The clear potential of three-dimensional (3D) systems to provide new models suitable for studying cell interactions in both basic and more specialized research, revolutionizing cell culture technology, and offering alternative methods for animal experimentation, has prompted the scientific community to develop different efficient methods to establish 3D cell cultures, all of which, in turn, affect 3D model characteristics. These techniques can be divided into two major categories: scaffold-free systems and scaffold-based systems. Scaffold-free systems are based on the self-aggregation capability of some cell types, which can be encouraged using specific cell plates and/or physical parameters that avoid cell attachment. On the other hand, in scaffold-based systems, cells are seeded in natural or synthetic materials, allowing cell proliferation, aggregation, and 3D organization.

1. Scaffold-Free Methods

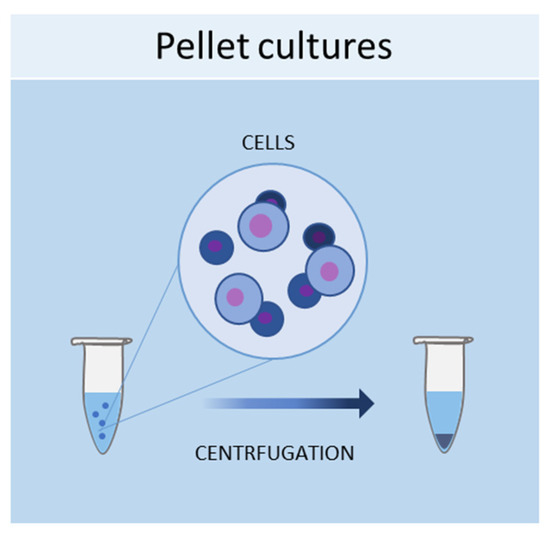

1.1. Pellet Cultures

One of the simplest methods of culturing cells in

three-dimensional (3D

) is represented by pellet cultures, in which cells are pelleted to the bottom of the tube through centrifugal force (

Figure 1). The supernatant is removed, while the pellet is suspended in a spheroid culture medium, and cells are seeded in multi-well plates with a cell-repellent surface

[1][40]. It has been demonstrated that this technique can stimulate the chondrogenic differentiation of MSCs

[2][41]. Using pellet cultures, dental pulp spheroids, bone marrow, and endothelial spheroids were also cultured

[3][4][42,43].

Figure 1.

Schematic representation of pellet culture method used to obtain 3D cell cultures.

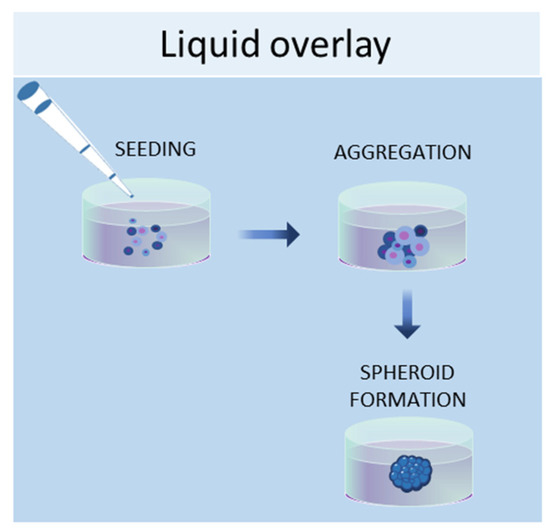

1.2. Liquid Overlay

The liquid overlay technique allows the growth of cells in 3D by using non-adherent surfaces, typically coated with hydrophilic and neutrally charged polymers (agar or agarose gel). This coating prevents the attachment of cells to the plate or flask, thus encouraging the cells to interact with each other and produce their own ECMs (

Figure 2). The formation of aggregates can be forced by continuous agitation and/or centrifugation. With this method, it is possible to establish 3D cell cultures containing one or more cell types, with a spherical morphology and a variable size (50–150 μm)

[5][44]. Human iPSCs were seeded in 96-well ultra-low attachment plates to create a model of multicellular human liver organoids

[6][45]. The liquid overlay technique was successfully employed to obtain other 3D cell cultures, such as neural organoids

[7][46], fibroblast spheroids

[8][47], cancer spheroids

[9][48], and MSC spheroids

[10][49].

Figure 2.

Schematic representation of liquid overlay technique used to obtain 3D cell cultures.

