1. Introduction

The rechargeable battery revolution has led to substantial advancements in global and daily-life-applied electrification, since the first developed rechargeable lead-acid battery in 1860 by Gaston Planté

[1]. Rechargeable batteries are key components in modern portable electronics, including cell phones, laptop computers, and remote digital systems (cameras, radios, music players, sensors, controls, etc.). Rechargeable lithium-ion batteries (LIBs) are particularly significant for their high-energy density, long lifespan, and efficiency, making them crucial in the sustainable transition to electric vehicles (EVs) with energy densities of up to 500 Wh L

−1 and specific capacities of 350 Wh kg

−1, enabling driving distances beyond 500 km

[2][3][2,3].

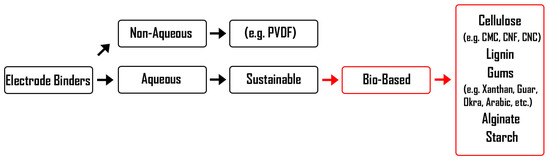

2. Bio-Based Binder Development for Anodes

The development of novel bio-based binder systems in the LIB industry is emerging to meet the current requirements of sustainability and improved battery performance to optimize resource usage. In particular, the use of binders soluble in aqueous-based systems is of high interest and importance for sustainable development

[4][5][6][7][8][9][21,24,26,31,32,33]. Due to health concerns and in line with the impending ban of perfluoroalkyl and polyfluoroalkyl substances (PFAS) in the European Union (as stated by ECHA’s Committee for Risk Assessment (RAC), ECHA/NR/23/10 and ECHA/NR/22/05), the development of environmentally friendly and non-toxic binder alternatives becomes essential for the near future. Water-soluble slurries are favorable to the introduction of environmentally friendly bio-based binders, such as cellulose

[4][9][10][11][12][13][21,33,34,35,36,37], gums

[14][15][16][17][18][19][20][30,38,39,40,41,42,43], starch

[21][22][23][44,45,46], lignin

[12][24][25][28,36,47], alginates

[26][27][48,49], etc.

[28][29][30][31][32][33][34][50,51,52,53,54,55,56]. The implementation of bio-based binders for LIBs offers a low environmental impact, a proven ability to improve electrode processing, and versatile functional properties with available functional and polar surface groups, such as carboxylic acid and hydroxyl groups. The bio-based binder class for anodes and cathodes, which is part of a broader sustainable polymer binder area, is the main focus of this re

svie

archw work, as illustrated in

Figure 1.

Figure 1. A sketch demonstrating the bio-based binder class focus of this resviearchw, including cellulose, lignin, various gums, sodium alginate, and starch binders for the preparation of LIB anode and cathode slurries.

The manufactured electrode performance is usually evaluated via measured parameters such as specific capacity (in mAh g

−1), the Coulombic efficiency (CE, in %), charging/discharging rate, cyclability, capacity retention (in %), etc. Coulombic efficiency evaluates the ratio of lithium charging capacity to the discharging capacity and is a measure of the electrochemical energy-storing reaction’s reversibility. Moreover, for the first cycle CE, a lower efficiency is usually observed for cathode and anode materials because of a change in the material cathode structure during delithiation

[35][57] and the formation of the SEI layer in the anode material

[36][37][11,58]. There are also other origins of Coulombic efficiency loss

[38][59]. Interestingly, SEI layer formation can be tuned by the binder selection toward improved cycling performance

[39][12]. The formation of a uniform and stable SEI layer due to binder properties was shown to improve the first cycle CE and reversible capacity for over 50 cycles

[40][41][60,61]. Thus, for new bio-based binder developments in LIB electrodes, it is important to evaluate the first cycle CE and the effect of binders on the formation of a stable SEI layer. The build-up of the SEI layer and the water content changes using aqueous binders and their effect on the battery performance were studied using X-ray photoelectron spectroscopy

[42][62].

