Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Alfred Zheng and Version 1 by Amin Mojiri.

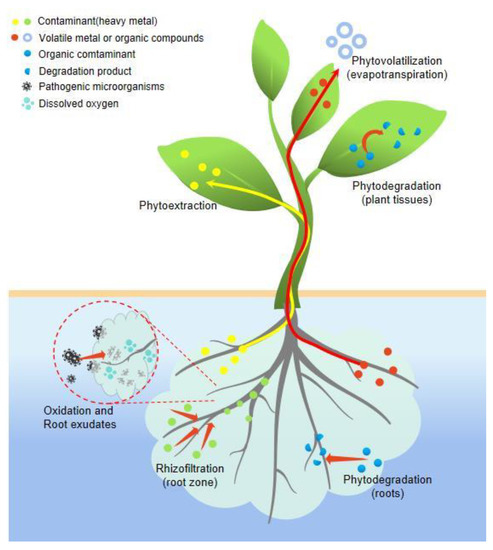

As the global population reaches eight billion, large quantities of wastewater (domestic, industrial, livestock) need to be treated in an efficient, green, and environmentally friendly manner. Wastewater hydroponics technology (HP) can efficiently remove various pollutants (conventional and emerging pollutants, heavy metals, and microorganisms) and create economic benefits. The principle of hydroponic wastewater purification is phytoremediation, which is a low-cost and solar-powered natural cleaning technology. Plants assist in the removal of pollutants in a variety of ways, including phytoextraction, phytovolatilization, phytodegradation, and rhizofiltration.

- hydroponics

- phytoremediation

- wastewater purification

- hydroponic plants

1. Introduction

Water is crucial for sustainable human and socio-economic development, energy and food production, ecosystem stability, and human survival. It also plays a central role in climate change adaptation and serves as a critical link between society and the environment. With rapid population and economic growth, large quantities of urban, industrial, and livestock wastewater are generated daily. According to the UN Water Sustainable Development Goal report, 44% of household wastewater worldwide remains untreated [1].

Domestic wastewater may contain potential pollutants, including detergents from bathrooms, food scraps and oils from kitchens, and excrement from toilets. As a result, it can contain pathogens, nutrients, and organic matter [2]. In recent years, the water industry has placed greater emphasis on treating and recycling wastewater due to social and environmental pressures. However, high-strength industrial wastewater still contains numerous persistent organic contaminants and inorganic pollutants, as well as heavy metals, presenting significant challenges to environmental safety [3]. In agriculture, the widespread use of chemical fertilizers and pesticides to enhance crop yields and livestock quality poses a significant threat to surface and groundwater [1].

Globally, 80% of wastewater is discharged into the environment without adequate treatment. As a result, approximately 1.8 billion people are exposed to fecal-contaminated drinking water sources, putting them at risk of diseases such as cholera, dysentery, typhoid, and infections of the spinal cord, as well as the risk of polio [4].

In addition to the direct harm caused by bacteria and viruses in water, heavy metal pollution poses another threat to human health. Lead (Pb), for instance, can adversely affect the human nervous system, particularly leading to learning deficits and a decline in IQ among infants and young children [5]. Arsenic (As) can seriously affect human skin and internal organs and cause various malignant tumors [6]. Chromium (Cr(VI)) facilitates UV-induced skin cancer [7].

Cadmium (Cd) has the potential to cause osteomalacia and osteoporosis, leading to severe damage to the liver, kidneys, reproductive system, and cardiovascular system. It is also recognized as a carcinogen, contributing to the development of cancer [8]. Furthermore, emerging contaminants such as cosmetics, pharmaceuticals, personal care products, and microplastics have been identified in wastewater treatment plants and natural water sources worldwide. These contaminants cannot be effectively eliminated, and may even be detected in drinking water, posing potential risks such as endocrine disorders, birth defects, developmental disorders, and impacts on fertility and reproductive health in humans [9,10][9][10]. Additionally, these pollutants can promote malignancy and increase the resistance of bacterial pathogens. In order to minimize potential harm to humans and ecosystems resulting from wastewater, various physical, chemical, and biological wastewater treatment technologies have been developed [11].

