Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 1 by Siamak Tavakoli.

In sub-surface drilling rigs, one key critical crisis is unwanted influx into the borehole as a result of increasing the influx rate while drilling deeper into a high-pressure gas formation. Although established risk assessments in drilling rigs provide a high degree of protection, uncertainty arises due to the behavior of the formation being drilled into, which may cause crucial situations at the rig. To overcome such uncertainties, real-time sensor measurements are used to predict, and thus prevent, such crises.

- drilling disaster

- feature selection

- forward selection

- sensitivity analysis

1. Basic Concepts

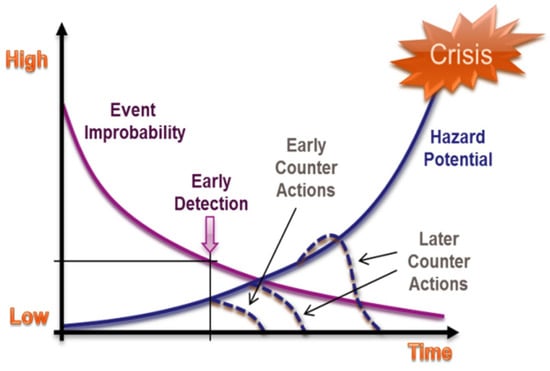

In sub-surface drilling, critical or crisis events, such as unwanted influx into the borehole, usually arise not abruptly, but have rather a more gradual nature. For instance, the hazard potential of an unwanted influx into the borehole is small, as long as the influx rate affected by the permeability of the formation is low, and as long as the accumulated volume of the influx down the hole is small, and thus both have no further impact. If the influx rate increases while drilling deeper into a high-pressure gas formation, the chance for a crisis to emerge will increase too. Figure 1 demonstrates the importance of crisis prevention among the interactions in drilling disasters [1].

Figure 1. Timeline for drilling interaction leading to a disaster. The vertical axis represents both curves of Event Improbability (the declining curve) and Hazard Potential (the growing curve) ranging between two generally defined bands of low and high.

Sensitivity Analysis (SA) allows for linking of normal operational events to the ones that may arise later to disrupt the overall system, i.e., crisis events. It is not always the case that operational events are understood when manually viewing the raw input data. Instead, a better understanding can be gained through analyzing features in the raw data. The next sections will explain the drilling events of interest and the types of features that can be analyzed. Moreover, it will be explained how those events can be linked using event-based Sensitivity Analysis.

2. Critical Drilling Operations

There are certain critical operations in the process of decision making for drilling disaster management. The schematic diagram in Figure 2 shows these operations in the time order that they may be applied.

Figure 2.

Four Critical Operations in Decision Making for Drilling Disaster Management.

The following sub-sections explain each critical operation.

2.1. Crisis Detection

The most important type of decision support is the just-in-time detection of an upcoming critical situation [2]. Note that in contrast to crisis prediction, described later, missing the detection of a critical situation leads to inevitable damages at physical entities, injury for humans, and last but not least financial losses.

2.2. Crisis Prediction

Early detection of an upcoming crisis may enable a system to avoid the occurrence of a critical event, or at least to limit its physical and financial impacts. It is evident that the prediction of a possible critical situation is uncertain. The longer the prediction periods are (i.e., the timespans between the predictions made and the actual times the critical events would occur) the more uncertain crisis prediction may be.

2.3. Counter-Action Support

Besides the detection of already occurring or possible upcoming crises, there is also a need for counter-action support. This means that the system provides guidelines and suggestions for the particular handling of crises to system operators. This can involve the use of simple electronic crisis handling checklists (similar to the practices used by aircraft crew). In addition, more sophisticated methods, e.g., semantic decision tables or even offline trained classifiers based on the experience of a large amount of rig data (aggregating offline knowledge from multiple rigs and boreholes), might be feasible [3].

2.4. Crisis Prevention

Crisis prevention is a type of system interaction where, even without any signs of an upcoming crisis occurring, recommendations for “crisis-prevention operations” (such as ream and wash operations) are provided to a system operator. First, an important aspect of this is the provision of feasible parameters for regular operations. For instance, the parameters to guarantee an appropriate pump startup should be proposed by the system so that the operation does not cause an evolution towards a potential critical situation. Second, a justification for the recommended system actions should also be generated. Third, the system should be aware of whether or not an operator has followed the system recommendations. Thus, in the case that the proposed counter-actions are ignored by operators, the system can adapt the recommendations to the new situation or even issue an alarm.

