Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Miguel Sanjuán | -- | 1499 | 2024-03-06 18:27:39 | | | |

| 2 | Jessie Wu | Meta information modification | 1499 | 2024-03-07 02:04:53 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Da Silva Rego, J.H.; Sanjuán, M.�.; Mora, P.; Zaragoza, A.; Visedo, G. The Brazilian Cement Sector. Encyclopedia. Available online: https://encyclopedia.pub/entry/55934 (accessed on 07 February 2026).

Da Silva Rego JH, Sanjuán M�, Mora P, Zaragoza A, Visedo G. The Brazilian Cement Sector. Encyclopedia. Available at: https://encyclopedia.pub/entry/55934. Accessed February 07, 2026.

Da Silva Rego, Joao Henrique, Miguel Ángel Sanjuán, Pedro Mora, Aniceto Zaragoza, Gonzalo Visedo. "The Brazilian Cement Sector" Encyclopedia, https://encyclopedia.pub/entry/55934 (accessed February 07, 2026).

Da Silva Rego, J.H., Sanjuán, M.�., Mora, P., Zaragoza, A., & Visedo, G. (2024, March 06). The Brazilian Cement Sector. In Encyclopedia. https://encyclopedia.pub/entry/55934

Da Silva Rego, Joao Henrique, et al. "The Brazilian Cement Sector." Encyclopedia. Web. 06 March, 2024.

Copy Citation

The worldwide cement industry plays an important role in addressing the climate change challenge. Brazil’s cement industry currently has 91 cement plants with an installed production capacity of 94 million tons per year and has started to calculate the net CO2 emissions to achieve a carbon-neutral cement sector by 2050. Accordingly, the carbon dioxide uptake due to mortar and concrete carbonation is subtracted from the carbon dioxide emitted by the chemical reaction for the calcination of lime, i.e., the calcination process performed during clinker production.

