The textile and clothing (T&C) industry is not usually viewed as an exemplar of sustainable development and the circular economy (CE), as the industry has hitherto developed its products in a linear fashion, with relatively little recycling of the finished goods.

- textile industry

- clothing industry

- sustainable development

- circular economy

- digital technology

- corporate social responsibility

- products

1. Introduction

The global textile and clothing (T&C) industry is the fourth largest consumer of primary raw materials and water after the food, housing, and transport industries, and the fifth largest producer of greenhouse gas emissions [1]. Less than 1% of all textiles worldwide are recycled into new textiles, and it is thus appropriate that the industry has a pivotal role in the European Commission’s Action Plan for the Circular Economy. The Action Plan aims to change the way products are designed, produced, and consumed by focusing on several key sectors such as textiles for the promotion of the circular economy (CE), which has been defined by the European Union [2] as an “economy where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste minimized” (p. 2).

The recent shift towards internationalization and cost optimization through low-tech systems and outsourcing has intensified competition in the T&C industry and has meant that today Germany is one of the largest textile importers worldwide. German companies therefore have a special role to play in the switch to closed-loop systems in the T&C industry.

2. Sustainability and the Circular Economy

The most widely used definition of “sustainability” is development “that meets the needs of the present without compromising the ability of future generations to meet their own needs” [24][3] (p. 16), where such development is in harmony with the natural environment. In recent years, the concept has also been steadily gaining importance in the corporate context [25][4]. Based on the triple bottom line, as put forward by Elkington [26][5], the view has prevailed that to be fundamentally sustainable in the long term, an organisation must consider all the contexts in which it operates. This includes the three dimensions of sustainability, namely, social, ecological, and economic, which are often also referred to as people, planet, and profit [27][6]. At the same time, sustainability can best be assessed within the value chain in which an organisation operates, thus encompassing the entire supply network and incorporating upstream and downstream supply chain processes [30][7].

Within the wide definition of sustainability, the concept of the CE is increasingly being viewed as a key lever with which to initiate the transition to a more sustainable future. It is of interest and relevance to both academics and practitioners as it offers principles and approaches regarding how companies can implement sustainability [22,36,37][8][9][10]. In its most basic form, “a circular economy can be loosely defined as one which balances economic development with environmental and resource protection” [38][11] (p. 373). In a similar vein, the CE has been defined by the European Commission [2] as an “economy where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste minimized” (p. 2). The CE concept encompasses all stages of a product’s life cycle from product design and production through marketing and consumption to waste management, reuse, and recycling.

3. Digital Technologies and the Circular Economy

In recent years, digital technology and CE concepts have attracted growing interest in both the business and academic communities, and a number of recent papers provide different perspectives on the relationship between the two concepts. Many of the early models and frameworks of digitalisation focused on the emergence of the technologies and their impacts on processes and organisational structures, possibly resulting in new business models [55][12]. More recently, Lang [56][13] identified sustainability as a driver of digital transformation, and product transformation as one of four key pillars, illustrating the relationships between sustainability, the CE, and digitalisation.

Digital technologies can be defined as electronic tools, automated systems, and technological devices that allow very large quantities of data to be processed, transmitted, and stored [7][14]. Two acronyms are often used as generic terms to encapsulate these technologies: SMAC (Social Media, Mobile, Analytics/Big Data, and Cloud) and BRAID (Blockchain, Robotics, Artificial Intelligence/Knowledge Work Automation, the Internet of Things, and Digital Fabrication). Some authors specify that some of these technologies are of particular significance with respect to promoting and supporting the CE. Bressanelli et al. [60][15], for example, explored how the IoT, big data, and analytics can support a transition to a CE. Owen-Jackson [61][16] observed that “Internet-connected sensors can track the location, condition, and availability of assets in a supply chain. Direct exchange of information via secure, decentralised channels like blockchain can keep these communications secure. Together, these innovations can optimise resources, extend lifecycles, and help regenerate natural resources” (para. 10). As regards the T&C industry, there are very few studies on the use of digital technologies in the context of the CE.

