| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Foivos Psarommatis | -- | 7801 | 2024-04-23 08:08:34 | | | |

| 2 | Catherine Yang | + 4 word(s) | 7805 | 2024-04-23 08:43:47 | | |

Video Upload Options

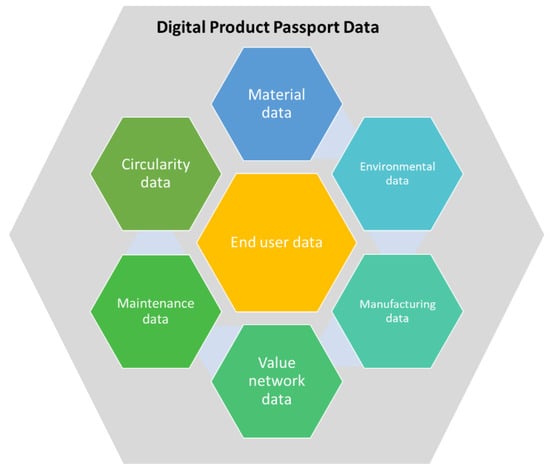

Digital Product Passport (DPP)’s impact on supply chain transparency, providing crucial product lifecycle information that bolsters decision-making and facilitates optimal resource management. DPP model, when applied to sectors such as electronics manufacturing, promises transformative results.

1. Introduction

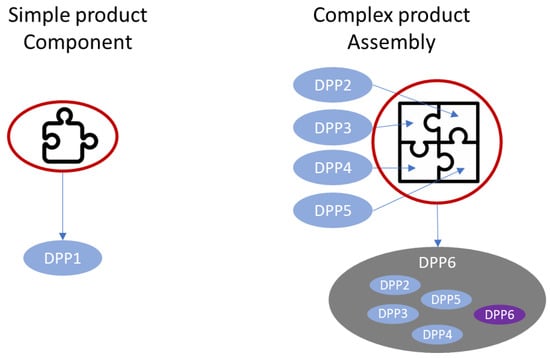

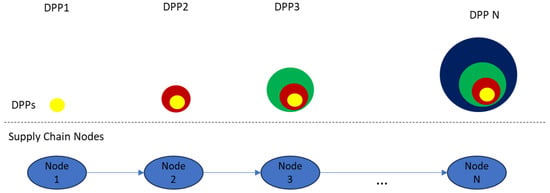

2. Digital Product Passport Model

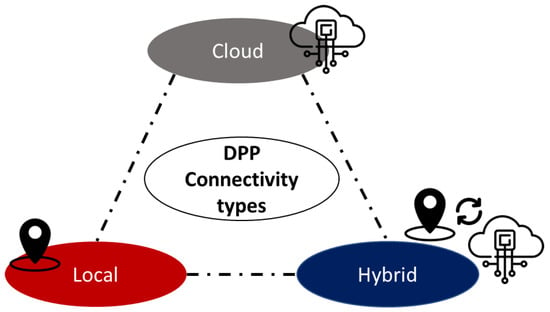

2.1. Digital Product Passport Connectivity

2.2. Digital Product Passport Data Update Frequency

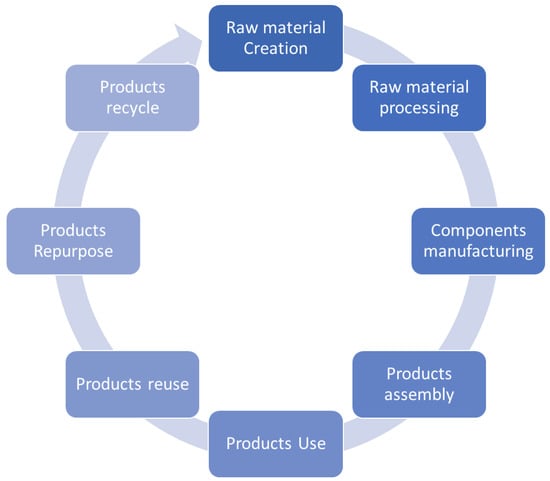

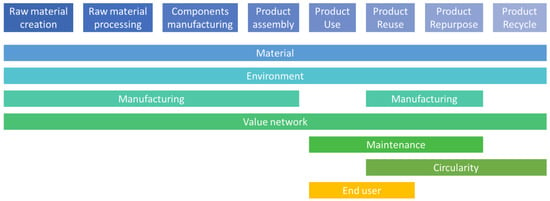

2.3. Digital Product Passport in Relation to the Product Life Cycle

2.4. Actors Involved in Digital Product Passport and Data Types

-

OEM;

-

End user;

-

Maintenance;

-

Distributor;

-

Value chain partner;

-

Recycler;

-

DPP data analyzer.