carbon neutrality

climate change

carbonation

carbon dioxide uptake

carbon dioxide capture and utilization

mitigation

1. Introduction

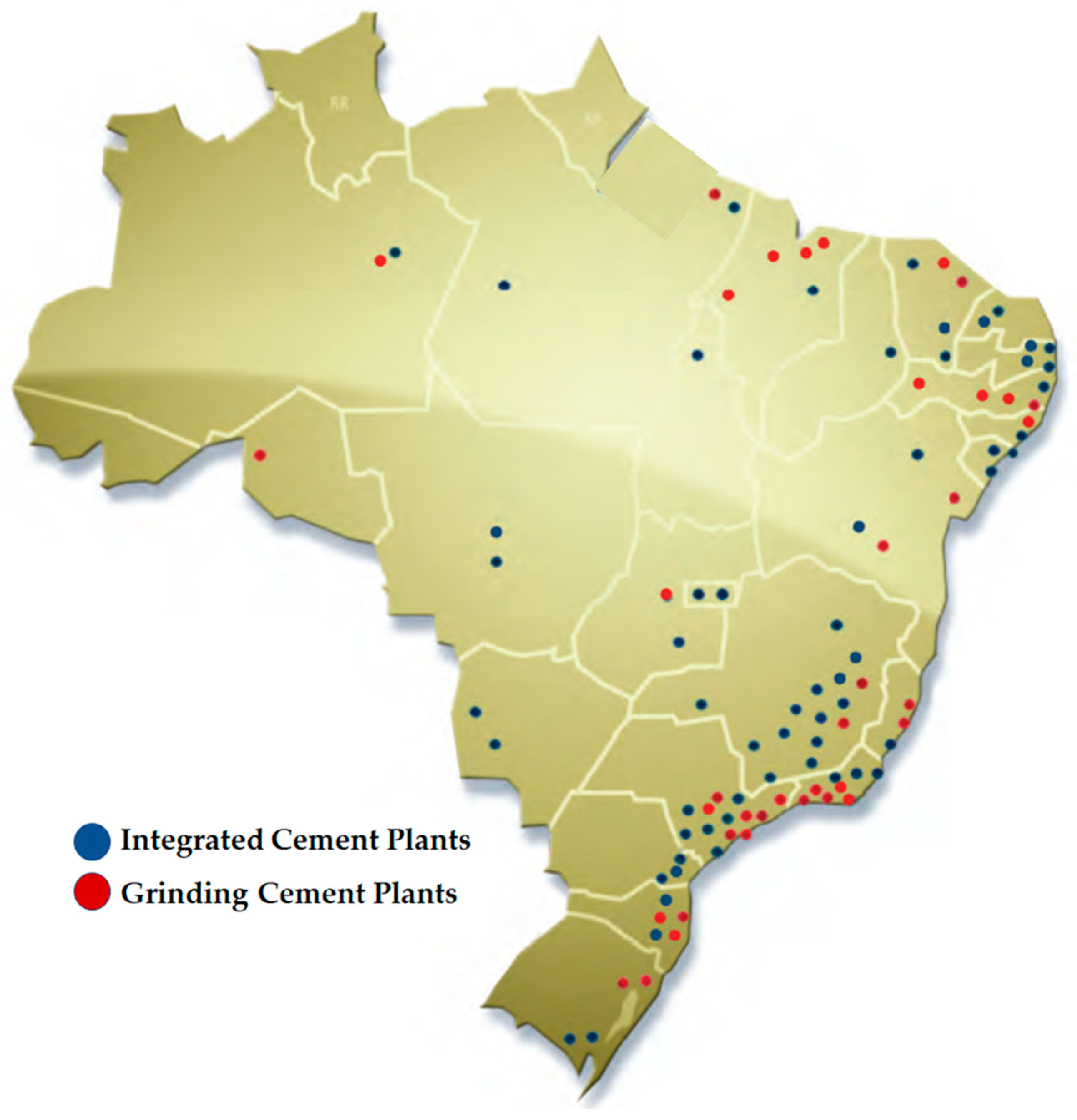

Brazil counts 91 cement manufacturing plants (Figure 1) controlled by 23 industrial groups (Table 1) [1] with a capacity of 94 million tons of cement per year (2022) [1]. The cement production and cement sales were 65.8 and 64.7 million tons in 2021, respectively. Further, the apparent consumption was 64.395 million tons in 2021 (Figure 2). Infrastructure building, housing construction work, and property development contributed to the rise by 6.6% year-to-year from the 2020 cement consumption levels. By contrast, cement sales decreased by 3% year-to-year to 63.1 million tons in 2022, according to the Brazilian National Cement Industry Association (SNIC). This is due to the fact that dispatches dropped in the Southeast, Northeast, and South areas, although sales increased elsewhere in Brazil. In addition, exports fell to 0.40 million tons (2022) from 0.47 million tons (2021). However, the sales forecast for 2023 is an increase of 1%, which would result in a mass market close of up to 64 million tons [2].

Figure 1. Brazilian integrated and grinding cement plants (2022).

