Regional and international conventions, in addition to most national laws, do not address the removal of offshore pipelines. The decommissioning process is triggered by a forecast of the decline in production from the field(s) to sub-economic levels, the loss of serviceability, or damage to the upstream system such that it may not be used commercially.

The timing of the decommissioning of a facility/structure/pipeline/umbilical/cable is predominantly governed by the operator/asset and existing management plans/field development plans/pipeline management plans and production licenses. All proposed decommissioning operations, be it mothballing or decommissioning parts or the whole of the field, must be in accordance with submitted and approved management and environment plans under the current legislative framework.

2. Input Data for Pre-Project Activities

2.1. Historical Record and Description of the Installations

Such data typically include the following:

-

Detailed descriptions and plans of the facilities and the field(s), including relevant parts of the design documentation, weight reports, process descriptions, well coordinates, buildings, platforms, access paths, drainage systems, waste disposal zones and sludge pits for onshore sites, overland/buried pipes, etc.

-

Hazardous and non-hazardous material inventories, to be collected through a survey if necessary.

-

Seabed survey data, including information on drill cutting piles, etc.

-

The architecture of the wells (vertical section).

-

Historical records and reports on past activity, including Well well Records records from the well production period (e.g., successive well completions, servicing, annulus pressure anomalies, corrosion, deposits, etc.).

-

Lists of the products presented on the site and their characteristics.

-

Accidentology (nature of the pollutant, quantity released, types of media affected, area covered, and actions engaged).

-

Archives, photographs, etc.

2.2. Environmental and Socio-Economic Data

Such data typically include the following:

-

General maps, showing the site’s position within its physical and socioeconomic environment.

-

Descriptions of the environment.

-

Hydro geological studies (locations of water tables).

-

Initial conditions of the environment prior to operations (baseline state).

-

Initial socio-economic conditions (land occupation and social and economic activities).

-

Information on potential sources of contamination and site impacts.

-

Other information for consideration, including the sensitivity of the site (water catchment, vulnerability of the water tables, and damp zones) and safety around the site.

To collate all that information, the following available site environmental studies and reports are used:

-

The initial state of the site before production operations, called the Environmental and Social Baseline Study (ESBS).

-

Environmental and Social Impact Assessment (ESIA).

-

Environment reviews.

-

Risk studies (Simplified and Detailed Risk Assessment).

-

Results of survey studies and surveillance undertaken as part of environmental monitoring.

A full environmental diagnosis of the site may have to be undertaken in case of a lack of adequate environmental monitoring during the production phase.

2.3. Regulatory Constraints

Regulatory requirements (international, national, local, and professional references) must be determined to establish the work programme’s decontamination objectives and choose the appropriate treatment to remediate the contaminated environments. It is critical to continuously monitor the evolution of applicable obligations (including local regulations and contractual requirements that may evolve rapidly), with particular attention on the following:

-

International laws, guidelines, and conventions (e.g., UN, IMO, etc.).

-

Regional conventions and protocols (e.g., Australia, Kuwait, etc.).

-

National laws (e.g., petroleum, maritime, trade, industry, environmental, interior, etc.).

-

Industry guidelines (e.g., Oil and Gas Producers Association (OGP) guidelines).

2.4. Construction, Maintenance, and Integrity Management

Construction, maintenance, and inspection records should be reviewed to determine the physical condition of the pipeline. The integrity management history of the pipeline should be reviewed to determine the current status of the pipeline’s integrity before decommissioning.

In particular, if a recent ILI (In-line Inspection) tool is run, then much data can be corroborated or derived from the record of the ILI. Typically, the following information is useful in planning decommissioning activities:

-

Minimum pipe wall thickness.

-

Bend geometry.

-

The presence and locations of dents, cracks, ovalities, gouges, and corrosion (refer to

Appendix C for more details regarding the corrosion associated with carbon steel pipes).

-

The presence and locations of metallic features, e.g., valves, doublers, branches, and other appurtenances.

-

The most recent successful pressure test duration, test pressure, and test medium.

-

The locations of any free spans or soil or seabed erosion that could lead to future free spanning or pipe exposure.

-

Areas requiring trenching or burial for long-term stability.

-

Any other information pertaining to the maintenance history of the pipeline is useful in assessing the pipeline’s integrity status.