Cellulose is the most-abundant biopolymer on Earth, exhibiting renewable, degradable, biocompatible, and cost-efficient properties. Cellulosic binders are available in various forms, from cellulose nanofibers (CNFs) of a high aspect ratio, cellulose nanocrystals (CNCs), microparticles of carboxymethyl cellulose (CMC), and microscale pulp fibers. In the LIB applications, CMC (a derivative of cellulose with carboxymethyl groups of varying degrees of substitution), as well as nanocelluloses including CNFs have been reported as binders. CMC has shown promising results and is currently used commercially in anode formulations because of its low cost and sustainability compared to PVDF and its favorable solubility in water. Moreover, the surface chemistry of CMC decorated with carboxymethyl groups provides a favorable chemical bonding with the graphite active material. Although CMC is performant as a binder and provides shear-thinning behavior to the slurry

[43][63], it possesses high stiffness and a small fracturing strain, which can affect the overall mechanical properties and long-term performance. Hence, CMC is commonly combined with a rubber (typically SBR) to optimize the mechanical properties of the slurry coated on the current collector. In particular, Na-CMC combined with fossil-based SBR copolymer provides a cost-efficient binder solution of anodes in LIBs

[10][34]. It has been demonstrated that, in comparison with other common binders, a CMC-based binder solution in LIB Si-based anodes can provide a specific capacity of about 1153 mAh g

−1 for 35 cycles

[44][23] and 1100 mAh g

−1 for 70 cycles

[45][64]. The cyclic performance of an active mass loading of 2.5 mg Si cm

−2 using the CMC binder with a binder content from 4 to 8 wt% also demonstrated a high capacity of 1000 mAh g

−1 (4 wt% binder) to 1900 mAh g

−1 (8 wt% binder) for 50 cycles

[46][65]. Furthermore, CMC promotes a specific bonding between the carboxylic groups and the OH groups on the Si oxide surface. Another study has demonstrated a specific capacity of 1544 mAh g

−1 after 100 cycles when CMC binder was used

[24][28]. The initial CE was 85.3% with a further gradual increase after the first cycles. In the case of common graphite electrodes, CMC combined with SBR and crosslinked poly(acrylic acid) (PAA) provides a stable specific capacity of more than 300 mAh g

−1 for the first 35 cycles

[40][60]. The capacity retention was reported to be 96.6% at 0.5 C over 35 cycles in the case of a coin half-cell test. It was also found that such a binder combination (CMC/SBR/PAA) is very efficient for a thick graphite anode and enhances electrochemical performance. Sulfobetaine methacrylate modification of carboxymethyl cellulose has also demonstrated improved binding properties and a specific capacity of 141 mAh g

−1 at a 0.1 C rate using a graphite anode in LiFePO

4 [13][37] in comparison to 108 mAh g

−1 for pure CMC. The SEI layer was formed during the first three cycles at a 0.1 rate, and the discharged capacity loss was 12.2% for CMC binder and 6.6% for carboxymethyl cellulose with sulfobetaine methacrylate modification. The first step CE for both binders was 75% (CMC) and 83% with a gradual improvement to about 90 and almost 100% after three cycles. The limitations of using CMC as a binder in LIB anodes are the possibilities for trapping electrons within the carbon coating and decreasing the electronic conductivity and possible decrease of Coulombic efficiency due to the formation of -CH

2COOLi groups

[8][47][32,66]. Furthermore, the binder decomposition can contribute to the formation of a solid electrolyte interphase layer. In the context of sustainable development and health safety

[48][67], the required use of fossil-based SBR in combination with CMC is also a limitation that remains to be addressed toward fully bio-based binders for anode slurries. The CMC and Na-CMC binder effect on the anode slurry’s rheological properties and interaction with graphite and carbon black was studied in the literature

[49][50][68,69]. The Na-CMC binder has also demonstrated good coating properties and a good performance of about 300 mAh g

−1 at 0.1 C at a binder content of 10 wt%

[51][70]. The first cycle CE was about 90% with a further increase to above 99.5%, which can be attributed to the formation of the SEI layer

[42][51][62,70]. The carboxymethyl cellulose lithium binder synthesized using a weak acid was also evaluated and compared to the Na-CMC binder

[52][53][71,72].

Bio-based CNFs are an interesting binder candidate for aqueous-based anode slurry preparation as their high aspect ratio enables the formation of a strong web-like network around the graphite active material for freestanding and flexible anodes

[54][55][73,74]. Modified cellulosic fibers, particularly those with aldehyde and carboxyl functionalities

[56][75], hold promise as effective binders for graphite anodes in LIBs, offering both improved electrochemical performance and mechanical strength. In particular, TEMPO–periodate-oxidized cellulose electrodes showed higher specific capacities at high cycling rates (10% increase at 400 mA/g), because of the enhanced chemical compatibility with both graphite and the electrolyte, as well as an ability to form a strong fibrillar network that prevents structural damage upon graphite expansion

[57][76]. Additionally, a sustainable approach was reported to produce freestanding CNF–graphite hybrids (90 wt% graphite) exhibiting energy storage performance (330 mAh/g) and processing speed on par with commercial graphite anodes

[58][77]. These eco-friendly electrodes possess the remarkable ability to be completely recycled, reformed, and reused without compromising their original performance. TEMPO-oxidized CNFs as a binder demonstrated excellent electrochemical performance with a specific capacity of graphite electrodes of 345 mAh/g at C/10, comparable to PVDF graphite anodes (350 mAh/g)

[54][73]. TEMPO-oxidized CNFs have also been used in combination with CMC for the stabilization of Si-anodes in LIBs, where the CNFs act both as the reinforcing material and binder additive

[54][73].

