Originally regarded as auxiliary additives, nanoparticles have become important constituents of polyelectrolyte multilayers. They represent the key components to enhance mechanical properties, enable activation by laser light or ultrasound, construct anisotropic and multicompartment structures, and facilitate the development of novel sensors and movable particles.

- nanoparticles

- polymers

- layer-by-layer

- films

- LbL

- coatings

- capsules

1. Introduction

Versatile LbL (layer-by-layer) polyelectrolyte multilayer coatings have steadily drawn the increasing attention of researchers. This is driven by various factors including the versatility of the approach and an extensive range of applications, which is steadily continuing to increase. Originally, LbL was developed as planar layers [1]. In such an assembly [2], the structure of polyelectrolytes, the influence of water, pH, and salts on the LbL assembly have been investigated Various interactions and assembly methods [3][4][3,4] in the LbL assembly have been explored, including the electrostatic interaction, hydrogen bonding [5], while micrometre thick films have been also developed [6]. The extensive range of application of planar LbL coatings has included antifog [7]and ultraviolet (UV)-protective coatings [7], cell adhesion and tissue engineering [8]. A fundamental understanding of the interaction of polyelectrolytes has opened opportunities for versatile assembly of polymers incorporating diverse building blocks. Nanoparticles (NPs) have been explored as components of the LbL assembly in earlier publications [9][10][11][9–11] but their full potential has been recognised somewhat later, after enabling remote opening, increasing the efficiency of the effect of ultrasound on affecting the polyelectrolyte coatings, enhancing mechanical properties of capsules, extending the range of materials for sensors.

Originally developed for planar structures and substrates, the LbL approach has been transferred to spherical templates, which led to preparation of an LbL assembly freely suspended in water. This can be done by applying the LbL coatings onto colloidal particles, and subsequently dissolving the colloidal particle, which is also called a template for LbL assembly. The spherical shells, also called capsules, enable the polyelectrolytes to be freely suspended in an aqueous solution: the substrate holding the planar polyelectrolyte multilayers is thus not present. In this case, the zeta-potential of capsules can be easily measured, and polyelectrolytes are bound to each other directly, without a substrate. As a result, various stimuli can now be applied to control the LbL assembly [12], as it was shown, for example, studying the influence of pH and salt on the interaction of polyelectrolytes [13][14][13,14].

2. Functionalization of Polyelectrolyte Multilayers—Organic versus Inorganic Building Blocks

2.1. Incorporation of Dyes in Layer-by-Layer (LbL) Coatings—Bringing Multifunctionality through Organic Moieties

Various materials [15][16][17][18][19][20][21] [21] can be incorporated into self-assembled LbL coatings. Although charged molecules have been traditionally employed in the LbL assembly, non-charged molecules or dyes can be ordered in LbL films by means of chemical bonding or by carriers. Pyrene molecules were shown to be incorporated in polyelectrolyte layers in a liposome-mediated process. In this regard, pyrene molecules were encapsulated into poly(acrylic acid)-stabilized cetyltrimethylammonium bromide micelles followed by LbL assembly of the micelles in a poly(diallyldimethylammonium chloride) (PDADMAC) framework [22], where optical signal is detected by detecting optical resonances of light propagating around a sphere, also referred to as whispery gallery modes. Moreover, the inclusion of dye into nanocomposite LbL-assembled film was found to be a simple method to provide spectroscopic analysis of stability (both structural and chemical) and adsorption properties of the film [23]. Additionally, fluorescent dyes bound to non-fluorescent particles via LbL films were shown to generate a strong whispering gallery modes signal for bioanalysis [24]. Incorporated in LbL layers electroactive dyes have also received substantial attention. It was shown that the way to incorporate electroactive anthraquinone dye to LbL films strongly influences its electrochemical properties and chemical properties [25]. Metachromic cationic dye methylene blue was investigated for organization in the LbL framework [26]. In addition, photocleavable chromophores [27], laser absorbing dye (IR-806) [28], bacteriorhodopsin [29], phthalocyanine [30], porphyrin [31][32][31,32], and naphthalocyanine [33] have been also incorporated in microcapsules for remote opening by laser light, but it was also noticed that inorganic nanoparticles appeared to be much more effective laser light absorbers

2.2. Incorporation of Nanoparticles in LbL Coatings—Hardness Enhancement and Additional Properties through Inorganic Building Blocks