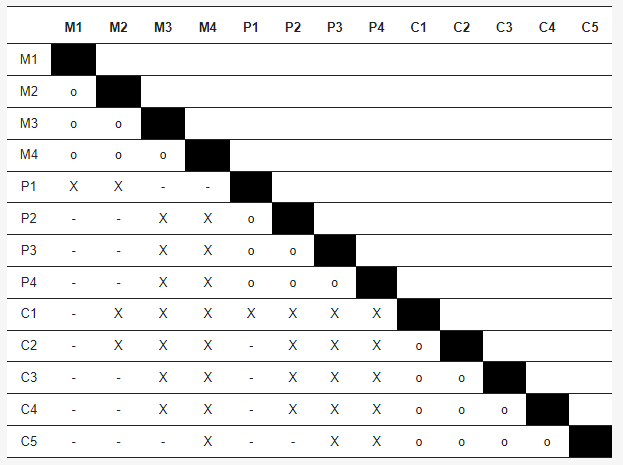

2.5. Digital Product Passport Level of Detail

| Levels | Name | Description |

|---|---|---|

| Level M0 | No DPP | No information for the manufacturing of the product is saved. |

| Level M1 | Generic batch information | Level M1 implies that only generic information for a specific batch of products is saved. This includes basic information such as the batch number, date, time started and finished, number of products, and batch destination. The machines used in the process should also be listed. |

| Level M2 | Specific batch information | Level M2 contains all the information from M1, along with more specific data regarding the manufacturing of this specific batch. This may include data about the processing of the different products in the batch, quality inspection reports, and a generic list of the materials used in the product. Interactive data, such as the next manufacturing station or other information that operators or automated systems will update, and a detailed tracking of the personnel who handled the batch and manufacturing steps are also included. |

| Level M3 | Generic individualized product information | The M3 level includes information similar to M1, but for each single product rather than a batch. Additionally, it includes the product bill of processes and bill of materials. |

| Level M4 | Specific individualized product information | The M4 level includes information similar to M2, but for each single product rather than a batch, and M3. This level provides the most comprehensive information possible for the manufacturing process of a product. For example, it may also include time series directly from the sensors or PLC of machines related to the specific product instance. |

| Levels | Name | Description |

|---|---|---|

| Level P0 | No DPP | No information for the product operation phase is saved. |

| Level P1 | Basic information for the product family | In Level P1, basic information about the product family, such as an owner’s manual and generic maintenance plan, is included. In this level, no update of the information of the DPP will be made during the life of the product. |

| Level P2 | Basic information for the specific product | Level P2 includes all the information from P1, along with more specific data about the individual product. These data include the manufacturing date, seller details, purchase date, warranty information, and owner details. In this level, no updates to the DPP will be made after the sale of the product. |

| Level P3 | Detailed information on the specific product | Level P3 includes all the information from P2, plus additional data added during the product’s operation, such as maintenance records or other information defined by the product OEM. These data are meant to be manually entered when there is a change to the product. |

| Level P4 | Interactive information on the specific product | Level P4 includes all the information from P3. In addition, the product can interactively store operational data in the DPP and, vice versa, retrieve historical data from the DPP. |

| Levels | Name | Description |

|---|---|---|

| Level C0 | No DPP | No information for the product circularity phase is saved. |

| Level C1 | Basic recycling information | This level includes different materials involved in the product to facilitate recycling. In this level, no updates to the DPP will be made; the DPP information is fixed. |

| Level C2 | Basic product reuse information | Level C2 includes all the information from C1, plus instructions on how to reuse the product, including generic checklists with common problems and practices for reusing the specific product. No updates to the DPP will be made in this level; the DPP information is fixed. |

| Level C3 | Detailed product reuse information | Level C3 includes all the information from C2. In addition, it provides disassembly sequences and procedures for the proper repair or upgrade of the product. It also specifies where the product should go to be remanufactured for reuse. Any change performed on the product in the reuse process is documented in the DPP. |