Lignin, another biopolymer present in woody biomass, is currently experiencing a high research interest in many relevant areas, as well as various industrial applications. Recent publications in the field of bio-based binders for LIBs have also demonstrated that lignin offers good applicability and has a positive impact on electrochemical performance when introduced to anodes

[12][24][25][59][60][28,36,47,78,79]. Lignin is a macromolecule, and its mechanical properties need to be optimized for a binder implementation

[49][68]. The usual strategy is using plasticizers such as polyethylene glycol (PEG)

[25][47], grafting, for instance with poly(acrylic acid)

[24][28], and other synthesis routines

[61][80]. In the case of the LiFePO

4 cathode material and the anode material consisting of graphite, it has been shown that the lignin content needs to be increased up to 8 wt%, and a stable specific capacity of 305 mAh g

−1 was achieved

[25][47] at 0.1 C with a Coulombic efficiency of above 99% for the first 10 cycles. The specific capacity was shown to decrease to 160 mAh g

−1 at a higher rate of 1 C. The CE was about 84% in the first cycle and increased above 98% after four cycles. The stability was demonstrated to be good at a C/4 rate for 50 cycles

[25][47]. Grafting lignin with polyacrylic acid and copolymeric binders has also demonstrated favorable applicability for the next-generation anode containing Si-nanoparticles

[24][28]. A stable specific capacity limited at 800 mAh g

−1 remained for over 940 cycles for the silicon microparticle anode with a maximum reached specific capacity of 1914 mAh g

−1 [24][28]. The initial CE was 91% with a gradual increase after the first cycles. In the case of silicon-/graphite-based electrodes, the implementation of a grafted lignin binder resulted in a specific capacity of 492 mAh g

−1, which remained stable for 100 cycles

[24][28]. Lignin (L) binder modification with polyacrylic acid (PAA) copolymeric binders (L-co-PAA) has also demonstrated promising results

[62][81]. It has been shown that a stable specific capacity of 939 mAh g

−1 was obtained for more than 1000 cycles using the silicon-based electrodes

[62][81].

Various

polysaccharides, such as guar gum

[15][16][63][38,39,82], gum arabic

[14][30], okra gum

[17][40], xanthan gum

[18][41], tragacanth gum

[19][42], carrageenan

[33][55], etc.

[31][64][65][66][53,83,84,85], are often applied as a binder for LIB anodes including current and next-generation technologies utilizing Si. The gums offer good mechanical property flexibility, available hydroxyl groups, promoting chemical bonding with Si nanoparticles, and often, improved ion conductivity. It has been demonstrated that the introduction of guar gum led to better mechanical and viscosity properties. Furthermore, a specific capacity of 2222 mAh g

−1 was obtained after 100 cycles

[63][82]. The initial CE was 88.3%, and the maximum reached 99.5% after 100 cycles. The specific capacity of 1000 mAh g

−1 remained over 930 cycles for Si-nanoparticle-based anodes

[63][82]. Modification of guar gum with hydrogenated carboxyl nitrile rubber has demonstrated improved flexibility to accommodate Si volume expansion and improved electrochemical performance for Si-based anodes in LIBs

[16][39]. A performance with a specific capacity of 1402 mAh g

−1 for 500 cycles at 800 mA g

−1 and 1128 mAh g

−1 at 6000 mA g

−1 was reported. The good electrochemical performance was attributed to the formed covalent and hydrogen bonds between the binder and Si particles

[16][39]. Introducing guar gum into graphite-based anodes in LIB has demonstrated a stable specific capacity of 310 mAh g

−1 and a capacity retention of 96% for 50 cycles at a C/10 rate

[65][84]. Enhanced mechanical and electrochemical efficiencies were also observed in the case of a xanthan gum binder for LIBs

[18][47][41,66]. The specific capacity was found to be relatively stable for the graphite anode and was near 250 mAh g

−1 after 180 cycles

[18][41]. The initial CE was 91.2%. Furthermore, graphite-based electrodes demonstrated a favorable and stable rate capability when the specific capacity remained above 300 even at a 2 C rate

