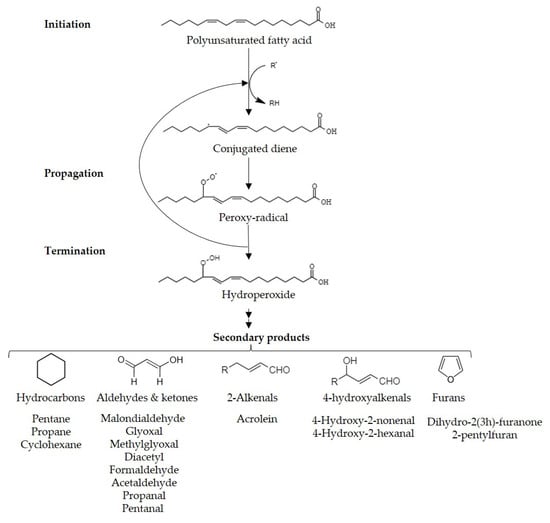

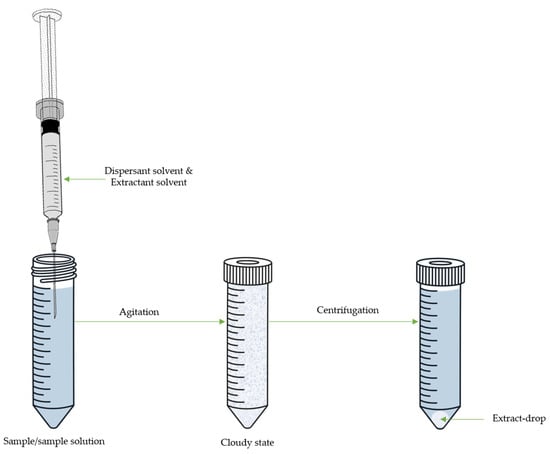

Lipid peroxidation, the most aggressive reaction in food, results in the formation of reactive organic compounds that detrimentally impact food sensory qualities and consumers’ health. While controlled lipid peroxidation can enhance flavors and appearance in certain foods, secondary peroxidation products lead to sensory deterioration in a variety of products, such as oils, alcoholic beverages, and meat. Dispersive liquid-liquid microextraction (DLLME), solid-phase microextraction (SPME), and gas-diffusion microextraction (GDME). These techniques offer efficient and sensitive approaches to extracting and quantifying lipid oxidation products and contribute to the understanding of oxidative deterioration in various food products.

- food analysis

- gas-diffusion microextraction

- lipid peroxidation

- dispersive liquid-liquid microextraction

- solid-phase microextraction

1. Introduction

| Secondary Product | CAS Number | IARC Category | Tolerable Daily Intake µg/Kg bw/Day |

Reference | |

|---|---|---|---|---|---|

| Saturate Carbonyls | Formaldehyde | 50-00-0 | 1 | 150 | [22] |

| Acetaldehyde | 75-07-0 | 2B | 185 | ||

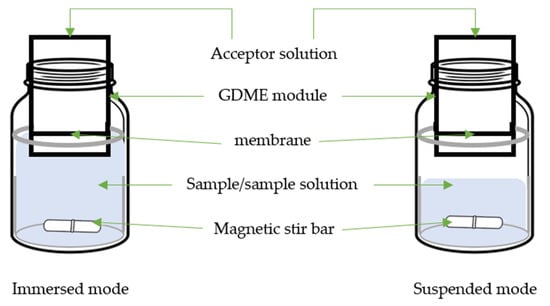

2. Gas Diffusion Microextraction

| Target Compound | Sample | GDME | Derivative Reagent | Determination | LOD µg/L or µg/Kg |

Recovery % |

Ref. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Mode | Vacceptor solution mL |

t min |

T °C |

|||||||

| 1,3-pentadione Diacetyl |

Beer | Immersed | 0.5 | 15 | 40 | O-PDA | HPLC-UV | 3.8–4.6 | - | [48] |

| 2 aldehydes & Furfural |

Beer | Immersed | a | 0.75[23] | ||||||

| 5 | 30 | DNPH | ||||||||

| Target Compound | Sample | SPME | Derivative Reagent | Determination | LOD µg/L or µg/Kg |

Recovery % |

Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mode | t min |

T °C |

Fiber | Tdesorption °C |

|||||||

| 14 aldehydes & ketones | Vegetable oil | HS | 30 | 20 | DVB/CAR/PDMS | 270 | - | GC-FID & GC-MS | 0.04–2.24 | - | [64] |

| HPLC-UV | 1.5–12.3 | - | [ | 54 | ] | ||||||

| 4-HNE | Oils & porcine liver | DI | 15 | 40 | Hexanal | 66-25-1 | - | ||||

| PDMS/DVB | 5 aldehydes | Beer | Suspended780 * | 0.5[24] | |||||||

| 20 | 40 | HBA | |||||||||

| Target Compound | Sample | DLLME | Derivative Reagent | Determ. | LOD µg/L or µg/Kg |