2.5. Others

Such data typically include the following:

-

Relevant production license information, including conditions, clauses on decommissioning, expiry, etc.

-

Descriptions of relevant legal aspects, termination of ownership, possible indefinite liabilities, etc.

-

Relevant financial and fiscal aspects.

-

Preliminary Risk Management Plans.

-

Residual Value Reports.

-

Follow-ups of previous cessation-related actions indicated in pre-development environmental impact assessments.

-

Records of all contacts and consultations with stakeholders (authorities, communities, contractors, etc.) from preliminary discussions to formal approval.

3. Applicable Regulations

There are several relevant regional and international conventions/protocols

[20][21][22][23][24][25][26][27][28][29][30][31][32][33][34][35][36][37][38][39][40]. They are applicable to decommissioning and abandonment. The regulatory requirements in the country in which the pipeline/umbilical/cable is situated may define the standards that apply to that pipeline/umbilical/cable that is decommissioned.

4. Project Execution and Government/Regulatory Approvals

4.1. Planning

Decommissioning activities require planning prior to commencing. The roles and responsibilities should be clearly identified, and a decommissioning programme should be established to manage and support the planning process and approval requirements. The decommissioning process should take into consideration the appropriate state, national, and international legislation, guidelines, and standards.

4.2. Management and Responsibilities

A specified decommissioning project team is responsible for preparing a Decommissioning and Closure Plan and for developing a decommissioning programme. The project team interfaces with the operations team to ensure all activities are considered. The selection process is like the selection of a brownfield concept, concluding with the business case, cost, and schedule forecast and an outline plan for the selected decommissioning concept. In the subsequent development phase, responsibility is transitioned from operations to the project team responsible for the decommissioning activities. Consideration is given when selling an asset to a third party, such that the purchaser takes reasonable care to dismantle/recycle/dispose of the asset.

4.3. Decommissioning Process

The decommissioning process is typically prompted by a forecasted decline in production to sub-economic levels or loss of serviceability. The economic assessment for end-of-field-life justification is detailed in the business case of the facility to be decommissioned. The criteria for stopping production depend on oil/gas prices and operating costs. The operating costs used for such a decision need to be the actual incremental costs of running a facility (i.e., excluding, for example, overheads which would continue once the facility is decommissioned). The cut-off point, in principle, is the point where incremental OPEX (excluding overheads not directly related to the facility) is greater than the value of incremental production. Decommissioning projects is typically split into four distinct phases:

-

The decision to initiate (ASSESS).

-

The concept selection phase (SELECT).

-

Project planning and preparation (DEVELOP).

-

Project implementation (EXECUTE).

The key project focus decisions, deliverables, and government approval submissions required are summarised in Table 1.

Table 1. Key stages of a typical decommissioning programme.

| Phase |

Key Focus Decision |

Deliverables |

| Assess |

|

-

Project initiation note

-

Development team

-

Steering committee

|

| Select |

-

Stakeholder identification

-

Identify commitments made to the government/regulators and stakeholders

-

Preliminary discussions with the government/regulator

-

Develop and price options for decommissioning and disposal operations

-

Initiate the government approval process

-

Stakeholder consultation

-

Select the preferred decommissioning and disposal option

-

Contracting strategy

|

-

Concept selection report

-

Contracting strategy

-

Preliminary BOD (basis of design)

-

Plan for the Develop Phase

-

Feasibility report

-

Class II cost estimates (+25% to −15%) and project schedules for decommissioning options

-

Stakeholder management plan

-

HSE management plan

-

Government/regulatory approval plan

-

Sea dumping permit application

|

| Develop |

-

Detailed design

-

Coordination with other operations in the area

-

End-of-field-life trigger date set

-

Equipment disposal option finalised

-

Stakeholder approval

|

-

Final project cost, scope, and schedule (from the cessation of production operations)

-

Long-term commitments

-

Class III cost estimates

-

Final basis of design

-

Project execution plan (PEP)

-

HSE documentation

-

Final investment decision (FID)