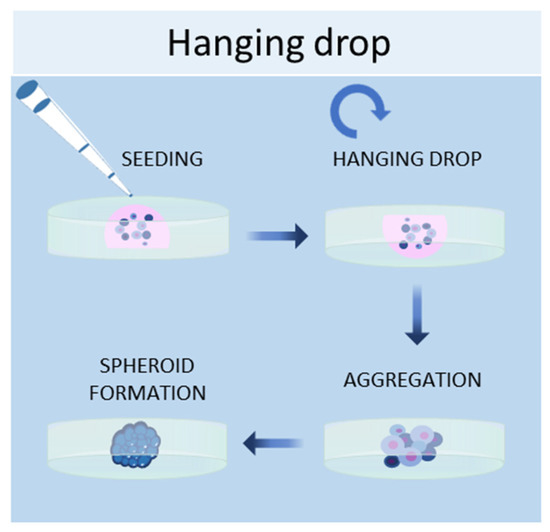

1.3. Hanging Drop Method

Another scaffold-free technique to culture cells in 3D is the hanging drop method, in which cells are placed in a suspended drop of medium, thus allowing them to aggregate and form spheroids at the bottom of the droplet (

Figure 3)

[11][50]. Once the cell suspension is prepared, a drop of the culture medium containing the desired number of cells is dispensed into the wells of a mini-tray, and then the mini-tray is inverted upside-down, while the drop containing the cell suspension remains attached to the mini-tray by surface tension. This method takes advantage of surface tension and gravitational force to form a 3D cell aggregate in the droplets, and it is possible to control the size of the spheroid since it depends on the size of the drop and the concentration of the cell suspension

[12][13]. Bartosh et al. used hanging drop methods to culture MSCs in 3D, demonstrating that MSCs grown in 3D secreted more anti-inflammatory molecules than those grown in 2D

[13][51]. Other groups established hepatic spheroids

[14][52], cancer spheroids

[15][53], a model of tumor angiogenesis

[16][54], mammary fibroblasts spheroids

[17][55], and pancreatic islet spheroids

[18][56] through this technique.

Figure 3.

Schematic representation of hanging drop method used to obtain 3D cell cultures.

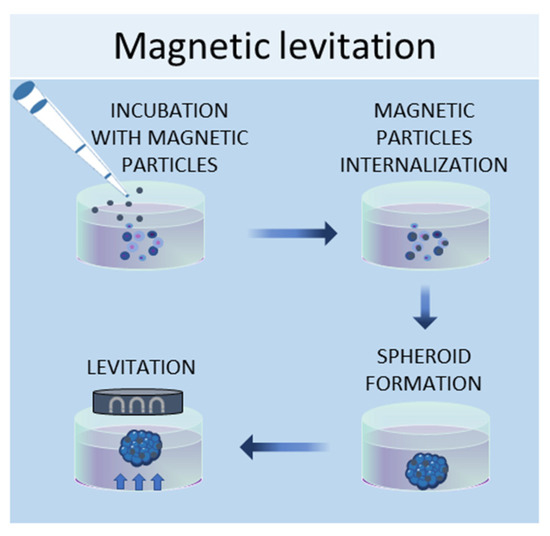

1.4. Magnetic Levitation Method

In the magnetic levitation method, cells are mixed with a solution of magnetic nanoparticles and subjected to a magnetic force

[19][57]. The magnetic nanoparticles are incubated with the cells overnight to allow their internalization. Then, the cells are detached and seeded in low-adhesive plates. A magnet is placed on the top of the plate lid and produces a magnetic force, which causes the cells to levitate against gravity, promoting cell–cell contacts and, therefore, leading to cell aggregation (

Figure 4). By using this system, it is possible to culture different cell types, such as

[20][58], MSCs

[19][57], hepatocytes

[21][59], cancer cells

[22][23][60,61], and osteoblasts

[24][62].

Figure 4.

Schematic representation of magnetic levitation method used to obtain 3D cell cultures.

2. Scaffold-Based Methods

The development of regenerative medicine based on engineered biomaterials offers a plethora of scaffolds that can be used as a template for tissue formation

[25][63]. These scaffolds must possess specific characteristics, such as chemical composition, shape, structure, and porosity scaffolds, in order to promote cell migration, adhesion, and tissue production

[26][64]. Additionally, for a biomaterial to be considered applicable in tissue engineering, it must meet the following requirements, which include high biocompatibility, reactivity to cell adhesion, biodegradability, elasticity, and minimal toxicity. The shape, porosity, and surface morphology are also important aspects to create a suitable scaffold that can represent the real architecture of the tissue to be repaired and replicate its vascularization and multicellularity of the tissues

[27][65], ensuring better transport of mass of the nutrients and oxygen

[28][66]. Hydrogel scaffolds, such as gelatin and Matrigel, are natural

[29][30][67,68] or synthetic

[31][69] crosslinked hydrophobic biomaterials that can absorb and retain water, thus reproducing the natural ECM in compositional and structural terms

[25][63]. Hydrogels have been used for various applications, such as for unicellular or multicellular 3D cultures to regenerate or study healthy or diseases tissues

[32][33][70,71], or for the development of tumor spheroids

[34][35][72,73] to study the tumor microenvironment. Commonly used scaffolds for 3D culture include naturally derived matrices and synthetic materials, which are discussed below.