Rec. % |

Ref. | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mode | Disperser | Extracting Solvent | T min |

T °C |

||||||||||||||||||||||||

| Formaldehyde | Beverages | MW-IL- | ACN | IL 3453W | 1.5 | - | DNPH | HPLC-UV | 0.12 | 85–95 | [108][112] | |||||||||||||||||

| Acrylamide | Brewed coffee | - | ACN | DCM | - | - | - | UPLC-MS/MS | 900 | 97–106 | ||||||||||||||||||

| HPLC-DAD | 1.2–1857.7 | >96% | [ | 55 | ||||||||||||||||||||||||

| α,β-Unsaturated Carbonyls | Acrolein | 107-02-8 | 2A | 7.5 | [25] | |||||||||||||||||||||||

| ] | ||||||||||||||||||||||||||||

| DNPH | HPLC-SP | 0.001–1.42 | 66–87% | [ | 65 | ] | [ | 109 | ] | [113] | ||||||||||||||||||

| PCB and acrylamide | Milk/Coffee | IL | [HeOHMIM][Cl] | [BMIM][NTf2] | - | - | - | HS-GC-ECD-MS | - | - | [110][114] | Diacetyl 1 | Wine | Immersed | 0.4 | |||||||||||||

| MDA, acrolein, 4-HNE | 20 | 65 | Beverages | O-PDA | US | ACN | CH3Cl | 5HPLC-UV | 3.8 | 60 °C- | [ | DNPH56] | GC-MS | 50–200 | 94–102 | [111] | 4-hydroxy-2-nonenal | 75899-68-2 | 3 | 1.5 ** | [26] | |||||||

| Acetaldehyde 1 | Wine | Immersed | 1.0 | 15 | 50 | DNPH | HPLC-UV | 800–1100 | - | [57 | ||||||||||||||||||

| MDA | Cod liver oil | HS | 10 | RT | PDMS/DVB | 200 | N-MH | GC-NPD | 0.74 | 91% | [66] | |||||||||||||||||

| Hexanal | Hazelnut | HS | 10 | 60 | CAR/PDMS | 300 | - | GC-FID | 8.01 | - | [67] | [115] | ] | |||||||||||||||

| 7 aldehydes | ||||||||||||||||||||||||||||

| Formaldehyde | Peanut, soybean and olive oils | HS | 15 | Milk | IL | MeOH50 | CAR/PDMS | 250 | IL 3453W | 0.75 | 45 °C- | GC-FID | 4.6–10.2 | 85–110 | [ | ACAC68 | UV | 100 | 91–103] | 4-hydroxy-2-hexenal | 17427-21-3 | 3 | 1.5 ** | [26] | ||||

| [ | 112 | ] | Diacetyl | Wine & beer | Suspended | 1.0 | 10 | 60 | O-PDA | DPV | 0.053 | |||||||||||||||||

| [ | 116 | ] | 3 α,β-UC | Sunflower oil digestion phases | HS | 60 | ||||||||||||||||||||||

| Acrylamide | Coffee, chocolate, roasted nuts, French fries, cereals, biscuits, chips, bread, and caramelized fruit |

SSA | SUPRAS-2 | - | (SDS/TBABr/AlCl3) | 50 | [ | 58 | ] | DVB/CAR/PDMS | 250 | 2 | - | - | UVGC-MS | - | - | 0.2 | 93–96 | [113][69] | [117] | Acrylamide | 79-06-1 | 2A | NE | [27 | ||

| α-DCC | Wine; black tea & soy sauce | Immersed 2 | ] | |||||||||||||||||||||||||

| 0.5 | 10 | 55 | O | -PDA | HPLC-UV | 50–200 | - | [ | 59 | ] | ||||||||||||||||||

| 100 carbonyl compounds | Cod liver oil | HS | 60 | 50 | DVB/CAR/PDMS | 220 | - | GC-MS | - | - | [70] | |||||||||||||||||

| Acrylamide | Nuts and seeds | - | PCE | EtOH | 3 | - | Xanthydrol | GC-MS | 0.6 | 95 | [114][118] | Crotonaldehyde | 4170-30-3 | 2B | - | |||||||||||||

| MDA | ||||||||||||||||||||||||||||

| 18 VOC | ||||||||||||||||||||||||||||

| Acrylamide | Potato chips | UAE | - | |||||||||||||||||||||||||

| Vegetable oil | Suspended | 0.5 | 30 | 65 | TBA | HPLC-UV/FLD | 250–350 | ≥82% | Sunflower oil emulsions | [60] | HS | 30 | 50 | DVB/CAR/PDMS | 250 | - | GC-MS | - | - | [71] | Dicarbonyls | Malondialdehyde | 102-52-3 | 3 | 30 ** | |||