[18][41]. The implementation of xanthan gum as a binder on a Si-based graphene anode has also demonstrated an improved specific capacity of 725 mAh g

−1 for 50 cycles

[66][85] at 400 mA g

−1. Gum arabic and okra gum have also demonstrated good applicability to next-generation Si-based anodes. A specific capacity of above 2000 mAh g

−1 for 300 cycles was achieved using gum arabic binder at a C/10 rate

[14][30], while the initial CE was below 90%. Limiting the specific capacity at 1000 mAh g

−1 demonstrated improved long-term stability for 1000 cycles at 1 C

[14][30]. The application of gum arabic binder in a graphite-based anode has also demonstrated a good performance, and a specific capacity above 200 mAh g

−1 was obtained for 50 cycles at a 0.1 C rate

[65][84]. A stable high specific capacity of 1434 mAh g

−1 and a CE of 99% for 50 cycles at a rate of 0.1 C was achieved for a Si-based anode using okra-extracted gum

[17][40]. Carrageenan is another natural polysaccharide, usually extracted from seaweeds, with available hydroxyl and sulfonyl surface groups of high suitability for strong hydrogen bonding with Si and improving ion conductivity

[65][84]. The specific capacity was measured around 2031 mAh g

−1 after 100 cycles for the Si-based anode at a rate of 0.5 C

[33][55]. The reversible capacity was found to be around 1623 mAh g

−1 with a capacity retention of 51.49% after 300 cycles

[33][55]. In the case of graphite-based anodes, the specific capacity using a carrageenan-based binder was found to be around 300 mAh g

−1 for the first 20 cycles at 0.1 C

[65][84].

Sodium alginate is another natural and linear polysaccharide with surface carboxyl groups, which is derived from, e.g., algae biomass. Sodium alginate has been investigated as a water-soluble binder in the literature; see

[26][27][67][48,49,86]. The implementation of sodium alginate as a binder in a graphite-based anode has demonstrated a stable specific capacity of about 300 mAh g

−1 for about 300 cycles at a rate of 0.1 C

[65][84]. In Si-based anodes, the addition of sodium alginate has also demonstrated an improved and stable specific capacity. A Si–graphene-based anode with a sodium alginate binder provided a specific capacity of 780 mAh g

−1 after 50 cycles with a retention capacity of about 43.8% of initial performance. Grafting and cross-linking of alginate with polyacrylic acid have improved the stability and electrochemical efficiency of graphite–silicon anodes

[27][49]. A stable specific capacity of 849 mAh g

−1 for 100 cycles at a 0.1 C rate was achieved. It was also demonstrated that pristine alginate and only grafted alginate without cross-linking did not provide a high stable capacity

[27][49]. The initial CE was improved from 68.9% to 72.8% for the cross-linked alginate binder. In another study, the specific capacity was found to decrease to around 1000 mAh g

−1 for 200 cycles at a1000 mA g

−1 rate for a Si-based anode

[32][54].

Starch is another attractive water-based binder for LIBs due to its low price and high biodegradability. Furthermore, starch functional surface groups can be tuned via various modification processes

[21][22][23][28][44,45,46,50]. The introduction of starch into silicon-based anodes provided discharge capacity values of below 500 mAh g

−1 after 100 cycles, whereas fluorinated starch has demonstrated a more-stable and significantly improved capacity of 1864–2874 mAh g

−1 after 100 cycles

[23][46]. The discharge capacity of around 600 mAh g

−1 after 200 cycles was achieved using fluorinated starch as a binder in Si–graphite anodes

[23][46]. Starch modification with polyethylene glycol has also demonstrated favorable applicability for Si-based anodes, and a specific capacity of about 1100 mAh g

−1 was reached after 300 cycles at a CE of 99.9%

[22][45]. The initial CE for pure starch was only 59%, whereas the modified starch’s initial CE was around 85%. These results were reported to be better than for the CMC-, starch-, and PVDF-based systems

[22][45]. Cross-linking starch with maleic anhydride was reported to improve the charge capacity to about 2106 mAh g

−1 after 200 cycles, whereas uncross-linked starch demonstrated a gradual decrease of capacity below 500 mAh g

−1 after 500 cycles for Si-based anodes

[28][50]. Starch oxidation contained oxidized amylose, and amylopectin was also proposed as a binder system for Si-based anodes in LIBs, for which a specific capacity of about 2000 mAh g

−1 for 120 cycles was reached

[21][44]. The development and implementation of new bio-based binders for LIBs is not limited to this re

svie

archw, and new results are reported continuously.