The recent increase in the use of carbonless energy systems have resulted in the need for reliable energy storage due to the intermittent nature of renewables. Among the existing energy storage technologies, compressed-air energy storage (CAES) has significant potential to meet techno-economic requirements in different storage domains due to its long lifespan, reasonable cost, and near-zero self-decay.

- depth of discharge

- energy density

- round-trip efficiency

- hydropneumatic

- battery energy storage system

- compressed-air energy storage

1. Introduction

2. Compressed Air Energy Storage System

In medieval times, compressed air first found an energy application in air injection (AI). The use of compressed air energy storage at utility-scale was not popular because compressed air was used directly at that time due to a lack of pressure storage technologies. For small-scale applications, hand, foot, and even animal-powered bellows were used to pressurize air to increase the temperature of burning shells or wood, which acted as fuel. Increasing the burning efficiency seems to have been the main aim, although the higher temperatures attained due to AI made it possible to use compressed air in foundries. With the emergence of compressed-air storage capabilities, CAES works in a supporting role, providing power augmentation in fuel-powered generators to increase the efficient combustion of fuel.

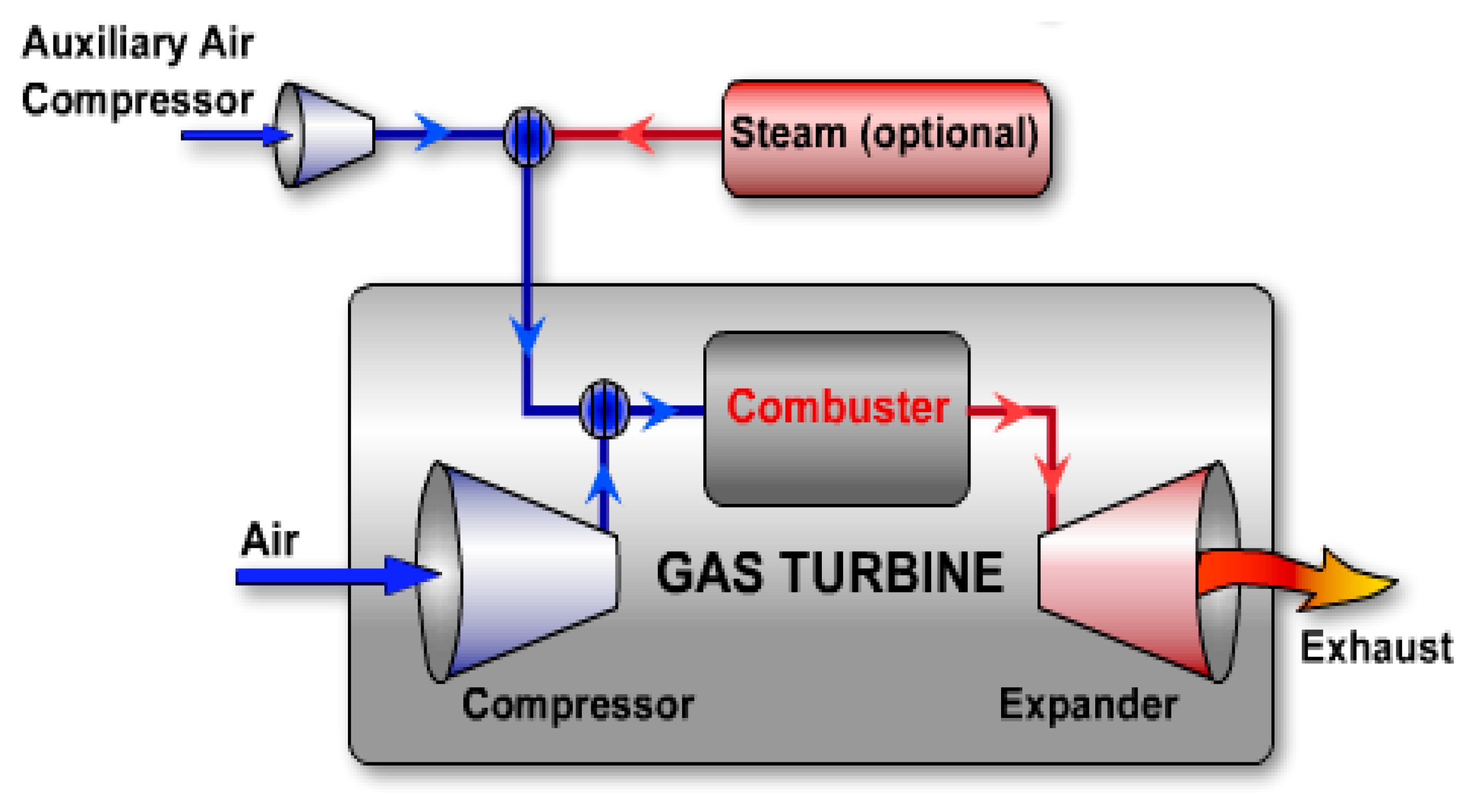

As demonstrated in Figure 1, the auxiliary injection of compressed air into the combustors not only increases the power output but also helps the main compressor pull more compressed air into the gas turbine.

2.1. A Basic CAES System

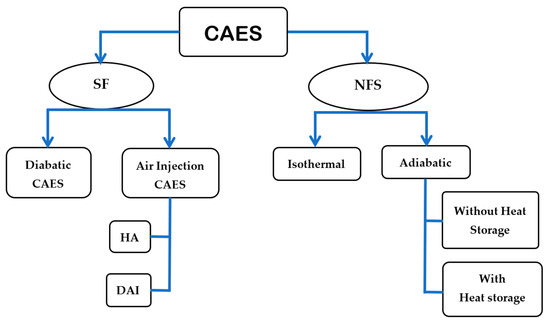

2.1.1. Classification of CAES Systems

Supplementary Fuel CAES:

Air Injection CAES:

Diabatic CAES:

Non-Supplementary Fuel CAES:

Adiabatic CAES (A-CAES):

Advanced Adiabatic CAES (AA-CAES):

Isothermal CAES:

2.2. Flaws of Early CAES

2.3. The Evolution of Energy-Converter Machines in CAES Systems

2.4. Isothermal CAES Based on Hydropneumatic Converters