Among them, popular approaches widely used for wastewater treatment and resources recovery include adsorption by activated carbon and biochar, advanced oxidation processes (such as photocatalysis), biological methods (such as constructed wetlands-CWs), and hybrid methods based on membrane technology. These methods offer different treatment performances, depending on the specific requirements and characteristics of the wastewater being treated [12,13][12][13]. However, these technologies often suffer from the issue of high implementation and maintenance costs [14]. For instance, the production cost of biochar and filtration membranes is significant, resulting in higher overall investment and operational expenses [15]. Additionally, certain treatment technologies can generate significant amounts of by-products or residues. If these by-products or residues are not properly treated, they can result in secondary pollution. For example, in the case of biochar or membranes used for adsorption or filtration, recycling or appropriate treatment is necessary to ensure their harmlessness and prevent any negative environmental impact [16]. Advanced oxidation processes often require the addition of oxidants and catalysts, which can also produce by-products [17]. Furthermore, some technologies have strict operating conditions and environmental requirements, which can make widespread adoption challenging. For instance, cultivating microorganisms for biofiltration requires a significant amount of time [18], while membrane technology requires pressure control to prevent clogging, fouling, or rupture [19]. Therefore, it is crucial to identify a method that is easy to implement, involves low investment and operating costs, and offers economic value through by-products. Hydroponic systems have gained significant attention for their ability to support plant growth in controlled environments. This soil-less method of plant cultivation utilizes water-based nutrient solutions to provide plants with the essential elements they need for healthy development. Hydroponics offers several advantages, including efficient resource utilization, optimal nutrient uptake, and higher crop yields compared to traditional soil-based farming. Beyond its application in conventional agriculture, hydroponic systems also hold great potential for wastewater treatment. Wastewater hydroponics is one such method, which is derived from traditional hydroponics. Traditional hydroponics involves growing plants without soil utilizing mineral nutrient solutions [20]. This method serves as an excellent alternative to mitigate the drawbacks of soil media, which consume substantial amounts of freshwater and fertilizers. In traditional hydroponics, nutrients are directly delivered to the plant roots, providing optimal conditions for plant growth and ensuring consistent yields [21]. Wastewater hydroponics, however, employ wastewater instead of traditional hydroponic nutrient solutions, allowing for wastewater purification while simultaneously obtaining economically valuable by-products [22].

2. Mechanism of Hydroponic Plants to Purify Wastewater

The principle of hydroponic wastewater purification is phytoremediation, which is a low-cost and solar-powered natural cleaning technology. Plants assist in the removal of pollutants in a variety of ways, including phytoextraction, phytovolatilization, phytodegradation, and rhizofiltration (Figure 1). Phytoextraction refers to the absorption and transport of pollutants by plant roots from soil or water. Phytoextraction occurs either through metal hyperaccumulators or fast-growing plants for continuous extraction or application of acidifying chemical (NH4)2SO4 to enhance plant uptake and transport of metals [38][23]. In addition, phytomining is a special method of phytoextraction with excellent commercial potential, which utilizes the absorption and accumulation of metals by plants to extract and accumulate noble metals from dispersive sources. This technology is widely used to recover nickel from contaminated land [39][24]. Dinh et al. [40][25] summarized nearly two decades of research on the phytomining, enrichment, and extraction of various precious metals, especially gold and silver. They believed that, in the case of depleted reserves, phytomining is a promising approach to recover noble metals from low-grade ores or secondary resources. However, this technology is only aimed at polluted soil, industrial wastewater, or mine wastewater that may also contain a large quantity of precious metals. So far, there is no relevant research on this type of wastewater hydroponics. Moreover, given the significant rise in rare earth prices and industrial demand in recent years, the utilization of phytomining for extracting rare earth elements has yet to be extensively explored and implemented in practical applications. This approach holds great promise as a sustainable and eco-friendly method for extracting rare earth elements from both wastewater and ores [40,41][25][26].

Figure 1.

Schematic diagram of phytoremediation processes in wastewater hydroponics.