| Level C4 | Detailed product repurpose information | Level C4 includes all the information from C3. In addition to all this information, if the product is repurposed, detailed instructions on what should happen to each of the product’s components according to their individual DPPs are included. Any change made to the product in the repurposing process is documented in the DPP. |

| Level C5 | Interactive product circularity | Level C5 includes all the information from C4. In this level, data from the product is sent to the DPP interactively. The product owner is informed about the product status and suggested solutions, maintenance for reuse, or any other information the OEM wants to communicate to the product owner related to circularity. |

| Minimum DPP Connectivity Capabilities | DPP Data Update Frequency | Involved Actors | |

|---|---|---|---|

| M1 | Local | Once | OEM |

| M2 | Local | During manufacturing process | OEM |

| M3 | Cloud | During manufacturing process | OEM, value chain actor |

| M4 | Cloud | During manufacturing process | OEM, value chain actor |

| P1 | Local | Once | OEM, end user |

| P2 | Local | Once | OEM, end user, distributor |

| P3 | Local | Every time changes happen to the product | OEM, end user, distributor, maintenance |

| P4 | Cloud | Continuously | OEM, end user, distributor, maintenance, recycler |

| C1 | Local | None | OEM, recycler |

| C2 | Local | None | OEM, recycler |

| C3 | Local | Every time changes happen to the product | OEM, recycler, maintenance |

| C4 | Local | Every time changes happen to the product | OEM, recycler, maintenance, distributor |

| C5 | Cloud | Continuously | OEM, recycler, maintenance, distributor |

2.6. Digital Product Passport Access

-

Local access to the DPP using some of the product’s systems.

-

Local access to the DPP using a wireless or wired connection to a laptop, smart phone, or tablet.

-

The product has a QR code or similar, and, by using the DPP application (laptop, smart phone, or tablet), the QR code is scanned, and basic information about the product appears.

-

The product has a QR code or similar, and the user is redirected to the product’s DPP online.

-

The OEM has developed a DPP platform for the product, and the corresponding actor enters some credentials (e.g., serial number, etc.) and they access the DPP online.

-

If the product is using an RFID, the user scans the RFID and reads the information saved in the DPP.

2.7. Digital Product Passport Template

| DPP Overall Design Template | ||

|---|---|---|

| 1 | DPP fundamental information | |

| DPP name: | [Enter DPP name] | |

| DPP code: | [Enter DPP code] | |

| Product Name: | [Enter Product Name] | |

| Product Code: | [Enter Product Code] | |

| Product type: | [Single component/Assembly] | |

| Overall connectivity: | [Define the overall connectivity of the DPP. The specific connectivity of each variable will be defined at a later stage] | |

| DPP static or dynamic | Static: The DPP is read-only and it is present only for informative reasons. Dynamic: The DPP information is updated at given periods. |

|

| Involved actors for saving information to the DPP | [Define all the actors that will save information to the DPP] | |

| Involved actors for reading information from the DPP | [Define all the actors that will read information from the DPP] | |

| Inherits information from other DPP | [Yes/No] | |

| 2 | Overall DPP variable information | |

| Total number of DPP variables: | [Define the total number of variables that will be stored in the DPP] | |

| Detailed list with the different variables of the DPP | [Create a detailed list with the variables in the DPP. These variables should exclude the variables that will be inherited from other DPPs]:

|

|

| 3 | DPP information inheritance from other DPPs | |

| Detailed list with the DPPs that will be inherited by the current DPP | DPP1 |

|

| DPP2 |

|

|

| … | … | |

2.8. Blockchain Technology and Data Carrier in DPP

3. Critical discussion on DPP

The scope of the current chapter is to set the foundations for the explanation and the standardization of the DPP concept. Currently, DPP domain is very immature and no clear path exists. The proposed model seems that can bring light and unification among the researchers and industries in this domain.

3.1. Implications of the DPP Model

The proposed DPP model stands to profoundly impact the industrial manufacturing ecosystem by offering a digitized, centralized, and standardized product-information management system. This new model aims to transform the way manufacturers, consumers, and stakeholders interact with the product and its associated data throughout its lifecycle.

With the DPP model, the researchers can expect a remarkable improvement in manufacturing efficiency. The model allows for an enhanced decision-making process based on the accurate and detailed data it provides. As such, manufacturers could drastically reduce waste and improve product quality. In the automobile industry, for instance, DPPs could provide real-time information on each vehicle component, enabling manufacturers to anticipate potential issues, streamline production lines, and enhance overall output.

