Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by George Xiroudakis and Version 2 by Rita Xu.

Gold has been a highly prized commodity throughout history and has played a significant role in humanity’s economic and cultural progress.

- alluvial gold

- “Golden Fleece”

- gold mining

1. Introduction

Gold is a metal whose value has been recognized by all cultures over the centuries for different reasons and was originally extracted from alluvial deposits. Some scientists believe that the exploitation began in the early Iron Age, others in the second half of the 8th century BC, or even in the 7th century BC. More recently, scientists argued that the Pactolus gold was already mined in the third millennium BC. The Egyptians recovered gold on the coasts of the Nile and Sudan (Nubia) approximately in the 5th millennium BC [1]. Analyzing samples with a higher degree of fineness than naturally occurring gold can suggest the use of refining techniques, and the presence of unusual alloys may indicate evidence of such practices in Ancient Egypt. Unfortunately, this method is open to certain difficulties. Ancient Egyptian gold articles are not as common as might be generally expected and are often not available for analysis from crucial time periods. These factors present obstacles to fully comprehending the refining techniques and alloys employed by ancient civilizations such as the Egyptians [2].

According to Greek mythology and historical sources, the ancient Georgian Kingdom of Colchis was renowned for its wealth in “gold sands,” and the indigenous people mined this precious metal from the rivers. They employed special wooden vessels and sheepskins for the extraction process. Apart from the references to the Argonautic expedition by Strabo (book-XII; Pliny the Elder I), the perspective of the Roman historian Apianos Alexandrinos (90–170 AD), who accepted the Argonauts’ trip to the Colchis kingdom in quest of the “Golden Fleece” as a true occurrence, is adopted by analyzing geological information, artifacts, myths, and historical sources [3]. Next, the processes were developed significantly with the introduction of Emperor Augustus’ new mining techniques during the Roman Empire period, such as hydraulic mining (hushing) and ground sluicing methods [4].

The Renaissance period was accompanied by Georgius Agricola’s book “De Re Metallica”, an innovative manual of mining techniques still used in today’s industrially advance era. In particular, Agricola highlights a groundbreaking technical advancement in his writings, describing a new type of pump that brought about a revolution in mining techniques. He applies his rigorous taxonomical approach to detail various types of pumping systems, including both discontinuous methods involving buckets, goatskins, or tubs assisted by ordinary hoists, and continuous methods utilizing a chain of buckets, reciprocating piston pumps, or pater noster pumps. His great work, De Re Metallica, carefully depicted and described all facets of mining from ores to mining machinery. Until that time, Pliny the Elder’s work Historia Naturalis was the main source of information on metals and mining techniques. Agricola acknowledged his debt to ancient authors, such as Pliny and Theophrastus, and made numerous references to Roman works. In geology, Agricola described and illustrated how ore veins occur in and on the ground. He described prospecting for ore veins and surveying in detail, as well as washing the ores to collect the heavier valuable minerals, such as gold and tin. Agricola’s work offers insights into the utilization of water mills in mining operations, including a device designed to raise personnel and materials in and out of mine shafts. Water mills played a significant role in processes like crushing ores to liberate fine particles of gold and other dense minerals. Furthermore, Agricola described their application in operating large bellows to forcefully introduce air into the confined spaces of underground mines [5][6][5,6].

Gold was primarily collected from alluvial deposits in the ancient world using gravity techniques and mercury (amalgams) [7], which are still employed today in small-scale alluvial gold resources. Large-scale hard rock mining first employed cyanide in the 1880s to extract commodities, including gold, silver, copper, and other precious metals [7]. New techniques were utilized during the colonization of the Americas by the Spanish, who took advantage of the highly effective procedures of the natives. Refining by amalgamation consisted essentially of grinding the ore to coarse dust and sprinkling a small amount of mercury over it. From this, pure gold could be obtained by applying enough heat to volatilize the mercury. Other ingredients were added to increase the speed and effectiveness of the process: water, to bind the dust into a loose mud; common salt; iron filings; and copper sulphate.

