Lignocellulosic biomass is a powerful approach to produce sustainable biofuels and the further achievement of the goal of biomass conversion into a second-generation clean energy that can cope with the depletion of fossil reserves and rising energy requirements. In the conversion process, a pretreatment is essential to overcome the recalcitrance of the lignocellulosic biomass; accelerate its disintegration into cellulose, hemicellulose, and lignin; and, in turn, obtain an optimal yield of fermentable sugars in the enzymatic hydrolysis. In addition to this, it should be industrially scalable and capable of enhancing fuel properties and feedstock processability. Here, steam explosion technology has stood out due to its results and advantages, such as wide applicability, high efficiency in the short term, or lack of contamination despite its conventionality.

- steam explosion pretreatment

- sugarcane bagasse

- lignocellulosic biomass

- bioethanol

- feedstock

1. Introduction

2. Sugarcane Bagasse as a Potential Raw Material for Bioethanol Production

Sugarcane (Saccharum oficinarum L.) is a tropical grass that belongs to the Gramineae family and the Saccharum spp. genus [22][10] and is characterized for being large and perennial. The sugarcane cultivation requirements are 6–12 months to grow with 60–100 cm3 of water [23][11]. Brazil, China and India are the main producers of SCB, with almost 500 MT generated every year from the sugarcane industry, which provides an important contribution to economic development [9,22,24][9][10][12]. SCB yielded the highest crop straw production between 2012 and 2022 according to the Food and Agricultural Organization Corporate Statistical Database (FAOSTAT) [25][13]. Sucrose is the main product of sugarcane, which accumulates in the internodes of the stalk [9]. However, the percentage of waste generated during sugarcane production varies between 25 and 30% [8], which may represent 125–150 MT of residues. The residues produced by the sugarcane industry are mainly two types, and they can be classified as straw, which is the harvest residue, and as bagasse, which is the fibrous fraction after the extraction of the sugarcane stem juice [22][10]. These two by-products are characterized by their lignocellulosic composition, with cellulose, lignin and hemicellulose being the major components and having also extractants and ashes in their composition [26][14]. SCB is composed of approximately 45–50% cellulose, 25–30% hemicellulose, 25% lignin and 2.4–9% ash [9]. Nevertheless, this may vary depending on different factors such as chemical composition of the soil, climatic conditions and variety of the crop, among others [9]. Table 1 shows variations in the composition of SCB, sugarcane fiber and sugarcane straw. The relative abundances of component units are usually calculated on the basis of the volume integration of the raw material and are expressed in percentage of dried weight [27][15]. The chemical characterization of vegetal biomass is highly relevant for their consideration as potential sources of carbon to produce bioethanol. Indeed, for bioethanol production, it is important to evaluate the cellulose, hemicellulose and lignin composition of the raw material [9]. Owing to its high yield of sugar and lignocellulosic biomass, SCB is regarded as an excellent alternative energy source to substitute fossil fuels [28,29][16][17].| RM | Pretreatment before Measurement | Cellulose | Hemicellulose | Lignin | Xylan | Sucrose | Ash | Ref. |

|---|---|---|---|---|---|---|---|---|

| SCB | Not specified | 57.68 | 12.41 | 7.89 | - | - | 2.20 | [30][18] |

| SCB | Dried in an oven at 65 °C | 29.19 | - | - | 16.51 | 25.75 | - | [31][19] |

| SCB | Air-dried at 50 °C | 36.4 | 20.1 | 29.9 | - | - | 5.4 | [27][15] |

| SCF | Dehydration in hot air oven at 60 °C | 39.70 | 36.39 | 7.37 | - | - | 5.63 | [32][20] |

| SCB | Dried at 105 °C | 38.8 | 26 | 32.4 | - | - | 2.8 | [33][21] |

| SCS | Air-dried until a 10% final humidity | 33.5 | 27.1 | 25.8 | - | - | 2.5 | [34][22] |