Comparison between Wastewater Hydroponics and Constructed Wetlands

Similar to wastewater hydroponic systems, CWs are widely used in sewage purification through microbial degradation, plant absorption, and substrate filtration due to their low treatment costs and stable operation. By simulating natural wetlands, CWs utilize the triple synergistic effects of natural ecosystems in physical, chemical, and biological states to achieve sewage purification. Thus, plants and media are the key elements in applying CWs in sewage treatment. However, there are many differences between wastewater hydroponic systems and CWs. Wastewater hydroponics are shallow wastewater treatment systems that typically treat low-intensity polluted wastewater. CWs are usually deep-water treatment systems, which can be used to treat landfill leachate, usually as the secondary or tertiary treatment stage of wastewater treatment plants [75][60]. CWs use a large number of media fillers to settle, filter, adsorb, and trap important pollutants in sewage [76][61]. With the accumulation of contaminants, many non-degradable solids enter the CW system. At the same time, microbial metabolism produces colloidal sludge with high water content and low density, resulting in a gradual decrease in the porosity of the filling layer, blocking the water flow channel, and ultimately affecting the effectiveness of treatment and operating life of the CW [47,48][32][33]. Wastewater hydroponic systems, on the other hand, use almost no media filtration, which means there is no risk of system clogging, thereby extending system life. Hydroponic systems are mostly set up in a greenhouse environment or condition. Greenhouses protect crops from harsh weather (extreme temperatures, extreme rainfall, and strong winds) and pests, providing favorable climatic conditions for plant growth. In contrast, most of the CWs are outdoors, and purification performance varies with the seasons [77][62]. In winter, plants may wither and release nutrients, causing secondary pollution. There are still a lot of uncertainties about the economics of these two technologies. A notable feature of hydroponics compared to CWs is that crops or flowers with a higher economic value can be used to remediate wastewater. The harvested vegetables, fruits, and flowers can generate sizable economic benefits. In recent years, the development of vertical farming has made it possible for hydroponic wastewater treatment technology to require less space, and it can also be implemented on-site. The yield of hydroponic crops is several times higher than that of traditional soil-based planting [78][63]. However, high initial investment requirements and huge energy consumption also significantly affect the economics of this technology. In contrast, CWs also require a specific initial investment, and a suitable location needs to be selected for site construction. However, the whole system has low energy consumption and simple operation. The CW itself can be used as a natural habitat and flood control facility, which can improve the aesthetic significance of suburban and rural areas, but the economic benefits are not obvious [75][60]. Based on the characteristics of the two technologies, Gong et al. [79][64] attempted a combination of CW and hydroponic vegetable (HV) systems to test the purification effect. The four systems tested included HV, subsurface flow constructed wetland (SFCW), HV followed by SFCW (HV/SFCW), and SFCW followed by HV (SFCW/HV). Among them, the HV/SFCW system achieved the best performance, by removing 39.1% COD, 61.1% TN, and 55% TP. They therefore suggested that HV/SFCW was most suitable for rural sewage tail water treatment.References

- United Nations Summary Progress Update 2021: SDG 6—Water and Sanitation for All. Available online: https://www.unwater.org/publications/summary-progress-update-2021-sdg-6-water-and-sanitation-all (accessed on 1 July 2023).

- Idris-Nda, A.; Aliyu, H.K.; Dalil, M. The Challenges of Domestic Wastewater Management in Nigeria: A Case Study of Minna, Central Nigeria. Int. J. Dev. Sustain. 2013, 2, 1169–1182.

- Saxena, G.; Bharagava, R. Organic and Inorganic Pollutants in Industrial Wastes. In Environmental Pollutants and Their Bioremediation Approaches; CRC Press: Boca Raton, FL, USA, 2017; pp. 23–56.

- United Nations Environment Programme 2017 UN World Water Development Report, Wastewater: The Untapped Resource. Available online: https://www.unep.org/resources/publication/2017-un-world-water-development-report-wastewater-untapped-resource (accessed on 1 July 2023).

- Wani, A.L.; Ara, A.; Usmani, J.A. Lead Toxicity: A Review. Interdiscip. Toxicol. 2015, 8, 55–64.

- Choong, T.S.Y.; Chuah, T.G.; Robiah, Y.; Gregory Koay, F.L.; Azni, I. Arsenic Toxicity, Health Hazards and Removal Techniques from Water: An Overview. Desalination 2007, 217, 139–166.

- Costa, M.; Klein, C.B. Toxicity and Carcinogenicity of Chromium Compounds in Humans. Crit. Rev. Toxicol. 2006, 36, 155–163.

- Rafati Rahimzadeh, M.; Rafati Rahimzadeh, M.; Kazemi, S.; Moghadamnia, A.-A. Cadmium Toxicity and Treatment: An Update. Casp. J. Intern. Med. 2017, 8, 135–145.

- Poongothai, S.; Ravikrishnan, R.; Balikrishna Murthy, P. Endocrine Disruption and Perspective Human Health Implications: A Review. Internet J. Toxicol. 2007, 4, 10–1210.

- Raghav, M.; Eden, S.; Mitchell, K.; Witte, B. Contaminants of Emerging Concern in Water; The University of Arizona: Tucson, AZ, USA, 2013.