Except the implication of the DPP in the manufacturing stage of a product it has many other implications in the steps after the manufacturing. The distribution actors have will be able to monitor and manage in a better and more efficient way their products and also will allow them to implement more sophisticated optimization strategies. At the same time, the end-users of the products will be able to have better overview of the product and using the potential services from the manufactures be able to take full advantage of their product and avoid unnecessary costs and contribute to the minimization of the environmental impact.

3.2. Enhanced Product Lifecycle Management

The lifecycle of a product, from inception to disposal, could be significantly improved through the application of DPPs. Service personnel would have immediate access to essential information about the product, allowing for more effective maintenance and repair strategies [28]. This could result in extended product longevity, reducing the frequency of new product purchases, and thereby, contributing to a more sustainable economy [9].

The DPP model also shines in the context of recycling. Effective recycling or repurposing strategies are possible by leveraging the information stored within the DPP. This fosters a circular economy, especially pertinent given the increasing complexity of materials in modern manufacturing.

3.3. Potential Challenges and Mitigation Strategies

Despite the evident benefits, implementing a DPP system is not without hurdles. Data privacy and security pose a significant challenge [29]. With sensitive consumer and product information at stake, robust cybersecurity measures must be in place to prevent unauthorized access or misuse. This can be tackled through encryption, strict access control mechanisms, and regular security audits [30].

Integrating the DPP system into existing processes is another considerable challenge. It demands substantial coordination among all stakeholders. Resistance could stem from those viewing the DPP as an unwelcome complexity or a cost burden [31]. Here, the key lies in transparently communicating the DPP system benefits, such as improved efficiency, cost reduction, product longevity, and its role in fostering sustainability.

For the concept of DPP to work properly and companies be able to harvest its advanced capabilities there is the need that in a value chain all nodes are utilizing the DPP concept otherwise the capabilities of the DPP implementation in a global scale are reduced. Also from the business perspective, DPP is not a technology that aims at providing its benefits at short terms but rather in mid and long term.

3.4. Guidelines for Implementing DPP

For manufacturers aiming to transition into this new era of data-centric operations by implementing DPP, the following detailed guidelines should be thoroughly considered:

- Standardization: Begin by ensuring the DPP model follows current industry standards for data management, security, and privacy. This is a prerequisite to ensure interoperability between different systems and stakeholders, while concurrently safeguarding sensitive data against potential threats. Additionally, conforming to standardized practices can assist in attaining certifications or qualifications that may be required in certain industries or regions, further enhancing the product’s marketability.

- Integration: DPP implementation should be planned and executed as a seamless extension of the existing manufacturing and operational processes. To accomplish this, one needs to map out the current processes, identify the points where DPP interactions would occur, and design systems to minimize disruption and maximize value addition. Remember, the DPP is not meant to replace existing processes but to augment them by providing rich, comprehensive, and accessible data.

- Training: Ensuring that employees across the organization, from shop-floor workers to top-level management, understand the DPP system and its benefits is crucial. Training programs must be comprehensive and ongoing, providing instruction on how to access, input, interpret, and secure data. By fostering a deep understanding and comfort with the system, employees will be able to harness the DPP’s full potential.

- Stakeholder Communication: Effective and transparent communication with all stakeholders, including suppliers, distributors, and customers, is paramount. This entails highlighting the benefits that the DPP system offers, such as improved product traceability, quality assurance, and potential for cost reduction. Open dialogues can mitigate resistance and encourage adoption, fostering a shared vision for a more efficient, sustainable manufacturing landscape.

- Gradual Implementation: Implementing a DPP system is a complex process that involves significant changes to existing operations. To manage this transition effectively, it could be beneficial to phase in the DPP, starting with a pilot project on a single product line or component. This allows for real-time adjustments and fine-tuning of the system before full-scale implementation, minimizing potential disruptions to the operation.

- Continuous Evaluation: After implementation, it is critical to continuously evaluate and improve the system based on performance metrics and stakeholder feedback. Leveraging the metrics proposed in this paper can provide insights into the DPP’s effectiveness and guide its optimization.