| SCS | Not specified | 44.5 | 30.4 | 12.3 | - | - | 7.5 | [35][23] |

| SCB | Non-treated | 40.1 | 23.8 | 23.6 | - | - | 3.5 | [10][24] |

| SCB | Non-treated | 38.7 | 23 | 16.9 | - | - | - | [36][25] |

| SCB | Air-dried at NST | 43.1 | 31.1 | 11.4 | - | - | 5.5 | [37][26] |

| SCB | Not specified | 57.68 | 12.41 | 7.89 | - | - | 2.20 | [30][18] |

| Pretreatment | Operational Conditions | Recovery (%) | Ref. | ||

|---|---|---|---|---|---|

| Temp (°C) | Time (min) | Pressure (atm) | |||

| SE+AHS | 195 | 7.5 | 18 | 73.8 bEtOH, 0.58 g/L/h EtOH | [7] |

| AHS | 200 | 10 | - | 51.88–66.67 bEtOH (11.96 g/L) | [48][37] |

| K3PO4 6.4% | 144 | 60 | - | 53.04 bEtOH | [51][40] |

| SE | 160 | 30 | 6.8 | >150 mg/g TC, 87.16 mg/mL EtOH | [47][36] |

| H2SO4 10% | 100 | 60 | - | 251.1 mg/g TC, 58.7 mg/mL EtOH | |

| SE+H2O2 | 210 | 15 | - | 86.9 C; 92.4 HM; 29.7 Lig | [46][35] |

| SF-CO2+H2O2 | 187 | 60 | 154 | 97.8 Glu | [49][38] |

| SF-CO2+Ultrasound | 240 | 65.8 Glu | |||

| SF-CO2 | - | >55 Glu | |||

| NaOH 0.7% | 70 | 360 | - | 53.3–68.8 Glu; 67.8–74.7 xylose ⟶ 10.67 g/L | [50][39] |

| NH4-OH-H2O2+IL | 100 | 360 | - | 87.4 Glu; 55.5 glucan; 19.8 xylan 0.42 g EtOH/g G, 14.1 g/L EtOH | [36][25] |

| Imidazole | 160 | 60 | - | 55.7 solid | |

| HOAc | 107 | 30–90 | - | 80 bEtOH | [52][41] |

| Na2CO3 | 195 | 15 | - | 69.1 C; 4.1 HM; 9.5 lignin ⟶ 16.1 g EtOH/100 g biomass | [37][26] |

