1. Introduction

Food waste exists in solid, semi-solid and liquid form and is rich in compounds, including proteins, carbohydrates, lignin, lipids, cellulose, and other elements. These substances usually exist in the diluted form in liquid food waste such as potato-processing wastewater, apple residue sludge and whey from the dairy industry [1][2][3][36,37,38]. Because of this rich composition, food waste is categorised as an inexpensive, high-potential second-generation raw material [4][39]. The foundation of any procedure for valorising food waste is the composition of the generated food waste [5][40]. Food waste has a diverse and inconsistent composition that depends on a specific population’s region, season, and dietary patterns. Typically, heterogeneous food waste could comprise above 50% of total sugars, over 40% of starch, 45% of proteins, and less than 2% of cellulose [6][41]. The substances in food waste can be used for the manufacture of developing biofuels, bulk chemicals, enzymes, food supplements, nutraceuticals, bio-adsorbents (e.g., activated charcoal), antimicrobial products (e.g., antibiotics), bio-based fertilisers, bioplastics, among several other applications [2][7][8][37,42,43].

2. Composting

Food waste composting is a controlled process in which a complex microbial community degrades food wastes into their basic constituents in the presence or absence of oxygen

[9][10][47,48]. Composting is divided into four stages: mesophilic, thermophilic, cooling, and maturation. Several factors influence the duration of composting, including pH, Carbon-Nitrogen (C/N) ratio, moisture, feedstock nature (type and composition of food waste), oxygen availability (aeration), and composting technology

[11][12][49,50]. Aerobic composting is the most efficient type of degradation, producing mature compost in a shorter period (4 weeks) compared to anaerobic composting, which can take up to 2 or 3 years

[13][51]. Composting can be hastened by turning the compost pile and shredding the feedstock materials (i.e., food waste) on a regular basis, as well as using efficient microbial species, chemical nitrogen activators, worms, natural minerals, plant-based bulking agents (e.g., agricultural waste) and a variety of additives and amendments, like biochar

[14][52].

The product of composting is a stabilised substance that is rich in organic matter known as compost. Compost finds use in agriculture because it promotes soil fertility as well as crop development and growth. It has been employed as an organic fertilizer to replace chemical fertilizers, whose excessive and uncontrolled usage has negatively affected soil quality indices and agricultural yields over time. It also serves as a natural soil conditioner

[15][53]. Compost is packed with nutrients and humic substances. Humic compounds, which include humic acids (HAs), fulvic acids (FAs), and humin, are heterogeneous organic molecules. Humic compounds increase soil fertility by boosting soil physiochemical characteristics and enhancing soil structure and texture

[16][54]. Furthermore, applying compost derived from bio-transformed food waste to soils enhances soil aggregation, water-retentiveness, and porosity

[17][55]. Humic substances present in compost favourably impact plants’ physiological, metabolic, and developmental processes. Humic substances activate genes related to nitrate uptake in plants as well as plasma membrane H+-ATPase, which is involved in nutrient uptake and transport. According to research studies, humic compounds stimulate stomatal opening, which is necessary for photosynthesis and respiration. They have a significant role in land resource restoration through phytoremediation and vegetation revival in impoverished arable soils, in addition to increasing the composition of soil organic matter

[16][18][19][54,56,57].

Besides its numerous benefits, composting still has the disadvantages of long mineralisation times, long process duration, the potential presence of thermotolerant pathogens and limited nutritional content. The release of odorous substances and chemicals (such as hydrogen sulphides released under anaerobic conditions), as well as greenhouse gases (CO

2, N

2O, and CH

4), are additional downsides of this biological waste treatment process

[10][20][48,58]. One of the key restrictions on the usage of compost as biofertilizer is the fact that the availability of nutrients to plants, particularly N and P, is uncertain due to their existence in both inorganic and organic forms, which are not all readily available for intake by crops. Yet, less compost is needed in successive applications to attain the same nutritional load as mineral fertilisers because compost keeps releasing nutrients over an extended period. In practice, it would take less than eight times as much of this compost (1% N) over four years to provide the same quantity of nitrogen as mineral-based fertilizer

[21][59]. On the other hand, compost is made up of a mixture of nutrients, and soil health will greatly benefit from the ability to extract certain nutrients (such as N, P, K, etc.) but not all. For example, matured compost contains trace elements within permissible levels, but when applied to the soil for bioremediation, some trace elements can be added to the soil’s already present trace elements rather than being removed, thereby negatively impacting the soil quality

[20][58].