The further improvement of CAES to ensure near-isothermal operation becomes necessary. This is to prevent the thermally induced losses that are common with adiabatic and diabatic types of CAES. To create an ECM capable of near-isothermal operation, the approaches used in medieval times give an idea of the principle of hydropneumatics, which was first developed as tromps [19][20] in the 1700s. Tromps are near-isothermal river-flow-charged hydraulic compressors that operate based on the reciprocatory movement of a fluid in a column. The application of this principle without the use of a river’s flow was first achieved by Humphrey to pump water at a low pressure and high volume in [21]. An LP compressor operates by opening the inlet valve to pull in air to be compressed. The fluid level in the LP chamber is reduced by pumping out its fluid content until the bottom dead center is reached. After the intake stroke, the inlet valve is closed, after which the hydraulic pump injects fluid into the LP chamber to raise the fluid level. Increasing the fluid level pressurizes the trapped air until the desired pressure or top dead center is reached. The outlet valve can be opened to allow compressed air into the storage vessel. Similar to solid piston compressors, continuous compression strokes will occur until the desired storage pressure is attained. In the expander mode, high-pressure air is allowed into the fluid-filled chamber through the inlet valve while the outlet valve is closed. According to Pascal’s law, the distribution of pressure ensures that the fluid and air pressures are the same except when the contact surface areas are not of the same ratio. The base hydraulic valve is opened to allow pressurized fluid to flow out of the chamber to drive the hydraulic motor downstream. The mechanical work generated by the motor can be used to drive the generator. The trapped compressed air expands as its pressure value reduces toward the ambient while pushing down the hydropneumatic interface until the bottom dead center is reached. Using self-sealing moving fluid, LPs do not have the problems of friction or seal abrasion that plague conventional solid-piston energy converters. This enables them to operate at lower noise levels and eliminate seal maintenance. Near-reversible attributes ensure minimal losses regardless of the mode of operation, either as a compressor or an expander. Therefore, it is possible to use a single device in different modes to eliminate the cost and complexity problems of having separate units in the same CAES system. Liquids have good form factors, enabling them to conform to the geometry of the different containers in which they are placed.2.4.1. Accumulator-Based Isothermal CAES