| SE | 200 | 10.5 | 14.2 | 52 C; 3.9 HM; 33.1 Lig | [45][34] |

| SE+H2SO4 | 180 | 4 | 10 | 50.5 C; 6.9 HM; 30.8 Lig | |

| SE+H3PO4 | 195 | 7.5 | 14.2 | 50.2 C; 2.7 HM; 35.2 Lig | |

3. Steam Explosion as Lignocellulosic Biomass Pretreatment

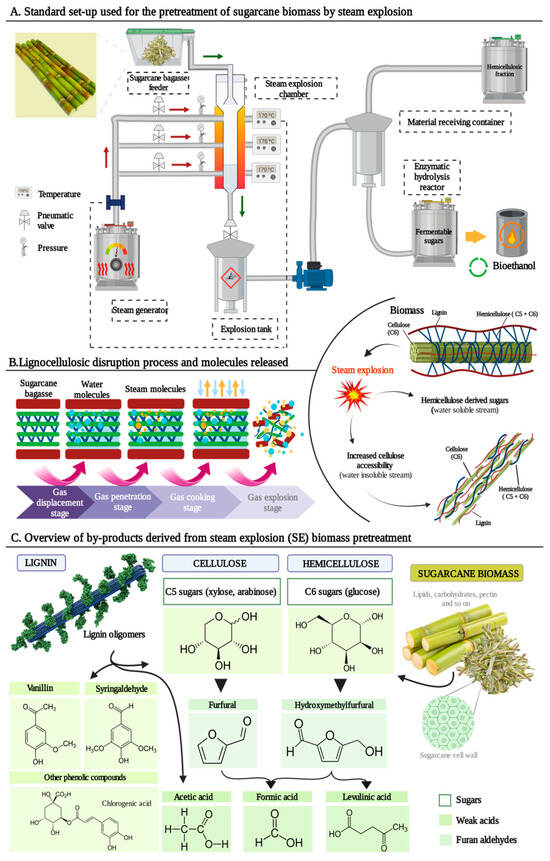

SE was pioneered and patented as a biomass pretreatment process in 1926 by Mason [53][42]. SE pretreatment is a physicochemical modification technology that couples autohydrolysis and biomass alteration through high temperature and explosive decompression with application in food raw materials [43][32]. SE processes can be operated in continuous or batch mode. Batch reactors are usually used for laboratory-scale pretreatment, while continuous systems are typically used for large-scale industrial processes [43,53][32][42]. The lignocellulosic materials that can be treated with SE are extensively diverse [54][43]. Indeed, its competence has been successfully demonstrated in the fractionation of a broad range of lignocellulosic raw materials, such as wheat straw, hay, SCB, corn stover, birch wood and numerous other chemical platforms from a large range of lignocellulosic feedstocks [55,56][44][45]. Figure 1A shows a schematic diagram of the continuous operation process of SE using SCB as biomass where the main three parts of the equipment are represented: steam generator, steam explosion chamber, and material receiving container [57][46].

References

- Soares de Carvalho Freitas, E.; Xavier, L.H.; Oliveira, L.B.; Guarieiro, L.L.N. System Dynamics Applied to Second Generation Biofuel in Brazil: A Circular Economy Approach. Sustain. Energy Technol. Assess. 2022, 52, 102288.

- D’Amato, D.; Korhonen, J.; Toppinen, A. Circular, Green, and Bio Economy: How Do Companies in Land-Use Intensive Sectors Align with Sustainability Concepts? Ecol. Econ. 2019, 158, 116–133.

- Khaire, K.C.; Moholkar, V.S.; Goyal, A. Bioconversion of Sugarcane Tops to Bioethanol and Other Value Added Products: An Overview. Mater. Sci. Energy Technol. 2021, 4, 54–68.

- Moharana, C. (Ed.) Agriculture Waste Management and Bioresource, 1st ed.; Wiley: Pondicherry, India, 2023; ISBN 9781119808138.

- Kesharwani, R.; Sun, Z.; Dagli, C.; Xiong, H. Moving Second Generation Biofuel Manufacturing Forward: Investigating Economic Viability and Environmental Sustainability Considering Two Strategies for Supply Chain Restructuring. Appl. Energy 2019, 242, 1467–1496.

- Kirshner, J.; Brown, E.; Dunlop, L.; Franco Cairo, J.P.; Redeker, K.; Veneu, F.; Brooks, S.; Kirshner, S.; Walton, P.H. “A Future beyond Sugar”: Examining Second-Generation Biofuel Pathways in Alagoas, Northeast Brazil. Environ. Dev. 2022, 44, 100739.

- Neves, P.V.; Pitarelo, A.P.; Ramos, L.P. Production of Cellulosic Ethanol from Sugarcane Bagasse by Steam Explosion: Effect of Extractives Content, Acid Catalysis and Different Fermentation Technologies. Bioresour. Technol. 2016, 208, 184–194.

- Vaish, S.; Kaur, G.; Sharma, N.K.; Gakkhar, N. Estimation for Potential of Agricultural Biomass Sources as Projections of Bio-Briquettes in Indian Context. Sustainability 2022, 14, 5077.

- Niju, S.; Swathika, M. Delignification of Sugarcane Bagasse Using Pretreatment Strategies for Bioethanol Production. Biocatal. Agric. Biotechnol. 2019, 20, 101263.

- Antunes, F.; Mota, I.F.; da Silva Burgal, J.; Pintado, M.; Costa, P.S. A Review on the Valorization of Lignin from Sugarcane By-Products: From Extraction to Application. Biomass Bioenergy 2022, 166, 106603.

- Moore, P.H. Sugarcane and Sugarbeet. In Encyclopedia of Applied Plant Sciences; Elselvier: Amsterdam, The Netherlands, 2017; pp. 273–280.

- Bhardwaj, N.K.; Kaur, D.; Chaudhry, S.; Sharma, M.; Arya, S. Approaches for Converting Sugarcane Trash, a Promising Agro Residue, into Pulp and Paper Using Soda Pulping and Elemental Chlorine-Free Bleaching. J. Clean. Prod. 2019, 217, 225–233.

- Gao, Z.; Alshehri, K.; Li, Y.; Qian, H.; Sapsford, D.; Cleall, P.; Harbottle, M. Advances in Biological Techniques for Sustainable Lignocellulosic Waste Utilization in Biogas Production. Renew. Sustain. Energy Rev. 2022, 170, 112995.

- del Río, J.C.; Lino, A.G.; Colodette, J.L.; Lima, C.F.; Gutiérrez, A.; Martínez, Á.T.; Lu, F.; Ralph, J.; Rencoret, J. Differences in the Chemical Structure of the Lignins from Sugarcane Bagasse and Straw. Biomass Bioenergy 2015, 81, 322–338.