-

Revised field development plan

-

Decommissioning the safety case

-

Environment plan

-

Revised well operations management plan/well abandonment plan

-

Revised pipeline management plan/pipeline decommissioning plan

-

Production licence surrender application

-

Diving approvals

-

Maritime approvals

-

Disposal approvals

|

| Execute |

|

-

Execution tender and awards

-

Well abandonment programmes

-

Subsea work programmes

-

Topsides work programmes

-

Verifying surveys, audits of decommissioning works, and monitoring of material left in situ

-

Review and lessons learned

-

Survey/audit reports

-

Decommissioned field report

|

4.4. Deferral and Phased Decommissioning

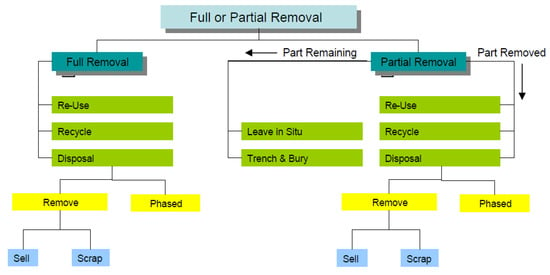

Each decommissioning scenario has several unique steps to consider depending on the selected method or techniques. The systems can be entirely removed, partially removed, or left in situ. A phased decommissioning process may be required where decommissioning activities are complex and/or multiple decommissioning methods are necessary. This may require several phases or stages to carry out and complete the activities. Figure 1 shows the possible solutions for decommissioning. The following definitions also apply:

Figure 1. Decommissioning options.

-

Re-use: To keep in situ and conditioned for future use.

-

Recycle: To condition and remove for reclaiming for other purposes.

-

Disposal: Conditioning and removing to be discarded.

-

Phased: To have sections isolated, conditioned, and removed in stages to be discarded.

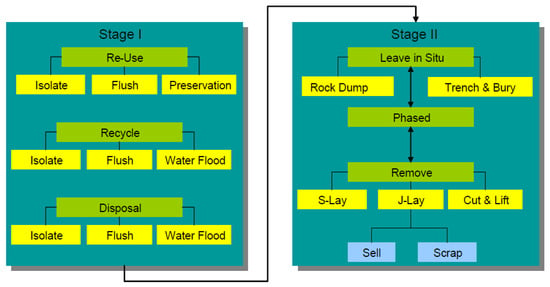

The implementation and execution of decommissioning activities are often split into two stages. Stage 1 of the decommissioning process typically involves the conditioning of the system. This incorporates several proprietary steps to safely isolate, flush, and preserve the system. Stage 2 of the process involves the completion of the decommissioning activities to remove equipment and/or leave it in situ, as determined by the selection process. Figure 2 shows the processes through the two stages.

Figure 2. Decommissioning stages.

5. Decommissioning/Abandonment Options for Pipelines

The main issues to be considered in deciding which option to choose are as follows:

-

Legal requirements, including compliance with license conditions.

-

Operator/asset holder commitments.

-

Environmental impacts.

-

Stakeholder impacts (fishing, navigation, and shipping).

-

Economic considerations.

-

Safety.

-

Liability.

-

Technical feasibility.

-

Reputation.

It is impossible to determine the legislative requirements that will be in place at the end of a field life, and there are no international regulations to date that specifically dictate how to decommission pipelines. Current regulations, however, require decommissioning activities to be included in the pipeline management plan and safety management case, and prior to engaging in such activities, written approval must be submitted and obtained from the DA. In addition, the conservation and protection of natural resources should be maintained, and any damage to the seabed or subsoil should be repaired to the satisfaction of the designated authority. The options currently available for pipeline decommissioning include the following:

-

Re-classification;

-

Disposal in situ;

-

Removal.

6. Post-Decommissioning Requirements

6.1. Monitoring

All pipelines that are left in situ require continued monitoring and maintenance, where necessary, to reduce any risk to the safety and environment of the surrounding area.

As part of the agreed decommissioning assessment and consultation procedures, any facilities left in place may be subject to a monitoring programme at appropriate intervals. A suitable monitoring programme is devised in agreement with the regulator. Details of the monitoring programme are included in the decommissioning and closure management plan and the decommissioning programme submitted to the relevant government agencies.

The duration and types of monitoring depend on the circumstances and, if necessary, should be adapted with time. Inspection reports may be required to be submitted to the relevant designated authority, together with any proposals for maintenance or remedial work that may be required.