3. Anaerobic Digestion

Anaerobic digestion is the degradation of organic materials by microorganisms in an environment devoid of oxygen. This procedure generates biogas, which can be utilised as a source of energy. The steps of anaerobic digestion include hydrolysis, acidogenesis, acetogenesis, and methanogenesis

[22][60]. Anaerobic digestion of food waste offers numerous advantages, including lowering methane emissions at landfills and providing an on-site, renewable energy source. Anaerobic digestion produces a digestate as a by-product rich in nutrients (e.g., nitrogen and phosphorus) extracted from the food waste substrate

[23][61]. A long-term release of nutrients is achievable from the decomposition of fine organic matter retained within the cultivated soil following the application of fertilizer because organic fertilizers like food waste anaerobic digestate are very rich in organic matter. However, dissolved synthetic fertilizers provide nutrients available in their formulations prone to nutrient leaching and fixation, which restricts the quantity of nutrients plants can absorb over time

[24][62]. Chemical fertilizers provide nutrients and have no positive influence on the physical state of the soil, unlike organic fertilizers, such as anaerobic digestate, that enhance soil fertility and properties

[25][63]. The results of Panuccio et al.

[25][63] demonstrated the application of anaerobic digestate as soil amendment increased the contents of vitamin C, phenols, and flavonoids in tomato fruits

[26][64]. Furthermore, some research has indicated that the proper application of digestate can prevent the spread of soil-borne illnesses and may even lessen nutrient runoff, all while preserving crop productivity

[27][65].

This waste treatment process outperforms ordinary compost when applied as a soil biofertilizer. Anaerobic digestion is recommended over composting and landfilling to treat and dispose of high-moisture biomass, such as food waste

[28][66], because anaerobic digestion releases fewer odours and greenhouse gases. Additionally, the production of high-value products like bio-CNG (biogas) by anaerobic digestion might be economically advantageous on a large scale

[29][30][67,68]. Despite the aforementioned benefits, the food waste utilised as the substrate for anaerobic digestion is typically a source of pathogenic microbes and some pathogens, such as Listeria and spore-formers, can survive the anaerobic digestion treatment and remain in the digestate, posing potential hazards to the environment, and cause serious illnesses in both humans and animals

[31][32][69,70]. The incorrect calculation of fertilizer dose and nutrient availability can result in improper biofertilizer application and imbalanced release of nutrients that could compromise soil quality and crop growth

[28][33][66,71]. The high water content of the digestate poses challenges and increases transportation and storage costs.

[23][61]. Consequently, an existing need exists to increase the suitability of anaerobic digestate as a bio-based fertilizer. Moreover, the high capital cost required for anaerobic digestion is a common challenge for the implementation of this technology

[30][68].

4. Bioconversion

Biotransformation, also called bioconversion is the process of converting organic resources, for example, biomass from animal or vegetative waste, into marketable products or renewable energy sources via biological reactions or agents, such as microbial species, enzymes, etc.

[34][72]. Bioconversion of food wastes involves converting them into value-added products which include feed and food additives, bio-based fuels, animal feeds, enzymes, food-grade pigments, fertilizers, single cell protein (SCP), and other useful biochemicals or bioproducts thereby improving food security and supporting sustainable development

[35][73]. Bioconversion has various advantages, including high value in terms of biomaterial and energy recovery, reduction in landfill areas, lower technology costs, and increased farmer income through sales of agricultural/horticultural waste

[36][74].

Numerous scientists explored the production of useful products, through the utilisation of food wastes, as an alternative source of raw materials. For example, the production of single-cell protein via fermentative bioconversion is intended to address global protein deficits and has demonstrated huge benefits because it is not reliant on climate, soil health, and land available for cultivation

[37][75]. For the production of single-cell protein, food waste is broken down into simpler compounds by microbial cells like algae, yeast, bacteria, and fungi during fermentation, which produces high-quality protein sources for consumption by fish, livestock, and humans

[38][39][76,77]. SCP can be a good substitute for expensive conventional protein sources like soy meal as well as protein-based ingredients included in the formulation of animal feed such as fishmeal and meat meal

[40][78]. Research has demonstrated single-cell protein production from waste derived from oranges, lemon, corn stover

[38][76], pineapple, mango, banana, apple, cashew apple, jackfruit, cacao, pomegranate

[41][79], cheese, coffee

[42][80], and fish

[37][75]. On the other hand, regulatory obstacles and uncertainties about the safety of the products in relation to harmful or antinutritional substances still exist. In addition, it is critical to assess the environmental sustainability of these waste-to-nutrition processes at an early stage when attempting to substitute traditional food ingredients such as proteins to prevent undesirable implications and burden-shifting

[39][77].