- Pereira Marques, F.; Lima Soares, A.K.; Lomonaco, D.; Alexandre e Silva, L.M.; Tédde Santaella, S.; de Freitas Rosa, M.; Carrhá Leitão, R. Steam Explosion Pretreatment Improves Acetic Acid Organosolv Delignification of Oil Palm Mesocarp Fibers and Sugarcane Bagasse. Int. J. Biol. Macromol. 2021, 175, 304–312.

- Huang, J.; Khan, M.T.; Perecin, D.; Coelho, S.T.; Zhang, M. Sugarcane for Bioethanol Production: Potential of Bagasse in Chinese Perspective. Renew. Sustain. Energy Rev. 2020, 133, 110296.

- Valim, I.C.; Rego, A.S.C.; Queiroz, A.; Brant, V.; Neto, A.A.F.; Vilani, C.; Santos, B.F. Use of Artificial Intelligence to Experimental Conditions Identification in the Process of Delignification of Sugarcane Bagasse from Supercritical Carbon Dioxide; Elsevier Masson SAS: Amsterdam, The Netherlands, 2018; Volume 43, ISBN 9780444642356.

- Farias, J.P.; Okeke, B.C.; De Ávila, F.D.; Demarco, C.F.; Silva, M.S.; Camargo, F.A.d.O.; Menezes Bento, F.; Pieniz, S.; Andreazza, R. Biotechnology Process for Microbial Lipid Synthesis from Enzymatic Hydrolysate of Pre-Treated Sugarcane Bagasse for Potential Bio-Oil Production. Renew. Energy 2023, 205, 174–184.

- Qiu, Z.; Han, X.; Fu, A.; Jiang, Y.; Zhang, W.; Jin, C.; Li, D.; Xia, J.; He, J.; Deng, Y.; et al. Enhanced Cellulosic D-Lactic Acid Production from Sugarcane Bagasse by Pre-Fermentation of Water-Soluble Carbohydrates before Acid Pretreatment. Bioresour. Technol. 2023, 368, 128324.

- Hongrattanavichit, I.; Aht-Ong, D. Nanofibrillation and Characterization of Sugarcane Bagasse Agro-Waste Using Water-Based Steam Explosion and High-Pressure Homogenization. J. Clean. Prod. 2020, 277, 123471.

- Da Silva, A.S.A.; Inoue, H.; Endo, T.; Yano, S.; Bon, E.P.S. Milling Pretreatment of Sugarcane Bagasse and Straw for Enzymatic Hydrolysis and Ethanol Fermentation. Bioresour. Technol. 2010, 101, 7402–7409.

- Costa, S.M.; Mazzola, P.G.; Silva, J.C.A.R.; Pahl, R.; Pessoa, A.; Costa, S.A. Use of Sugar Cane Straw as a Source of Cellulose for Textile Fiber Production. Ind. Crops Prod. 2013, 42, 189–194.

- Gómez, E.O.; de Souza, R.T.G.; Rocha, G.J.d.M.; de Almeida, E.; Cortez, L.A.B. Sugarcane Trash as Feedstock for Second Generation Processes. In Sugarcane Bioethanol—R&D for Productivity and Sustainability; Editora Edgard Blucher Ltda.: São Paulo, Brazil, 2014; pp. 637–660.

- Espírito Santo, M.C.D.; Cardoso, E.B.; Guimaraes, F.E.G.; deAzevedo, E.R.; da Cunha, G.P.; Novotny, E.H.; Pellegrini, V.D.O.A.; Chandel, A.K.; Silveira, M.H.L.; Polikarpov, I. Multifaceted Characterization of Sugarcane Bagasse under Different Steam Explosion Severity Conditions Leading to Distinct Enzymatic Hydrolysis Yields. Ind. Crops Prod. 2019, 139, 111542.

- Zhu, Z.; Zhu, M.; Wu, Z. Pretreatment of Sugarcane Bagasse with NH4OH–H2O2 and Ionic Liquid for Efficient Hydrolysis and Bioethanol Production. Bioresour. Technol. 2012, 119, 199–207.

