Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Dean Liu and Version 3 by Dean Liu.

Although orthotropic steel decks (OSDs) have been widely used in the construction of long-span bridges, there are frequently reported fatigue cracks after years of operation, and the bridge deck overlay also presents severe damage due to OSD crack-induced stiffness reduction. Ultra-high performance concrete (UHPC), recognized as the most innovative cementitious composites and the next generation of high-performance materials, shows high strength, ductility, toughness, and good performance on durability. After its first application to the OSD bridge in the early 2000s, the orthotropic steel–UHPC composite deck has been comprehensively studied worldwide.

- composite deck

- OSD

- UHPC

- stress behavior

- fatigue

1. Introduction

For bridge engineering applications, the fundamental function of the bridge deck is to directly bear, distribute, and transfer the wheel loads. The bridge deck may also react as part of the main girder to bear force acting on the bridge superstructure. Highway bridges normally adopt three types of bridge decks, namely the concrete deck, steel deck, and steel–concrete composite deck [1]. It is well known that under the action of wheel loads, the concrete decks produce small deformation due to the high stiffness of the deck system. However, its heavy dead load and low tensile strength of concrete limit its application in bridge engineering. The steel bridge deck is usually made of an orthotropic steel deck (OSD), which has light weight, high bearing capacity, and significant overloading capacity. However, this type of deck system can produce large deformation under wheel load due to its low structural stiffness. As a result, fatigue cracking and pavement damage are frequently reported after years of operation. The steel–concrete composite deck includes several types of structures, such as the orthotropic steel–concrete composite deck, the orthotropic steel–steel fiber reinforced concrete composite deck, and the orthotropic steel ultra-high performance concrete (steel–UHPC) composite deck. The first two can only be applicable to medium and small-span bridges because of the large thickness overlay and its significantly increased dead loads. They may also be prone to cracks under concentrated wheel loading due to the low tensile strength of concrete. With the development of the UHPC, the orthotropic steel–UHPC composite deck is widely used in various types of bridge structures with different span lengths, especially in long-span bridges.

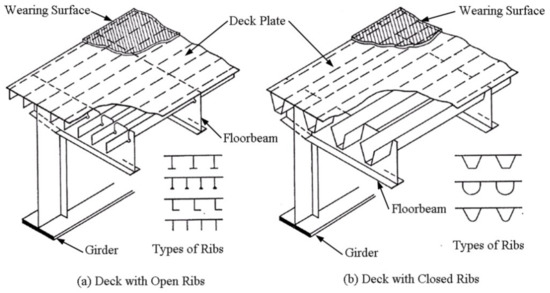

The OSD, consisting of the deck plate, respectively, stiffened by the floorbeam and the ribs in bridge transverse and longitudinal directions, presents different structural properties in two orthogonal directions. The OSD was first used in Germany as the bridge deck to build the steel bridge. After the Second World War, the growing demand for post-war traffic recovery made OSDs widely used in bridge engineering [2]. Since the Severn Bridge in the UK adopted the OSD steel box girder for the first time, the OSD has become the most popular deck system for long-span bridges. Figure 1 shows two structural forms consisting of open ribs or closed ribs, with the traditional pavement on the deck plate.

Figure 1. Typical structural layout of OSD.

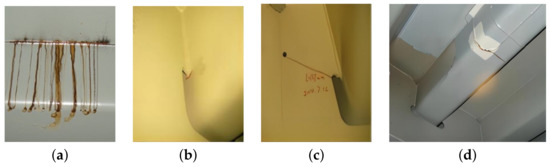

The OSD has been widely used in long-span suspension bridges and cable-stayed bridges due to its remarkable advantages, but the OSD is not a perfect structure since there are many welds in the orthotropic steel bridge deck, which have small defects. Under the cyclic loading of the vehicle, the defects lead to the emergence of fatigue cracks. With the extent of the fatigue cracks, the cross-section weakens significantly and the stress concentration is severe [3][4][5]. Fatigue cracking is frequently reported on bridges, particularly for those with large traffic volumes and serious overloading trucks, the typical locations of fatigue cracking are shown in Figure 2 [6]. The fatigue cracking may also lead to frequent maintenance and replacement of bridge deck pavement, which presents a great impact on local traffic. Therefore, avoiding fatigue cracking and pavement damage is one of the major long-term considerations in the bridge engineering community.