Implementing these guidelines will facilitate a smoother transition to a DPP system, equipping manufacturers to leverage the potential of data in fostering efficiency, sustainability, and value creation in their operations.

In addition to the guidelines outlined, the following strategies are proposed to further enhance the adoption and effective use of DPP among stakeholders:

Partnership Development: Forge partnerships with industry leaders and influencers to showcase successful DPP integrations, creating case studies that highlight tangible benefits.

Demonstration Projects: Implement DPPs in pilot projects or flagship products, allowing stakeholders to witness firsthand the advantages and operational improvements.

Regulatory Alignment: Engage with policymakers to align DPP implementation with emerging regulations and standards, ensuring compliance provides a direct incentive for adoption.

Technology Integration Support: Provide technical assistance and toolkits to integrate DPPs with existing enterprise systems, lowering the barrier to adoption due to technological challenges.

Feedback Mechanisms: Establish channels for regular feedback from stakeholders, using their insights to continuously refine the DPP system.

By implementing these additional promotional tools alongside the guidelines previously mentioned, manufacturers can create a robust ecosystem that not only supports the technical implementation of DPPs but also fosters a culture of adoption and sustained use throughout the product lifecycle.

3.5. Application Framework

The application of a DPP system could be systematically executed following the expanded framework below:

- Requirement Analysis: The first step involves a comprehensive understanding and documentation of product information requirements. This includes identifying necessary product data, desired functionalities of the DPP system, and all potential stakeholders. Additionally, it's essential to assess the current operational workflow, IT infrastructure, and compatibility requirements to ensure seamless integration of the DPP system later on.

- System Design: Once the requirements are clear, designing the DPP system can commence. This involves creating an architecture that meets the requirements identified in the analysis phase while aligning with industry standards. The design should prioritize usability and security, facilitating efficient and safe data handling. A user-friendly interface can encourage stakeholder acceptance and expedite the learning curve.

- Integration: The implementation of the DPP system into the existing manufacturing process is a critical phase. Given the magnitude of the change, it's recommended to adopt a gradual approach. Start by integrating the DPP system in less critical operations or smaller product lines. This approach allows for real-time feedback and adjustments without major disruptions to existing operations.

- Testing: Once integrated, extensive testing should be conducted to validate the system's functionality. This step involves stress testing, regression testing, and user acceptance testing to identify and fix bugs, validate data integrity, and ensure that the system aligns with user expectations and requirements.

- Training and Rollout: After thorough testing, training programs should be established for all relevant employees and stakeholders. A clear understanding of the system's functionality and benefits can mitigate resistance and promote usage. The system can then be officially launched, starting with smaller scales or pilot areas before a full-scale rollout, thus ensuring that the system functions effectively under operational conditions.

- Monitoring and Evaluation: Post-launch, the DPP system should be continuously monitored and evaluated against set performance metrics and user feedback. This iterative process will guide necessary tweaks and enhancements to optimize the system over time.

- Continuous Improvement: The application framework does not end at launch. Given the dynamic nature of data and technologies, it's crucial to maintain an attitude of continuous improvement. Regular system reviews should be conducted, technological advancements should be continually integrated, and user training should be refreshed periodically to ensure the DPP system remains relevant and beneficial.

Following this application framework provides a systematic roadmap for manufacturers to implement a DPP system effectively, ensuring they are well-prepared to navigate the challenges and harness the immense potential that DPP offers.

3.6. Real-world Applications

To further illustrate the applicability and benefits of the DPP model, let's delve into the electronics manufacturing industry, particularly, the smartphone segment. A smartphone is a perfect exemplar of a complex product with numerous components sourced from various suppliers across the globe.

3.6.1. Supply Chain Transparency

Implementing a DPP system in this context could provide unprecedented transparency into the supply chain. With each component assigned a digital passport detailing its origins, manufacturers, consumers, and regulators would have access to a product's complete backstory. Such visibility can allow manufacturers to better manage their supply chain, reducing the risk of delays and promoting ethical sourcing by avoiding suppliers associated with unsustainable practices or unfair labor conditions [32].