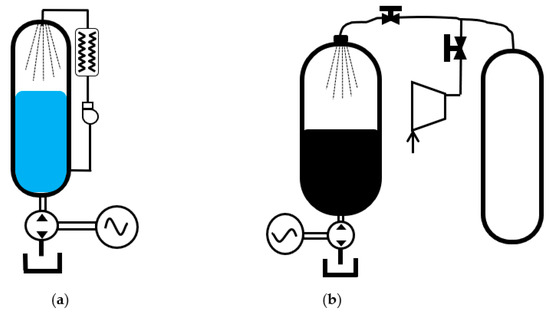

Accumulator-based CAES gained popularity due to its simplicity and similarity in principle to pumped hydroelectricity storage (PHS), except it is a smaller device. Generally, accumulators are applied in short-term energy storage in hydraulic systems to reduce the size of the pump and the prime mover. Accumulators are used in regenerative breaking [22][23] and to absorb pressure surges and reduce shocks. Unlike the dedicated storage unit in many CAES systems, the advantage of an accumulator is its combined role as an energy storage and converter device. Aside from their simplicity, accumulators enable direct integration into the generated asset [24][25]. The team at Oak Ridge Laboratory used a regenerative pump using static pressure already in the vessel to generate a mist that cools the chamber, as shown in Figure 4a. A mist-generating pump can have its feed line integrated with a heat exchanger for heat injection or removal.

2.4.2. Liquid Piston Based CAES

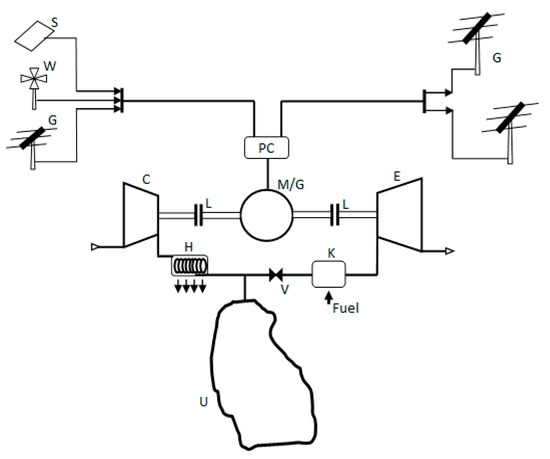

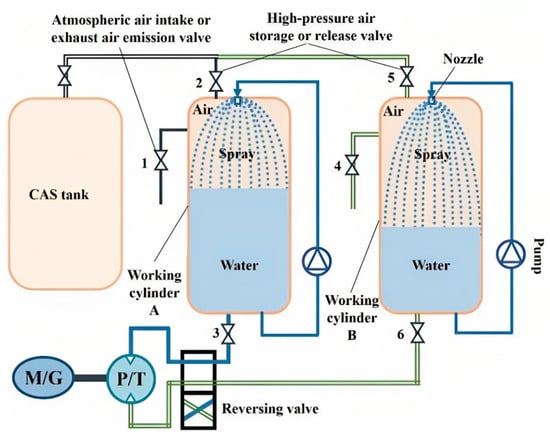

The combined role of accumulators as energy converters and storage is plagued by poor efficiency and energy density problems. Rapid declines in pressure also impose a load profile that must follow declines in storage pressure or the system risks overload and shutdown. This necessitates a system subunit that works effectively as a converter or as storage only. A purpose-developed energy-converting machine should have better performance attributes for specific needs. A liquid piston using an air–fluid interface fits into the already established advantages of hydropneumatics, as previously explained. Described as a switch-mode liquid piston (SMLP), its operation is similar to that of the paired accumulators in Figure 5. To improve the quasi-isothermal conditions, the LP chamber has copper tubes arranged in a honeycomb manner which act as heat exchangers and thermal storage integrated into the liquid piston chamber. The alternately switched LPs can operate in either compressor mode or expander mode, depending on the position of the directional valve.