- Crini, G.; Lichtfouse, E. Advantages and Disadvantages of Techniques Used for Wastewater Treatment. Environ. Chem. Lett. 2019, 17, 145–155.

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W. Adsorptive Removal of Antibiotics from Water and Wastewater: Progress and Challenges. Sci. Total Environ. 2015, 532, 112–126.

- Xu, B.; Liu, S.; Zhou, J.L.; Zheng, C.; Weifeng, J.; Chen, B.; Zhang, T.; Qiu, W. PFAS and Their Substitutes in Groundwater: Occurrence, Transformation and Remediation. J. Hazard. Mater. 2021, 412, 125159.

- Palansooriya, K.N.; Yang, Y.; Tsang, Y.F.; Sarkar, B.; Hou, D.; Cao, X.; Meers, E.; Rinklebe, J.; Kim, K.-H.; Ok, Y.S. Occurrence of Contaminants in Drinking Water Sources and the Potential of Biochar for Water Quality Improvement: A Review. Crit. Rev. Environ. Sci. Technol. 2020, 50, 549–611.

- Qiu, B.; Tao, X.; Wang, H.; Li, W.; Ding, X.; Chu, H. Biochar as a Low-Cost Adsorbent for Aqueous Heavy Metal Removal: A Review. J. Anal. Appl. Pyrolysis 2021, 155, 105081.

- Chen, W.-H.; Hoang, A.T.; Nižetić, S.; Pandey, A.; Cheng, C.K.; Luque, R.; Ong, H.C.; Thomas, S.; Nguyen, X.P. Biomass-Derived Biochar: From Production to Application in Removing Heavy Metal-Contaminated Water. Process Saf. Environ. Prot. 2022, 160, 704–733.

- Carra, I.; Sánchez Pérez, J.A.; Malato, S.; Autin, O.; Jefferson, B.; Jarvis, P. Performance of Different Advanced Oxidation Processes for Tertiary Wastewater Treatment to Remove the Pesticide Acetamiprid. J. Chem. Technol. Biotechnol. 2016, 91, 72–81.

- Sun, Y.; Xue, S.; Li, L.; Ding, W.; Liu, J.; Han, Y. Sulfur Dioxide and o -Xylene Co-Treatment in Biofilter: Performance, Bacterial Populations and Bioaerosols Emissions. J. Environ. Sci. 2018, 69, 41–51.

- Antony, A.; Low, J.H.; Gray, S.; Childress, A.E.; Le-Clech, P.; Leslie, G. Scale Formation and Control in High Pressure Membrane Water Treatment Systems: A Review. J. Memb. Sci. 2011, 383, 1–16.

- Sardare, M.D.; Admane, S.V. A Review on Plant without Soil-Hydroponics. Int. J. Res. Eng. Technol. 2013, 02, 299–304.

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153.

- Magwaza, S.T.; Magwaza, L.S.; Odindo, A.O.; Mditshwa, A. Hydroponic Technology as Decentralised System for Domestic Wastewater Treatment and Vegetable Production in Urban Agriculture: A Review. Sci. Total Environ. 2020, 698, 134154.

- Greipsson, S. Phytoremediation. Nat. Educ. Knowl. 2011, 30, 7.

- Chaney, R.L. Phytoextraction and Phytomining of Soil Nickel. In Nickel in Soils and Plants; CRC Press: Boca Raton, FL, USA, 2018; pp. 341–374.

- Dinh, T.; Dobo, Z.; Kovacs, H. Phytomining of Noble Metals—A Review. Chemosphere 2022, 286, 131805.

- Dang, P.; Li, C. A Mini-Review of Phytomining. Int. J. Environ. Sci. Technol. 2022, 19, 12825–12838.

- Nagata, T.; Morita, H.; Akizawa, T.; Pan-Hou, H. Development of a Transgenic Tobacco Plant for Phytoremediation of Methylmercury Pollution. Appl. Microbiol. Biotechnol. 2010, 87, 781–786.

- Zayed, A.; Pilon-Smits, E.; deSouza, M.; Lin, Z.-Q.; Terry, N. Remediation of Selenium-Polluted Soils and Waters by Phytovolatilization. In Phytoremediation of Contaminated Soil and Water; CRC Press: Boca Raton, FL, USA, 2020; pp. 61–83.

- Wang, L.; Hou, D.; Shen, Z.; Zhu, J.; Jia, X.; Ok, Y.S.; Tack, F.M.G.; Rinklebe, J. Field Trials of Phytomining and Phytoremediation: A Critical Review of Influencing Factors and Effects of Additives. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2724–2774.