Figure 2. The typical locations of fatigue cracking: (a) Rib-to-deck crack; (b) Rib-to-floorbeam crack; (c) Cutout crack; (d) Rib splice crack.

With the growing increase in bridge main span and the rapid increase in traffic volume, fatigue cracking of the OSD becomes a severe challenge in bridge engineering. Hence, many scholars have conducted extensive research on this topic, including laboratory model tests, FEM analyses, and field tests. Wang [7] conducted full-scale fatigue tests on the OSD of a cable-stayed bridge, and found that the impact of welding residual stress on the fatigue life of structural details in the compressive stress zone cannot be ignored. Zhang’s [8] research shows that there are significant differences in the fatigue of vulnerable parts of OSDs, and the stress distribution in the vicinity of fatigue cracks constantly changes as the cracks propagate. Zweraeman [9] believes that the small stress amplitude generated by high-order vibration of steel bridges under random traffic flow, which is lower than the fatigue cutoff limit, can also cause fatigue damage to the steel bridge. Connor [10][11] conducted controlled loading tests and random vehicle flow tests on two different bridges, and studied the effect of out-of-plane deformation on the fatigue life of the diaphragm based on on-site test data.

The deck of a steel bridge faces the challenges of orthotropic deck cracking and easy damage to the pavement layer, which conventional techniques cannot fundamentally solve [12]. Only by relying on breakthroughs in materials and developing corresponding new structural systems can researchers find effective solutions to the difficult problems in traditional steel bridges and steel–concrete composite bridges. Compared with traditional orthotropic bridge decks, the steel–UPHC composite bridge structure has the following two characteristics: Firstly, it can significantly improve the stiffness of the bridge deck. Secondly, the synergistic effect of the UHPC layer and orthotropic steel plate can significantly reduce the fatigue stress amplitude in the orthotropic plate under local wheel loads. The steel–UHPC composite bridge structure is in its initial stage of practical application, and its superior performance needs to be known and accepted through a process. Therefore, summarizing existing literature and analyzing the characteristics of static, shear, and fatigue performance of composite structures under different conditions have important guiding significance for subsequent theoretical research, experimental development, and engineering applications of this structure.

Mechanical properties and fatigue problems have always been difficult and hot issues that must be faced in the development of orthotropic bridge deck structures and even the entire steel structure field.

2. The Orthotropic Steel–UHPC Composite Deck

The UHPC is an innovative cement-based composite material, which was first developed by French scholars in 1993. The material consists of cement, silica fume, fine aggregate, fiber, water reducer and other materials, as shown in Figure 3 and is constructed according to the principle of maximum compactness [13][14]. The goal is to minimize the internal pores and micro-cracks of the material, so as to obtain excellent mechanical properties and durability.

Figure 3. Material used to form UHPC: (a) Cement; (b) Silica fume; (c) Quartz sand; (d) Fly ash; (e) Water reducer; (f) Fiber.