3.6.2. Process Optimization and Quality Assurance

The detailed product information derived from DPP could aid manufacturers in optimizing processes. For instance, if a component regularly fails quality checks, the DPP could help trace the issue back to a specific batch or supplier, allowing the manufacturer to address the issue directly and efficiently. Such preventive and corrective actions could lead to improved product quality, decreased waste, and enhanced customer satisfaction. The adoption of DPP will significantly affect positively the performance of Zero Defect Manufacturing (ZDM) implementation, as more information will be available which is the key for the implementation of approaches like ZDM to be implemented [32][33]. Furthermore, the data in the DPP could also significantly help on the maintenance of all the different artificial intelligence, machine learning, digital twin models in order to adapt to the changes over time [34].

3.6.3. Improved After-sales Services

For after-sales service providers, DPPs can serve as comprehensive product histories, outlining the precise specifications, the history of repairs or modifications, and even the conditions under which the product was used [35]. This can expedite the troubleshooting process, making repairs more efficient, and extending the product's lifespan.

3.6.4. Streamlined Recycling Processes

Furthermore, the DPP model could dramatically simplify the recycling process by providing accurate and detailed material composition information. For example, smartphones contain precious metals like gold and rare-earth elements that could be recovered and reused. Currently, identifying and extracting these materials can be a complex and costly process. With DPP, recyclers could access a precise blueprint of the materials in a given product, enabling more effective and profitable recycling.

3.6.5. Consumer Engagement

For consumers, DPP can offer insights into a product’s entire lifecycle - from the sourcing of its components, the conditions of its assembly to the product maintenance and condition of use. This level of transparency could empower consumers to make more informed, sustainable purchasing decisions, favoring products with responsible supply chains, and high recycling potential. By extrapolating from this smartphone example, the benefits of DPP implementation could extend across industries, contributing to more efficient and sustainable manufacturing landscapes [44]. In conclusion, while the DPP model poses some challenges, the benefits, which range from enhanced manufacturing efficiency to improved lifecycle management and a strengthened circular economy, present a strong case for adoption. With detailed planning, strict security measures, and open communication among all stakeholders, the DPP system could be a game-changer for product lifecycle management.

3.7. Practical Challenges and Barriers in DPP Adoption

While the DPP offers transformative potential for the manufacturing industry, its implementation is not without challenges. Key barriers include:

- Integration Complexity: Incorporating DPPs into existing manufacturing systems can be technically complex and costly, particularly for smaller enterprises. Developing user-friendly, scalable DPP platforms could mitigate this challenge.

- Stakeholder Resistance: Resistance from various stakeholders, including manufacturers and suppliers, may arise due to perceived complexity or cost implications. Targeted educational campaigns and demonstrable benefits can be instrumental in overcoming this resistance.

- Data Privacy and Security: Handling sensitive data in DPPs raises concerns about privacy and cybersecurity. Implementing robust encryption and strict access controls is crucial for maintaining data integrity and trust.

- Standardization and Interoperability: The lack of standardized DPP formats may hinder interoperability between systems. Collaborative efforts towards standardization are essential for seamless integration across different platforms and industries.

- Cost Implications: The initial setup and maintenance costs of DPP systems could be a significant barrier, especially for smaller manufacturers. Financial incentives or support from regulatory bodies may encourage wider adoption.

To overcome these barriers, a multi-faceted approach involving technological innovation, stakeholder engagement, policy support, and education is necessary. By addressing these challenges proactively, the manufacturing industry can fully leverage DPPs to achieve enhanced transparency, efficiency, and sustainability.

3.8. DPP's Relevance to Modern Manufacturing

The DPP model is particularly relevant in the context of modern manufacturing, which is increasingly characterized by digitalization, sustainability, and interconnected supply chains. The DPP framework aligns with these contemporary trends by providing a digital means to track and manage product lifecycle data efficiently. This capability is crucial for modern manufacturing processes that require high levels of transparency, compliance with sustainability standards, and efficient resource utilization. By integrating DPPs, manufacturers can not only enhance operational efficiency but also contribute to more sustainable and circular manufacturing practices.

3.9. Proposed Methodology for Industry-Specific DPP Development

Recognizing the critical role of DPPs in various sectors, the researchers propose a generalized methodology to guide the development of industry specific DPPs. This approach encompasses the following steps:

Industry Analysis: Conduct a thorough analysis of the target industry to understand unique operational processes, supply chain dynamics, and regulatory requirements.

Stakeholder Identification: Identify all relevant stakeholders within the industry, including suppliers, manufacturers, regulators, and end-users, to understand their data needs and interactions.

