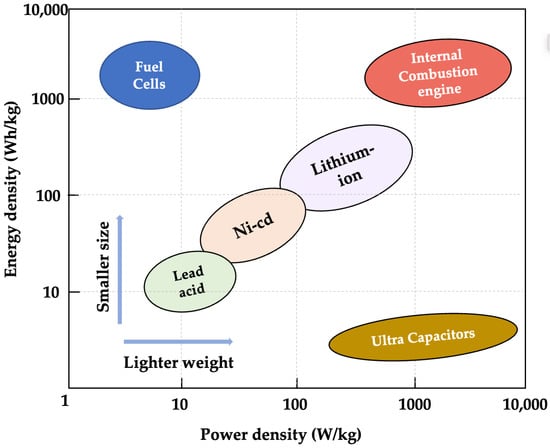

The energy required by AVs can be supplied from different sources, like batteries, Ultra-Capacitors (UC), and Fuel Cells (FC). The two important criteria of energy sources are high energy density and high power density. High-energy sources can provide long ranges, while high power sources aid in maximizing acceleration. Other characteristics required for the perfect energy source are fast charging, long life cycle, long service and less maintenance, and lower cost

[19][36].

Batteries have been considered the most prominent energy source for a long time for electrical vehicles (EVs) and have many different technologies that are still in research and development. Some common battery technologies used in EVs are Li-ion, Li-polymer, Ni-Cd Na-S, Ni-MH, Zn-air, Ni-Zn, lead-acid, and graphene. Various battery kinds possess advantages and disadvantages that should be carefully studied when choosing among them. Batteries represent a remarkable reason for concern because of the pack size and how much weight they add to the vehicle. The battery has an impact on the range and charging time as well. In general, many useful battery technologies have already been invented, but at this point they are limited and not being pursued due to their exorbitant costs

[20][21][37,38].

Ultra-Capacitors (UCs) physically store charges in two electrodes separated by an ion-enriched liquid dielectric. This technology can provide significantly high power density. Also, while no chemical reaction takes place in the electrodes, the UC life cycle is often long. However, the absence of these reactions makes them lower energy density. Additionally, their internal resistance is low, making them highly efficient, but if charged at an extremely low state, it can result in a large output current

[22][39]. Fuel Cells (FCs) consist of an anode, cathode, and electrolyte between them and can generate electricity by electro-chemical reaction after applying fuel (i.e., hydrogen) to the anode. Electric Vehicles that are powered by FCs can gain many advantages like fast refueling, low or no emissions, durability, and the capacity to produce high-density current outputs. On the other hand, FU technology is high cost, requires larger fuel tanks since hydrogen has less density compared to petroleum, and has a lower response time compared to batteries and UCs

[23][24][40,41]. In

[25][42], the authors present an optimal control model to determine a Puma robot’s point-to-point trajectories while maximizing the energy regenerated and stored in the UCs. The research demonstrates that the developed model effectively reduces energy consumption by approximately 10% to 22% as the Puma robot’s operating time increases. Since hydrogen has no color, leaking hydrogen can be seriously harmful and difficult to detect. Additionally, it is highly flammable and explosive in the event of collisions. The car industry has taken steps to assure the tank’s integrity in response to these issues; they have encased them with carbon fibers. There are procedures to lock the tank outlet in case of a high-speed collision, and the hydrogen-handling components can be positioned outside the cabin, allowing the gas to disperse easily in case of a leak

[26][43].

After mentioning the power problems regarding EVs, in contrast, charging is considered an essential issue. Since the charge is stored as DC in batteries and UCs, various voltage and current configurations are available for AC or DC charging. AC supply systems require AC-DC converter circuits to obtain the charging from the grid. DC supply systems need special cabling and installation to be mounted on stations and garages

[27][44]. EVs are regarded as high-power loads that influence the power distribution system

[28][45]. Therefore, random and uncoordinated charging actions can overwork the distribution system by raising peak demands. It can also cause extreme voltage fluctuations, increasing losses, hastening the aging of transformers and cables, lowering system efficiency and economy, and raising the possibility of blackouts as a result of network overload

[29][30][31][46,47,48]. Load management and network energy efficiency can be improved by integrating smart grid functions in networking, communication, and monitoring

[32][33][34][49,50,51].

The time required to reach full charge is one of the most important factors; the long-time charging of batteries and UCs represents the main downside issue in EVs

[4][21]. Charging might take anywhere from a few minutes to several hours, depending on the battery pack and type of charger. Uncontrolled charging (also referred to as dump charging) occurs when there is no concern about the timing of power drawn from the grid. This can cause unbalancing the load, instability, minimizing reliability, and reducing power quality. Nowadays, many fast-charging technologies exist and are being researched

[35][52]. Wireless charging is the technology of transferring energy between primary and secondary circuits without using cabling. However, due to the health and safety issues with this technique, it is not common for commercial EVs, which are regulated by the standardization organizations in each country. While FC vehicles do not need to be charged as other EVs do, they require enough hydrogen filling stations and a practical method to produce the hydrogen

[36][37][53,54].