| 4 aldehydes Acrolein & MDA | Vegetable oil | |||||||||||||||||||||||||||

| Aldehydes & 2-pentylfuran | [ | Suspended | 26 | ] | ||||||||||||||||||||||||

| Soybean oils | 1.0 | 10 | 60 | DPNH | GC-MS | 50–100 | ≥95% | [ | 10 | ] | Glyoxal | 107-22-2 | - | 200 | [28] | |||||||||||||

| Methylglyoxal | 78-98-8 | 3 | - | - | ||||||||||||||||||||||||

| Diacetyl | 431-03 | - | 900 * | [28] | ||||||||||||||||||||||||

| Furans | Dihydro-2(3H)-furanone | 96-48-0 | 3 | - | - | |||||||||||||||||||||||

| Furfural | 98-01-1 | 3 | 500 | [29] | ||||||||||||||||||||||||

| PCE | |||||||||||||||||||||||||

| EtOH | |||||||||||||||||||||||||

| 2 | |||||||||||||||||||||||||

| - | |||||||||||||||||||||||||

| Xanthydrol | GC-MS | 0.6 | 97 | [ | 115 | ] | [ | 119 | ] | ||||||||||||||||

| HS | 55 | 50 | DVB/CAR/PDMS | 250 | - | GC-MS | - | - | [ | 72 | ] | ||||||||||||||

| Acrylamide | Cereal products | - | PCE | EtOH | 1 | - | Xanthydrol | GC-MS | 0.6 | 95 | [116][120] | 2 ketones & diacetyl | Ground bread | Suspended | 0.5 | 15 | 65 | O-PDA | HPLC-UV | 6–12 | - | [61] | |||

| VOC | Peanut oil | HS | 40 | ||||||||||||||||||||||

| Acrylamide | Bread | UAE | 50 | PDMS/DVB | 250 | PCE | MeOH | 1 | - | Xanthydrol | GC-MS | 0.54 | 98 | [ | 27 carbonyl compounds 3 | Green & roast coffee beans | Suspended | 0.5 | 16 | 40 | O-PDA | HPLC-DAD | 50–200 | - | [62] |

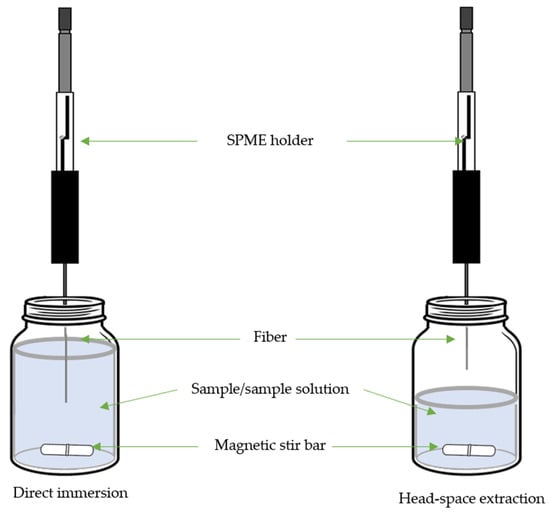

3. Solid-Phase Microextraction

SPME (Figure 3) is a well-established sample preparation technique commonly used in analytical chemistry to extract and concentrate target compounds from various sample matrices before analysis [49][51][63][49,51,63]| - |

| GC-MS | |||||||||||||||||||||||

| - | |||||||||||||||||||||||

| - | |||||||||||||||||||||||

| [ | |||||||||||||||||||||||

| 73 | |||||||||||||||||||||||

| ] | |||||||||||||||||||||||

| 117 | ] | [ | 121 | ] | 4 aldehydes & 1 ketone | Roast & boiled duck | HS | 40 | 45 | CAR/PDMS | 280 | - | GC-MS | - | - | [74] | |||||||

| 4 aldehydes Acrolein & MDA | Vegetable oil | US | ACN | CH3Cl | 5 | 60 | DPNH | GC-MS | 50–100 | ≥95% | 10 | 3 aldehydes | Chicken patties | HS | 10 | 60 | DVB/CAR/PDMS | 250 | - | GC-FID | - | - | [75] |

| Hexanal | Pig sausages | HS | 30 | 50 | DVB/CAR/PDMS | 220 | - | GC-MS | - | - | [76] | ||||||||||||

| 2 aldehydes & 2 dialdehydes | Cod | HS | 30 | 50 | CAR/PDMS | 260 | - | GC-FID | - | - | [77] | ||||||||||||

| 8 aldehydes | Fish | HS | 15 | 60 | PDMS/DVB | 260 | PFBHA | GC-MS | 1.4–6.1 | 79–102 | [78] | ||||||||||||