Table 1. UHPC and NC main mechanics and durability index.

| Material Type | UHPC | NC | References |

|---|---|---|---|

| Compressive strength/MPa | 120~230 | 30~60 | [16][17][18][19][20] |

| Flexural Strength/MPa | 15~60 | 2~5 | [16][17][18][19][20] |

| Elasticity modulus/GPa | 40~60 | 30~40 | [18][19][20] |

| Creep coefficient | 0.2–0.3 (High temperature steam curing) | 1.4~2.5 | [18][19] |

| Diffusion coefficient of chloride ion/(m22/s) | <0.02 × 10−11−11 | >1 × 10−11−11 | [16][18][20] |

| Electrical resistivity/(kΩ·�·cm) | 1133 | 96 (C80) | [18] |

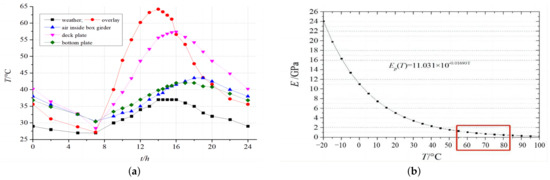

Figure 4. Measured temperature of deck overlay and its elastic modulus of EAC against temperature: (a) Measured temperature of steel girder and its overlay; (b) Elastic modulus of EAC against temperature.

Figure 5. UHPC construction process.

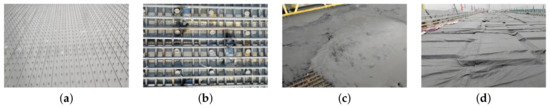

Figure 56. UHPC construction process: (a) Welded shear stud; (b) Steel mesh; (c) Pouring UHPC; (d) Steam curing.

3. Engineering Application of Orthotropic Steel–UHPC Composite Deck

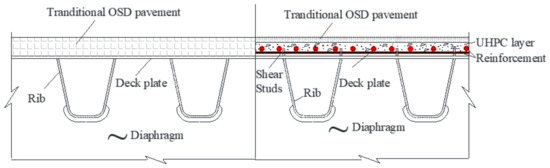

De Jong and Kolstein first proposed the combination of the UHPC and the OSD to repair existing steel bridge cracks [23]. They first removed the bridge deck pavement of the Dutch Garland Bridge (Caland Bridge) and replaced it with RHPC (reinforced high-performance concrete), as shown in Figure 67. Then, they carried out FEM and laboratory tests and found that the local bending stress was reduced by 80% on the deck plate side. Although they proposed the idea to reduce the fatigue stress of OSD, the steel and UHPC are not treated as a composite structure since the UHPC layer and steel panels worked together through a thin bonding layer between them, in which the composite action is weak and only the load distribution function of the UHPC layer could be considered.

Figure 67. Deck replacement of Galand Bridge using glued UHPC layer.

Figure 78. Mafang Bridge using steel–UHPC composite deck: (a) Under construction; (b) After 12 years in service.

Figure 89. Bridge deck under construction: (a) Fochen New Bridge; (b) Hangrui Dongting Lake Bridge; (c) Queshi Bridge; (d) Fengxi Bridge.

Table 2. Newly built bridge using orthotropic steel–UHPC composite deck in China.

| Bridge Name | Location | Span Arrangement/m | Type | Year |

|---|---|---|---|---|

| Fochen | Foshan, Guangdong | 58.51 + 112.8 + 58.51 | ① | 2014 |

| Hexi Trans. Hub | Changsha, Hunan | 54 | ① | 2015 |

| Beiguan Tonghuihe | Tongzhou, Beijing | 11.5 + 60 + 18.5 | ② | |

| Haihe | Tianjin | 310 + 4 × 48 | ③ | |

| Longxi Interchange Ramp | Jiangmen, Guangdong | 28 + 50 + 28 | ① | 2016 |

| Shendang | Jiaxing, Zhejiang | 72 |

① girder bridge; ② arch bridge; ③ cable-stayed bridge; ④ suspension bridge.

