Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Fatima tuz Zahra and Version 2 by Camila Xu.

The term “drug delivery” refers to administrating the therapeutic effect of a pharmaceutical compound to humans or animals. Progress in the field of disease exploration is widely acknowledged, leading to ongoing research and development of advanced techniques for advanced drug delivery systems (DDSs). Electrospinning is a cost-effective and simple tool that is used for the preparation of drug delivery systems using natural, synthetic, and blended polymers.

- electrospinning

- polyvinyl alcohol (PVA)

- nanofibers

- drug delivery

- wound dressing

1. Introduction

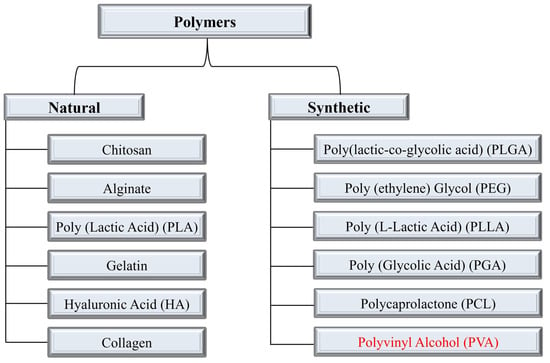

The term “drug delivery” refers to administrating the therapeutic effect of a pharmaceutical compound to humans or animals. Progress in the field of disease exploration is widely acknowledged, leading to ongoing research and development of advanced techniques for advanced drug delivery systems (DDSs). Some of the key factors in developing an effective and controlled drug delivery system include its inertness, non-toxicity, biocompatibility, high mechanical strength, patient comfort, and high drug-loading capability. To streamline and optimize the performance of this domain, an extensive array of polymers has been researched and effectively employed. The polymeric drug delivery systems have various categories such as microparticles, micelles, hydrogels/transplants, nanoparticles, and drug conjugates [1][2][3][4][5][6][7][1,2,3,4,5,6,7]. These systems are employed to improve controlled drug release, targeted drug delivery, and solubility. Generally, polymers are categorized as natural or synthetic polymers. Figure 1 illustrates the most frequently used polymers in both categories for the development of DDSs. Natural polymers are sometimes blended with synthetic compounds to chemically modify their functional groups, resulting in what is known as semi-synthetic polymers. Chitosan (CS) is one of the most commonly explored natural polymers and various studies have been reported on its potential in developing advanced drug delivery systems [8][9][10][11][12][8,9,10,11,12]. Synthetic polymers are sub-divided into hydrophobic and hydrophilic groups which are utilized in DDSs as core–shell nanoparticles depending on the required criteria. The drug release and drug loading efficiency of hydrophilic polymers is believed to be higher than those of hydrophobic polymers [13]. Combining hydrophobic and hydrophilic synthetic polymers in various proportions has also been employed for the development of drug nanocarriers. For instance, the combination of poly(ethylene glycol) (PEG) and polycaprolactone (PCL) has been utilized to investigate the endocytosis pathways into cells [14]. Polymeric capsules have been developed for cancer therapy by incorporating targeting ligands, thereby mitigating the accompanying side effects and toxicity [15]. Polymers are commonly used to develop transdermal DDSs, wound dressings, cancer therapy, tissue engineering, and oral DDSs. The disadvantages associated with commonly used synthetic/natural polymers such as PCL, PLGA (poly(lactic-co-glycolic acid)), and PLA (poly(lactic acid)) include the slow degradation and biocompatibility issues due to the formation of acidic degradation products [16][17][16,17].

Figure 1. Categories of polymers and the most used polymers in each category for DDSs. The polymer under discussion Polyvinyl Alcohol (PVA) is highlighted in synthetic polymers category.

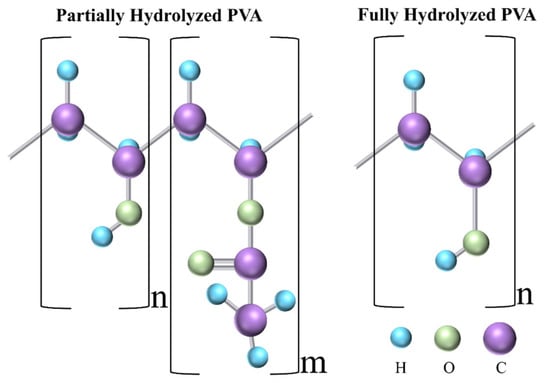

Polyvinyl alcohol (PVA) is a synthetic biopolymer that has been used for decades as a blending polymer with natural and synthetic polymers to improve the efficacy of DDSs. It is synthesized by the hydrolysis of polyvinyl acetate (PVAc) [18]. Depending on the degree of hydrolysis, which varies between 80 and 99%, PVA [CH2CH(OH)]n is subdivided into two categories, i.e., partially hydrolyzed and fully hydrolyzed. Figure 2 shows the molecular structure of both categories.

Figure 2. Molecular structure of partially and fully hydrolyzed PVA. C, O, and H refer to carbon, oxygen, and hydrogen, respectively.

PVA possesses a semicrystalline solid structure and is not only biocompatible, biodegradable, non-toxic, and hydrophilic, but also has a good spinning capability, and thus holds significant potential in electrospinning-based DDSs. There have been a few review papers that have examined the use of PVA in drug delivery systems for specific applications, such as tissue engineering and cancer therapy [19][20][19,20].