6.2. Sampling

Post-decommissioning environmental seabed sampling may be required to monitor the level of any residual hydrocarbons, heavy metals, and other contaminants in sediment, flora, and fauna. There is a greater need to survey more sensitive shallow water areas closer to shore due to the higher population of flora and fauna. Deepwater areas from the escarpment require a less rigorous sampling survey.

Monitoring programmes are used to ensure that sampling and analysis are completed correctly in conjunction with the relevant designated authority as required. Details of the agreed survey/sampling strategy are included in the decommissioning and closure management plan and the decommissioning programme.

6.3. Debris Clearance

Upon completion of each decommissioning and abandonment operation, applicable surveys are expected to be carried out to identify and recover any debris on the seabed that has arisen from the decommissioning operation. The most likely situation for this to be a requirement is when the area will be used by other sea users and remaining debris could provide a safety hazard, or when sensitive environments are located close to the decommissioning areas and impacts upon these areas could be reasonably expected.

The survey area depends on a case-by-case situation. The UK DBERR Guidelines

[39] state that the minimum required survey area has a radius of 100 m on either side of the decommissioning pipeline over its entire length. The US Minerals Management Service (MMS) decommissioning regulations require trawling in a circular radius between 200 and 400 m around the entire length of the pipeline, or side-scan sonar, diving, and remotely operated vehicle surveys over a grid of 200 m to 400 m centred around the entire length of the pipeline, to verify there are no obstacles left on the seabed that could impede other users of the sea.

7. Conclusions

The environmental impact of each potential decommissioning option should be assessed as part of the decommissioning strategy definition process. Environmental impacts that may occur during the decommissioning process itself should be considered along with the potential environmental impacts foreseeable if the decommissioned pipeline is left in place. The process by which a decommissioning option is selected can be summarised as follows:

-

Selection of the system that is to be decommissioned.

-

Identification of the elements that will be involved in the decommissioning process.

-

Assessment of the system’s condition and other factors that may affect the decommissioning process.

-

Identification of all possible decommissioning options.

-

Initial screening of decommissioning options.

-

Detailed assessment of decommissioning options.

-

Selection of a decommissioning option.

-

Peer review of the selected decommissioning option and process.

-

Approval of the selected decommissioning option, or a repetition of the process starting with a detailed assessment of decommissioning options.

-

Submission of the decommissioning option for “governmental or regulatory body approval”.

-

Approval of the selected decommissioning option by the “governmental or regulatory body”, a modification of the option, or a repetition of the process starting with a detailed assessment of decommissioning options.

-

Execution of the approved decommissioning option.

Different decommissioning arrangements may be considered for this comparative exercise, subject to local, regional, and international laws, regulations, conventions, and applicable contracts. The decommissioning philosophy should also consider the following:

-

Relevant production license information, including conditions, clauses on decommissioning, expiry, etc.

-

Descriptions of relevant legal aspects, termination of ownership, possible indefinite liabilities, etc.

-

Relevant financial and fiscal aspects.

-

Preliminary Risk Management Plans.

-

Residual Value Reports.

-

Follow-ups of previous cessation-related actions indicated in pre-development environmental impact assessments.

-

Records of all contacts and consultations with stakeholders (authorities, communities, contractors, etc.) from preliminary discussions to formal approval.

Regulatory requirements (international, national, local, and professional references) must be determined to establish the work programme’s decontamination objectives and to choose the appropriate treatment to remediate the contaminated environments. It is critical to continuously monitor the evolution of applicable obligations (including local regulations and contractual requirements that may evolve rapidly), with particular attention on the following:

-

National laws (e.g., petroleum, maritime, trade, industry, environmental, interior, etc.)

-

Industry guidelines (e.g., Oil and Gas Producers Association (OGP) guidelines)

When it is proposed that a near-shore pipeline should be cut and dragged to deeper water for disposal to reduce safety hazards to other users of the sea, a clear case should be made as to why this option has been chosen over disposal onshore, since this proposal might be considered “dumping”, in which case a dumping permit from the government/regulator is required. It is recommended to follow the Best Practical Environmental Option (BPEO) method for all decommissioning activities and to use environmental impact assessment (EIA) as a tool to document this approach.