Table 3. Deck replacement using steel–UHPC composite structure.

| Bridge Name | Location | Span Arrangement/m | Type | Year | ||||

|---|---|---|---|---|---|---|---|---|

| Mafang | Zhaoqing, Guangdong | 14 × 64 | ① | 2011 | ||||

| Queshi | Shantou, Guangdong | 518 | ③ | 2016 | ||||

| Riyue-Chengwen Road Expressway | Chengdu, Sichuan | 37 + 46 + 46 (Left) 46 + 46 + 42 (Right) | ① | 2018 | ||||

| Junshan | Wuhan, Hubei | 48 + 204 + 460 + 204 + 48 | ③ | |||||

| Lanzhou Donggang Interchange | Lanzhou, Gansu | 595 | ① | 2019 | ||||

| ① | ||||||||

| Songpu | JShanghai | 419.6 | ① | 2020 | Jiaoshanmen | Jiaxing, Zhejiang | 36.5 | ① |

| Fute Bay | ||||||||

| Shengli Yellow River | Dongying, Shandong | 682 | ③ | Beiguan Street | Tongzhou, Beijing | 30 + 40 + 70 + 40 + 30 | ② | |

| Foshan, Guangdong | ||||||||

| 112 + 2 × 200 + 112 | ||||||||

| ① | ||||||||

| Hongtang | Fuzhou, Fujian | 50 + 150 + 150 + 50 | ④ | Lichuan | Dongguan, Guangdong | 138 | ③ | |

| Fengxi | Zhuzhou, Hunan | 300 | ④ | |||||

| Chetian River | Guiyang, Guizhou | 32 + 56 + 32 | ① | 2017 | ||||

| Tongguan | Changsha, Hunan | 50 + 50 | ① | |||||

| Wuyi | Huzhou, Zhejiang | 60 + 128 + 60 | ① | |||||

| Gangxia North Trans. Hub | Shenzhen, Guangdong | 30 + 2 × 46 + 34 + 32 | ① | |||||

| Shele | Taiyuan, Shanxi | 30 + 150 + 150 + 30 | ③ | |||||

| Hangrui Dongting Lake | Yueyang, Hunan | 1480 | ④ | |||||

| Zhaohua | Xiangtan, Hunan | 168 + 228 | ④ | |||||

| 2018 | ||||||||

| 2021 | Jinan Guodian Interchang | Jinan, Shandong | 21.5 + 22 + 26 + 22 + 20 | ① | ||||

| Beiyuan Expressway West | ||||||||

| Yichang Yangtze River | Yichang, Hubei | Jinan, Shandong | 30 + 47 + 30 | ① | ||||

| 960 | Da’an North Interchange | Baicheng, Jilin | 31.2 | ① | ||||

| Tiansheng Harbour and Ferry | Nantong, Jiangsu | 141.5 + 336 + 141.8 | ② | |||||

| Beijiang River Fourth | Qingyuan, Guangdong | 100 + 218 + 100 | ③ | |||||

| Maogang River | Shanghai | 110 + 225 + 110 | ③ | |||||

| Tianbaowan | Chengdu, Sichuan | 230 | ① | 2019 | ||||

| Hongfenglu | Changsha, Hunan | 30 + 70 + 30 | ① | |||||

| Longsheng | Huizhou, Guangdong | 40 + 185 + 40 | ② | |||||

| ④ | Haiwen | Haikou, Hainan | 230 + 230 | ③ | ||||

| Zhongxing | Ningbo, Zhejiang | 64 + 86 + 400 + 86 + 64 | ③ | |||||

| Jingzhou Yangtze River | Jingzhou, Hubei | 98 + 182 + 518 + 182 + 98 | ③ | |||||

| Yunlongwan | Chengdu, Sichuan | 30 + 80 + 205 + 80 + 30 | ④ | |||||

| Qinglongzhou | Yiyang, Hunan | 60 + 110 + 260 + 110 + 60 | ④ | |||||

| Dashahe 1st Road Crossing | Shenzhen, Guangdong | 75 | ② | 2020 | ||||

| Hutong Yangtze River | Suzhou, Jiangsu | 140 + 462 + 1092 + 462 + 140 | ③ | |||||