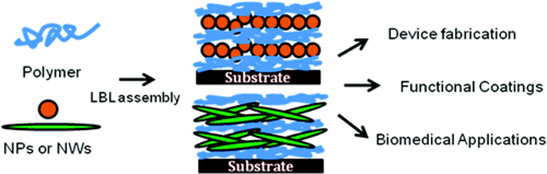

Although nanoparticles have been perhaps most frequently used for LbL functionalization, various nanostructured building blocks, nanocomposite films with nanoparticles embedded in the layered structure have been shown to be a highly effective class of material to tune various properties (among which mechanical stiffness) with a high accuracy [34], Figure 1. Various methods have been used for LbL assembly with nanoparticles, where in addition to a dipping or incubation, spin-spray LbL assembly [35], spin-coating [36], spray assisted alignments [37], and cross-linking after infiltration [38] were used. Nanocomposite LbL films containing immobilized ZnO/SiO2 nanoparticles were investigated to provide UV protection properties [39]. Alternating layers of cerium oxide nanoparticles (CONP)/alginate were fabricated on top of beta cells via LbL exhibiting robust antioxidant activity and providing excellent protection to these cells upon exposure to 10−4 M of H2O2 without affecting the metabolism of the cells [40].

Figure 1. Schematics of incorporation of inorganic nanoparticles, nanowires and nanosheets in layer-by-layer (LbL) assembly. Reproduced with permission from [34]. Copyright 2008 American Chemical Society.

3. Planar LbL Coatings and Their Functionalization by Nanoparticles

Nanoparticles have been essential components of planar layers, where they were used for enhancement of mechanical properties, remote activation, controlling the stiffness of the coatings, for quantum dots incorporation and corrosion protection.

3.1. Enhancement of Mechanical Properties and Remote Acteivation of LbL Coatings

Mechanical stability of capsules and films plays an essential role in enabling practical applications. The addition of nanoparticles would thus increase the shell stiffness. It should be added that the same concept of strengthening mechanical properties of LbL by adding nanoparticles has been also shown for planar coatings. In regard with mechanical properties of planar coatings, mechanical properties of nanometre-thin [41] [41] LbL films [42] (each LbL layer was reported to be 1–2 nm) resemble those of the substrate on which they are assembled (often glass, metal or plastic). But thicker LbL films [43], with a high molecular dynamic of polyelectrolytes [44], are rather soft, hindering cell growth in biomedical applications. One way to increase the stiffness of the coatings is to use chemical cross-linking [45][46][45,46]. Another possibility to improve the mechanical properties and enable the adherence of cells on the coatings is to functionalize the surface with metal nanoparticles [47]. Recently, particles and nanoparticles have been used to stimulate cell adhesion on the planar and soft hydrogel coatings relevant for osteoblasts and different types of cells [48].

3.2. Passive and Active Activation of LbL Coatings

Passively active coatings are those in which they or some of their components exhibit a certain functionality. For example, alternating layers of hyaluronic acid–dopamine conjugate with silver nanoparticles demonstrated a remarkable antibacterial [49][50][49,50] effect as well as improved adhesion, proliferation, and viability of cells to the surface, which promoted the formation of an apatite layer resembling bones [51]. In another example, incorporating of inorganic particles [52] into hybrid (organic-inorganic) coatings enabled effective cell growth, which is seen of a particular importance to various areas of tissue engineering [53].

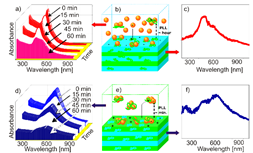

An active functionality of nanoparticles was to functionalize the micrometre thick LbL coatings with nanoparticles and use them as active absorption centres for remote laser action. Nanoparticle functionalization of such a soft LbL coating is depicted in Figure 2 (left), where step-by-step assembly is presented for non-aggregated (red) and aggregated (blue) states of nanoparticles. Choosing proper aggregation state of nanoparticles and laser wavelength corresponding to the maximum absorption of NPs, one can locally cross-link the surface of films exposed to laser, Figure 2 (right). Even more drastic action of laser-nanoparticle interaction has been implemented in cell detachment [54], differentiation [55], and cell death induction [56].