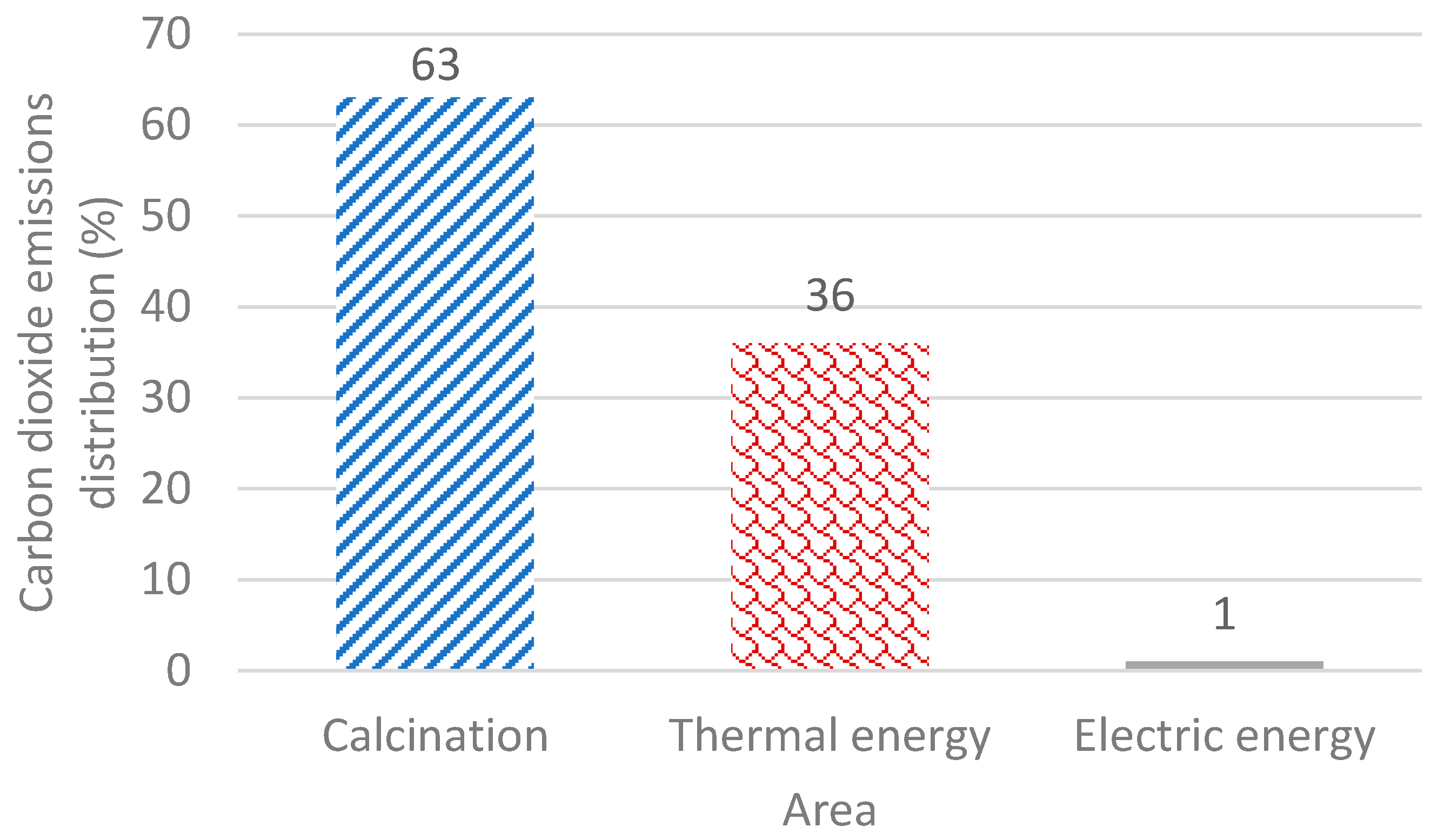

Figure 2. Carbon dioxide emissions broken down by area by the cement production in Brazil (2022) «source: author original».

Table 1. Cement Plants in Brazil (Data from: http://snic.org.br/fabricas-localizacoes.php, accessed on 10 January 2023.

| Company | Cement Plants | ||

|---|---|---|---|

| APODI | Pecém—CE | Quixeré—CE | |

| BRENNAND | Pitimbu—PB | Sete Lagoas—MG | |

| CARMOCAL | Pains—MG | ||

| CIMENTO BRAVO | São Luís—MA | ||

| CIMENTO FORTE | Cabo de Santo Agostinho—PE | ||

| CIMENTO VERDE DO BRASIL | Açaiândia—MA | ||

| CIMENTO ZUMBI | Marechal Deodoro—AL | ||

| CIMENTOS LIZ | Vespasiano—MG | ||

| CIPLAN | Sobradinho—DF | ||

| CRH * (Buzzi and Grupo Ricardo Brennand) | Arcos—MG | Matozinhos—MG | |

| Cantagalo—RJ | Santa Luzia—MG | ||

| CSN | Arcos—MG | Volta Redonda—RJ | |

| ELIZABETH | Alhandra—PB | ||

| ELO | Currais Novos—RN | ||

| ICIBRA | Bacabeira—MA | ||

| INTERCEMENT ** (Former Camargo Corrêa Cimentos) | Apiaí—SP | Brumado—BA | Cabo de Santo Agostinho—PE |