A fed-batch fermentation process combined with in-situ separation was carried out for the bioconversion of restaurant leftovers and bakery waste by

Starmerella bombicola ATCC 22214 into sophorolipids. Although this method proved to be practical with high productivity, further optimisation of the separation process could be applied at an industrial scale

[43][81]. Sophorolipids are biodegradable molecules with great potential for use in the food and agricultural sector to compete with chemical surfactants

[44][82]. Potential applications include increasing crop productivity by enhancing the solubility and mobility of nutrients

[45][83], and the development of bio-preservatives and active packaging for food safety enhancement due to their effective antimicrobial properties

[46][47][84,85]. Fed-batch fermentation was equally employed to produce vinegar from discarded onion juice by microbial fermentation using

Acetobacter tropicalis KFCC 11476P

[48][86]. Fermentation techniques, particularly, solid-state fermentation (SSF) is a widely researched and effective procedure for the bioconversion of agro-industrial food waste, which produces inexpensive enzymes, organic acids, vitamins, fermented feeds and aroma compounds

[49][50][87,88]. SSF offers the following advantages: lower production cost, a higher output, less amount of waste generated, simpler equipment design, and organic culture media produced with solid food/agricultural waste

[51][89]. Compared to alternative fermentation methods, SSF has many benefits, including improved end-product recovery, superior product activity and quality, the absence of extraction solvents, and greater product stability and efficiency

[52][90]. In addition, SSF is an efficient method for degrading antinutritional factors and insoluble macromolecules, improving nutrient utilisation and uptake

[53][91]. Li et al.

[48][86] investigated the use of

Saccharomyces cerevisiae,

Candida utilis, and

Yarrowia lipolytica in SSF for the bioconversion of food waste obtained from a canteen to prepare fermented feed destined for crayfish farming. The study highlighted that replacing the basal diet with 30% of the food waste-derived fermented feed is suitable for crayfish growth

[49][87]. SSF was previously investigated for the production of the packaging material poly-3-hydroxybutyrate (PHB) using a medium containing sugarcane molasses

[54][92]. Moreso, food and kitchen waste were also tested to produce PHB by five different microbial consortiums. Consortium A, which consisted of three

Bacillus species (

B. pumilus MPTDFH,

B. cereus MPTDC, and

B. sonorensis MPTD1), yielded the highest PHB concentration (0.91 g/L)

[55][93]. Although SSF is an attractive technology, several challenges need to be addressed. For instance, the low moisture content of the waste substrates used in SSF inhibits enzymatic activity and restricts the transport of nutrients and metabolites, leading to a slower microbial growth rate. Additionally, SSF is limited to microorganisms that have the ability to survive in low moisture conditions

[56][94].

A rather novel waste valorisation approach, insect-based bioconversion, has been recently explored for the manufacture of valuable products following insects’ breakdown of food waste. During this process, value can be created at several stages, for example, the elimination of food waste enables a reduction in disposal expenses, selling insect-based biomass as protein-rich food and feed, commercialisation of fractionated secondary products (i.e., biomolecules), and selling the leftover bio-converted by-product as soil amendments for agriculture/horticulture

[57][95]. In contrast, consumer acceptance of the produced goods is one of the challenges that insect-based food waste valorisation techniques face

[58][96]. Using food waste as a feed source in insect farming has several environmental and economic benefits. Firstly, many insects, including grasshoppers, flies, and crickets, thrive on leftover food that humans and livestock cannot consume. Secondly, introducing insects into human diets helps to achieve a bioeconomy by utilising food that would otherwise be wasted to feed the insects, which people then eat. Moreover, this would help maintain a balance between the world’s supply and demand for animal protein

[59][97].

Hermetia illucens (black soldier fly) is an excellent insect for bioconversion. This insect has a short reproductive cycle and the larvae have a high food conversion rate, an insatiable appetite and may eat a variety of organic waste, including food waste

[60][98]. Black soldier fly larvae (BSFL) have received a lot of attention because they have good nutritional value. They have high quantities of lipids, proteins, minerals, vitamins and essential amino acids

[61][99]. This makes them good edible insect candidates to be included in the human diet, particularly because they are good sources of proteins and can contribute to meeting the increasing protein demand. However, Bessa et al.