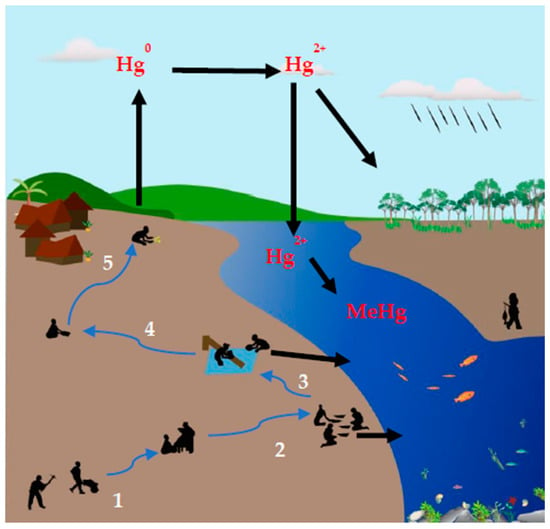

It is acknowledged that the mercury method poses a severe threat to the environment and the miners’ health. Small-scale mining produces the highest mercury emissions (the mercury cycle presented with black arrows in Figure 1), with South America producing 340 tonnes annually [8][9][8,9]. Modern industrial and artisanal gold extraction is subject to significantly less stringent enforcement standards than is necessary for industrial mining, particularly in the Amazon Basin region, as demonstrated in the work of Costa and Rios [10]. The effects are also amplified by the widespread use of amalgamating gold with mercury and the localized use of cyanide leaching. Mercury is routinely released into the environment through the latter approach, contaminating waterways and harming all connected ecosystems, including human settlements and the food supply chain [10].

-

Mercury pollution;

-

Disposal of tailings and effluents into rivers;

-

River damage in alluvial areas;

-

Erosion damage and deforestation;

-

Landscape destruction;

-

Socio-economic consequences.

Small-scale alluvial gold miners in Tadó, Dept, Chocó, generate “green gold” using readily available plant extracts as part of a unique method employed in Colombia to substitute mercury. Instead of using mercury, a frothy liquid made from the crushed leaves of Balso (Ochroma pyramidale) and Malva (Hibiscus furcellatus) is poured into the gold pan (type batea) [12].

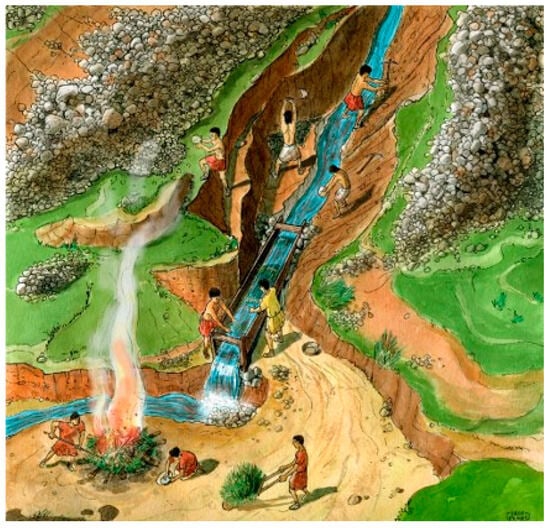

Figure 1. Gold extracting in small-scale placer involving the stages (presented with blue arrows): (1) excavation, (2) grinding and sifting, (3) washing, (4) panning, and (5) gold–Hg-amalgam burning.

Apart from analyzing the abovementioned critical historical periods and the conditions that led to the foundation of the alluvial gold mining and processing methods, the technical characteristics and operating principles of the devices applied from 4000 BC to the present day will be described in detail. Over the years, there have been rapid advancements in gold mining and extraction methods. New machines and methods [13][14][15][16][13,14,15,16] have been developed in our modern society to enable more precise excavation while minimizing environmental impact.