| Cajati—SP | Campo Formoso—BA | Candiota—RS | |

| Cezarina—GO | Cubatão—SP | Ijaci—MG | |

| Jacareí—SP | João Pessoa—PB | Nova Santa Rita—RS | |

| Pedro Leopoldo—MG | Santana do Paraíso—MG | São Miguel dos Campos—AL | |

| Bodoquena—MS | |||

| ITAMBÉ | Balsa Nova—PR | ||

| JOÃO SANTOS | Barbalha—CE | Capanema—PA | Cachoeiros de Itapemirim—ES |

| Codó—MA | Fronteiras—PI | Goiana—PE | |

| Itaituba—PA | Ituaçu—BA | Manaus—AM | |

| Mossoró—RN | Nossa Senhora do Socorro—SE | ||

| HOLCIM (CSN) *** | Barroso—MG | Caaporã—PB | Candeias—BA |

| Cantagalo—RJ | Cocalzinho de Goiás—GO | Itapeva—SP | |

| Montes Claros—MG | Pedro Leopoldo—MG | Rio de Janeiro—RJ | |

| Santa Luzia—MG | Serra—ES | Sorocaba—SP | |

| MIZU | Baraúna—RN | Manaus—AM | Mogi das Cruzes—SP |

| Pacatuba—SE | Rio de Janeiro—RJ | Vitória—ES | |

| PETRIBÚ | Carnaíba—PE | ||

| POZOSUL | Capivari de Baixo—SC | ||

| SUPREMO SECIL | Adrianopolis—PR | Pomerode—SC | |

| TUPI | Carandaí—MG | Mogi das Cruzes—SP | Volta Redonda—RJ |

| VOTORANTIM CIMENTOS | Cantagalo—RJ | Corumbá—MS | Cubatão—SP |

| Cuiabá—MT | Edealina—GO | Esteio—RS | |

| Imbituba—SC | Itajaí—SC | Itaú de Minas—MG | |

| Laranjeiras—SE | Nobres—MT | Paulista—PE | |

| Pecém—CE | Pinheiro Machado—RS | Porto Velho—RO | |

| Primavera—PA | Ribeirão Grande—SP | Rio Branco do Sul—PR | |

| Salto de Pirapora—SP | Santa Cruz—RJ | São Luis—MA | |

| Sobradinho—DF | Sobral—CE | Vidal Ramos—SC | |

| Votorantim—SP | Xambioá—TO | ||

* In 2021, CRH Brazil was bought by the Brazilian BCPAR joint venture (Buzzi Unicem owns 50% and Grupo Ricardo Brennand owns 50%). ** In 2011, Camargo Corrêa Cimentos was rebranded as InterCement. *** In September 2022, Holcim sold its business in Brazil to CSN (Companhia Siderúrgica Nacional). Then, CSN Cimentos became the third-largest cement producer by production capacity after Votorantim and InterCement in Brazil.

Cement manufacturing starts with clinker production in kilns. This stage is the time when direct carbon dioxide emissions occur. Normally, from 30% to 40% of the direct carbon dioxide emissions result from the combustion of fuels and the remaining 60–70% are intrinsic to the chemical process involved in the conversion of limestone to calcium oxide in the formation of clinker (calcination). About 5% of carbon dioxide emissions occur indirectly, primarily because of the electrical consumption by the factory.

In Brazil, fuels combustion represents 36% of the global carbon dioxide emissions, whereas calcination contributes another 63% to the carbon dioxide emissions (Figure 2). In addition, electrical energy contributes approximately one per cent to the global emissions, since renewable sources currently have the largest share in electric power capacity in Brazil (74%).