[62][100] argued that there are several existing challenges that slow down the adoption of BSFL as a safe food source for human consumption. Consumers are willing to consume BSFL as processed food but little is known about its food safety since BSFL has been used predominantly as animal feed.

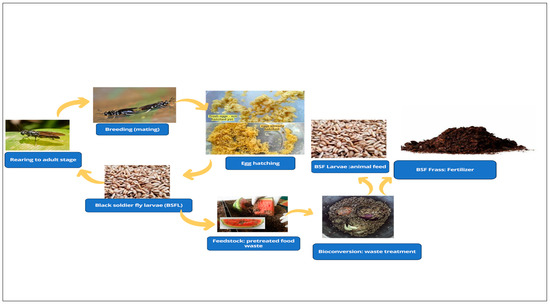

Figure 1 below illustrates the bioconversion process of food waste by BSFL.

Figure 1.

Insect-based bioconversion by black soldier fly larvae, and the life cycle of black soldier fly.

Despite these advantages, insect rearing can produce huge quantities of low-value organic waste, including frass, exuviae, and uneaten feed, often disposed of by spreading on farmlands

[58][96]. To prevent potential hazards, researchers have expressed their concerns and recommended further studies before implementing large-scale insect-based valorisation and commercial cultivation of insects. This is because some insects contain substances that are toxic to human beings, such as cyanide or thiaminases, which reduce their nutritional value. Therefore, ecological studies on selecting safe species for domestication and consumption must go hand in hand with research on the nutritional content and safety of insects for food and feed applications. Concerns have also been raised about the threat of ecosystem imbalance from insects that escape from insect farms

[63][101].

5. Upcycling Food Waste

Upcycled food is a novel idea in the arsenal of strategies for reducing/valorising food waste. Upcycled foods are formulated with ingredients that usually are not intended for human consumption, such as damaged (rejected) food, underutilised food parts, residues, by-products, and food processing and preparation leftovers and waste. Upcycling, therefore, results in an increase in the value of the waste material and by-products by processing them into functional and nutritive ingredients that can be reintroduced in the food supply chain as components of new food items. Upcycled ingredients/foods are sometimes referred to as waste-to-value food products or value-added surplus products.

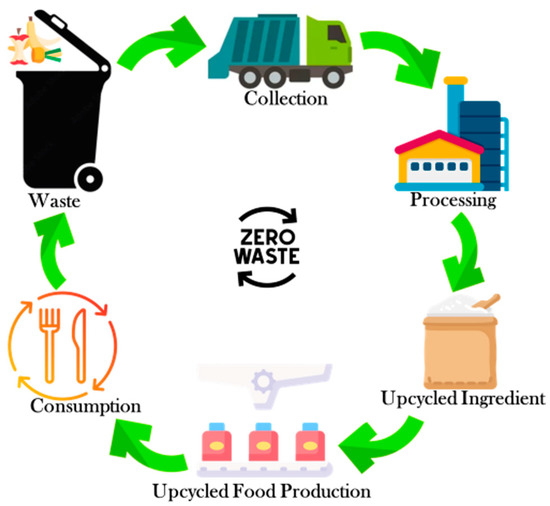

[64][65][66][102,103,104]. The production of upcycled foods (

Figure 2) makes use of ingredients that are still usable but are generally thrown away

[67][105]. For instance, the peel is typically removed before consuming carrots. However, the discarded carrot peels are healthy and safe to consume and can be repurposed as an ingredient in other foods, such as a powdered vegetable soup mix prepared from dried peels

[68][106].

Figure 2.

Closing the loop with the production of upcycled foods/ingredients.

Food losses such as fruit and vegetable by-products, among others, are sources of high-value nutrients (e.g., bioactive compounds and dietary fibre) that can provide nutritional benefits to consumers. Trigo et al.

[69][107] analysed grape pomace and pomegranate peel and found relatively high antioxidant activity and total phenolic content. The previously mentioned attributes are likely responsible for the frequent application of food processing by-products in a variety of fortified foods, including sauces, beverages, dairy products, pastry, and animal products

[69][107].