Efficient Energy-Saving Methods in Autonomous Vehicles

The advancement in the AV industry promises to revolutionize the future of transportation systems and stands out as a significant stride towards safer, more efficient, and accessible mobility. Optimizing energy consumption is crucial for their efficiency and environmental impact. In general, the optimization aspects for saving energy methods can be categorized into two primary aspects:

-

The design aspects: They primarily include the configuration of vehicle components, namely batteries, motors, and body structure. These elements are recognized as foundational factors contributing to the AV driving range extension.

-

The control aspects: They pertain primarily to control various vehicle subsystems, including the braking system, steering system, and active suspension system.

Considering these mentioned aspects, numerous automobile manufacturers today are actively incorporating various energy-saving approaches into their cutting-edge vehicle models as stated below:

-

Regenerative Braking: This involves converting kinetic energy into electrical energy during braking and storing it in the vehicle’s battery.

-

Predictive Cruise Control: This optimizes speed and acceleration patterns based on road circumstances.

-

Efficient Powertrains: They utilize high-efficiency electric motors and power electronics.

-

Low-Rolling Resistance Tires: These reduce the energy required to move the vehicle.

[41][42][57,58,59].

Besides the advantages of UAVs in solving many problems in different fields, a potential drawback arises with this technology regarding energy consumption, where the drone is an electric device powered by embedded batteries with a limited lifetime. This has an effect on limiting the flight time of drones. Therefore, most UAV applications are unable to reach their entire target. Nowadays, researchers in many literature reviews are placing their focus on minimizing energy consumption in UAV missions to deal with this topic.

Nowadays, UAV manufacturers of professional drones are betting everything on great autonomy. The American drone Tailwind has broken all records by flying for 4 h 30 min in the Californian sky. Other models use Fuel Cells, kerosene, or solar energy

[43][61]. Some examples of the most powerful models, like the DJI Mavic 2 Pro, the Yunnec Mantis Q, or the Fimi X8 SE, can expect to fly for about thirty minutes at maximum. Apart from the capacity of the battery capacity expressed in mAh, several factors are taken into account to affect the power/energy consumption of the drone, so the autonomy is limited

[44][62]:

-

Impact of taking off;

-

Impact of movement (hovering, horizontal movement and vertical movement);

-

Impact of payload: Increasing the mass of the drone affects the gravitational force, where energy is needed to keep the drone flying by keeping the stability;

-

Weight Reduction: This reduces the overall weight of the vehicle by using lightweight materials.

-

Aerodynamic Design: This streamlines the vehicle’s shape to reduce air resistance.

-

Battery Management Systems (BMSs): They monitor and manage the battery’s state to optimize charging and discharging processes, extend the battery’s life, and maintain its efficiency.

-

Smart HVAC (heating, ventilation, and air conditioning) Systems: Using predictive climate control algorithms can help manage the vehicle’s interior temperature with minimal impact on the battery.

-

Energy-Efficient Software Algorithms: Software algorithms for decision-making, navigation, perception, and control algorithms contribute to overall energy savings.

-

Dynamic Route Planning: Real-time traffic and road condition data are utilized to optimize routes, avoid congestion, and reduce energy consumption.

2. Energy Consumption Problems in Unmanned Aerial Vehicles

UAV (acronym of “unmanned aerial vehicle”), known as a drone, is an uninhabited aircraft in the field of aerial robotics. The system can be autonomous or remotely piloted

[38][55]. The drones can carry out various missions for civil or military uses depending on their type: this is based on the characteristics and control capabilities in different environments. A drone’s performance is measured by how it reacts to the various factors of the environment, such as aerodynamic phenomena, disturbances (winds), etc.

[39][56]. With the evolution of electronics and embedded systems technology, the production of miniaturized embedded systems and sensors became possible. Therefore, the internal body of the drone became small and optimized. In this context, the quadrotor type presents a great example of mini drones, where its usage in real life has been increasing, especially in the last four years with the appearance of the pandemic and COVID-19 crisis; these systems became an excellent solution for delivery purposes and fulfilling logistics tasks

[40]

-

Impact of speed: Increasing the drone’s velocity is achieved by increasing the torque of the rotors, which require a high current;

-

-

Impact of wind: The wind is a disturbance that affects the drone’s movement. Therefore, an opposite force should be applied to compensate for it. This opposite force is generated with higher energy consumption;

-

Impact of communication: Internal communication is executed with different sensors, between the controller and sensors such as GPS, Gyroscope, accelerometer, etc.