3. Optimization Strategies for Hydropneumatic Energy Converters

The LP compression process follows a compressed-push sequence. After a full compression stroke, the LP charges the storage chamber unit freely until the pressure gradient between the storage chamber and the LP chamber is near zero. This is in line with Fick’s law of diffusion. Additional compression energy is needed to push the remaining compressed air content of the LP chamber into the storage unit after the initial isochoric charging. The last isobaric charging process requires the hydropneumatic interface to move upward until a dead volume is reached. Both processes can be explained via an extensive analysis of pneumatic power, as in [29], and the pneumatic flow assessment presented in [30]. The total pneumatic power in the LP chamber is deemed to have two components: real power that can be converted into useful work through the expansion process and transport power which is needed to push the real power downstream, usually from its present location to the desired location. Decreases in diffusion while the vessel is being filled from the LP chamber due to a decline in pressure and a simultaneous increase in the compressibility of the storage unit due to an increasing storage pressure create a mismatch. In all studies that used an SMLP with only a single-stage ECM, a substantial residual pressure remains unused in each LP chamber after each expansion stroke due to incomplete expansion. It is discharged away through exhaust valves, contributing to conversion losses. Using residual energy that remains in the LP chamber after the expansion stroke is a key effort needed to improve the RTE. It can reduce conversion losses for SMLP-configured CAES and also ensure a better load-handling profile. Instead of a dedicated pressure intensifier or booster, a novel approach that prevents the waste of exhaust pressure and turns it into useful output work was patented in [31]. Series-linked LPs with geometry designed for a specific pressure range were used to spread the pressure ratio of each stage over two-stage compressors. In compression mode, each LP has an optimal pressure ratio of 4 to raise the final pressure to 200 bar from the pressure input of 12.5 bar. The expansion process works in a similar way, ensuring that the exhaust pressure is close to the ambient pressure. Due to the wider range of operating pressure capability of LP compressors, the effect of a rapid decline in vessel pressure is lessened but is still present. The limitations of this configuration are the irreversible thermodynamic losses of the machine and the process itself, the limited DoD, and the complexity.4. Strategies for Optimizing CAES Systems

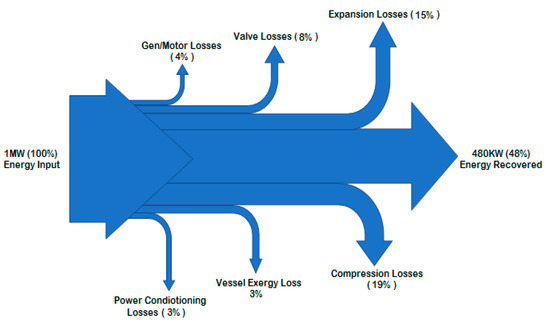

The characterization of losses gives insight into the flow of energy and where optimization can focus to improve performance. Using average values of CAES subunit losses retrieved from the literature, estimates at each stage can be computed and used to analyze cycle loss. Although ideal thermodynamic tubes/pipes that form connecting links among all subunits are assumed, in reality, this is not possible. As indicated in the energy map of a generic CAES system in Figure 6, energy converters, regulating valves, and directional control valves account for substantial losses. These losses are due to the poor polytropic indices of energy-converting machines and changing storage pressure. Far from ideal scenarios, the prospect of polytropic tuning to shift it from an adiabatic-leaning value of 1.4 towards a near-isothermal value of 1 in hydropneumatic CAES is desired. In adiabatic CAES, efficient thermal capture is the main goal to prevent or reduce thermal losses.

4.1. Optimization Strategies for a Liquid Piston Compressor/Expander

An LP’s prospect of meeting the requirements needed for efficient operation in different storage domains led to an increase in interest in and a search for various methods that will further enhance its performance. This caused a significant increase in research output, most of which was carried out to address specific or combined needs. Although previous research focused on improvements in near-isothermal operation, other areas like power density, integration with power generation assets, isobaric control, and even hybridization with solid pistons are now common areas of research. Optimization strategies are designed to maximize these desired performance metrics and reduce losses. To minimize compression losses, a near-isothermal process is sought. The ideal isothermal energy used to compress a given volume of air V by a compression ratio r in an ideal isothermal scenario is given by Although impossible to attain, schaolrs can use this as a measure of compression efficiency to benchmark the performance of compressors. An analogous expansion scenario can be applied to derive the expansion efficiency. The rate of the injection of a fluid into the LP chamber follows a trajectory that creates a compression profile ζc, which is different from the ideal isothermal profile. If schaolrs compare both conditions, schaolrs can derive the compression efficiency as Similarly, the expansion efficiency can be defined as where 𝑊𝑖𝑛(ζc) is the work done using the compression profile ζc, and 𝑊𝑜𝑢𝑡(ζe) is the actual expansion work that follows the trajectory of ζe. The energy generated from 𝑊𝑜𝑢𝑡(ζe) is lower than ideal expansion work 𝐸𝑉. Ideally, the time needed to attain isothermal compression will be so long as to allow for a thermal gradient of zero. In reality, this is not the case; compression takes less time and generates heat that cannot be dissipated away faster than it is generated. The changes in the rate of the flow in and out of the hydropneumatic chamber create two parameters that require optimization. Different approaches are already in use, while other methods are still being studied.4.2. Power Density Improvement Strategies

