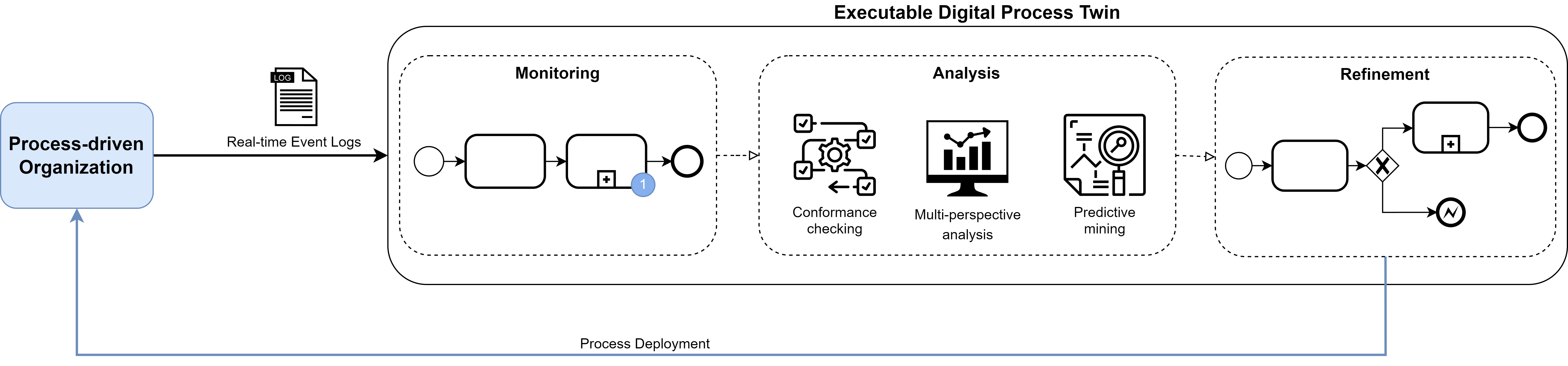

An Executable Digital Process Twin (xDPT) is a digital twin specifically designed for process-driven systems. It enriches the monitoring and analysis functionalities of a digital process twin with the possibility of actively driving the execution of the entire system. An xDPT receives real-time event logs from the running organization and allows direct monitoring by marking the status of the system in the running process. Moreover, it can exploit existing process mining techniques to check the conformance of the executed behavior, to provide an enriched view over multiple system perspectives, and to store historical data to predict process evolution. Finally, the process driving the system behavior can be refined and deployed into the organization. The main objective of an xDPT is to enable the monitoring and analysis of a system but also to execute it. In this regard, the process should serve both for performing monitoring and analysis stages and for enacting and controlling the whole system execution.

- digital process twin

- process-driven system

- BPMN

1. Digital Process Twin

-

Multiple and interdependent processes;

-

Agents capable of making choices, learning from experience, and achieving goals;

-

Models showing different aspects of the organization;

-

Simulation and prediction capabilities to understand how the organization might behave when it faces different situations.

2. Executable Digital Twin

3. Executable Digital Process Twin

| DPT | xDT | xDPT | |

|---|---|---|---|

| Representation | ✓ | ✗ | ✓ |

| Prior knowledge | ✗ | ✓ | ✓ |

| Prediction | ✓ | ✓ | ✓ |

| Improvements | ✗ | ✗ | ✓ |

| Deployment | ✗ | ✓ | ✓ |

References

- Parmar, R.; Leiponen, A.; Thomas, L.D. Building an organizational digital twin. Bus. Horiz. 2020, 63, 725–736.

- Caesar, B.; Hänel, A.; Wenkler, E.; Corinth, C.; Ihlenfeldt, S.; Fay, A. Information Model of a Digital Process Twin for Machining Processes. In Proceedings of the Emerging Technologies and Factory Automation, Vienna, Austria, 8–11 September 2020; pp. 1765–1772.

- Caporuscio, M.; Edrisi, F.; Hallberg, M.; Johannesson, A.; Kopf, C.; Perez-Palacin, D. Architectural concerns for digital twin of the organization. In Proceedings of the Software Architecture, L’Aquila, Italy, 14–18 September 2020; pp. 265–280.