Some producers of upcycled ingredients/foods are releasing their finished products on the market. Examples of companies and products include Coffee Cherry Company (US) and Kaffe Bueno (Denmark), which use coffee grounds in making baked products. Remashed (UK) and Regrained (US) are upcycling spent grains from beer production to produce granola bars, and the leftover generated from rapeseed or sunflower oil processing is converted into food-grade protein-rich powders by Planetarians (US) and NapiFeryn BioTech (Poland)

[66][104]. The Upcycled Food Association initiated a scheme to certify upcycled ingredients and foods to make it easier for producers to manufacture these foods

[64][102]. These foods offer an appealing economic and environmental response to partly alleviate the food waste issue. Upcycling waste to the food industry is a major circular economy concept that is consistent with policy trends favouring ‘closing the loop’ in major sectors, including food and agriculture

[70][44], hence, simultaneously taking advantage of nutrients (e.g., protein and fibre) that are still present in the waste material and creating a circular food system

[68][106]. Another advantage is that the upcycled food sector seeks to utilize the whole waste resources in place of extracting bioactive ingredients and nutrients from food waste, resulting in a net reduction of food waste

[71][108].

Although upcycled foods can reduce food waste and improve food security, there is limited knowledge of the ideal marketing approach to maximize consumer acceptability for these products

[67][105]. Regarding consumers’ perceptions, one of the greatest concerns is that they may imagine the products are less valuable than they are. This may result from one’s association with garbage, which is typically considered useless and frequently considered repugnant and harmful. This view might also lead to the fear that upcycling may give rise to foods with diminished quality and safety

[65][103]. Moreover, neophobia might lead to the reluctance of consumers towards these novel products

[68][106]. Creating a label that could be added to the item’s packaging formalizes the concept of “upcycled food”. Similarly to existing labels such as clean or sustainability labels, this label would aid the buyer in making a purchasing decision by emphasising the benefits of “upcycling” to promote a circular economy

[72][109]. The upcycled food market appears to have significant growth potential, as 85% of consumers in the UK would be open to purchasing foods and beverages that contain upcycled ingredients. In another study in Italy (2020), 56% of participants claimed they would purchase a food item manufactured with waste or by-products. If the food produced using wastes or by-products additionally had a lower production-related environmental burden, this percentage increased to 69%.

[66][104]. Also, when potential consumers are informed that upcycled foods can be helpful to reduce food waste, they are prepared to pay a higher price

[73][110]. Therefore, upcycling could respond to a significant market desire for sustainable development

[72][109].

Table 1 summarises some waste valorisation strategies used in the manufacture of products as well as their potential applications in the food industry.

Table 1.

Value-added products obtained from various food waste sources and their potential use in the food industry.

| Food Waste Type |

Processing Method |

Product |

Application |

Reference |

| Tomato skins and seeds |

Supercritical CO2 extraction |

Trans-lycopene |

Colouring and antioxidant agent |

[74][111] |

| Soy molasses |

Solid-state fermentation |

Single cell protein |

Protein supplement in animal feed |

[75][112] |

| Yam peels |

Solid state fermentation |

Citric acid |

Food additive (flavouring and preservative) |

[76][113] |

| White bread waste |

Enzymatic hydrolysis |

Growth substrate |

Baker yeast production |

[77][114] |

| Potato peel |

Ethanolic extraction coupled with heat |

Antioxidant (polyphenols and flavonoids) |

Preservative (controls oxidation) |

[78][115] |

| Rice, noodles, vegetables, and meat waste obtained from a cafeteria |

Anaerobic fermentation |

Volatile fatty acids |

Production of bio-based food packaging material |

[79][116] |

| Mixed beverages and food waste (fruit juices, energy drinks, soft drinks, oatmeal and potato chips) from retailers |

Enzymatic saccharification |

Sugar-rich hydrolysate |

Production of liquid sweetener (i.e., high-fructose syrup) |

[80][117] |

| Bakery waste (cake skins, cake waste, and expired breads and cakes) and eggshells |

Composting |

Compost |

Agricultural fertilizer |

[81][118] |

| Rejected unripe plantain pulp |

INFOGEST static in vitro simulation of gastrointestinal food digestion |

Isomalto-oligosaccharides syrup |

Prebiotic compound |

[82][119] |

| Vegetable waste (rejected carrots, carrot steam peels, green beans cutting waste, leek cutting waste and celeriac steam peels) |

Extraction with ethanol and acetone, and fractionation |

Pectin |

Functional food ingredient and gelling agent |

[83][120] |

| Food waste from restaurants |

Batch and continuous Fermentation |

Lactic acid |

Food ingredient (preservative flavouring) and bioplastic (poly-lactic acid) production |

[84][121] |

| Mussel meat waste |

Enzymatic hydrolysis |

Extract rich in proteins and bioactive peptides |

Functional food ingredients with antioxidant and anti-hypertensive properties |

[85][122] |