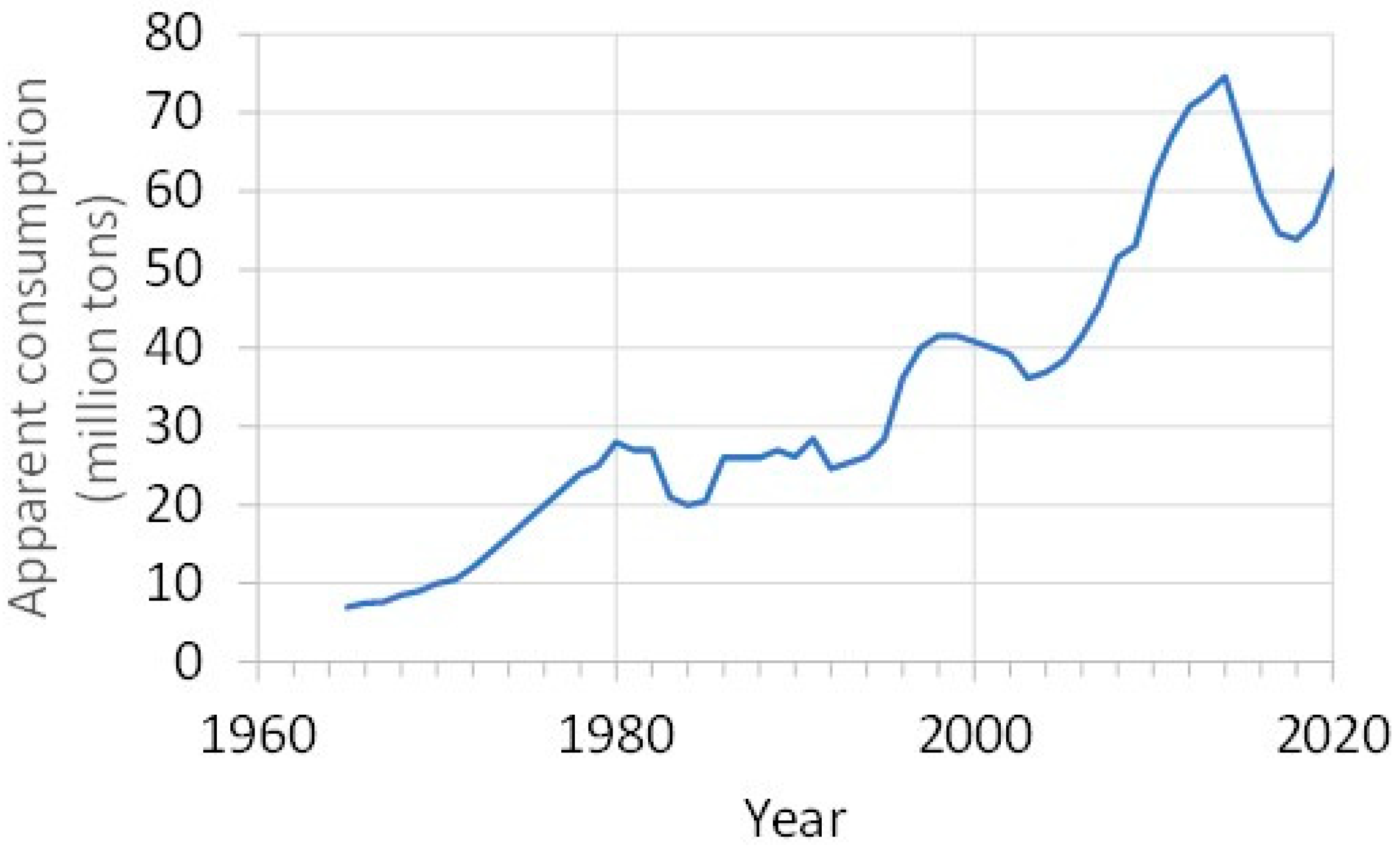

The period of time between 1965 and 1981 was called the Brazilian economic miracle, while the 1981–2003 period entailed market consolidation with cement consumption ranging from 20 to 40 million tons of cement (Figure 3). From 2003 until 2014, a sharp growth was observed, i.e., from about 35 to around 70 million tons. Later, after a decrease in four years, between 2015 and 2018, there was a rise in the apparent consumption up to values of about 65 million tons (Figure 3).

Figure 3. Apparent consumption in Brazil from 1965 to 2022 (million tons per annum) «source: author original».