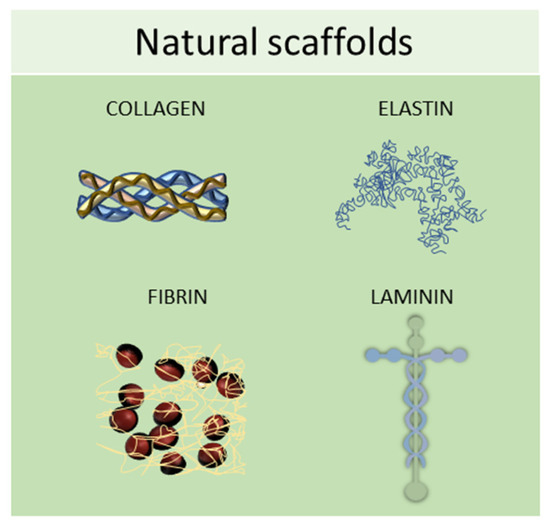

2.1. Natural Scaffolds

Natural scaffolds are represented mainly by decellularized scaffolds or composed of typical components of the ECM, such as collagen, elastin, laminin, or fibrin. Scaffolds made from natural compounds are biodegradable and biocompatible and can promote cellular interactions, adhesion, and signaling

[36][74]. However, some of them showed major limitations, such as inconsistent purity resulting from batch-to-batch variability and difficulty in sterilization and purification. To find solutions to these limitations, tissue engineering continually searches for natural biomaterials from plant and animal sources, such as silk fibroin, chitosan, alginate, gelatin, or Matrigel, or from the glycosaminoglycan family, such as hyaluronic acid, heparin, derman sulfate, chondroitin sulfate, or heparan sulfate (

Figure 5)

[25][63].

Figure 5. Schematic representation of some of the most used natural scaffolds (collagen, elastin, fibrin, and laminin) employed in scaffold-based 3D cell cultures.

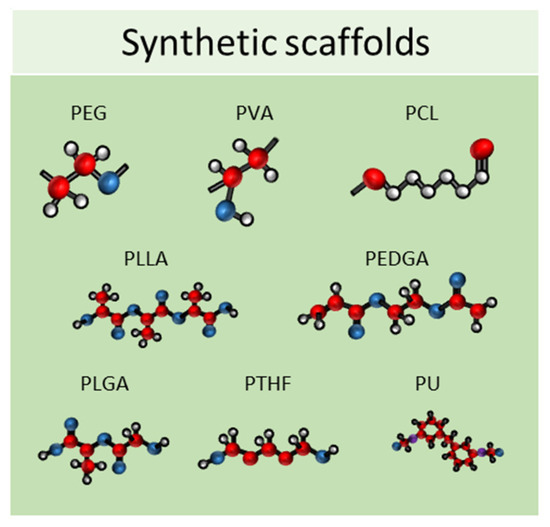

2.2. Synthetic Scaffolds

Synthetic scaffolds are represented mainly by polyethylene glycol (PEG), polyvinyl alcohol (PVA), polylactide-coglycolide (PLG), polycaprolactone (PCL), poly L-lactic acid (PLLA), poly (ethylene glycol) diacrylate (PEGDA), poly lactic-co-glycolic acid (PLGA), polytetrahydrofuran (PTHF), polyurethane (PU), and polyethylene terephthalate (PET); or by ceramics, such as calcium phosphate biomaterials, bioactive hydroxyapatite, and tricalcium phosphate or their associations (HA/TCP) and metals (

Figure 6)

[37][38][75,76]. All these materials meet the criteria needed for tissue engineering because they have higher biocompatibility, excellent biodegradability, and minimal toxicity.

Figure 6. Schematic representation of some of the most used synthetic scaffolds used in scaffold-based 3D cell cultures. PEG: polyethylene glycol, PVA: polyvinyl alcohol, PCL: polycaprolactone, PLLA: poly L-lactic acid, PEGDA: poly (ethylene glycol) diacrylate, PLGA: poly lactic-co-glycolic acid, PTHF: polytetrahydrofuran, PU: polyure-thane.