- Martín, C.; Klinke, H.B.; Thomsen, A.B. Wet Oxidation as a Pretreatment Method for Enhancing the Enzymatic Convertibility of Sugarcane Bagasse. Enzym. Microb. Technol. 2007, 40, 426–432.

- Rocha, G.J.d.M.; Nascimento, V.M.; Gonçalves, A.R.; Silva, V.F.N.; Martín, C. Influence of Mixed Sugarcane Bagasse Samples Evaluated by Elemental and Physical-Chemical Composition. Ind. Crops Prod. 2015, 64, 52–58.

- Katakojwala, R.; Venkata Mohan, S. Multi-Product Biorefinery with Sugarcane Bagasse: Process Development for Nanocellulose, Lignin and Biohydrogen Production and Lifecycle Analysis. Chem. Eng. J. 2022, 446, 137233.

- Pan, S.; Zabed, H.M.; Wei, Y.; Qi, X. Technoeconomic and Environmental Perspectives of Biofuel Production from Sugarcane Bagasse: Current Status, Challenges and Future Outlook. Ind. Crops Prod. 2022, 188, 115684.

- Negrão, D.R.; Grandis, A.; Buckeridge, M.S.; Rocha, G.J.M.; Leal, M.R.L.V.; Driemeier, C. Inorganics in Sugarcane Bagasse and Straw and Their Impacts for Bioenergy and Biorefining: A Review. Renew. Sustain. Energy Rev. 2021, 148, 111268.

- da Fonseca, Y.A.; Silva, N.C.S.; Fernandes, A.R.A.C.; Faria, M.V.; Adarme, O.F.H.; Passos, F.; Baêta, B.E.L. Steam Explosion Pretreatment of Coffee Husks: A Strategy towards Decarbonization in a Biorefinery Approach. J. Chem. Technol. Biotechnol. 2022, 97, 1567–1574.

- Yu, Y.; Wu, J.; Ren, X.; Lau, A.; Rezaei, H.; Takada, M.; Bi, X.; Sokhansanj, S. Steam Explosion of Lignocellulosic Biomass for Multiple Advanced Bioenergy Processes: A Review. Renew. Sustain. Energy Rev. 2022, 154, 111871.

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic Biomass to Bioethanol, a Comprehensive Review with a Focus on Pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93.

- Espirito Santo, M.C.; Fockink, D.H.; Pellegrini, V.O.A.; Guimaraes, F.E.G.; DeAzevedo, E.R.; Ramos, L.P.; Polikarpov, I. Physical Techniques Shed Light on the Differences in Sugarcane Bagasse Structure Subjected to Steam Explosion Pretreatments at Equivalent Combined Severity Factors. Ind. Crops Prod. 2020, 158, 113003.

- Rabelo, S.C.; Vaz Rossell, C.E.; de Moraes Rocha, G.J.; Zacchi, G. Enhancement of the Enzymatic Digestibility of Sugarcane Bagasse by Steam Pretreatment Impregnated with Hydrogen Peroxide. Biotechnol. Prog. 2012, 28, 1207–1217.

- Bernier-Oviedo, D.J.; Rincón-Moreno, J.A.; Solanilla-Duqué, J.F.; Muñoz-Hernández, J.A.; Váquiro-Herrera, H.A. Comparison of Two Pretreatments Methods to Produce Second-Generation Bioethanol Resulting from Sugarcane Bagasse. Ind. Crops Prod. 2018, 122, 414–421.

- Zhang, W.; Zhang, X.; Lei, F.; Jiang, J. Co-Production Bioethanol and Xylooligosaccharides from Sugarcane Bagasse via Autohydrolysis Pretreatment. Renew. Energy 2020, 162, 2297–2305.

- Phan, D.T.; Tan, C.S. Innovative Pretreatment of Sugarcane Bagasse Using Supercritical CO2 Followed by Alkaline Hydrogen Peroxide. Bioresour. Technol. 2014, 167, 192–197.

- Jin, Y.; Shi, Z.; Xu, G.; Yang, H.; Yang, J. A Stepwise Pretreatment of Sugarcane Bagasse by Alkaline and Hydroxymethyl Reagent for Bioethanol Production. Ind. Crops Prod. 2020, 145, 112136.