Figure 2. (Left) Kinetics of adsorption of non-aggregated (a–c) and aggregated (d–f) nanoparticles onto biocompatible poly-L-lysine (PLL)/hyaluronic acid (HA) films. (Adsorption on (PLL/HA)24 films are shown in (a–c), while adsorption on (PLL/HA)24PLL films is demonstrated in (d–f)). Ultraviolet–visible (UV/Vis) absorption spectra of the supernatant solution during adsorption in (a) and (d) were recorded at 15 min time intervals. Schematics of the interaction of nanoparticles and the films in non-aggregated and aggregated states are demonstrated in (b) and (e), and the corresponding UV/Vis absorption spectra of the films after nanoparticle adsorption are given in (c) and (f), respectively. (Right) Confocal laser scanning microscope images of a (PLL/HA)24 film functionalized with aggregated gold nanoparticles (a). The zoomed-in area shown in (b) was exposed to a near-infrared (NIR) laser leaving characteristic dark spots, (c). The dark spots (c) affected by the near-IR laser can be also seen in the transmission image, (d). The scale bars in (a–d) correspond to 15 µm. The technique described in (a–d) is used to write MPI-KG (Max-Planck Institute of Colloids and Interfaces (German spelling)) (e), the scale bar here corresponds to 20 µm. Reproduced with permission from [57]. Copyright 2010 Wiley-VCH Verlag GmbH.

However, this is not the only functionality of the nanoparticles in the coatings—they can be also used to control the masking for fabricating Janus particles.

3.3. Assembling Janus Particles and Capsules Using LbL Coatings

Janus particles have at least two different surfaces referred to one structural unit [58]. Interest in Janus capsules is associated with a combination of delivery [59][12,59] for various therapies and self-propelled micro-/nanomotor approaches [60][61][62][60–62]. Applied to the encapsulation process, Janus particles combine different properties and provide a range of functions such as delivery, recognition, release of therapeutics, enzymatic activity, physical and chemical sensing [63][64][63,64]. In particular, drug delivery is focused on: (i) encapsulation of active chemicals [65], (ii) targeted delivery [66], and (iii) stimuli-responsive release [12]. Therefore, approaches for Janus structure creation aim for a high loading capacity [67] via hierarchical organization.

Methods for fabrication of the Janus particles can be grouped into three main approaches: direct synthesis, chemical modification of particles at biphasic interfaces, and topographically selective modification of particles [68][69][70][68–70]. Typically, the following methods are used for fabrication: sputtering [71], gel trapping [72], microcontact printing[73] [73], and masking [74]. Another example of such an application is where nanoparticles were used to control the stiffness of the coatings, which, in turn, were used as a substrate-template for assembly of Janus particles and capsules [75]. The embedding has been regulated by the stiffness of the coatings, which is proportional to the concentration of nanoparticles incorporated into the surface of the coatings.

An interesting uncomplicated way of polyampholyte Janus-like particles formation was shown recently [76]. There, sites of molecules with opposite charge were pooled apart. The polyampholyte structure suggests that such Janus-like particles are dependent on both pH of the solution and its temperature. To create biocompatible Janus polyelectrolyte particles with a high monodispersity, the layer-by-layer technique was combined with multiphasic fabrication and patterned wettability [77]. Engineering self-propelled motors having a controllable speed can be of interest for many applications. For example, it was suggested to use bubble propulsion to move Janus polyelectrolyte particles [78]. Janus microcapsules were formed by grafting polyelectrolyte salt-responsive brushes onto preformed (poly(styrene sulfonate) PSS/(polyallylamine hydrochloride) PAH)4 microcapsule protected from one side. Depending on the presence of chlorate and polyphosphate anions brush modulation between hydrophobic and hydrophilic configurations was achieved. Upon gradually changed ion concentration, brushes could partially change their state, thereby adjusting the speed of the particle. In other words, it was possible to create particles with continuously propagating with adjustable speeds completely autonomously due to the surrounding chemical concentration gradients in the solution.

