Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Ashoka Sriyani Gamage and Version 2 by Fanny Huang.

As a novel post-harvesting strategy, edible films and coatings for fruits and vegetables offer preservation measures to meet the growing needs of hunger and agricultural management. Biopolymers, including polysaccharides, proteins, and lipids, are the main sources of preparing edible films and coatings. These biomacromolecules make stable colloidal dispersions that deliver processing convenience with various formulation, blending, casting, coating, and film-forming methods.

- biopolymers

- edible films and coatings

1. Introduction

Rapid population growth and the food supply chain crisis have exacerbated global hunger management. In addition, many geopolitical, socio-economical, and concurrent post-pandemic events have further aggravated the global food crisis. Global food waste generation in 2009 was 1.3 billion tons. It has been reported that 32% of food produced for human consumption is wasted across the worldwide supply chain [1][2][1,2]. As per the United Nations’ Food and Agriculture Organization (FAO), approximately one-third (or 1.3 billion tons) of the global food production designated for human consumption is wasted annually [3]. The main challenge in modern agronomy is resolving the hunger crisis while delivering adequate agricultural products and services. As a result, there is significant importance in developing novel food preservation and waste management strategies.

The magnitude of food waste can be equally expressed in terms of 3.3 gigatons (or 8% of the world’s total) of CO2 [4] or 250 km3 of blue water consumption that would spread across 1.4 billion hectares (28% of the world’s total) of agricultural landscape [4][5][6][7][4,5,6,7]. Global food waste is responsible for nearly USD 2 trillion, including environmental costs (USD 700 billion) and social costs (USD 900 billion) [8], which compounds to approximately 10% of the USD 23 trillion gross domestic product (GDP) of the United States of America [9]. Across the globe, developed and developing countries contribute between USD 680 billion and less than USD 310 billion in food waste on average [10]. As a result, under the sustainable development goals in 12.3, the United Nations has vowed to reduce per-capita food waste by 50% by 2030 through enhancements in food security and environmental sustainability as a hunger management strategy amid projected exponential population growth [11]. Therefore, sustainable, innovative, and high-performance packaging and coating solutions are required to accomplish the defined sustainable development goal.

Primary food commodities that generate food losses and wastes are classified into 10 subcategories according to FAO [12][13][12,13]: (a) cereal products (wheat, maize and rice), (b) roots and tubers (potatoes, sweet potatoes and cassava), (c) oilseeds and pulses (from various sources such as peanuts, soybeans and olives), (d) fruits, (e) vegetables, (f) meat, fish, and seafood, (g) dairy and dairy-related products, (h) eggs, and (i) products that cannot be specified. Among the abovementioned 10 subcategories, fruits and vegetables undergo the largest fraction of food losses and wastes in all regions, from high- to low-income countries [3][14][3,14]. On average, the total weight of vegetables (25%) and fruits (12%) contributes to total food waste [14]. Assessing wastage measures relevant to fruits and vegetables has many challenges. However, the mechanisms of waste generation that spread throughout the entire food chain can be indicated as follows [15]:

-

primary production (in agricultural production and harvesting),

-

secondary production (in postharvest handling and storage, processing, distribution, and retailing),

-

consumption (in-household and out-of-home).

Food that fails to meet the quality measures is considered food waste, and food losses lead to a decrease in food quantity or quality. Food waste and losses arise for various reasons, including contamination, poor handling and storage, spoilage, microbial-fungal growth, and other factors [16][17][17,18].

Edible films and coatings have recently been investigated as a commercially viable post-harvesting preservation strategy for fruits and vegetables. Interestingly, food can be consumed without removing the film or coating [18][19][20][19,20,21]. Edible films and coatings act as a thin protective barrier that extends shelf life of food in the post-harvesting, processing, transportation, storage, and consumption stages; prevents dehydration, deterioration, and spoilage; and preserves the color, freshness, flavor, and nutrients of the food [21][22][22,23]. Furthermore, edible films and coatings do not devalue or alter the nutritional value of fruits and vegetables.

The applications of edible coatings and films are subjected to extreme safety guidelines. These involve good manufacturing practices and the use of food-safety materials monitored by the Food and Drug Administration (FDA) [23][24][24,25]. Another safety measure is the use of Generally Recognized as Safe (GRAS) materials already approved by the FDA [25][26]. However, not all GRAS substances are considered consumer safe, as there can be rare allergic reactions caused by them, including lactose intolerance from milk and Celiac disease from wheat gluten. Apart from the FDA, the International Organization for Standardization (ISO) and the European Union (EU) are established regulatory organizations that maintain guidelines for the safe application of edible films and coatings [26][27].

Edible films and coatings for fruits and vegetables exhibit the potential to minimize preventable losses and waste and thus offer sustainable solutions to the global food crisis and hunger management.

2. Characteristics and Functionalities of Edible Films and Coatings

The definition of edible films and coatings is generally a thin barrier with a thickness of 0.3 mm and made from material that can be directly consumed [27][28]. Edible films and coatings are widely applied in contact with minimally processed fruits and vegetables. Even though the main functionality of edible films and coatings is similar, their processing techniques are different. For instance, edible films are pre-formed before contact with fruits and vegetables. In contrast, edible coatings are usually formed on the surfaces of fruits and vegetables, and layer formation occurs directly [28][29][29,30]. Both techniques form thin barriers from rigid matrices that can be further functionalized for extended applications.