- Fu, Y.; Gao, H.; Yu, H.; Yang, Q.; Peng, H.; Liu, P.; Li, Y.; Hu, Z.; Zhang, R.; Li, J.; et al. Specific Lignin and Cellulose Depolymerization of Sugarcane Bagasse for Maximum Bioethanol Production under Optimal Chemical Fertilizer Pretreatment with Hemicellulose Retention and Liquid Recycling. Renew. Energy 2022, 200, 1371–1381.

- Zhao, X.; Wen, J.; Chen, H.; Liu, D. The Fate of Lignin during Atmospheric Acetic Acid Pretreatment of Sugarcane Bagasse and the Impacts on Cellulose Enzymatic Hydrolyzability for Bioethanol Production. Renew. Energy 2018, 128, 200–209.

- Bandyopadhyay-Ghosh, S.; Ghosh, S.B.; Sain, M. The Use of Biobased Nanofibres in Composites. In Biofiber Reinforcements in Composite Materials; Faruk, O.M.S., Ed.; Elsevier Ltd.: Pilani, India, 2015; p. 647. ISBN 9781782421276.

- Galbe, M.; Wallberg, O. Pretreatment for Biorefineries: A Review of Common Methods for Efficient Utilisation of Lignocellulosic Materials. Biotechnol. Biofuels 2019, 12, 294.

- Michalak, L.; Knutsen, S.H.; Aarum, I.; Westereng, B. Effects of PH on Steam Explosion Extraction of Acetylated Galactoglucomannan from Norway Spruce. Biotechnol. Biofuels 2018, 11, 311.

- Zhao, Z.M.; Yu, W.; Huang, C.; Xue, H.; Li, J.; Zhang, D.; Li, G. Steam Explosion Pretreatment Enhancing Enzymatic Digestibility of Overground Tubers of Tiger Nut (Cyperus esculentus L.). Front. Nutr. 2023, 9, 1093277.

- Ma, C.; Ni, L.; Guo, Z.; Zeng, H.; Wu, M.; Zhang, M.; Zheng, B. Principle and Application of Steam Explosion Technology in Modification of Food Fiber. Foods 2022, 11, 3370.

- Ziegler-Devin, I.; Chrusciel, L.; Brosse, N. Steam Explosion Pretreatment of Lignocellulosic Biomass: A Mini-Review of Theorical and Experimental Approaches. Front. Chem. 2021, 9, 705358.

- Yu, Z.; Zhang, B.; Yu, F.; Xu, G.; Song, A. A Real Explosion: The Requirement of Steam Explosion Pretreatment. Bioresour. Technol. 2012, 121, 335–341.

- Capolupo, L.; Faraco, V. Green Methods of Lignocellulose Pretreatment for Biorefinery Development. Appl. Microbiol. Biotechnol. 2016, 100, 9451–9467.

- Bhukya, B.; Keshav, P.K. An Evaluation of Steam Explosion Pretreatment to Enhance the Digestibility of Lignocellulosic Biomass. In Lignocellulose Bioconversion through White Biotechnology; Chandel, A.K., Ed.; John Wiley & Sons Ltd.: Telangana, India, 2022; pp. 83–98. ISBN 9781119735984.

- Conrad, M.; Häring, H.; Smirnova, I. Design of an Industrial Autohydrolysis Pretreatment Plant for Annual Lignocellulose. Biomass Convers. Biorefinery 2021, 11, 2293–2310.

- Abouelela, A.R.; Nakasu, P.Y.S.; Hallett, J.P. Influence of Pretreatment Severity Factor and Hammett Acidity on Softwood Fractionation by an Acidic Protic Ionic Liquid. ACS Sustain. Chem. Eng. 2023, 11, 2404–2415.

- Zhang, Z.; Harrison, M.D.; Rackemann, D.W.; Doherty, W.O.S.; O’Hara, I.M. Organosolv Pretreatment of Plant Biomass for Enhanced Enzymatic Saccharification. Green Chem. 2016, 18, 360–381.

- Ruiz, H.A.; Galbe, M.; Garrote, G.; Ramirez-Gutierrez, D.M.; Ximenes, E.; Sun, S.N.; Lachos-Perez, D.; Rodríguez-Jasso, R.M.; Sun, R.C.; Yang, B.; et al. Severity Factor Kinetic Model as a Strategic Parameter of Hydrothermal Processing (Steam Explosion and Liquid Hot Water) for Biomass Fractionation under Biorefinery Concept. Bioresour. Technol. 2021, 342, 125961.