Recently, near-infrared (IR) irradiation was used to induce propulsion of Janus motors [79]. There, the particles constructed with erythrocyte membrane-cloak were used to ablate thrombus. Positively charged chitosan and negatively charged heparin were assembled using the LbL approach for building biocompatible and biodegradable capsules. The sensitivity to near infrared irradiation of capsules was achieved by using a sputtered gold layer on a part of the capsule. We note also that other polyelectrolyte systems modified with Au, e.g., hyaluronic acid (HA)/poly-L-lysine (PLL) (HA/PLL)12 [75], became sensitive to near-infrared irradiation. Due to asymmetric coverage of particles with gold IR irradiation crates a local thermal gradient. That led to self-propulsion of the particles, based on thermophoresis effect. Consequently, the intensity of the irradiation directly influences the motile of the particles up to on-off switching behaviour. Besides Au, other nanoparticles, e.g., Pt, and enzymes, were assembled to self-propel capsules [80][81][80,81]. In addition, bending and rotational motions of micromotors were also implemented [82] in polymer tubes with poly(allylamine hydrochloride) as positively charged and poly(acrylic acid) as negatively charged polyelectrolytes. Alkaline treatment of one longitudinal side of the tube leads to asymmetry in action (swellability), thereby providing a bent motion. When placed in a fuel solution, such supramolecular structure demonstrates bending for soft connector tubes, and stable rotation for rigid angled ones. In addition, the connection angle determines the rotation velocity. It was noted that such structures could find their application in micro- and nano-machine engineering and biomedicine, such as microscale surgery and drug delivery.

Systematic description and comparison of the influence of grafting density onto interface properties [83] showed that swelling on planar and curved substrates upon changing of grafting density behave in different ways. In other applications, moving Janus capsules was suggested for separation of organics [84], where a reversible adsorption of organic dye by multilayered polyelectrolyte structure was shown. Thus, it is claimed to adsorb about 90% of dye species at pH higher than 9.0 and to release them back at the neutral pH value. The adsorption process is presumably ruled by electrostatic interaction of positive sites of polymer structure and the anionic form of dyes. Application of the above structures in water analysis has been proposed. Contrary to the approach used in classical drug delivery [85], a method of HeLa controlled transportation of cells was also presented. The system is based on relatively known and popular bubble-propelled particles, constructed of polyelectrolytes. It is reported that cells survive both the Janus particle attachment and subsequent movement in 5% H2O2 solution for over 20 min. A magnetic field is also claimed to be guideline technique by tuning the friction of moving object. Thereby, up to 90% of moderation could be achieved. Similarly, a high suitability of anisotropic shell for cell or cellular compartments has been also highlighted [86].

Janus capsules coated with leucocyte membranes were proposed as the possible treatment of some cancer cases [87]. The photothermal effect combined with a rapid water evaporation was used to deliver and attach capsules to the cancer cell wall and subsequently induce a damage to cells. Another publication [88] also highlights the possibility of coating Janus particles with leucocyte membrane to adhere to cancer cells. The second step of phagocytose is also observed for such cells labeled by Janus particles. Janus particles constructed to exhibit thermophoresis were applied for welding of mouse tissue via infrared laser heating [89] with the photothermal heating confined on single particles. Eventually, mechanical restoration of welded mouse tissue was proved with a set of mechanical characterization techniques.

Nanoparticle functionalization of planar LbL coatings has been shown to play an important role in controlling the patches of Janus particles and capsules, but nanoparticles have been also directly applied to release adsorbed materials on the surface coatings [90].

3.4. Corrosion Protection of the Coatings

Application of polyelectrolyte layer-by-layer deposition spurred interest in the field of corrosion protection as a possible way to replace toxic Cr(VI)-compounds [63]. One of the main advantages of polyelectrolyte structures is their light, pH, and humidity responsiveness, which would enable a self-healing process by changes of environment that existed at the beginning of the corrosion. Such a system seems to be useful both for steel alloys [91] [91] and non-ferrous materials [92][93][94][63,64,92–94].

The protective layer can consist of pure polyelectrolytes [92] (optionally with corrosion protective additives) and could be multi-layered with sol-gel [64] and/or corrosion inhibitor coatings [91]. The more sophisticated way is based on creation micro- and nanocapsules with PE coatings. Capsules can be templated (the template is the dissolvable core) on SiO2 particles [93][95][63,93,95], TiO2 nanoparticles [95], nanotubes, and pure polyelectrolyte nanocapsules [96][97][96,97]. Different corrosive protection substances, such as benzotriazole [93][94][95][64,93–95] and its derivatives [97], and monomers for filling scratches for further induced polymerization, could be loaded inside these capsules. They are then incorporated in a more complex matrix such as sol-gel [98][93,95,98], epoxy [97] coatings, or polyelectrolyte multilayers [96]. Combined, these structures demonstrate mechanical strength, corrosion protection, and self-healing processes [99], triggered by initiation of corrosion or laser irradiation.