2. The Historical Progression of Alluvial Gold Mining and Processing Technologies

2.1. Early Finds of Gold in Greece, Egypt, and Asia Minor (5000–1000 BC)

Gold was first found at the surface level near rivers in Asia Minor, such as the Pactolus in Lydia, and was also mined underground from 2000 BC by the Egyptians and later by the Romans in Africa, Portugal, and Spain. Electrum (a natural alloy of gold and silver) was used in jewellery by the Egyptians from 5000 BC. The Egyptians recovered gold along the Nile and Nubia (Sudan), specifically from the highlands east of the Nile in the Red Sea region. The oldest geological map discovered is the Turin Papyrus of the Wadi Hammamat gold mines and greywacke stone quarries used by ancient Egyptians [17]. The gold was initially derived from eroded surface material and then from underground shafts and tunnels in these deposits. Egypt served as the primary source of gold in the ancient Mediterranean world, holding this prominent position before the peak of Greece’s influence. Before 1500 BC, the Egyptians developed a method known as fire assaying to assess the purity of gold. Chemical analysis as reswearchers know it today has its roots in the assaying procedure used to handle precious metals, particularly gold [18]. The initial gold artefacts uncovered in Greece included a gold earring discovered in Dimini, a fortified settlement in Thessaly near Volos, dating back to the early fifth millennium BC. Shortly afterwards, a gold bead was discovered during the Final Neolithic period at the Sitagroi settlement in Drama, also located in Greece (4600–4200 BC). Archaeologists generally agree that the role of gold was associated with people of high social status and symbolized their power and authority. The motivation for producing a noble but impractical metal for the time indicates that its value was more closely linked to the social structure and hierarchy of cultures rather than the metallurgical expertise of the artisans involved [19]. Today, there is evidence that the initial gold production in Asia Minor dates between the Late Chalcolithic and Early Bronze Age. An early example of gold used in Asia Minor comes from the ancient city of Melid (or Arslantepe), where a gold disc was found around 3000 BC. The presence of this artefact, along with a spiral ring found in subsequent royal tombs, suggests the existence of a gold smelting industry that had likely already emerged and was operational inland. During the middle of the third millennium BC, there was considerable interest in the exploration of gold. Its production increased significantly with large quantities of artefacts being made from the second level of the “Troy” excavation, in the catacombs of Alaca Höyük and other sites in the Eastern Mediterranean, particularly in the royal tombs of the city of Ur (Mesopotamia). The enduring fascination with gold in Anatolia (Asia Minor in Greek) during this period could be attributed to the dynamic changes that occurred due to metallurgical operations: extensive exploitation of polymetallic ore deposits took place, the population increased, and a socially based demand for luxury goods developed in earnest [20]. The high demand for gold led to the depletion of primary sources. It is believed that at some point, alluvial and placer deposits could no longer provide the necessary quantities of gold. As a result, miners of the time moved to different sources. They quickly realized that the gold-bearing ores accumulating in the rivers came from an initially higher altitude, and it took them only a short time to detect their primary source. In this case, the gold was trapped in the host rock, commonly in amalgamated quartz at the highest point. Gold was initially subjected to a panning process. In order to achieve separation from the gangue minerals, the miners carried out the scrubbing process in which the gold-bearing quartz was washed by the action of water. Then, the pulp was poured onto a shaking table, with the heavier particles collected in its holes and pockets. The process mentioned above could be repeated as many times as possible to obtain the highest possible quantity of gold without the existence of gangue minerals [20]. Since the New Kingdom, gold has been recovered from quartz ores found in the weathered debris of the wadi beds, in addition to the mined gold quartz veins that are visible at the surface. So-called placers or nuggets had a minor significance in Egypt’s ancient gold mining history due to the arid environment. Such placers had, however, at the latest, been extracted since the Early Arab Period, typically in the form of extremely fine gold grains from alluvial sands in the wadi beds.2.2. The Argonautic Expedition and the Retrieval of Gold from the Riverbeds of COLCHIS (1330 BC)