When developing edible films and coatings, assessment of the following considerations is critical [30][31]:

- (a)

-

interactions with the food texture and surface;

- (b)

-

aging and prolonged performance of the shelf life of the food in contact;

- (c)

-

changes in flavor, color, and texture of food due to interactions with edible films and coatings;

- (d)

-

response and sensitivity under storage/environmental conditions;

- (e)

-

processing conditions, including temperature, color and thickness.

2.1. Key Functionalities of Edible Films and Coatings

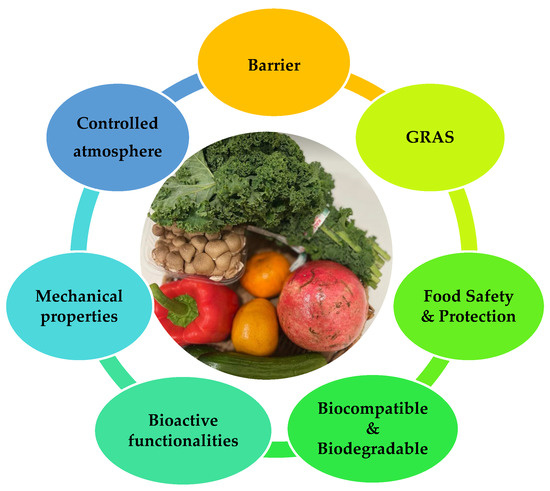

Edible films and coatings act as protective barriers and provide a controlled atmosphere around fruits and vegetables. Figure 1 summarizes the key functionalities of edible films and coatings in fruit and vegetable preservation.

Figure 1. Major functionalities of edible films and coatings in fruit and vegetable preservation.

-

Protection from transport, handling, mechanical damages, and UV radiation;

-

Barrier properties:

- (a)

-

Moisture barrier: minimizes water vapor transmission to prevent dehydration;

- (b)

-

Gas barrier: controls oxygen and carbon dioxide levels as they pass through the protective layer;

- (c)

-

Volatile organic compounds (VOC) barrier: protects against organic vapors such as aromas and solvents and other additives and pigments.

-

Prolongation of shelf life;

-

Bioactivity: shows antimicrobial and antifungal properties and acts as probiotics;

-

Biodegradability;

-

Structural integrity: melts above 40 °C without decomposition, water resistant, easily emulsifiable, non-sticky, or non-tacky, and delivery efficient drying;

-

Maintenance of food quality: minimal influence on texture, flavor, or color;

-

Formulated from economical, relatively abundant, consumer-safety GRAS materials.

-

2.2. Common Preparation Methods of Edible Films and Coatings

When processing edible films and coatings, the raw material and number of layers used play a significant role. In addition, the nature of the edible film may determine the overall film strength, solubility, surface activity, appearance, flavor, and texture in the mouth [23][24]. Edible films are primarily manufactured as sheets or thin wrap films and later used to cover food intact. Edible films and coatings are commonly prepared using melt extrusion and solvent casting techniques.

2.2.1. Melt Extrusion Method

The main steps in the melt extrusion method include formulation, melt blending, extrusion, cooling, and storage. Sheet extrusion, blown film extrusion, and reaction extrusion are commercialized melt extrusion techniques applied to prepare edible films [33][34][34,35]. Generally, the extruder temperature and operating conditions are determined by the thermal and rheological properties of polymers. Interestingly, biopolymers with thermo-plastic properties exhibit superior performance in melt extrusion. However, process aids and plasticizers are added to enhance polymer melt flow during the extrusion [35][36]. The film quality and clarity are ultimately determined by the degree of crystallinity of the polymeric matrix and the cooling rate. The polymeric matrix in the melt state undergoes re-crystallization when cooling and may change its polymorphic state [36][37]. Higher crystallinity may deliver extended barrier performance in highly amorphous polymers. However, the amorphous fraction of the polymers may significantly influence the optical properties and thereby control the clarity and transparency of films. The thickness of the films can be adjusted from the rotor speed and extruder parameters. However, formulation errors may lead to phase separation, non-uniform distributions, and irregularities in thickness.

2.2.2. Solvent Casting Method

Solvent casting is another widely used film processing method [37][38]. Unlike melt extrusion, solvent casting can be complicated depending on the solvent system and intended application [38][39]. Hence, stable colloidal systems need to be designed based on the solubility parameters of the polymers and the pre-selected solvent system. Moreover, to obtain stable and uniform films, essential process aids, such as emulsion stabilizers and oil- or wax-based surfactants, are added to facilitate the mixing. In addition, wetting and leveling agents are added to control the uniform wetting, surface tension, and surface defects, such as bubbles, pinholes, craters, and defoaming agents, to avoid the aeration of colloids [39][40][40,41]. Solvent removal and solidification are critical factors in the solvent-casting method. The solidification process is vital for the quality of the film or coating and is facilitated by a precise drying system because drying transforms fluid into a solid-state transition. Factors including coating formulation, number of layers, wet film/coating thickness, viscosity, solution solids, solution temperature, coating accuracy, and coating substrate must be considered when designing the coating or film using the solvent casting method.

Various drying systems are used in the solvent casting method. The drying system that is used depends on the requirements. Hot air convection, hot air impingement, steam, infrared, hot air flotation, and zoned drying are commonly employed drying systems. In addition, the rod, knife, and spin-coating methods are used in the batch film and coating processes [41][42]. In recent approaches, multilayer films and coating have been tested to enhance performance [42][43]. Moreover, lamination, calendaring, slot extrusion coating methods, dip coating, and spraying have also been employed in edible films and coating processes [43][44].