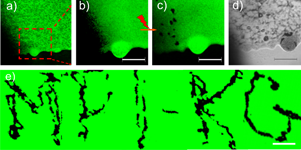

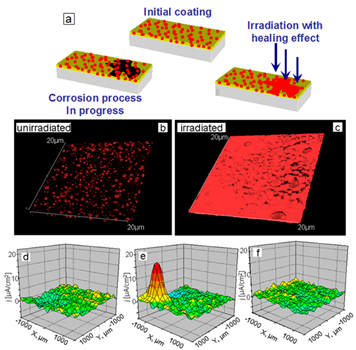

We highlight here the development of light-sensitive capsule-based active materials [100][101][102][95,100–102]. The principle of the approach is shown in Figure 3. Corrosion mitigating inhibitors encapsulated in the capsule with mesoporous core and light-controlled permeability of the shell have been used for developing coatings with self-healing functions, which are enabled by controllably releasing the inhibitor upon exposure to laser (infra-red) irradiation. Titania nanoparticles [100] can provide multilayers with photosensitivity. Thus, titania was used both as containers for loading benzotriazole (BTA) for corrosion inhibition and as photosensitive agents. Such capsules were then covered with polyelectrolytes, and they released inhibitor upon UV light irradiation.

Figure 3. (a) Scheme of light-responsive protective coating. Luminescent confocal images of polyelectrolyte containers with titania cores incorporated into SiOx-ZrOx films. The images are obtained (b) before and (c) after UV irradiation. The particles in the figures correspond to aggregates of nanocontainers. Three-dimensional (3D) maps of the ionic currents above the surface area correspond to a mechanical defect in sol-gel coating loaded with TiO2(benzotriazole)/(PEI/PSS)2 containers: (d) at the beginning moment on the artificial defect; (e) after 64 h of corrosion; (f) is (e) after UV-irradiation and inhibitor release. Solution: 0.1 M NaCl. Reproduced with permission from [100]. Copyright 2009 The Royal Society of Chemistry.

The conformational structure of polyelectrolytes depends on the pH of the environment. Thus, change in pH for certain configurations will result in different permeability of the structure. Thereby, the system could demonstrate both self-healing and self-regulation behaviour when pH changes due to corrosion process starts self-healing process. The reversible changes of polyelectrolyte permeability could be explained by locally changed pH of the solution, as the consequence of photocatalytic degradation of water on the titania. The end of irradiation or corrosion cause thus system relaxation, and particle returns to their initial structure. Visualization of local pH gradient is possible by model physico-chemical properties—scanning ion-selective electrode technique (SIET) [103][104][105][103–105].

The inclusion of metal nanoparticles via LbL procedure enabled the synthesis of materials for unusual applications too. Electroactive (2 nm in diameter) polyelectrolyte-capped Pt nanoparticles assembled into LbL arrays have been used in catalytic production of H2 [106]. Photocatalytic reduction [107] of noble metal particles on titania core [95] leads to dual-wavelength responsiveness: in the UV to near-IR regions of electromagnetic spectrum. It is possible to regulate photocatalytically (auto-catalytic) waves of enzymatic reactions [108], switch biofilm fluorescence [109], build a platform for a chemical logic device [110], and perform sustainable diagnostics [111][112][113][111–113]. The trend in the field of encapsulated systems is to combine different functions in one capsule matrix. One such functionality is to control the release of biocides together with corrosion inhibitors [114], while a prospective approach can lead to building self-regulating biocide systems [115].

3.5. Development of Sensors and Biosensors Based on Layer-by-Layer Assembled Coatings

Gold nanoparticles (AuNP) embedded into the polyelectrolyte matrices on the top of optical fibre exhibited a high accuracy pH sensing functionality based on the localized surface plasmon resonance (SPR) [116]. Measurement of pH shifts [117] was also implemented by incorporating gold nanorods, by detecting the surface plasmon shift of dispersed nanorods upon pH rise [118]. In another application, starch-stabilized silver nanoparticles in 3-n-propylpyridinium silsesquioxane chloride matrices were shown to function as SPR-based electrochemical sensors [119].