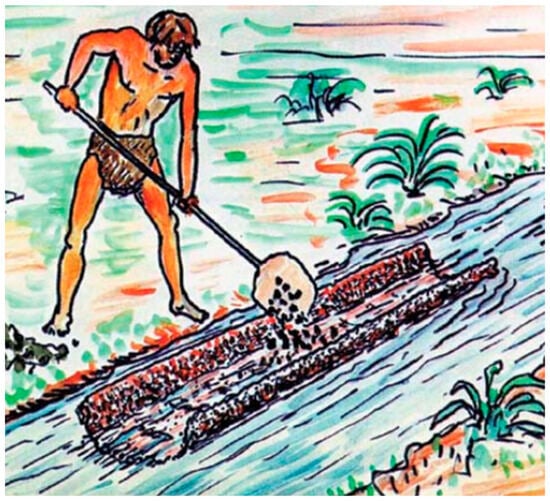

The mountains of the Caucasus have had a strong connection with gold for millennia. According to the legends told by Greek and Roman writers, Jason was sent on an impossible mission to find the Golden Fleece in Colchis (a part of today’s Georgia in Eastern Europe) [21], from which his usurper uncle and king of Iolkos, Pelias, assumed he would never return. The rivers flowing through Colchis, particularly in the Svaneti province, carried coarse sand and particles of gold. The local inhabitants employed special wooden sluice boxes designed to concentrate the sands, with the finer fractions being captured in the lower section of the device, lined with sheepskin. The remarkable and distinctive mechanism described above gave rise to the legend of the Golden Fleece, which originated in a country with abundant silver palaces and golden halls of ancient kings. Thus, the legend of the magnificent wealth of Colchis, like the rumours of the wealth of its rulers, is said to have excited the business avarice of the Argonauts [22]. Appian of Alexandria, a Greek-born Roman historian (90–170 BC), and other historians expressed that actual mining practices inspired the Golden Fleece. The description of the Golden Fleece alludes to the use of sheepskin to extract gold from riverbeds (Figure 2).

Figure 2. Representation of the use of the sluice-box. Its wooden base is covered by a fleece.

Figure 3. The path taken by the Argonauts and the regions containing the most significant deposits of the era.

2.3. The Revolutionary Techniques for Processing Alluvial Gold Deposits during the Roman Empire Era (27 BC–476 AD)

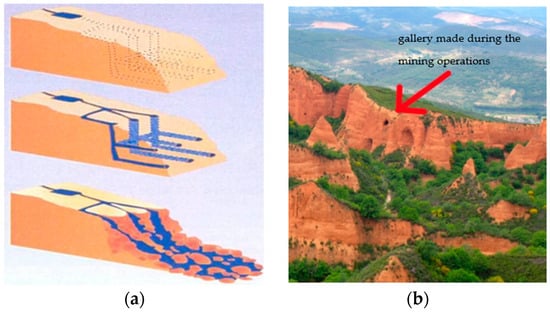

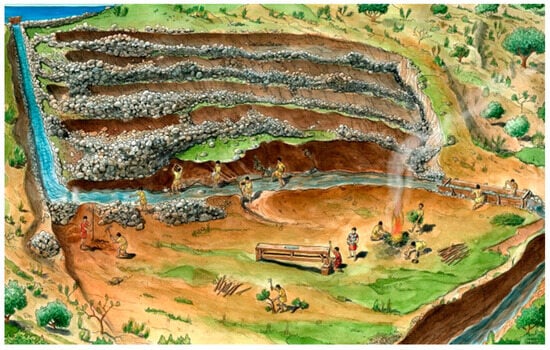

The growth of the Roman Empire demonstrated a significant need for metals, leading to the search for additional sources. Gold mining played a crucial role within the territories of the Roman Empire, including those conquered, primarily serving to support the military and its infrastructure. Over time, gold gained prominence and became a vital foundation of Roman society. It served not only as a currency during that era but also as an indicator of wealth and a catalyst for global trade. The Romans mined at least fourteen locations for gold, copper, and silver. In the Astur region, Aurifers were primarily found in Galicia and Lusitania, according to Rodrigues [24][25]. The Porto area in this final region had the most well-known mines [25][26]. The Ruina Montium method, the most impressive mining technique invented by Roman engineering and recorded by Pliny in his Natural History, was used in several mines [26][27]. The same concept was applied in Roman settlements on Portuguese territor. This method required moving an extensive amount of water to the area to be exploited and building channels (80 to 100 km) and reservoirs with a maximum capacity of 18,000 m3. The ruina montium was built using the methodical application of hydraulic force [27][28][28,29]. The flow of water (Figure 4a) through the excavation system leads to the erosion of the mountain. Such an excavation is marked with the red arrow in Figure 4b.

Figure 4. Ruina montium method to Las Médulas (a) water flow erosion; (b) remaining gallery from the operations.

Figure 5. Exploiting alluvial gold deposits using hydraulic mining.

Figure 6. A different illustration of the exploitation of alluvial gold reserves using hydraulic power.