2. The Brazilian Cement Industry’s Potential for Reducing Carbon Dioxide Emissions by 2050

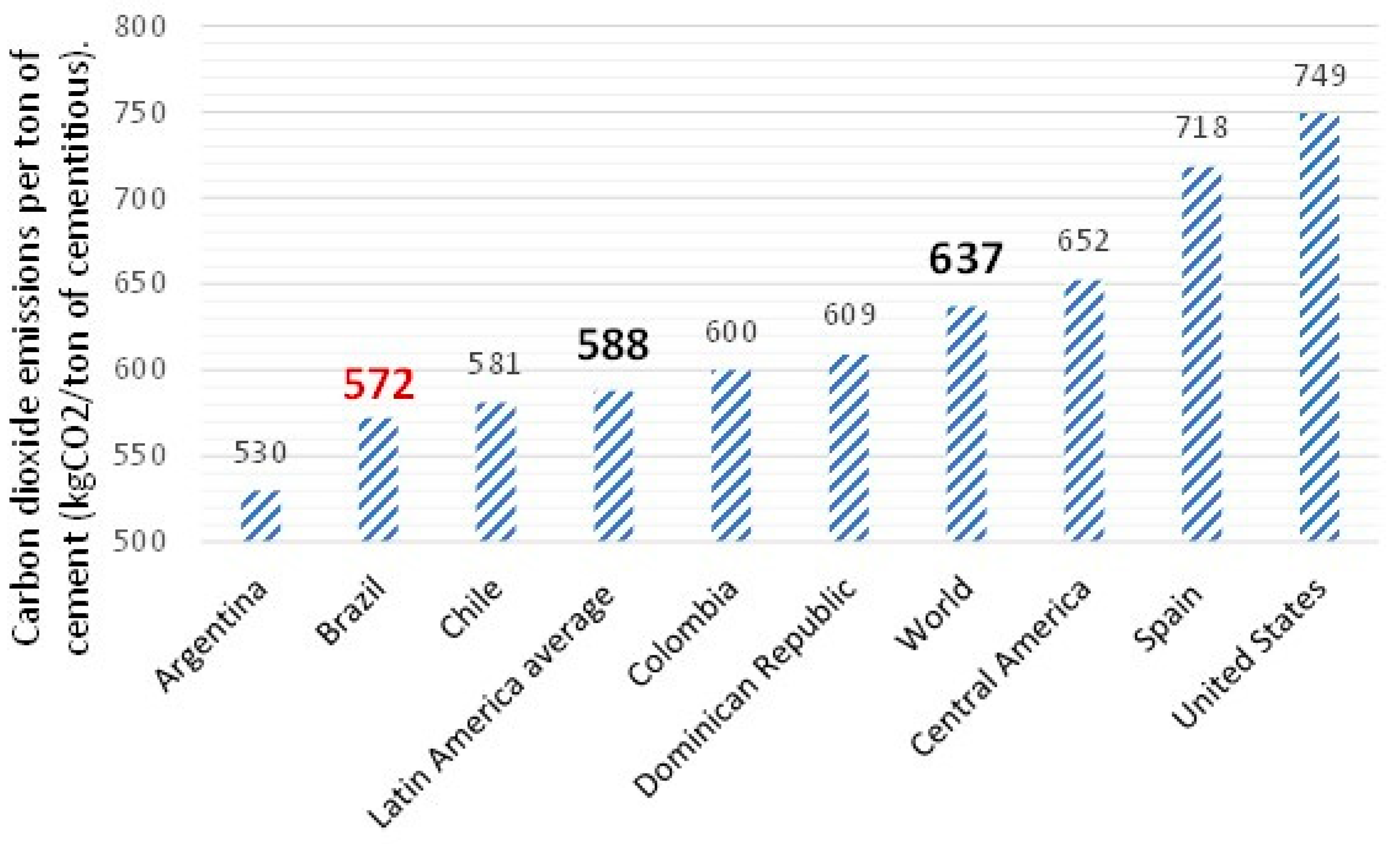

As a developing country, Brazil has a significant infrastructure program to be implemented in the wake of the increase in population and urbanization patterns. Therefore, the demand for cement in the coming decades will rise. The energy-intensive and emission-intensive cement industry would thus be obliged to limit the emission of greenhouse gases. The cement industry globally accounts for approximately 7.4% (2.9 Gtons in 2016) [3] of all anthropogenic carbon dioxide emissions. By contrast, this share is about 2.6% in Brazil because of a set of actions that the Brazilian cement sector has been implementing for years. Consequently, Brazil is one of the countries worldwide that emits the lowest amount of carbon dioxide per ton of cement. Figure 4 shows a comparison of the carbon dioxide emissions per ton of cement (2015) between Brazil (572 kg CO2/ton of cementitious) and some other countries. The Latin American and world average in 2015 were 588 and 637 kg CO2/ton of cementitious, respectively.

Figure 4. Comparison of the carbon dioxide emissions per ton of cement in some countries (kgCO2/ton of cement) «source: author original».