2. Electrospinning for DDSs

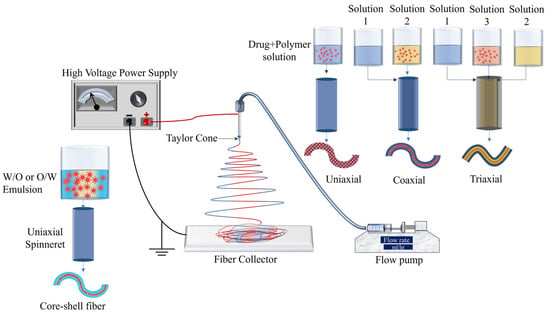

Electrospinning is a cost-effective and simple tool that is used for the preparation of drug delivery systems using natural, synthetic, and blended polymers. Figure 3 shows the schematic of the electrospinning process. In the electrospinning process, generally, the flow pump, spinneret, collector (e.g., a plane conducting sheet, rotating drum), and high voltage power supply are the main components. The spinneret is connected to a high-voltage source while the collector is grounded. The flow rate is set using the flow pump and it depends mainly on the viscosity of the polymer solution. Once the voltage is applied, the positively charged solution travels from the needle tip toward the grounded collector. The formation of the Taylor cone on the tip of the needle is an important factor without which the fibers may not be formed. Electrospinning has excessively been used for the development of different drug delivery systems and the process parameters mentioned above significantly affect the fiber morphology. For example, a higher flow rate can lead to high bead density, higher viscosity leads to an increase in diameter, lower viscosity results in bead formation, and longer needle-to-collector distance can result in instability of the electric field and hence negatively affect the fiber formation [21]. Therefore, it can be concluded that optimization of the processing parameters is an important phase in obtaining fine and bead-free fibers and surface morphology. Natural and synthetic polymers that have been most widely used in electrospun drug delivery systems are listed in Table 1.

Figure 3.

Schematic of electrospinning and its types.

Table 1.

Limitations and advantages of the most commonly used natural and synthetic polymers for electrospun DDSs.

| Polymer, Type of Polymer |

Limitations | Advantages | Ref. |

|---|---|---|---|

| Chitosan Natural |

Extremely hydrophilic which leads to loss of nanofibrous structure, high degradation rate, and poor mechanical strength | Non-toxic, and biodegradable qualities make it biocompatible with a wide range of organs, tissues, and cells. | [9][22][9,22] |

| Gelatin Natural |

Rapid degradation, poor mechanical strength, and complete dissolution | Intrinsic bioactivity, high biocompatibility, cell adhesion, biodegradability, low immunogenicity | [23][24][23,24] |

| Hyaluronic Acid Natural |

High viscosity, high surface tension, low evaporability, high electrical conductivity that may lead to electrospinning circuit failure | Biocompatibility, non-immunogenicity, biodegradability, excellent tumor-targeting ability | [25][26][27][28][25,26,27,28] |

| Collagen Natural |

Variability in enzymatic degradation rate (depending on enzyme concentration), difficult to maintain its dimension in vivo due to swelling, poor mechanical strength, in vivo (not suitable for load-bearing tissues) | Biocompatible, non-antigenic, non-toxic, biodegradable (degradation can be regulated via crosslinking), compatible with synthetic polymers, promotes blood coagulation | [29][30][29,30] |

| Alginate Natural |

Low solubility, high viscosity due to high MW, high density of hydrogen bonding, polyelectrolyte nature of aqueous solution, and lack of appropriate organic solvent. | High water content, nontoxicity, soft consistency, biocompatibility, biodegradability, low immunogenicity | [31][32][31,32] |

| PLA Natural |

Poor mechanical strength, low cell adhesion because of its hydrophobicity, biological inertness, acidic degradation products, inflammation in vivo | Biocompatible, biodegradable by hydrolysis and enzymatic activity, low immunogenicity | [33][34][33,34] |

| PLGA Synthetic |

Poor hydrophilicity, poor cell adhesion, higher viscosity, production of acids upon degradation | Strong biodegradability, suitable for controlled-release drug delivery of medicines, peptides, proteins, and other substances | [35][36][35,36] |

| PCL Synthetic |

High hydrophobicity, poor bioactivity, low mechanical strength, and higher amount of PCL reduces the swelling capability of DDS | Slower degradation rate, shorter in vivo adsorbable time, generation of a minimal acidic environment during degradation | [37][38][37,38] |

| PEG Synthetic |

Low molecular weight makes it challenging to electrospin | Non-toxic, non-immunogenicity, good biocompatibility, and anti-protein adsorption | [39][40][39,40] |

The bold and italic texts in Column 1 signify the name of the polymer and its category, respectively.

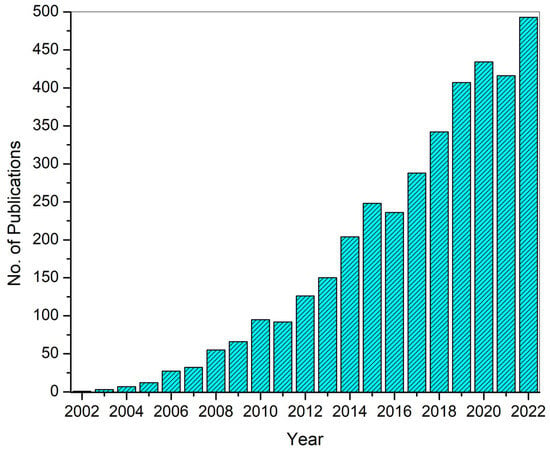

Figure 4. Number of publications until 2022 on electrospinning-based DDSs. The data were extracted from Web of Science (WoS).