The power density of an LP compressor/expander can be derived from isothermal expansion work, LP displacement, and the compression or expansion time described in Equations (6) and (7). In pneumatics, poor power density problems are generally solved by oversizing the energy converter and storage to ensure that surge loads do not cause a forced shutdown. In LPs, such an approach only worsens the already-poor power density parameter. Aside from the high capital cost of acquiring machines with larger ratings, running costs increase due to the power consumption of an oversized electric motor and hydraulic pump. Various strategies used to increase the power density of hydropneumatic systems are also applicable to improving their efficiency. Although reducing fluid displacement plays a significant role in power density improvement, it is difficult to combine such a method with conversion efficiency improvement. From Equations (6)–(9), the competing natures of conversion efficiency and power density show that the optimization of one parameter imposes a trade-off on the other. Therefore, improving both metrics requires an optimization strategy that combines power density improvement with near-isothermal operation to increase efficiency. The following strategies have been used to improve the power density of LPs. Some of the listed strategies improve both the power density and conversion efficiency.5. Storage Units for Compressed-Air Energy Storage Systems

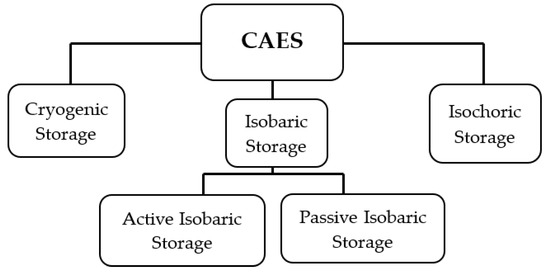

5.1. Types of Storage Units for CAES

Storage units for CAES are of three different types based on their design and peculiarities of operation, as demonstrated in Figure 7. The classification also indicates efforts to improve the energy density and RTE of storage units and improve the suitability of CAES for different domains of application. Without regard to scale, classification is based on pressure variation and how it is controlled while focusing on the state of the stored compressed air. The following figure captures various types of pressurized storage used for CAES.

5.2. Energy Density and Storage Units for CAES

6. The Viability of CAES in Different Storage Domains

Down-scaling a utility-scale CAES design for small-scale, behind-the-meter, and standalone systems or integrating it into a power generation system using the same types of subunit devices is not suitable. The way in which the subunits are connected together forms a topology that works best when used in specific domains. A careful analysis of the combination of subunit types and topology is necessary so as not to worsen performance metrics. Since the highest losses in CAES come from energy conversion, an optimized ECM design is needed regardless of the scale or domain of use. The focus of this analysis is on subunit-to-subunit and subunits with topology selection. Application domain requirements differ; therefore, the types of topology or component units should be such that they ensure that the domain needs are met.

6.1. Grid-Scale Batteries

6.2. Behind-the-Meter Application

Due to the use of energy from utility suppliers that carry tariff charges, storage and conversion efficiency are metrics that guide the selection of components for CAES in this domain. Although an efficient system is desired, the availability of electricity is often a higher priority in micropower systems. The high power density of rotating converters, which is due to their high angular speed, is negated by their poor efficiency. Combinations of high-pressure hydropneumatic-type ECMs and storage units that operate at constant pressures are the most suitable. Storage units can be aboveground or fit into physical structures. The storage needs to be sized to provide a predetermined power rating for on-demand energy, as illustrated in [38][39][40] for a given autonomy and not long-term storage like utility-scale types. The optimization of CAES to meet requirements of behind-the-meter applications will require the problems of low RTE and energy density values to be solved [41]. Pressure and speed controllers for load governors can be replaced or better improved with power electronic ancillaries for effective power and efficiency tracking [42].6.3. Generation-Integrated Storage