| Jiangxinzhou Yangtze River | Nanjing, Jiangsu | 80 + 218 + 2 × 600 + 218 + 80 | ③ | |||||

| Rongjiang | Jieyang, Guangdong | 400 | ③ | |||||

| Xinglinbao | Zhangjiakou, Hebei | 217 | ③ | |||||

| Taizicheng No.1 | Zhangjiakou, Hebei | 50 + 100 + 100 + 50 | ③ | |||||

| Honghe | Yuanyang, Yunnan | 700 | ④ | |||||

| Qiushi Road Steel | Urumqi, Xinjiang | 42 + 68 + 68 + 42 | ① | 2021 | ||||

| Shennong Lake | Changzhi, Shanxi | 130 + 130 | ③ | |||||

| Qipanzhou | Huangshi, Hubei | 340 + 1038 + 340 | ④ | |||||

| Shachong | Dongguan, Guangdong | 9 + 88 + 9 | ② | 2022 | ||||

| Binhai Bay | Dongguan, Guangdong | 60 + 200 + 200 + 60 | ③ | |||||

| Sangyuanzi Yellow River | Lanzhou, Gansu | 949 + 328 + 959 | ③ | |||||

| Fulong Xijiang Grand | Foshan, Guangdong | 500 | ③ | |||||

| Danjiangkou Shuikute | Danjiangkou, Hubei | 106.2 + 760 + 106.2 | ③ | |||||

| Yellow River Fenghuang | Jinan, Shandong | 70 + 168 + 428 + 428 + 168 + 70 | ④ |

① girder bridge; ② arch bridge; ③ cable-stayed bridge; ④ suspension bridge.

References

- Zhao, Q. Steel Bridge-Steel Structure and Composite Structure Bridge; China Communications Press: Beijing, China, 2017; pp. 39–45.

- Wang, T.; Zhu, Z.W.; Xiang, J.J. Stress response characteristics of arcuate notch of orthotropic steel bridge panel under random traffic flow. Highw. Eng. 2016, 41, 66–71.

- Yang, S.L.; Shi, Z. Current Research of Fatigue Damage in Orthotropic Deck Plates of Long Span Steel Box Girder Bridges in China. Bridge Constr. 2017, 47, 60–65.

- Kim, T.W.; Baek, J.; Lee, H.J.; Lee, S.Y. Effect of pavement design parameters on the behaviour of orthotropic steel bridge deck pavements under traffic loading. Int. J. Pavement Eng. 2014, 15, 471–482.

- Zhang, Q.H.; Bu, Y.Z.; Li, Q. Review on Fatigue Problems of Orthotropic Steel Bridge Deck. China J. Highw. Transp. 2017, 3, 15–28.

- Zhu, Z.W.; Huang, Y.; Wang, T.; Wen, P.X.; Xiang, J.J. Fatigue performance evaluation of composite bridge panels of Fochen Extension Bridge under random traffic flow. Highw. Eng. 2016, 31, 3267–3277.

- Wang, C.S.; Fu, B.N.; Zhang, Q.; Feng, Y.C. Fatigue Test on Full-scale Orthotropic Steel Bridge Deck. China J. Highw. Transp. 2013, 3, 69–76.

- Zhang, Q.H.; Cui, C.; Bu, Y.Z.; Li, Q. Study on fatigue features of orthotropic decks in steel box girder ofHong Kong-Zhuhai-Macao Bridge. China Civ. Eng. J. 2014, 9, 110–119.

- Zweraeman, F.J.; Frank, K.H. Fatigue Damage under Variable Amplitude Loads. J. Struct. Eng. 1988, 114, 67–83.

- Connor, R.J.; Fisher, J.W. Consistent Approach to Calculating Stresses for Fatigue Design of Welded Rib-to-Web Connections in Steel. J. Bridge Eng. 2006, 11, 517–525.