The Brazilian cement sector has developed a Cement Technology Roadmap presenting some alternatives for mitigating carbon dioxide emissions from the national industry in the short- and long-term, and for the commitment of reducing carbon dioxide [4]. Accordingly, the Brazilian cement sector has committed to a 34% reduction in carbon dioxide emissions due to the cement production, to 375 kg/ton of cement by 2050 from 564 kg/ton of cement recorded in 2019.

3. The Brazilian Cement Sector Roadmap

Brazilian cement production expanded at rates well above 273 per cent between 1990 and 2014, i.e., from 26 million to 71 million tons. By contrast, global carbon dioxide emissions increased by 223% over this period. This result was mostly due to the 18% reduction in carbon dioxide emissions intensity from 700 kg CO2/ton cement to 564 kg CO2/ton cement over this period. Accordingly, the Brazilian cement industry has one of the lowest worldwide levels of specific carbon dioxide emissions, on account of mitigation measures implemented by the Brazilian industry over recent decades [4].

One of the main mitigation measures is the increase in cement constituents, such as limestone and calcined clay, to partially replace the clinker in the final blended cement. It is expected there will be a sharp clinker/cement ratio reduction from 67% (2014) to 52% in 2050, allowing for significant CO2 emissions reduction (290 million tons in the period). Therefore, the carbon dioxide mitigation due to the clinker substitution will represent a 69% decrease.

The average thermal consumption and electricity consumption in Brazil is 3.5 GJ/t of clinker and 113 kWh/t of cement, respectively (Table 2). Although significant changes in cement production energy intensity are not expected by 2030, the replacement of obsolete installations with new lines according to the best available technologies (BATs) might start after 2030 in order to reach figures of 3.2 GJ/t of clinker and 91 kWh/t cement by 2050. These measures will lead to a cumulative carbon dioxide depletion of 38 million tons by 2050 (9% of the Brazilian industry mitigation).

Table 2. Key indicators for the Brazilian cement industry by 2030 and 2050 within the 2 °C scenario.

| Indicator | 2014 | 2030 | 2050 |

|---|---|---|---|

| Clinker factor (clinker/cement ratio) | 0.67 | 0.59 | 0.52 |

| Thermal consumption (GJ/t clinker) | 3.50 | 3.47 | 3.20 |

| Electrical consumption (kWh/t cement) | 113 | 106 | 91 |

| Alternative fuels (% of thermal substitution) | 14.8% | 35% | 55 |

| Global carbon dioxide emissions (Mt CO2/year) | 40 | 42 | 44 |

| Carbon dioxide emissions intensity (kg CO2/t cement) | 564 | 485 | 375 |

With regard to the substitution rate with alternative fuels (% of thermal substitution), some regional differences have been observed in Brazil. Therefore, the range of substitution could be 30–40% and 50–60% for 2030 and 2050, respectively. Consequently, the carbon dioxide mitigation due to the increase in alternative fuel’s usage is about 13%.

Finally, Carbon Capture, Usage, and Storage (CCUS) technologies will play a key role in decarbonization in the Brazilian cement sector and in addressing the challenge of global climate change. It is expected to reach a cumulative reduction of 38 million tons of carbon dioxide (9% of the Brazilian industry mitigation).

References

- The National Cement Industry Union (SNIC). Available online: http://snic.org.br/fabricas-localizacoes.php (accessed on 15 February 2023).

- ICR Newsroom. Brazilian Cement Consumption down 3% in 2022. 2023. Available online: https://www.cemnet.com/News/story/174147/brazilian-cement-consumption-down-3-in-2022.html (accessed on 15 February 2023).

- Sanjuán, M.A.; Argiz, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake in the Roadmap 2050 of the Spanish Cement Industry. Energies 2020, 13, 3452. Available online: https://doi.org/10.3390/en13133452 (accessed on 15 February 2023).

- SNIC. Cement Technology Roadmap—Carbon Emissions Reduction Potential in the Brazilian Cement Industry by 2050/Coordinated by Gonzalo Visedo and Marcelo Pecchio; SNIC: Rio de Janeiro, Brazil, 2019; p. 64. Available online: http://snic.org.br/assets/pdf/roadmap/cement-technology-roadmap-brazil.pdf (accessed on 15 February 2023).

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

5.3K

Revisions:

2 times

(View History)

Update Date:

07 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No