Data Requirements Mapping: Map out the specific data requirements for each stakeholder, ensuring the DPP captures all necessary information for a product's lifecycle within the industry.

Technology Assessment: Evaluate the current technology landscape of the industry to determine the best data carriers and platforms for DPP integration.

Regulatory Compliance: Ensure that the DPP framework aligns with industry-specific regulations and standards, facilitating compliance and adoption.

Pilot Testing: Develop and test a pilot DPP with a select group of industry participants to gather feedback and refine the DPP model.

Implementation Guidelines: Create detailed guidelines for full-scale DPP implementation, including integration strategies, training programs, and evaluation metrics.

This proposed methodology provides a blueprint for future research and practical applications, allowing for the adaptation of the DPP framework to meet the nuanced needs of different industries.

References

- Neves, S.A.; Marques, A.C. Drivers and Barriers in the Transition from a Linear Economy to a Circular Economy. J. Clean. Prod. 2022, 341, 130865.

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553.

- Liu, L.; Ramakrishna, S. (Eds.) An Introduction to Circular Economy; Springer: Singapore, 2021; ISBN 9789811585098.

- Cappelletti, F.; Rossi, M.; Germani, M. How De-Manufacturing Supports Circular Economy Linking Design and EoL—A Literature Review. J. Manuf. Syst. 2022, 63, 118–133.

- Kanellou, E.; Alexakis, K.; Kapsalis, P.; Kokkinakos, P.; Askounis, D. The DigiPrime KPIs’ Framework for a Circular Economy Transition in the Automotive Industry. Procedia Manuf. 2021, 54, 302–307.

- Barford, A.; Ahmad, S.R. A Call for a Socially Restorative Circular Economy: Waste Pickers in the Recycled Plastics Supply Chain. Circ. Econ. Sust. 2021, 1, 761–782.

- Valverde, J.-M.; Avilés-Palacios, C. Circular Economy as a Catalyst for Progress towards the Sustainable Development Goals: A Positive Relationship between Two Self-Sufficient Variables. Sustainability 2021, 13, 12652.

- Kelly, M.; Howard, T. The Making of a Democratic Economy: Building Prosperity for the Many, Not Just the Few; Berrett-Koehler Publishers: Oakland, CA, USA, 2019; ISBN 978-1-5230-9993-1.

- Psarommatis, F.; May, G. Achieving Global Sustainability Through Sustainable Product Life Cycle. IFIP Adv. Inf. Commun. Technol. 2022, 663 IFIP, 391–398.

- Al-Alawi, M.K.; Cugley, J.; Hassanin, H. Techno-Economic Feasibility of Retired Electric-Vehicle Batteries Repurpose/Reuse in Second-Life Applications: A Systematic Review. Energy Clim. Change 2022, 3, 100086.

- Porzio, J.; Scown, C.D. Life-Cycle Assessment Considerations for Batteries and Battery Materials. Adv. Energy Mater. 2021, 11, 2100771.

- Charles, R.G.; Douglas, P.; Dowling, M.; Liversage, G.; Davies, M.L. Towards Increased Recovery of Critical Raw Materials from WEEE– Evaluation of CRMs at a Component Level and Pre-Processing Methods for Interface Optimisation with Recovery Processes. Resour. Conserv. Recycl. 2020, 161, 104923.

- Chatziparaskeva, G.; Papamichael, I.; Voukkali, I.; Loizia, P.; Sourkouni, G.; Argirusis, C.; Zorpas, A.A. End-of-Life of Composite Materials in the Framework of the Circular Economy. Microplastics 2022, 1, 377–392.

- Bongers, A.; Casas, P. The Circular Economy and the Optimal Recycling Rate: A Macroeconomic Approach. Ecol. Econ. 2022, 199, 107504.

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and Recent Developments in Supply and Value Chains of Electric Vehicle Batteries: A Sustainability Perspective. Resour. Conserv. Recycl. 2022, 180, 106144.

- Anastasiadis, F.; Manikas, I.; Apostolidou, I.; Wahbeh, S. The Role of Traceability in End-to-End Circular Agri-Food Supply Chains. Ind. Mark. Manag. 2022, 104, 196–211.

- Santana, S.; Ribeiro, A. Traceability Models and Traceability Systems to Accelerate the Transition to a Circular Economy: A Systematic Review. Sustainability 2022, 14, 5469.