- Etim, E.E. Phytoremediation and Its Mechanisms: A Review. Int. J. Environ. Bioenergy 2012, 2, 120–136.

- Kristanti, R.A.; Ngu, W.J.; Yuniarto, A.; Hadibarata, T. Rhizofiltration for Removal of Inorganic and Organic Pollutants in Groundwater: A Review. Biointerface Res. Appl. Chem. 2021, 11, 12326–12347.

- Wang, H.; Sheng, L.; Xu, J. Clogging Mechanisms of Constructed Wetlands: A Critical Review. J. Clean. Prod. 2021, 295, 126455.

- Wang, M.; Chen, S.; Jia, X.; Chen, L. Concept and Types of Bioremediation. In Handbook of Bioremediation; Elsevier: Amsterdam, The Netherlands, 2021; pp. 3–8.

- Tonelli, F.C.P.; Tonelli, F.M.P.; Lemos, M.S.; Nunes, N.A.d.M. Mechanisms of Phytoremediation. In Phytoremediation; Elsevier: Amsterdam, The Netherlands, 2022; pp. 37–64.

- Bedabati Chanu, L.; Gupta, A. Phytoremediation of Lead Using Ipomoea Aquatica Forsk. in Hydroponic Solution. Chemosphere 2016, 156, 407–411.

- Khumanleima Chanu, H.; Gupta, A. Necrosis as an Adaptive Response to Copper Toxicity in Ipomoea Aquatica Forsk. and Its Possible Application in Phytoremediation. Acta Physiol. Plant 2014, 36, 3275–3281.

- Garousi, F.; Kovács, B.; Andrási, D.; Veres, S. Selenium Phytoaccumulation by Sunflower Plants under Hydroponic Conditions. Water Air Soil. Pollut. 2016, 227, 382.

- January, M.C.; Cutright, T.J.; Van Keulen, H.; Wei, R. Hydroponic Phytoremediation of Cd, Cr, Ni, As, and Fe: Can Helianthus Annuus Hyperaccumulate Multiple Heavy Metals? Chemosphere 2008, 70, 531–537.

- Wan, S.; Pang, J.; Li, Y.; Li, Y.; Zhu, J.; Wang, J.; Chang, M.; Wang, L. Hydroponic Phytoremediation of Ni, Co and Pb by Iris sibirica L. Sustainability 2021, 13, 9400.

- Lee, J.H.; Hossner, L.R.; Attrep, M., Jr.; Kung, K.S. Uptake and Translocation of Plutonium in Two Plant Species Using Hydroponics. Environ. Pollut. 2002, 117, 61–68.

- Dushenkov, S.; Vasudev, D.; Kapulnik, Y.; Gleba, D.; Fleisher, D.; Ting, K.C.; Ensley, B. Removal of Uranium from Water Using Terrestrial Plants. Environ. Sci. Technol. 1997, 31, 3468–3474.

- Lewis, B.G.; MacDonell, M.M. Release of Radon-222 by Vascular Plants: Effect of Transpiration and Leaf Area. J. Environ. Qual. 1990, 19, 93–97.

- Wang, J.; Wang, W.; Xiong, J.; Li, L.; Zhao, B.; Sohail, I.; He, Z. A Constructed Wetland System with Aquatic Macrophytes for Cleaning Contaminated Runoff/Storm Water from Urban Area in Florida. J. Environ. Manag. 2021, 280, 111794.

- Vymazal, J. Removal of Enteric Bacteria in Constructed Treatment Wetlands with Emergent Macrophytes: A Review. J. Environ. Sci. Health Part. A 2005, 40, 1355–1367.

- Dhir, B. Effective Control of Waterborne Pathogens by Aquatic Plants. In Waterborne Pathogens; Elsevier: Amsterdam, The Netherlands, 2020; pp. 339–361.

- Shingare, R.P.; Thawale, P.R.; Raghunathan, K.; Mishra, A.; Kumar, S. Constructed Wetland for Wastewater Reuse: Role and Efficiency in Removing Enteric Pathogens. J. Environ. Manag. 2019, 246, 444–461.

- Alufasi, R.; Gere, J.; Chakauya, E.; Lebea, P.; Parawira, W.; Chingwaru, W. Mechanisms of Pathogen Removal by Macrophytes in Constructed Wetlands. Environ. Technol. Rev. 2017, 6, 135–144.