2.4. The Colonialism of the Americas and the Evolution of Indigenous Mining Techniques (1492–1511)

During the Spanish colonization of the Americas, mines such as the well-known Potosí silver mines of southern Bolivia and the cinnabar mines of Huancavelica were significant operations controlled by the Spanish crown. Most evidence indicates that Inca mining was also quite extensive. They considered that gold symbolizes power and wealth and had been sent by the gods. As a result, gold played a significant role in Inca culture, both in religious rituals and in everyday life. According to historical sources, Incas had a complex system for mining, refining, and processing gold. The metal was mined from the Andes mountains and the Incas would extract it from the ore using the amalgamation process, which involved mixing ground gold ore with mercury. Then, the mercury–gold amalgam was burned in order to valorize the mercury and recover the gold [33][35]. The Incas had also developed efficient ways to control the production of wealth and systems of state control involving complex mining techniques that required central coordination of the workforce [34][35][36][36,37,38]. All European rulers coveted gold when Christopher Columbus (1451–1506) landed in the Americas in 1492. In 1494, the conquistadors made their first gold discovery on the island of Hispaniola (now the Dominican Republic/Haiti) [37][39]. The Spanish empire then reached Cuba, which at the time was the best gold source, Puerto Rico in 1508, Jamaica in 1509, and Puerto Rico again in 1511. Spain became the richest nation in the world due to the conquistadors’ incredible gold discoveries in the Americas. During the Spanish colonization of the American continent, miners began exploiting alluvial deposits as a starting point. The simplest method employed was the processing of conglomerates and sands located in rivers and lake bottoms using the gold concentration pans. At the same time, the use of sluice box devices was widespread in gold processing and was carried out in colonial New Granada. To implement this method, workers constructed a channel or dam beneath the surface containing mineral deposits or along slopes. By excavating the ground, they created a designated area for treatment. Subsequently, the soil from the site was carefully removed and fed into the sluice box device. In some cases, workers would direct the water flow towards the treatment surface, using its power to help excavate. Within these open-pit mines, a network of bamboo pipes was constructed, serving as small aqueducts to transport water from higher locations to the treatment zones where sluice boxes were located. The water would flow through the sluice boxes, causing the settlement of the larger minerals in the lower section of the device. Then, the workers would hand-sort the gold particles and remove the residue from the apparatus, which could be processed using gold concentration pans. By adding water to the mixture in the pan and shaking it vigorously, they could separate the lighter material from the top of the device. Consequently, the heavier material, including the concentrated gold, would settle at the bottom of the pan. Miners used many different techniques to separate metals from the bulk of the ore. When dealing with black sands containing gold flakes and iron oxides, miners adopted the approach of the natives. They would mix the concentrate with the sap derived from tropical plants, producing a foamy and sticky material that caused the “iron oxide flakes” to stick to its surface. As a result, pure gold would settle in the lower part of the ‘batea’s (open conical dish) gold concentration pan. In the 1880s, the technique of using magnets by Europeans could also help separate iron oxides from gold. In the Chocó region of northwestern Colombia, gold often appeared with platinum, and miners used mercury to separate the two metals at the time. However, until the mid-eighteenth century, platinum—Platino as it was called for its similarity to silver—was considered of little value [38][40].2.5. The Pioneering Machine Designs by Georgius Bauer Agricola (1494–1556)

After the fall of the Roman Empire (476 AD), there was a notable shift in demand for minerals and metals from the Mediterranean region to the highly productive mines of central Europe. During the early Renaissance (15th century AD), mining and metallurgy developed significantly. During this period, metal production reached unprecedented levels, setting new records, and constantly evolving as innovative technologies were employed. The primary sources of information regarding metallurgy and mining during that period were Georgius Agricola and Vannoccio Biringuccio, who made substantial contributions. Their main works, Pirotechnia (1540) and De Re Metallica (1556), covered most of the topics related to mining and metallurgy and became standard textbooks for the next two centuries. In 1556, almost a year after the death of its author, De Re Metallica was published in Basel. The publication of this book marked a crucial transition from the philosophical realm of metallurgy to a more empirical and scientifically grounded approach based on careful observation. Thus, De Re Metallica represents the first attempt to describe the nature, location, and means of obtaining and purifying metals from experience and experimentation. It is reflected in the ability to replicate the processes and experiments as they unfold and in the accuracy and detail with which they are described. Agricola’s De Re Metallica is considered one of the most famous engineering manuals of the 16th century. In his work, Agricola delves into the advanced machinery of the Erzgebirge (Germany) mines, mainly using pumps for water drainage and hoists for ore extraction. More specifically, readers can find thorough depictions of the various devices utilized for pumping water out of wells, as the excessive presence of water hinders mining activities. Unregulated water supply poses challenges to the efficient execution of underground mining operations. In cases where a proper drainage system is absent, it becomes crucial to excavate an appropriate well and construct a pump to control the water table [39][41]. The three innovative types of pumps that Agricola is presenting for the first time are the following:-

Bucket-line pumps;

-

Pater noster pumps;

-

Piston pumps.