3. Response Time

Response time is defined as the time to respond to significant events that may otherwise lead to an operational crisis. The required time strongly depends on the detected critical event. If the reaction is set earlier, it gives a higher chance of managing any crisis that develops, although early intervention may also be associated with more uncertainty as to how an event could develop and unfold. Thus, it would be not enough to answer the question for the timing of the response, as it should be the minimum possible. Nevertheless, it can be stated that the overall magnitude of a response time is in the range of seconds to minutes. For example, for a drill kick, the response time strongly depends on the parameters of the subsurface formation, such as permeability, fluid properties, as well as pressure conditions [4]—therefore, an extension in the magnitude of minutes may be required for the response time. Furthermore, often ream and wash operations are applied to prevent a stuck pipe, usually after a stand is drilled and before connecting a new stand to the drill string. Thus, waiting for a decision to recommend or not such an operation makes no sense if the response time is in the magnitude of the duration of that operation. Each decision support function has to meet estimated response time requirements, as shown in Table 1.

Table 1.

Required response time in drilling disasters.

| Event | Response Time |

|---|---|

| Kick | magnitude of minutes |

| Stuck pipe support | magnitude of seconds |

| Pump startup | magnitude of seconds |

| Lost circulation | magnitude of seconds |

During drilling, the driller needs continuous knowledge about the borehole stability and, even more urgently, about any significant borehole instability. The actual state of the borehole is used for any immediate or any eventual urgently required counter-actions or to make any revisions to improve the drilling plan. Its state is typically evaluated using a number of different information sources and is, as far as possible, incorporated into a geological model. Such information sources usually supply real-time data, measurements at regular intervals, and drilling reports [5].

Real-time data typically originate from sensors mounted at the surface, as well as, in some special cases, from down hole; the data are sampled and provided with an interval in the magnitude of seconds. Real-time data are, in general, used also by third-party data providers, such as mud-loggers and directional drillers, to supply an additional set of information in real time. Other measurements, such as mud properties, are provided in intervals in the magnitude of hours, and drilling reports are available on daily basis. Drilling reports contain much more information about the drilling process, wellbore geometry parameters such as diameter and depth, mud properties, wellbore trajectory data, and descriptions of normal and abnormal situations and corresponding counter-actions.

4. Features

In heuristic model-building, features usually play an important role. They are used as an input to reduce the required complexity of a subsequent (heuristic) problem-solver. Although feature calculation does not extend the information in the input data, it can prepare such information, in many cases, in a way such that the complexity of a given task reduces dramatically. As a rule of thumb, the lower the complexity of a heuristic model, the better is its generalization property, and the more successful it is at processing data that the model has never seen before [6].

In numerous practical cases, features relevant for solving a problem are well known, but in other cases such knowledge must be created from scratch. A common way to create features for such cases is to integrate domain know-how as much as possible and to create numerous features that might be relevant, sometimes based upon gut instinct. Currently, we need to be able to efficiently process large amounts of feature data, and thus we need to reduce the dimension of the generated features. Out of those, sometimes a huge number of features, the relevant ones, can be identified by use of sophisticated methods such as forward selection or backward elimination in combination with principal or independent component analysis [6]. However, these methods are computationally intensive. Therefore, we need to investigate incremental classification methods that could feasibly lend themselves to the problem of dimensionality reduction.

References

- Jandl, B.; Winter, M.; Fruhwirth, R.; Riedel, F.; Zeiner, H. Rig Side Online Drilling Support System for Prediction and Prevention of Upcoming Crises. In Proceedings of the EGU General Assembly 2012, Vienna, Austria, 22–27 April 2012; Volume 14. EGU2012-9363-1.

- Coppes, J.; Rudd, N.E. Blowout Prevention is Mistake Prevention. In Proceedings of the SPE European Spring Meeting, Amsterdam, The Netherlands, 8–9 April 1976; ISBN 978-1-55563-750-7.

- Christman, S.; Kelly, A.; Plaisance, M.; Kropla, S.; Metcalf, J.; Robinson, E.; Weddle, C. An Overview of the IADC Deepwater Well Control Guidelines. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 9–11 March 1999; ISBN 978-1-55563-370-7.

- Nunes, J.O.L.; Bannwart, A.C.; Ribeiro, P.R. Mathematical Modeling of Gas Kicks in Deep Water Scenario. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology, Jakarta, Indonesia, 8–11 September 2002; ISBN 978-1-55563-939-6.

- Freithofnig, H.J.; Spoerker, H.F.; Thonhauser, G. Analysis of Hook Load Data to Optimize Ream and Wash Operations. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 20–22 October 2003; ISBN 978-1-55563-972-3.

- Bishop, C.M. Neural Networks for Pattern Recognition; Oxford University Press Inc.: New York, NY, USA, 1995; ISBN 978-0-19-853864-6.

More