- Becker, M.C.; Pentland, B.T. Digital twin of an organization: Are you serious? In Proceedings of the Business Process Management Workshops, Rome, Italy, 6–10 September 2021; pp. 243–254.

- Park, G.; Comuzzi, M.; van der Aalst, W. Analyzing Process-Aware Information System Updates Using Digital Twins of Organizations. In Proceedings of the Research Challenges in Information Science, Barcelona, Spain, 17–20 May 2022; pp. 159–176.

- OMG. Business Process Model and Notation (BPMN), version 2.0; OMG: Milford, MA, USA, 2011.

- Riss, U.V.; Maus, H.; Javaid, S.; Jilek, C. Digital twins of an organization for enterprise modeling. In Proceedings of the Practice of Enterprise Modeling, Riga, Latvia, 25–27 November 2020; pp. 25–40.

- Lo, C.; Chen, C.; Zhong, R.Y. A review of digital twin in product design and development. Adv. Eng. Inform. 2021, 48, 101297.

- Hartmann, D.; der Auweraer, H.V. Digital Twins. arXiv 2020, arXiv:abs/2001.09747.

- Scurria, L.; Risaliti, E.; Buss, D.; Kubo, P.; Tamarozzi, T.; Cornelis, B. Executable digital twin-prevent the early failure of a truck anchorage using smart virtual sensors. Int. J. Adv. Curr. Pract. Mobil. 2022, 4, 1309–1317.

- Hartmann, D.; der Auweraer, H.V. The Executable Digital Twin: Merging the digital and the physics worlds. arXiv 2022, arXiv:abs/2210.17402.

- Allamaa, J.P.; Patrinos, P.; der Auweraer, H.V.; Son, T.D. Sim2real for Autonomous Vehicle Control Using Executable Digital Twin. IFAC-PapersOnLine 2022, 55, 385–391.

- Valderas, P.; Torres, V.; Serral, E. Modelling and executing IoT-enhanced business processes through BPMN and microservices. J. Syst. Softw. 2022, 184, 111139.

- Bourr, K.; Corradini, F.; Pettinari, S.; Re, B.; Rossi, L.; Tiezzi, F. Disciplined use of BPMN for mission modeling of Multi-Robot Systems. In Proceedings of the Forum at Practice of Enterprise Modeling, Riga, Latvia, 24–26 November 2021; Volume 3045, pp. 1–10.

- Valderas, P. Supporting the Implementation of Digital Twins for IoT-Enhanced BPs. In Proceedings of the International Conference on Research Challenges in Information Science, Corfu, Greece, 23–26 May 2023; pp. 222–238.

- van der Aalst, W. Concurrency and objects matter! Disentangling the fabric of real operational processes to create digital twins. In Proceedings of the Theoretical Aspects of Computing, Tbilisi, Georgia, 27–29 September 2022; pp. 3–17.

- Corradini, F.; Re, B.; Rossi, L.; Tiezzi, F. A Technique for Collaboration Discovery. In Proceedings of the Business Process Modeling, Development and Support, Leuven, Belgium 6–7 June 2022; Volume 450, pp. 63–78.

- Carmona, J.; van Dongen, B.; Weidlich, M. Conformance checking: Foundations, milestones and challenges. In Process Mining Handbook; Springer: Berlin/Heidelberg, Germany, 2022; Volume 448, pp. 155–190.

- Fahland, D. Process mining over multiple behavioral dimensions with event knowledge graphs. In Process Mining Handbook; Springer: Berlin/Heidelberg, Germany, 2022; Volume 448, pp. 274–319.

- Di Francescomarino, C.; Ghidini, C. Predictive process monitoring. In Process Mining Handbook; Springer: Berlin/Heidelberg, Germany, 2022; Volume 448, pp. 320–346.

- Flavio Corradini; Sara Pettinari; Barbara Re; Lorenzo Rossi; Francesco Tiezzi; A BPMN-driven framework for Multi-Robot System development. Robotics and Autonomous Systems 2023, 160, 104322.