A rapidly expanding global population and a sizeable portion of it that is aging are the main causes of the significant increase in healthcare costs. Healthcare in terms of monitoring systems is undergoing radical changes, making it possible to gauge or monitor the health conditions of people constantly, while also removing some minor possibilities of going to the hospital. The development of automated devices that are either attached to organs or the skin, continually monitoring human activity, has been made feasible by advancements in sensor technologies, embedded systems, wireless communication technologies, nanotechnologies, and miniaturization being ultra-thin, lightweight, highly flexible, and stretchable. Wearable sensors track physiological signs together with other symptoms such as respiration, pulse, and gait pattern, etc., to spot unusual or unexpected events.

- wearable sensors

- energy harvesting

- electrical sensing mediums

1. Introduction

2. Performance Comparison among Wearable Energy Harvesters

Piezoelectric wearable energy harvesters have the benefit of being able to produce high voltages, and their manufacturing processes could allow for further miniaturization. These devices are useful for a variety of applications, because they can effectively transform mechanical vibrations into electrical energy. They can be integrated into wearable devices due to their small size and high voltage output, which makes them suitable with many different electronic devices. Additionally, improvements in their manufacturing methods may result in PWHMSs that are even smaller and more effective. EWHMSs have a relatively simple fabrication method and allow flexibility with Micro-Electro-Mechanical Systems technology. They can produce large voltage levels and efficient low-frequency signal capture. Electrostatic harvesters need a small space between the plates to generate high power densities, however, this might cause the dielectric material to deteriorate with time. To begin energy generation, these devices need an initial voltage, which makes the system more complex. Despite these drawbacks, EWHMSs have demonstrated promise in absorbing energy from different kinds of motion. The integration of TWHMSs is quite simple. Depending on what temperature the device has, they can yield significant power densities. However, a method is needed to maintain this temperature difference, which would need the use of more power. Thermoelectric harvesters typically produce less energy and less voltage output than piezoelectric and electrostatic harvesters. However, they have the advantage of producing electricity from temperature gradients, making them appropriate for applications where there are substantial temperature changes. As a result, piezoelectric WEHs have the potential for further miniaturization and offer high voltage outputs. Electrostatic WEHs require a small gap and starter voltage, but are easy to fabricate and are adaptable with MEMS technology. Thermoelectric EHs have a lower energy production and output voltage requirements, but they are simple to incorporate and can generate large power densities based on temperature changes. The choice is based on the application requirements and environmental factors, as each technology has advantages and disadvantages of its own.3. Applications of Wearable Energy Harvesters

3.1. Heart Rate Monitoring

By picking up on the vibrations that the heartbeat causes, piezoelectric sensors can be used to determine heart rate. These sensors can be included in a wearable device, such as a wristband or chest strap, and used to continuously measure heart rate [41][190]. While piezoelectric sensors play an important role here, thermoelectric sensors can also be used in the same wearable devices for energy generation, which help in the monitoring of the heart rate for long periods, without the need to change the batteries, hence making them perfectly self-sustaining. This is great step, keeping in sight the concept of pacemakers that are used for abnormal heart monitoring. While this concept somewhat ancient and is in the implantable category, with the integration of piezoelectric and thermoelectric sensors, implantable heart-rate-monitoring technology can be shifted to self-sustaining wearable heart-rate-monitoring devices [42][191].3.2. Respiration Monitoring

The movement of the chest or abdomen during breathing can be detected using piezoelectric sensors, which can then be used to estimate respiration rate. Monitoring breathing patterns and spotting changes that can point to respiratory issues can be performed using these data [43][44][192,193]. The pressure or piezoresistive have shown great potential in this field, in the form of smart chest belts and smart shirts. Now, smart chest belts and shirts are simple, comprising smart piezoresistive sensors that sense the deformity caused due to the movement of the chest that is the result of breathing, and then the difference in the form of smart belts shows us breathing patterns and respiratory results [45][194].3.3. Movement Tracking

In a wearable device, piezoelectric sensors can be utilized to monitor movement and activity levels. These sensors, for instance, can pick up on limb movements during exercise or the vibration of footsteps [46][195]. An excellent example of such a principle are the insole devices used in shoes that use piezoelectric sensors, which sense changes in pressure through the steps of humans and can track simple human movements such as walking or running. Movement tracking is best for exercise purposes such as burning calories, through activities such as walking. The small and large deformations caused due to exercise provide the necessary data for health monitoring, which are collected by the pressure and strain sensors that are based on the piezoelectric principle [47][196].3.4. Sleep Monitoring

Piezoelectric sensors can be used to track sleep patterns by spotting motions and vibrations at odd hours. Using these data, one may monitor their sleep patterns and spot issues such as sleep apnea [48][49][197,198].3.5. Fall Detection

By monitoring the force with which a person’s body strikes the ground, piezoelectric sensors can be used to detect falls. In the event of a fall, this information can be used to contact the emergency services or carers. In addition, thermoelectric and electrostatic sensors are important here, because almost all physiological reactions of the human body result in heat and movements of different kinds, which can be sensed by different sensors based on the piezoelectric, electrostatic, and thermoelectric principles and cover the majority of the human body’s reactions. Based on the data collected by the sensors, an appropriate alert system and on-the-spot health measuring and monitoring can be performed, and the appropriate treatment methods can be prepared based on the same data compiled by the sensors’ monitoring.3.6. Smart Bandages

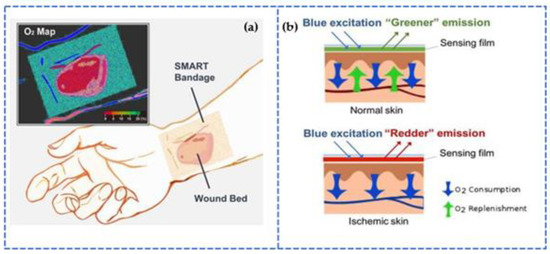

A new type of smart bandage that uses electrostatic sensors may make treating wounds simpler, more efficient, and less expensive. Despite traditional dressings, which are made of multiple layers of a sponge-like substance, smart bandages are made of a resilient and stretchable material with integrated circuitry and medicine. Electrostatic sensors keep an eye out for chemicals such lactate or uric acid, as well as pH or temperature changes in the wound that could indicate a bacterial infection or inflammation, which are shown in Figure 1a,b [50][199]. As shown in Figure 1b, a SMART bandage with an oxygen sensor is placed on healthy skin. Because of the high oxygen content in the tissue, the detecting phosphor’s red emission is quenched. The fluorescent reference dye causes the entire film to radiate a green color. Similarly, an oxygen-sensing SMART bandage is applied on ischemic skin at the bottom of the figure. Because there is less oxygen in the tissue, the bright red emissions of the detecting phosphor outperform the reference dye’s green fluorescence. The entire bandage is red in color.