Many isolated, off-grid energy storage systems have power generation assets integrated within them. Generation-integrated storage does not require electricity to be used as an input for the CAES battery. What is needed to charge this type of storage is either fluid power to charge hydropneumatics or even mechanical shaft power to drive hydraulic pumps. Both can be generated from energy sources without first converting the energy into electricity. In [43][44], energy from photovoltaic panels powered electric pumps to operate liquid pistons or accumulators. In [45], direct mechanical integration was used to replace the generator unit with a hydraulic pump that powered the liquid piston in wind power generation.7. Conclusions

CAES has the unique attributes of having a long lifespan, retaining its storage capacity throughout its useful life, and being able to store energy with almost zero self-decay. Its scale flexibility and long-term capabilities combine with reasonable cost. These attributes make CAES an attractive contender for energy cloud services and to ease the grid integration of renewables. However, its performance metrics like DoD, RTE, and ED are poor when compared to energy storage technologies in similar domains. Also, due to the utility-scale nature of early CAES, its subunits and design topology prevent its adaptation for small-scale or behind-the-meter use. Therefore, early CAES concepts result in poor metrics when used directly in other storage domains. The competing attributes of CAES performance metrics impose optimization trade-offs that negatively affect another preferred metric. Various single-objective optimization attempts to improve the performance metrics of a generic CAES topology and subunits have yielded little improvement. When connected with an inappropriate topology, subsystem parameters vary beyond their optimal range during charging or discharging operations. This leads to poor performance values for the main metrics, even when optimization is carried out on generic CAES designs. Before optimization can lead to satisfactory results, it is proposed that subunits must have the following attributes:-

The air storage pressure must be near-constant or vary within the optimal range of the energy-converting machine. This is necessary to retain peak efficiency regardless of the storage’s energy content level.

-

Passive isobaric control is desired due to its zero-energy attributes, but research efforts should be guided towards low-energy active pressure control in small-scale CAES in which passive methods are deemed complex or costly.

-

The selection of an energy-converting machine requires cognizance of the peculiarities of its domain of application. The storage type, energy converters, and a suitable topology that will yield the best metric must be considered together.

-

Although near-isothermal operation reduces the polytropic index and improves the conversion efficiency, it comes with other trade-offs. Therefore, ECM optimization strategies should combine conversion efficiency and power density simultaneously.

-

For the compression and expansion pressure ratios to be optimal, a series configuration is necessary to ensure that the final exhaust pressure is close to the ambient pressure during expansion. The compression process will benefit from a similar optimal compression ratio.

References

- Webber, M.E. Interruptible power. Mech. Eng. 2021, 143, 45–50.

- Operator, A.E.M. Preliminary Report: Black System Event in South Australia on 28 September 2016; Australian Energy Market Operator: Sydney, Australia, 2016.

- MacMillan, D.; Englund, W. Longer, more frequent outages afflict the US power grid as states fail to prepare for climate change. Wash. Post 2021. Available online: https://www.washingtonpost.com/business/2021/10/24/climate-change-power-outages/ (accessed on 15 April 2022).

- Energy, E.A. Pumped Hydro Storage; Brussels, Belgium. European Association for Storage Energy. Available online: www.ease-storage.eu (accessed on 12 June 2022).

- Deane, J.; Gallachóir, B.; McKeogh, E. Techno-economic review of existing and new pumped hydro energy storage plant. Renew. Sustain. Energy Rev. 2010, 14, 1293–1302.

- Moyo, P. Eskom’s Flagship Battery Energy Storage Systems (Bess); EE Publishers (Pty) Ltd.: Muldersdrift, South Africa, 2018.

- Tarascon, J.-M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367.

- Sharma, P.; Bhatti, T. A review on electrochemical double-layer capacitors. Energy Convers. Manag. 2010, 51, 2901–2912.

- Zhang, Q.; Rong, J.; Ma, D.; Wei, B. The governing self-discharge processes in activated carbon fabric-based supercapacitors with different organic electrolytes. Energy Environ. Sci. 2011, 4, 2152–2159.

- Horn, M.; MacLeod, J.; Liu, M.; Webb, J.; Motta, N. Supercapacitors: A new source of power for electric cars? Econ. Anal. Policy 2018, 61, 93–103.