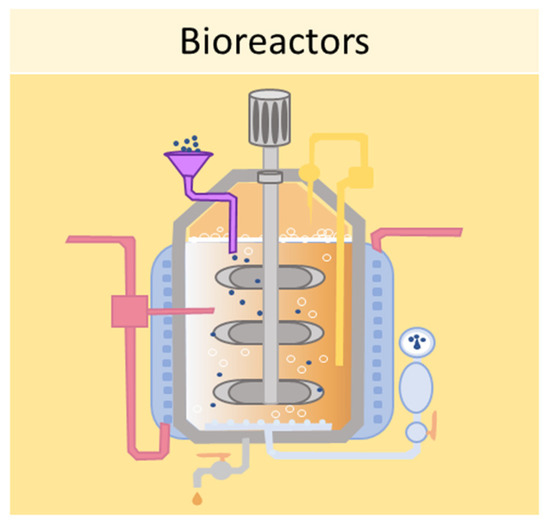

3. Three-Dimensional Culture in Dynamic Conditions

3.1. Bioreactors

One of the main limitations of using static cell culture conditions to obtain 3D models is the exchange of nutrients, as cell aggregates can reach 1–2 mm of thickness, making it difficult for the transfer of gases and waste products

[39][77]. Bioreactors allow for the establishment of dynamic 3D cell cultures, by controlling several parameters of the extracellular microenvironment, such as pH, temperature, flow rate, oxygen, nutrients, and waste products

[39][77]. Several designs for bioreactors are available, including rotating wall vessels, direct perfusion systems, hollow fibers, spinner flasks, and mechanical force systems. The spinner flask technique, for example, consists of seeding cells into spinner flask bioreactors, where the cell suspension is continuously mixed by stirring

[40][78]. It is crucial to choose the right convectional force of the stirring for the spheroid formation—if the force is too slow the cells will lay on the bottom of the container and not aggregate; conversely, if the force is too high the spheroids will be damaged

[1][40]. This system has been employed in dynamic cell cultures of MSCs, resulting in a high grade of adipogenesis and osteogenic differentiation

[41][79]. Another type of bioreactor is the rotating wall vessel, in which cells are subjected to microgravity by constant circular rotation

[42][80]. This constant rotation keeps the cells in suspension, thus modulating the differentiation capabilities of the MSCs. Sheyn et al. found that in microgravity conditions, adipogenic differentiation is favoured over osteogenic and chondrogenic differentiation

[43][81].

Figure 7 shows a schematic example of a bioreactor used to obtain 3D cell cultures.

Figure 7.

Schematic representation of a bioreactor which can be used to obtain 3D cell cultures.

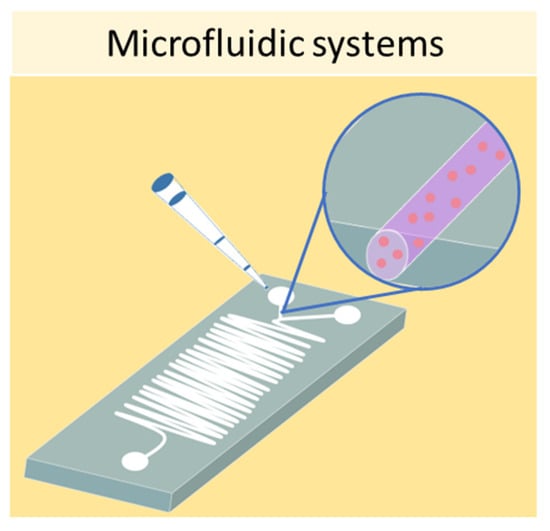

3.2. Microfluidic Systems

Finally, one of the most sophisticated methods to culture cells in 3D is represented by microfluidic devices, also known as organ-on-a-chip. Microfluidic systems are composed of microwells connected by microfluidic channels, thus allowing the continuous infusion of nutrients and growth factors (

Figure 8)

[44][82]. This is a key characteristic of microfluidic devices, as it addresses the main limitation of static 3D cell cultures, which is the inhomogeneous concentration of oxygen and nutrients in the cell aggregate. The resulting dynamic microenvironment reflects the in vivo conditions faithfully. This method has allowed the culture of hepatic spheroids with higher viability than those obtained with static culture conditions

[45][83]. Moreover, tumor spheroids were found to have higher resistance to drug treatment when cultured in flow conditions compared with static ones

[46][84]. Using microfluidic systems, it is also possible to co-culture different cell types, as demonstrated by Sun et al., who set up a model for drug screening by culturing spheroids composed of tumor cells and fibroblasts

[47][85].

Figure 8.

Schematic representation of a microfluidic device which can be used to obtain 3D cell cultures