- Walker, D.J.; Gallagher, J.; Winters, A.; Somani, A.; Ravella, S.R.; Bryant, D.N. Process Optimization of Steam Explosion Parameters on Multiple Lignocellulosic Biomass Using Taguchi Method—A Critical Appraisal. Front. Energy Res. 2018, 6, 1–13.

- Steinbach, D.; Kruse, A.; Sauer, J. Pretreatment Technologies of Lignocellulosic Biomass in Water in View of Furfural and 5-Hydroxymethylfurfural Production- A Review. Biomass Convers. Biorefinery 2017, 7, 247–274.

- Sulzenbacher, D.; Atzmüller, D.; Hawe, F.; Richter, M.; Cristobal-Sarramian, A.; Zwirzitz, A. Optimization of Steam Explosion Parameters for Improved Biotechnological Use of Wheat Straw. Biomass Convers. Biorefinery 2023, 13, 1035–1046.

- Jankovic, A.; Chaudhary, G.; Goia, F. Designing the Design of Experiments (DOE)—An Investigation on the Influence of Different Factorial Designs on the Characterization of Complex Systems. Energy Build. 2021, 250, 111298.

- Shrotri, A.; Kobayashi, H.; Fukuoka, A. Catalytic Conversion of Structural Carbohydrates and Lignin to Chemicals, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; Volume 60.

- Auxenfans, T.; Crônier, D.; Chabbert, B.; Paës, G. Understanding the Structural and Chemical Changes of Plant Biomass Following Steam Explosion Pretreatment. Biotechnol. Biofuels 2017, 10, 36.

- Leskinen, T.; Kelley, S.S.; Argyropoulos, D.S. E-Beam Irradiation & Steam Explosion as Biomass Pretreatment, and the Complex Role of Lignin in Substrate Recalcitrance. Biomass Bioenergy 2017, 103, 21–28.

- Steinbach, D.; Kruse, A.; Sauer, J.; Storz, J. Is Steam Explosion a Promising Pretreatment for Acid Hydrolysis of Lignocellulosic Biomass? Processes 2020, 8, 1626.

- Troncoso-Ortega, E.; Castillo, R.D.P.; Reyes-Contreras, P.; Castaño-Rivera, P.; Teixeira Mendonça, R.; Schiappacasse, N.; Parra, C. Effects on Lignin Redistribution in Eucalyptus Globulus Fibres Pre-Treated by Steam Explosion: A Microscale Study to Cellulose Accessibility. Biomolecules 2021, 11, 507.

- He, Q.; Ziegler-Devin, I.; Chrusciel, L.; Obame, S.N.; Hong, L.; Lu, X.; Brosse, N. Lignin-First Integrated Steam Explosion Process for Green Wood Adhesive Application. ACS Sustain. Chem. Eng. 2020, 8, 5380–5392.

- Onyenwoke, C.; Tabil, L.G.; Dumonceaux, T.; Cree, D.; Mupondwa, E.; Adapa, P.; Karunakaran, C. Investigation of Steam Explosion Pretreatment of Sawdust and Oat Straw to Improve Their Quality as Biofuel Pellets. Energies 2022, 15, 7168.

- Monlau, F.; Sambusiti, C.; Barakat, A.; Quéméneur, M.; Trably, E.; Steyer, J.P.; Carrère, H. Do Furanic and Phenolic Compounds of Lignocellulosic and Algae Biomass Hydrolyzate Inhibit Anaerobic Mixed Cultures? A Comprehensive Review. Biotechnol. Adv. 2014, 32, 934–951.

- Baksi, S.; Saha, D.; Saha, S.; Sarkar, U.; Basu, D.; Kuniyal, J.C. Pre-Treatment of Lignocellulosic Biomass: Review of Various Physico-Chemical and Biological Methods Influencing the Extent of Biomass Depolymerization. Int. J. Environ. Sci. Technol. 2023, 20, 13895–13922.

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and Physicochemical Pretreatment of Lignocellulosic Biomass: A Review. Enzym. Res. 2011, 2011, 787532.

- Zhao, G.; Kuang, G.; Wang, Y.; Yao, Y.; Zhang, J.; Pan, Z.H. Effect of Steam Explosion on Physicochemical Properties and Fermentation Characteristics of Sorghum (Sorghum bicolor (L.) Moench). Lwt 2020, 129, 109579.