- Maretto, L.; Faccio, M.; Battini, D. The Adoption of Digital Technologies in the Manufacturing World and Their Evaluation: A Systematic Review of Real-Life Case Studies and Future Research Agenda. J. Manuf. Syst. 2023, 68, 576–600.

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and Retrospect. J. Manuf. Syst. 2022, 65, 279–295.

- Meegoda, J.N.; Malladi, S.; Zayas, I.C. End-of-Life Management of Electric Vehicle Lithium-Ion Batteries in the United States. Clean Technol. 2022, 4, 1162–1174.

- European Commission Proposal for a REGULATION OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL Establishing a Framework for Setting Ecodesign Requirements for Sustainable Products and Repealing Directive 2009/125/EC 2022. Available online: https://data.consilium.europa.eu/doc/document/ST-7854-2022-INIT/en/pdf (accessed on 10 December 2023).

- Langley, D.J.; Rosca, E.; Angelopoulos, M.; Kamminga, O.; Hooijer, C. Orchestrating a Smart Circular Economy: Guiding Principles for Digital Product Passports. J. Bus. Res. 2023, 169, 114259.

- Berger, K.; Baumgartner, R.J.; Weinzerl, M.; Bachler, J.; Schöggl, J.-P. Factors of Digital Product Passport Adoption to Enable Circular Information Flows along the Battery Value Chain. Procedia CIRP 2023, 116, 528–533.

- Kang, K.; Zhong, R.Y. A Methodology for Production Analysis Based on the RFID-Collected Manufacturing Big Data. J. Manuf. Syst. 2023, 68, 628–634.

- Raihanian Mashhadi, A.; Behdad, S. Optimal Sorting Policies in Remanufacturing Systems: Application of Product Life-Cycle Data in Quality Grading and End-of-Use Recovery. J. Manuf. Syst. 2017, 43, 15–24.

- Wang, G.; Zhang, G.; Guo, X.; Zhang, Y. Digital Twin-Driven Service Model and Optimal Allocation of Manufacturing Resources in Shared Manufacturing. J. Manuf. Syst. 2021, 59, 165–179.

- Hasan, M.; Starly, B. Decentralized Cloud Manufacturing-as-a-Service (CMaaS) Platform Architecture with Configurable Digital Assets. J. Manuf. Syst. 2020, 56, 157–174.

- Psarommatis, F.; May, G.; Azamfirei, V. Envisioning Maintenance 5.0: Insights from a Systematic Literature Review of Industry 4.0 and a Proposed Framework. J. Manuf. Syst. 2023, 68, 376–399.

- Psarommatis, F.; Dreyfus, P.A.; Kiritsis, D. The Role of Big Data Analytics in the Context of Modeling Design and Operation of Manufacturing Systems. Des. Oper. Prod. Netw. Mass Pers. Era Cloud Technol. 2022, 243–275.

- Tuptuk, N.; Hailes, S. Security of Smart Manufacturing Systems. J. Manuf. Syst. 2018, 47, 93–106.

- Koppelaar, R.H.E.M.; Pamidi, S.; Hajósi, E.; Herreras, L.; Leroy, P.; Jung, H.-Y.; Concheso, A.; Daniel, R.; Francisco, F.B.; Parrado, C.; et al. A Digital Product Passport for Critical Raw Materials Reuse and Recycling. Sustainability 2023, 15, 1405.

- Psarommatis, F.; May, G.; Dreyfus, P.-A.; Kiritsis, D. Zero Defect Manufacturing: State-of-the-Art Review, Shortcomings and Future Directions in Research. Int. J. Prod. Res. 2020, 7543, 1–17.

- Liu, X.; Deng, Q.; Gong, G.; Lv, M.; Jiang, C. Service-Oriented Collaboration Framework Based on Cloud Platform and Critical Factors Identification. J. Manuf. Syst. 2021, 61, 183–195.

- Hapuwatte, B.M.; Seevers, K.D.; Jawahir, I.S. Metrics-Based Dynamic Product Sustainability Performance Evaluation for Advancing the Circular Economy. J. Manuf. Syst. 2022, 64, 275–287.

- Afshar-Bakeshloo, M.; Jolai, F.; Bozorgi-Amiri, A. A Bi-Objective Manufacturing/Remanufacturing System Considering Downward Substitutions between Three Markets. J. Manuf. Syst. 2021, 58, 75–92.