- Wang, Q.; Hu, Y.; Xie, H.; Yang, Z. Constructed Wetlands: A Review on the Role of Radial Oxygen Loss in the Rhizosphere by Macrophytes. Water 2018, 10, 678.

- von Martels, J.Z.H.; Sadaghian Sadabad, M.; Bourgonje, A.R.; Blokzijl, T.; Dijkstra, G.; Faber, K.N.; Harmsen, H.J.M. The Role of Gut Microbiota in Health and Disease: In Vitro Modeling of Host-Microbe Interactions at the Aerobe-Anaerobe Interphase of the Human Gut. Anaerobe 2017, 44, 3–12.

- Wu, S.; Carvalho, P.N.; Müller, J.A.; Manoj, V.R.; Dong, R. Sanitation in Constructed Wetlands: A Review on the Removal of Human Pathogens and Fecal Indicators. Sci. Total Environ. 2016, 541, 8–22.

- Curtis, T.P.; Mara, D.D.; Silva, S.A. Influence of PH, Oxygen, and Humic Substances on Ability of Sunlight to Damage Fecal Coliforms in Waste Stabilization Pond Water. Appl. Environ. Microbiol. 1992, 58, 1335–1343.

- Fernández, A.; Tejedor, C.; Chordi, A. Effect of Different Factors on the Die-off of Fecal Bacteria in a Stabilization Pond Purification Plant. Water Res. 1992, 26, 1093–1098.

- Headley, T.; Nivala, J.; Kassa, K.; Olsson, L.; Wallace, S.; Brix, H.; van Afferden, M.; Müller, R. Escherichia coli Removal and Internal Dynamics in Subsurface Flow Ecotechnologies: Effects of Design and Plants. Ecol. Eng. 2013, 61, 564–574.

- Stefanakis, A.I.; Bardiau, M.; Trajano, D.; Couceiro, F.; Williams, J.B.; Taylor, H. Presence of Bacteria and Bacteriophages in Full-Scale Trickling Filters and an Aerated Constructed Wetland. Sci. Total Environ. 2019, 659, 1135–1145.

- Haichar, F.e.Z.; Santaella, C.; Heulin, T.; Achouak, W. Root Exudates Mediated Interactions Belowground. Soil. Biol. Biochem. 2014, 77, 69–80.

- Seidel, K. Macrophytes and Water Purification. In Biological Control of Water Pollution; University of Pennsylvania Press: Philadelphia, PA, USA, 1970; pp. 109–121.

- RodrÃguez-Navarro, D.N.; Dardanelli, M.S.; RuÃz-SaÃnz, J.E. Attachment of Bacteria to the Roots of Higher Plants. FEMS Microbiol. Lett. 2007, 272, 127–136.

- Bais, H.P.; Weir, T.L.; Perry, L.G.; Gilroy, S.; Vivanco, J.M. The Role of Root Exudates in Rhizosphere Interactions with Plants and other Organisms. Annu. Rev. Plant Biol. 2006, 57, 233–266.

- Huang, X.-F.; Chaparro, J.M.; Reardon, K.F.; Zhang, R.; Shen, Q.; Vivanco, J.M. Rhizosphere Interactions: Root Exudates, Microbes, and Microbial Communities. Botany 2014, 92, 267–275.

- Mustafa, H.M.; Hayder, G. Evaluation of Water Lettuce, Giant Salvinia and Water Hyacinth Systems in Phytoremediation of Domestic Wastewater. H2Open J. 2021, 4, 167–181.

- Lu, S.; Zhang, X.; Wang, J.; Pei, L. Impacts of Different Media on Constructed Wetlands for Rural Household Sewage Treatment. J. Clean. Prod. 2016, 127, 325–330.

- Steer, D.; Fraser, L.; Boddy, J.; Seibert, B. Efficiency of Small Constructed Wetlands for Subsurface Treatment of Single-Family Domestic Effluent. Ecol. Eng. 2002, 18, 429–440.

- Romeo, D.; Vea, E.B.; Thomsen, M. Environmental Impacts of Urban Hydroponics in Europe: A Case Study in Lyon. Procedia CIRP 2018, 69, 540–545.

- Gong, L.; Chen, G.; Li, J.; Zhu, G. Utilization of Rural Domestic Sewage Tailwaters by Ipomoea Aquatica in Different Hydroponic Vegetable and Constructed Wetland Systems. Water Sci. Technol. 2020, 386–400.

More