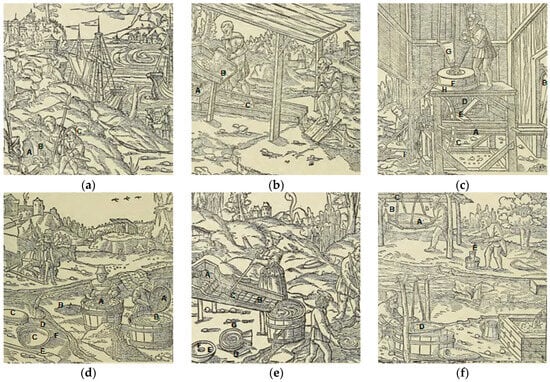

Figure 7. (a) The Argonauts using the fleece’s skin to extract gold from the riverbeds of Colchis; (b) trough with wooden scrubber for washing the metalliferous ores; (c) Agricola’s millstone complex system for material’s further milling; (d) Bohemians baskets one of the first methods of gold panning; (e) one of the first sluice box systems; (f) bowls used as gold concentration pans.

2.6. The Gold Rush Era in the Rivers of Western America (19th–Early 20th Century)

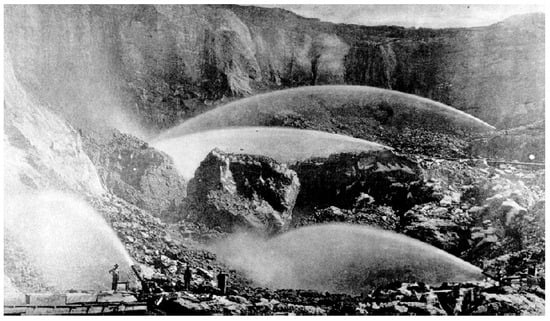

In 1849, a wave of people known as “49 ers” made an effort to make the long journey to California. By the end of the year, the non-native population in America had grown to about 100,000, a significant increase compared to 20,000 at the end of 1848 and only 800 in March 1848. Gold mining towns developed across the territory to serve the needs of the 49 ers, looking for profitability by this time. Following 1850, surface gold in California largely disappeared, even as miners continued to arrive. However, gold mining continued through the 1850s, peaking in 1852 when total profits from production reached about $81 million. After that year, total annual profits gradually decreased to $45 million by 1857. Settlement in California continued; however, by the decade’s end, the state’s population declined significantly [41][44]. During the gold rush period, the extraction of alluvial deposits was based on manual labour and water-based methods, thus mining sites were usually located along streams in tributary canyons. Miners used various equipment, including rocker (or cradle) boxes, Long Toms, and sluice boxes, and handheld equipment like pans, picks, and shovels. As time passed, more advanced techniques for mining alluvial deposits were adopted. The construction of dams, water pumps, and ditch-fed sluicing systems became essential for efficient operations. The introduction of hydraulic mining was one of the most significant improvements in mining alluvial deposits. Miners using these systems provided high-pressure water to wash away the overburdened materials and direct the gold-bearing particles into the sluice boxes. Water cannons, presented in Figure 8, played a vital role in removing impurities and overburden during the mining process. Smaller cannons were also used for washing the gold-bearing gravels within sluice box systems. Hydraulic mining systems flourished from the 1860s to the mid-1880s, when one of the first lawsuits concerning the generation of environmental pollutants was filed, which led to the strict control and end of this process [41][44]. Dredging was the final evolution of the mining methods for the alluvial deposits of the period, the most successful forms of dredging operated during the 20th century. The dredging fields were located at low altitudes, usually where rivers or large tributary streams emerged from the mountains. It is worth mentioning that the dregging technology originated in New Zealand in 1882. The largest gathering of dredges at work was reported in 1900 with 187 dredges operating among the gravels of the Clutha.

Figure 8. Hydraulic mining at Malakoff Diggings (Historic photograph taken by Watkins).