- Connor, R.J.; Fisher, J.W. Identifying Effective and Ineffective Retrofits for Distortion Fatigue Cracking in Steel Bridges Using Field Instrumentation. J. Bridge Eng. 2006, 11, 745–752.

- Shao, X.D.; Hu, J.H. The Steel-UHPC Lightweight Composite Bridge Structures; China Communications Press: Beijing, China, 2015; pp. 30–31.

- Bache, H.H. Model for strength of brittle materials built up of particles joined at points of contact. J. Am. Ceram. Soc. 1970, 53, 654–658.

- Bache, H.H. Densified cement ultra fine particle based materials. In Proceedings of the the Second International Conference on Superplasticizers in Concrete, Ottawa, ON, Canada, 10–12 June 1981.

- Zhao, M.; He, X.F.; Qiu, M.H.; Yan, B.F.; Shao, X.D. Research on Design and Application of Fully Prefabricated Steel-UHPC Lightweight Composite Girder in Medium and Small Span Girder Bridge. Highw. Eng. 2019, 44, 63–66.

- Wan, J.J.; Du, R.Y.; Jie, X.D.; Dai, L.; Zhou, X.P.; Lu, Y. Study on Preparation of Ultra High Performance Concrete (UHPC). Jiangxi Build. Mater. 2022, 12, 7–9.

- Yao, S.; Yang, Z.P.; Ge, W.J.; Hu, Y.X.; Li, W.; Sun, C.Z.; Yan, W.H.; Cao, D.F. Analysis on working and mechanical properties of ultra-high performance concrete. Build. Struct. 2023, 53, 142–147.

- Shao, X.D.; Qiu, M.H.; Yan, B.F.; Luo, J. A Review on the Research and Application of Ultra-high Performance Concrete in Bridge Engineering Around the World. Mater. Rep. 2017, 31, 33–42.

- Jiang, X.; Tang, D.Y.; Hu, S.T.; Zhang, Z.Y.; Shi, L. Application of Ultra-High Performance Concrete in Bridge Engineering all over the World. Railw. Eng. 2021, 61, 1–7.

- Shao, X.D.; Fan, W.; Huang, Z.Y. Application of Ultra-High-Performance Concrete in engineering structures. China Civ. Eng. J. 2021, 54, 1–13.

- Teng, H.J.; Zhu, Z.W.; Li, J.P. Research on Vertical Temperature Gradient of Steel Box Girders on Steel Bridge Deck Based on Field Measurements. J. Railw. Sci. Eng. 2021, 18, 30–37.

- Wang, Q.H.; Qiao, H.S.; Dario, D.D.; Zhu, Z.W.; Tang, Y. Seismic performance of optimal Multi-Tuned Liquid Column Damper-Inerter (MTLCDI) applied to adjacent high-rise buildings. Soil Dyn. Earthq. Eng. 2021, 143, 106653.

- De Jong, F.B.P.; Kolstein, M.H. Strengthening a bridge deck with high performance concrete. In Proceedings of the 2004 Orthotropic Bridge Conference, Sacramento, CA, USA, 25–27 August 2004.

- Ekkehard, F.; Kai, B.; Michael, S. Gärtnerplatz-Bridge over River Fulda in Kassel: Multispan Hybrid UHPC-Steel Bridge. In Proceedings of the UHPFRC 2009, Marseille, France, 17–18 November 2009.

- Ziad, H.; Marco, N.; Claude, S.; Grégory, G.; Davy, P.; Daniel, B. Innovative solution for strengthening orthotropic decks using uhpfrc: The Illzach Bridge. In Proceedings of the Symposium on Ultra-High Performance Fibre-Reinforced Concrete, UHPFRC 2013, Marseille, France, 1–3 October 2013.

- Li, J.; Feng, X.T.; Shao, X.D.; Gu, J.K. Research on Composite Paving System with Orthotropic Steel Bridge Deck and Thin RPC Layer. J. Hunan Univ. Nat. Sci. 2012, 39, 1–12.

More