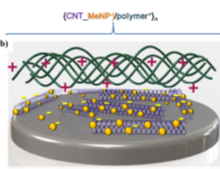

Hybrid materials assembled using carbon nanotubes and polyelectrolytes were shown to operate as effective membranes for the separation and rejection of ions [120]. Furthermore, the high electric conductivity of carbon nanotubes in a polymer framework allowed the development of multi-walled carbon nanotubes-based thin film electrodes transparent in the mid-IR (infrared) range [121].

It can be mentioned that sensory functions in planar coatings [122], Figure 4, represent a complementary area to those broadly implemented by polyelectrolyte multilayer capsules [123][124][125][123–125].

|

|

|

(a) |

(b) |

Figure 4. Schematics of LbL assemblies of: (a) polymer/nanoparticle (NP)/enzyme, and (b) carbon nanotube/NP/polymer sensors. Reproduced with permission from [122]. Copyright 2015 Elsevier.

3.6. Other Nanostructured Inorganic Building Blocks in LbL Planar Coatings

Recently, a variety of materials were applied to design advanced LbL coatings. Quercetin-loaded tripolyphosphate nanoparticles were ordered in a film (by an alternative with hyaluronic acid) resulting in a multilayer film capable to improve anticoagulation performance of surfaces [126]. Polysaccharides and nanogels were employed in polyelectrolyte multilayers proving that the presence of nanogel particles is beneficial for construction of a drug depot system [127]. Linear photochromic norbornene polymers assembled in LbL films exhibited a drastic decrease of the merocyanine band under a prolonged white light irradiation that potentially could be employed as photo-controlled drug depot system [128]. Bioactive thin films were prepared via encapsulation of biomacromolecules such as an enzyme (beta-lactamase, BlaP) into aluminosilicate halloysite nanotubes and their subsequent use for the fabrication of enzymatic coatings by LbL that potentially could act for effluent decontamination [129].

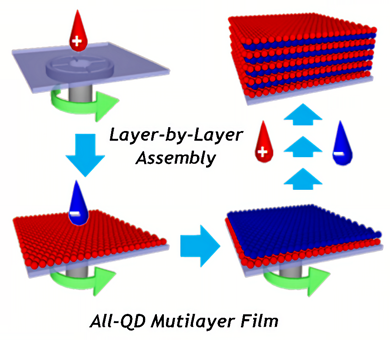

Application of quantum dots (QD) in capsules makes it possible to bring multifunctionality of encapsulation processes and sensor capabilities. Easily adjustable luminescence of QD has a high potential for applying QD-containing polyelectrolyte-based coatings and capsules for biological, particularly medical, and materials science as devices and theragnostic agents [130]. There are two trends in design of composite materials based on quantum dots and layer-by-layer technique. In the first approach, QD are incorporated into layer-by-layer films, Figure 5. For application of LbL technique, QDs are usually chemically modified with thioglycolic acid (TGA) [131], mercaptopropionic acid (MPA) [132], or mercaptoacetic acid (MAA) [133], and they have a negative zeta potential when cysteamine is applied [132].

Figure 5. Schematic for the preparation of all-quantum dot (QD) multilayer films based on spin-assisted layer-by-layer assembly by sequentially depositing oppositely charged QDs (blue QDs and red QDs represent negatively charged QDs (QD-mercaptopropionic acid (MPA)) and positively charged QDs (QD-cysteamine (CAm)), respectively). Reproduced with permission from [132]. Copyright 2010 American Chemical Society.

The first approach has been conducted by reducing the toxicity of QDs, stabilization of dispersity, and optimization of distribution, while the QD optical properties were unaffected [134]. CdSe is the typical material for quantum dots, which are used for layer-by-layer coating functionalization. For example, MAA-treated QDs were coated by alternatively applying polyallylamine and polyvinyl sulfonic acid [133].

Materials prepared by the second approach find applications in designing flexible, organo-electronic devices [135] [135]. Stabilization of QDs with polyelectrolytes provides the possibility of the energy transfer between bilayers of the charged polymers. The resulting film is reported to be sensitive for the detection of paraoxon [136] or deltamethrin. Incorporation of QD with graphene NPs in an alternative stacking manner in the PAH layers [137] leads to augmentation of the separation of charges and transport in GNs–CdS QDs composite film. A drawback of such methods is that CdSe nanoparticles undergo photooxidation in the polyelectrolyte matrix.