- Peña-Alzola, R.; Sebastián, R.; Quesada, J.; Colmenar, A. Review of flywheel based energy storage systems. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, Malaga, Spain, 11–13 May 2011.

- Schainker, R.B.; Nakhamkin, M. Compressed Air Energy Storage (CAES): Overview, Performance and Cost Data for 25MW to 220MW Plants. IEEE Trans. Power Appar. Syst. 1985, PAS-104, 790–795.

- Marshall, R.; Nakhamkin, M.; McNey, J.L.; Kobasa, J.; Abbas, A.; Saravani, M.S.; Al-Haddad, M.; Amano, R.S.; Maruyama, N.; Sadamichi, Y.; et al. Preliminary Engineering of a Second Generation Compressed Air Energy Storage Plant. In Proceedings of the 22nd Intersociety Energy Conversion Engineering Conference, Philadelphia, PA, USA, 10–14 August 1987; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1987.

- Razmi, A.R.; Afshar, H.H.; Pourahmadiyan, A.; Torabi, M. Investigation of a combined heat and power (CHP) system based on biomass and compressed air energy storage (CAES). Sustain. Energy Technol. Assess. 2021, 46, 101253.

- Barbour, E.; Mignard, D.; Ding, Y.; Li, Y. Adiabatic Compressed Air Energy Storage with packed bed thermal energy storage. Appl. Energy 2015, 155, 804–815.

- Wolf, D.; Budt, M. LTA-CAES–A low-temperature approach to Adiabatic Compressed Air Energy Storage. Appl. Energy 2014, 125, 158–164.

- Freund, S.W.; Finkenrath, M.; Botero, C.; Belloni, C.S.; Salazar, M.A.G.; Hoffmann, S.M.N. Adiabatic Compressed Air Energy Storage System with Liquid Thermal Energy Storage. Appl. Energy 2011, 155, 804–815.

- Reed, S.; Sugo, H.; Kisi, E. High temperature thermal storage materials with high energy density and conductivity. Sol. Energy 2018, 163, 307–314.

- Bassett, D.E. A Historical Survey of Low-Head Hydropower Generators and Recent Laboratory Based Work at the University of Salford; University of Salford: Salford, UK, 1989.

- Ahrens, F.; Berghmans, J. Preliminary evaluation of the use of hydraulic air compressors in water-compensated reservoir compressed air storage power plants. In Entrainment of Air Bubbles by a Column of Downward-Flowing Water; Argonne National Lab.: Lemont, IL, USA, 1978.

- Humphrey, H.A. An internal-combustion pump, and other applications of a new principle. Proc. Inst. Mech. Eng. 1909, 77, 1075–1200.

- Laussermair, F. Accumulator to Store and Release Braking Energy. U.S. Patent 4018052A, 19 April 1977.

- Vint, M.; Gilmore, D. Simulation of transit bus regenerative braking systems. Math. Comput. Simul. 1988, 30, 55–61.

- Qin, C.; Innes-Wimsatt, E.; Loth, E. Hydraulic-electric hybrid wind turbines: Tower mass saving and energy storage capacity. Renew. Energy 2016, 99, 69–79.

- Buhagiar, D.; Sant, T.; Farrugia, R.N.; Aquilina, L.; Farrugia, D.; Strati, F.M. Small-scale Experimental Testing of a Novel Marine Floating Platform with Integrated Hydro-pneumatic Energy Storage. J. Energy Storage 2019, 24, 100774.

- Odukomaiya, A.; Momen, A.M.; Abu-Heiba, A.; Gluesenkamp, K.; Abdelaziz, O.; Graham, S. Transient thermofluids analysis of a ground-Level integrated diverse energy storage (GLIDES) system. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2015.

- Yao, E.; Wang, H.; Liu, L.; Xi, G. A Novel Constant-Pressure Pumped Hydro Combined with Compressed Air Energy Storage System. Energies 2014, 8, 154–171.

- Chen, H.; Peng, Y.-H.; Wang, Y.-L.; Zhang, J. Thermodynamic analysis of an open type isothermal compressed air energy storage system based on hydraulic pump/turbine and spray cooling. Energy Convers. Manag. 2019, 204, 112293.