Energy Performance of Power Source in UAV

The power source system in the drone can be characterized by different types

[45][63], such as batteries, solar power, Fuel Cells, combustion engines, etc.

Figure 34 shows drone power sources with different types of material.

Figure 34.

Drone power sources with different types of material.

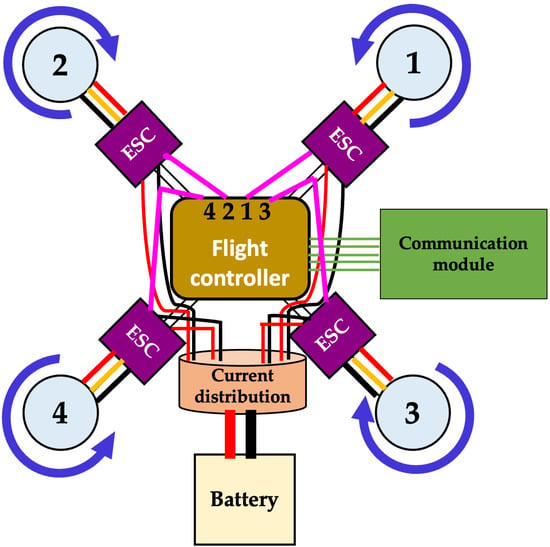

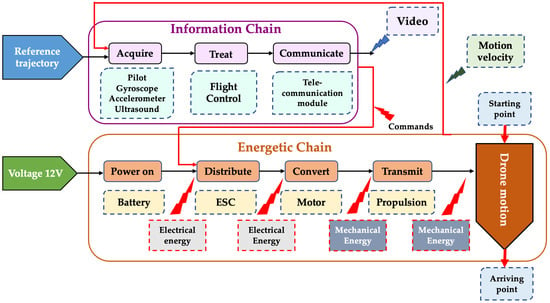

UAVs are usually powered by a 12 V battery. They are composed of different motors controlled by ESC motor controllers (electronic cards that allow the motors to turn more or less quickly). Thanks to the propellers connected to the axes, the drone can move with six degrees of freedom according to the three axes

[46][64]. Different sensors are board on the drone body:

-

The gyroscope measures the orientation of the drone;

-

The accelerometer measures the linear acceleration;

-

The ultrasonic measures the distance from a target.

These sensors send information to the flight controller. The telecommunication module allows receiving the orders transmitted by the pilot’s remote control to indicate the positioning and transmit the video signal. Figure 45 shows the drone body components, while Figure 56 shows the relation between these modules.

Figure 45.

Drone body components.

Figure 56.

Relation between the drone modules.

In batteries for example, several suggestions, such as lithium-ion, nickel cadmium, lithium polymer, lithium-air, and lithium-SOCl2. Every type depends on the usage and the drone’s size. Li-SOCl2 batteries afford two-times-higher energy density per Kg compared to others. While Li-air batteries can achieve results up to seven times higher, they are much more expensive than Li-Po and Li-ion. Usually, Li-ion batteries are suitable for EV applications.

The efficient battery type for a specific drone can be identified by analyzing the following criteria:

-

The power density affects the acceleration capabilities;

-

Energy density to identify the range;

-

Weight and volume, which affect the range of the system;

-

Cycle life to find out how often the battery should be replaced;

-

Cost regarding the budget;

-

Safety and maintenance.

The power density is the value that the power source can provide at a specific instance. In contrast, the energy density is the value that determines how long that amount of power can be delivered.

Many literature reviews highlighted several solutions regarding the drawbacks of drone battery systems and how to optimize the energy consumption of drones. Different solutions were proposed targeting the software and hardware level.

Some software solutions are focused on trajectory planning, which presents a reference input for the drone; based on the data received from that input, the drone will execute the commands. Therefore, generating an optimal trajectory from point to point can be an effective solution, almost avoiding the singularities of the system and the motions that require higher voltage for the rotors. Nowadays, the optimal trajectory is generated by combining AI algorithms such as genetic algorithm, Ta-bu search, etc. Another solution is adopted by researchers based on the design of an optimal control law by generating a cost function from velocity and trying to minimize it. Different strategies are adopted in this field, some of which are linear

[47][65], such as linear MPC (Model Predictive Control), LQR (Linear Quadratic Regulator), and H

∞, and some of which are nonlinear, such as nonlinear MPC, back-stepping and slave mode.

At the hardware level, a hybrid system implementation is recommended by utilizing different power sources instead of relying solely on one power source, which maintains the lightweight design of the drone. As the drone market has different types of batteries, using a good type can also solve the problem. The latest research started to include super-capacitor technology, which presents a great solution to solve the energy storing problem.