Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Lucjan Sajkowski and Version 3 by Fanny Huang.

Several elements found in New Zealand geothermal fluids are currently considered ‘critical’ for the transition to a carbon-neutral economy and are present in economically extractable quantities. Researchers estimate that each year, approximately 1100 tons of lithium pass as heat exchange fluids through Wairakei geothermal power station.

- geothermal fluid

- critical elements

- Lithium extraction

- Element distribution

1. Introduction

Building a low-carbon energy ecosystem for Aotearoa, New Zealand, will require access to new resources of specific elements and materials. Elements that play an important role in low-carbon future technologies—many of which are classified as ‘critical elements’—are unevenly distributed around the world [1]. Often, ‘critical element’ supply chains (both for mining and processing) are dominated by a few players that are granted a “near-monopoly” in a small number of countries. While global efforts to secure supply chains of critical elements have focused on traditional mineral ore bodies and material recycling, critical elements are known to occur in geothermal fluids in economically extractable quantities [2][3][4][5][6][7][8][2,3,4,5,6,7,8]. Geothermal fluids used to generate electricity represent a particularly interesting opportunity for critical element extraction, thanks to the existing substantial infrastructure. Although the process of economic recovery of aqueous critical elements presents technical challenges [3][9][3,9], it is certainly worth exploring, especially considering the potential added value to producing geothermal power stations [10].

2. Critical Elements

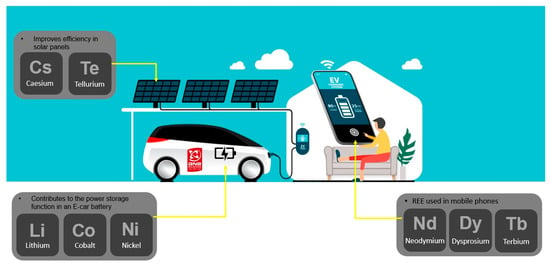

Critical elements are defined as those that are crucial to society for economic growth and/or national security but which are vulnerable to supply disruption (Figure 1) [11]. They are usually in high demand and have no practical substitutes. As such, the elements deemed ‘critical’ change through time due to social, technical, and political changes [12]. Presently, most of the elements classified as ‘critical’ are essential components for clean energy (i.e., solar, wind) and clean technology (i.e., electric vehicles, home battery devices) sectors and are therefore crucial in enabling the move to a global low-carbon economy. There are currently 50 elements and minerals listed as critical in the United States of America (USA) [13]. These are: aluminum, antimony, arsenic, barite, beryllium, bismuth, cerium, caesium, chromium, cobalt, dysprosium, erbium, europium, fluorspar, gadolinium, gallium, germanium, graphite, hafnium, holmium, indium, iridium, lanthanum, lithium, lutetium, magnesium, manganese, neodymium, nickel, niobium, palladium, platinum, praseodymium, rhodium, rubidium, ruthenium, samarium, scandium, tantalum, tellurium, terbium, thulium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Figure 1. Examples of the use of some critical elements in green technology (electric car batteries, solar panels) and high-tech electronics (i.e., smartphone batteries, magnets, and screens). The examples above include numerous other critical elements not shown that are essential to their various technologies (e.g., electric vehicles).

In comparison, the European Union defined its own list of critical materials (elemental groups and minerals) [14][15][14,15], including many of the elements listed as ‘critical’ by the US Geological Survey (USGS), but also including bauxite, borate, coking coal, natural rubber, phosphate rock, phosphorus, silicon metal, and strontium.

New Zealand does not currently have a list of elements considered ‘critical’ for societal, economic, and/or national security reasons. However, the necessity for the development of such a list has been recognized as a part of a plan to secure affordable resources to meet New Zealand’s future mineral and energy needs. As part of the Ministry of Business, Innovation and Employment’s (MBIE) 2019–2029 Resource Strategy for New Zealand, a list of critical minerals specific to New Zealand is in development [16].

3. Extraction of Critical Elements from Geothermal Fluids

Growing demand for carbon-neutral renewable energy is generating an incentive to grow geothermal developments worldwide. New Zealand is no different, and geothermally generated electricity accounts for c. 20% of New Zealand’s total electricity supply, with new field developments still ongoing. In addition to generating electricity, geothermal fluid can also be used as a direct source of heat energy in industrial, commercial, and residential sectors. In Iceland, geothermal heating utilizing geothermal fluids piped into buildings has provided heating and hot water for >90% of all of Iceland’s buildings for more than 20 years [17]. In New Zealand, geothermal heat is used to dry timber, manufacture milk powder, and heat glasshouses for horticultural purposes.

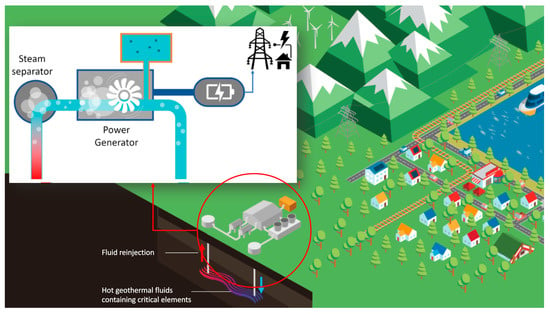

Well-managed geothermal resources are a source of clean, reliable, and sustainable energy. Once geothermal fluid has been extracted from a production well and has been used to generate electricity or supply heat, the energy-depleted fluid is reinjected back into the reservoir through reinjection wells some distance from the production well. The reinjected fluid flows through the fractured reservoir network (i.e., permeable zones in the rock), extracting more thermal energy from the rocks and mixing with the reservoir fluid as it flows back towards the production well [18][19][20][21][22][18,19,20,21,22].

In recent years, research has begun to examine the potential for the commercial extraction of various elements from geothermal fluids (Figure 2), (i.e., [3][4][6][23][24][3,4,6,23,24]. This new and emerging industry has the potential to develop into a significant multi-million-dollar industry both in New Zealand and internationally. However, multidisciplinary collaborative research is necessary to assist in removing implementation barriers [25]. Despite promising fluid compositions and the substantial volume of geothermal fluid production at numerous geothermal fields in the Taupo Volcanic Zone (TVZ), the additional opportunity for critical element extraction at a commercial scale in New Zealand is yet to be realized for minerals other than silica.

Figure 2. Cartoon highlighting the co-existence of geothermal energy production and critical element extraction from geothermal fluids (i.e., lithium).

4. Recovery of Elements from Geothermal Fluids

The concept of multi-element extraction from geothermal fluid is not new. In the 1960s, extraction of lithium, sodium, and potassium from the Wairakei geothermal field was considered [26]. In the early 1980s, a pilot plant at Wairakei was set up to separate solids (e.g., calcium silicate) from geothermal fluid [10]. Subsequently, over the years, many researchers and engineers have revisited the opportunity for mineral extraction from geothermal fluids [3][5][6][8][9][25][27][28][29][30][31][3,5,6,8,9,25,27,28,29,30,31].

Today a sustainable silica extraction plant is in operation at the Ohaaki geothermal power station in New Zealand, with a lithium extraction plant in the pilot stages of operation. In the USA, at Salton Sea, California, three companies are developing chemical processes to extract lithium in economic quantities from geothermal fluids [32]. Similarly, other countries, including the United Kingdom (UK) and Italy, are exploring opportunities to extract elements from geothermal fluids [33][34][35][33,34,35], and in Germany, the first example of battery-grade lithium has already been produced from geothermal fluids [36].