4. A Framework for Transitioning to the Circular Economy

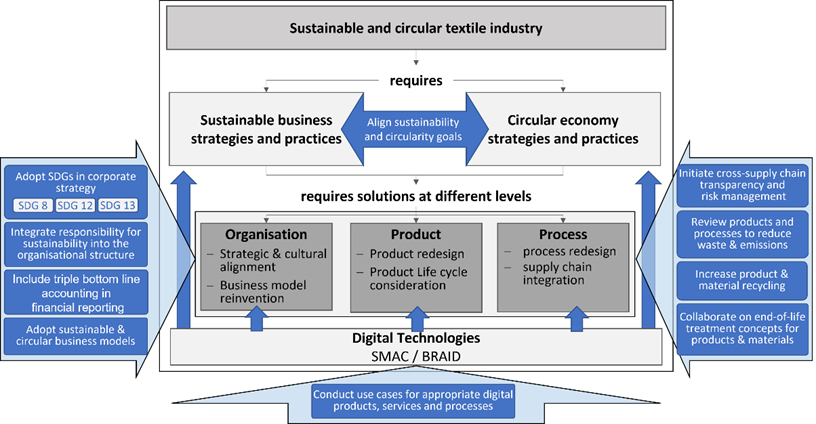

This preseaperrch focuses on the research of 29 small and medium sized largely German T&C companies. The findings indicate that the industry is at a turning point, with the circular economy gradually becoming a strategic priority. Some companies explicitly incorporate circularity into their sustainability strategies, while others adopt specific measures without linking them to strategic objectives. A practical operational framework can help to guide companies in transitioning to the circular economy (Figure 1) and can act as a top-level blueprint to kick-start and monitor transition.

Figure 1. Operational framework for transitioning of T&C companies to the CE.

This blueprint involves aligning circular economy strategies with broader sustainability goals and incorporating them into the overall business strategy. Initiatives to change organizational culture, training programs, structural changes, and product redesign are crucial. Additionally, collaboration among supply chain partners, end-of-life treatment, quality assessment, and data transparency are essential elements. The adoption of digital technologies, through pilot projects and wider technology change initiatives, will further facilitate this transition.

5. Conclusion

The T&C industry is transitioning towards a circular economy. With the integration of digital technologies, the industry has the potential to reshape its products, practices, and business models to achieve sustainability goals. Embracing the circular economy principles, fostering collaboration, and leveraging digital technologies are key steps in creating a more sustainable future for the T&C industry.

References

- European Commission. Sustainability Strategy for Textiles. Available online: https://ec.europa.eu/growth/industry/sustainability/strategy-textiles_en (accessed on 28 December 2021).

- European Commission. Closing The Loop—An EU Action Plan for the Circular Economy. Available online: https://ec.europa.eu/transparency/documents-register/api/files/COM(2015)614_0/de00000000332178?rendition=false (accessed on 11 March 2022).

- World Commission on Environment and Development. Our Common Future. Available online: https://digitallibrary.un.org/record/139811 (accessed on 1 May 2022).

- Montiel, I. Corporate Social Responsibility and Corporate Sustainability. Organ. Environ. 2008, 21, 245–269.

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; New Society Publishers: Gabriola Island, BC, Canada, 1998; ISBN 0865713928.

- Amini, M.; Bienstock, C.C. Corporate Sustainability: An Integrative Definition and Framework to Evaluate Corporate Practice and Guide Academic Research. J. Clean. Prod. 2014, 76, 12–19.

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710.

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32.

- Wynn, M.; Jones, P. Can Digital Technologies Deliver the Circular Economy? Breakthrough. 2022. Available online: https://breakthrough.neliti.com/digital-technologies-circular-economy/ (accessed on 25 April 2023).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232.

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380.

- Turchi, P. The Digital Transformation Pyramid: A Business-Driven Approach for Corporate Initiatives. Available online: https://www.thedigitaltransformationpeople.com/channels/the-case-for-digital- (accessed on 4 October 2021).

- Lang, V. Digitalization and Digital Transformation. In Digital Fluency; Lang, V., Ed.; Apress: Berkeley, CA, USA, 2021; pp. 1–50. ISBN 978-1-4842-6773-8.

- Wynn, M.; Jones, P. Digital Technology Deployment and the Circular Economy. Sustainability 2022, 14, 9077.

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in Supply Chain Redesign for the Circular Economy: A Literature Review and a Multiple Case Study. Int. J. Prod. Res. 2019, 57, 7395–7422.

- Owen-Jackson, C. Reducing Waste and Cutting Costs: How Digital Tech is Powering Up the Circular Economy. Available online: https://www.kaspersky.com/blog/secure-futures-magazine/circular-economy-it/31811/ (accessed on 28 March 2023).