| 6 aldehydes | Caviar | HS | 30 | 60 | DVB/CAR/PDMS | 250 | - | GC-MS | - | - | [79] | ||||||||||||

| 198 VOCs | Dry cured meat | HS | 30 | 37 | 260 | - | GC-MS | - | - | [80] | |||||||||||||

| Aldehydes | Infant formula | HS | 10 | 25 | PDMS/DVB | 250 | - | GC-MS | - | - | [81] | ||||||||||||

| 3 aldehydes & pentane | Infant formula | HS | 45 | 37 | CAR/PDMS | 250 | - | GC-FID | 0.02–1.05 | - | [82] | ||||||||||||

| 13 Carbonyl compounds | Milk powder | HS | 45 | 43 | 250 | - | GC-MS | 2–6 | - | [83] | |||||||||||||

| VOC | Smoked cheese | HS | 45 | 50 | CAR/PDMS | 260 | - | GC-MS | - | - | [84] | ||||||||||||

| VOC | Mozzarella | HS | 15 | 37 | 220 | - | GC-MS | - | - | [85] | |||||||||||||

| VOC | Portuguese cheese | HS | 45 | 50 | DVB/PDMS | 250 | - | GC-MS | - | - | [86] | ||||||||||||

| 9 aldehydes | Beer | HS | 60 | 50 | PDMS/DVB | 250 | PFBHA * | GC-MS | - | 89–114 | [87] | ||||||||||||

| 41 carbonyl compounds | Beer | HS | 40 | 60 | PDMS/DVB | 250 | PFBHA *,** | GC-MS | 0.003–20,000 | - | [88] | ||||||||||||

| 250 carbonyl compounds | Beer | HS | 20 | 45 | PDMS/DVB | 250 | PFBAH ** | GC-ITMS | 0.003–0.510 | 88–114 | [89] | ||||||||||||

| 6 carbonyl compound | Beer | HS | 60 | 55 | DVB/CAR/PDMS | 250 | TFEH ** | GC-MS | 0.03–0.5 | 90–105 | [16] | ||||||||||||

| 6 carbonyl compound | Craft beer | HS | 60 | 55 | DVB/CAR/PDMS | 250 | TFEH ** | GC-MS | 0.03–0.5 | 90–105 | [90] | ||||||||||||

| 18 carbonyl compound | Wine | HS | 45 | 40 | DVB/CAR/PDMS | 250 | - | GC-ITMS | 0.62–129.2 | 19–190 | [91] | ||||||||||||

| 80 VOC | Wine | HS | 30 | 40 | DVB/CAR/PDMS | 240 | - | GC-MS | - | - | [92] | ||||||||||||

| 6 carbonyl compound | Syrah wines | HS | 45 | 55 | DVB/CAR/PDMS | 250 | TFEH | GCxGC-TOFMS | 0.5–5.2 | 90–106 | [93] | ||||||||||||

| 3 aldehydes | Must & wine | HS | 45 | 55 | DVB/CAR/PDMS | 250 | TFEH | GC-qMS | 0.1–0.8 | 90–102 | [94] | ||||||||||||

| 38 carbonyl compound | Port wine | HS | 20 | 32 | PDMS/DVB | 250 | PFBHA | GC-MS | 0.006–0.089 | 88–119 | [95] | ||||||||||||

| 45 carbonyl compound | Wine | HS | 20 | 40 | PDMS/DVB | 250 | PFBHA | GC-MS/MS | - | 71–146 | [96] | ||||||||||||

| 9 aldehydes | Spirits and alcoholic beverages | DI | 15 | 20 | PDMS | 250 | PFBHA | GC-ECD | 0.05–0.5 | - | [97] | ||||||||||||

| VOC & SVOC | Beer, wine & whisky | HS | 60 | 30 | PDMS CAR/PDMS DVB/CAR/PDMS |

250 260 260 |

- | GC-MS | - | - | [11] | ||||||||||||

| 20 aldehydes | Green pomace distillates | HS | 40 | 55 | PDMS/DVB | 250 | PFBHA | GC-MS | 0.0007–0.02 | 76–110 | [98] | ||||||||||||

| 107 VOC | Cider | HS | 30 | 50 | DVB/CAR/PDMS | 250 | - | GC-MS | - | - | [99] | ||||||||||||

| 53 carbonyl compounds | Huangjiu (alcoholic beverage) | HS | 35 | 45 | DVB/CAR/PDMS | 250 | PFBHA | GC-MS/MS | - | 71–146 | [100] | ||||||||||||

| 2 α-DCC | Soybean paste, red pepper past, soy sauce, wine, beer, distilled liquor | HS | 20 | 85 | DVB/CAR/PDMS | 240 | TFEH | GC-MS | 0.7–1.1 | 92–104 | [101] |