The LbL-assembled polyelectrolyte capsules can be functionalized with QD as biocompatible fluorescent agents for live-cell targeting [138][139][140][138–140]. In this case, polyelectrolyte film decreases the typical cytotoxic effect of the QD with the fluorescence properties remained. For example, compared to empty PLL/polyglutamic acid (PGA) capsules that do not influence the cell viability, CdTe- labelling of the same capsules displayed a higher cytotoxicity, but lower compared to pure CdTe QD [140]. A prospective field of engineering structures with semiconductor nanocrystals involves construction of complex ordered building blocks similar to those used in photonic crystals. Thus, demonstrated luminescence in both the IR and visible ranges from CdTe and HgTe [141] could be a starting point for development of sophisticated optoelectronics and optical telecommunications devices.

Biologically active QD-based hybrid nanocrystal/polyelectrolyte structures with an outer layer of anti-immunoglobulin G (anti-IgG) were shown to render some bio-specific properties to particles [142]. Considering the interesting info-chemistry [143][144][143,144], the optical coding and multiplexing can be achieved at different wavelengths and intensities by bringing in QDs in polyelectrolyte multilayers. To achieve that effect, it is possible to create bits of information by tuning the amount of red, green, and blue QD for achieving some characteristic colour ration. Combining these structures with some receptors makes it possible to identify various bio-processes [145], while gradient coatings [146] can stimulate combinatorial studies [147][99,147].

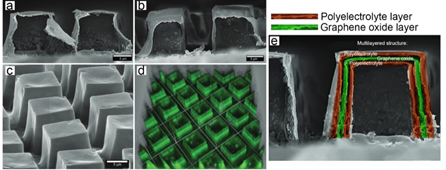

LbL were also functionalized by carbon-based fillers [148][148]. Polyelectrolyte-assisted layer-by-layer fabrication of carbon-containing coatings was proposed to order carbon fillers providing superior properties of the films. The unique combination of carbon materials properties together with versatility of the LbL assembly allows fabrication of multifunctional nanocomposite materials with improved mechanical, optical, thermal, electromagnetic, electrochemical properties [149]. The unique properties of graphene enabled high-performance capacitors and effective electromagnetic shielding [150]. A wide range of coatings functionalized by carbon fillers is aimed at the development of materials with a gas barrier function [151]. The change in permeability of microcapsules tuned by graphene oxide was also applied in drug delivery to reduce the permeability of low molecular substances [152]. Furthermore, coatings can be obtained on surfaces with complex shapes to provide additional functionality, for example, coatings containing arrays of closed cavities can be obtained (so-called microchambers) to store and release functional cargo in a controlled manner. Functionalisation of microchambers by graphene oxide enabled release on demand by near-infrared (NIR) laser in the “therapeutic window” [153], Figure 6. An unusual application of graphene oxide was shown by the binary hybrid-filled LbL coatings, composed of graphene oxide and β-FeOOH nanorods, which enabled the reduction of flammability of polyurethane foams [154]. AuNP assembled in unconventional LbL architectures enabled analysis of hybridization reactions with the ssDNA monitored via methylene blue as the electrochemical indicator. Such an architecture was used as DNA electrochemical biosensors [155] along with Pd nanoparticle-based RNA biosensor [156].

Figure 6. SEM (scanning electron microscopy) images of LbL-assembled microchambers constructed from a pure polyelectrolyte film (a) and functionalised by graphene oxide (b,c) and its corresponding confocal laser scanning microscopy (CLSM) image (d). Reproduced with permission from [153]. Copyright 2018 Wiley-VCH Verlag GmbH. (e) Schematics of the layered functionalization of microchambers by polyelectrolyte polymers and graphene.

In addition, carbon nanotubes and carbon-based fibres exhibit anisotropy upon ordering—a property useful in some applications, for example, in porous membranes [157]. It can be noted that many essential properties of LbL coatings, and particularly their permeability [158], depend on the concentration of polyelectrolytes, which was studied by the tangential streaming potential revealing that higher concentrations of polyelectrolytes are preferred for an effective adsorption [159]. In addition, some other nanostructured blocks, which extend functionalities of LbL coatings, include halloysites [160][161][160,161].