- Shi, Y.; Cai, M.; Xu, W.; Wang, Y. Methods to Evaluate and Measure Power of Pneumatic System and Their Applications. Chin. J. Mech. Eng. 2019, 32, 42.

- Cai, M.; Kawashima, K.; Kagawa, T. Power Assessment of Flowing Compressed Air. J. Fluids Eng. 2005, 128, 402–405.

- Lemofouet, S.; Rufer, A. Multistage Hydraulic Gas Compression/Expansion Systems and Methods. Patent CN101828029B, 4 December 2013.

- Guo, H.; Xu, Y.; Huang, L.; Zhu, Y.; Liang, Q.; Chen, H. Concise analytical solution and optimization of compressed air energy storage systems with thermal storage. Energy 2022, 258, 124773.

- Ladokun, T.; Nabhani, F.; Zarei, S. Accidents in pressure vessels: Hazard awareness. In Proceedings of the Lecture Notes in Engineering and Computer Science: Proceedings of the World Congress on Engineering 2010, London, UK, 30 June–2 July 2010; International Association of Engineers: Hong Kong, China, 2010.

- Al-Huniti, N.S.; Al-Habahbeh, O.M. Composite LPG cylinders as an alternative to steel cylinders: Finite element approach. In Proceedings of the International Conference on Manufacturing and Material Processing (ICMM 2006), Kuala Lumpur, Malaysia, 15–16 March 2006.

- Villalonga, S.; Nony, F.; Magnier, C.; Yvernes, J.L.; Thomas, C.; Delmas, B.; Mazabraud, P. Composite 700 bar-vessel for on-board compressed gaseous hydrogen storage. In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009.

- Li, P.Y.; Saadat, M. An approach to reduce the flow requirement for a liquid piston near-isothermal air compressor/expander in a compressed air energy storage system. IET Renew. Power Gener. 2016, 10, 1506–1514.

- Li, C.; Wang, D.; Liu, D.; Wu, J.; Li, Y.; Mao, C.; Wang, J. Mathematical Modelling of Large-Scale Compressed Air Energy Storage Systems. In Proceedings of the 2019 25th International Conference on Automation and Computing (ICAC), Lancaster, UK, 5–7 September 2019.

- Odukomaiya, A.; Abu-Heiba, A.; Graham, S.; Momen, A.M. Experimental and analytical evaluation of a hydro-pneumatic compressed-air Ground-Level Integrated Diverse Energy Storage (GLIDES) system. Appl. Energy 2018, 221, 75–85.

- Lemofouet, S.; Rufer, A.; Cyphelly, I.; Barrade, P.; Grasser, F. Principle of a Hybrid Compressed Air and Supercapacitors Energy Storage system with Maximum Efficiency Point Tracking; Swiss Federal Institute of Technology: Lausanne, Switzerland, 2003.

- Jannelli, E.; Minutillo, M.; Lavadera, A.L.; Falcucci, G. A small-scale CAES (compressed air energy storage) system for stand-alone renewable energy power plant for a radio base station: A sizing-design methodology. Energy 2014, 78, 313–322.

- Abuheiba, A.; Ally, M.R.; Smith, B.; Momen, A. Increasing Compressed Gas Energy Storage Density Using CO2–N2 Gas Mixture. Energies 2020, 13, 2431.

- Kokaew, V.; Sharkh, S.M.; Moshrefi-Torbati, M. Maximum Power Point Tracking of a Small-Scale Compressed Air Energy Storage System. IEEE Trans. Ind. Electron. 2015, 63, 985–994.

- Castellani, B.; Morini, E.; Nastasi, B.; Nicolini, A.; Rossi, F. Small-Scale Compressed Air Energy Storage Application for Renewable Energy Integration in a Listed Building. Energies 2018, 11, 1921.

- Cazzaniga, R.; Cicu, M.; Rosa-Clot, M.; Tina, G.; Ventura, C. Compressed air energy storage integrated with floating photovoltaic plant. J. Energy Storage 2017, 13, 48–57.

- Daneshi, A.; Sadrmomtazi, N.; Daneshi, H.; Khederzadeh, M. Wind power integrated with compressed air energy storage. In Proceedings of the 2010 IEEE International Conference on Power and Energy, Kuala Lumpur, Malaysia, 29 November–1 December 2010.