Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Gaydaa AlZohbi | -- | 1486 | 2024-02-07 09:42:27 | | | |

| 2 | Camila Xu | Meta information modification | 1486 | 2024-02-07 09:50:19 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Alzohbi, G. Economics of Hydrogen Generation. Encyclopedia. Available online: https://encyclopedia.pub/entry/54839 (accessed on 07 February 2026).

Alzohbi G. Economics of Hydrogen Generation. Encyclopedia. Available at: https://encyclopedia.pub/entry/54839. Accessed February 07, 2026.

Alzohbi, Gaydaa. "Economics of Hydrogen Generation" Encyclopedia, https://encyclopedia.pub/entry/54839 (accessed February 07, 2026).

Alzohbi, G. (2024, February 07). Economics of Hydrogen Generation. In Encyclopedia. https://encyclopedia.pub/entry/54839

Alzohbi, Gaydaa. "Economics of Hydrogen Generation." Encyclopedia. Web. 07 February, 2024.

Copy Citation

Hydrogen is known as the lightest and the most abundant element. It supplies energy to fuel the stars and the Sun. It is considered non-toxic, odorless, colorless, highly combustible, and unpolluted.

hydrogen energy

fuel cell

electrolytic

photolytic

thermal technique

1. Introduction

Hydrogen is known as the lightest and the most abundant element. It supplies energy to fuel the stars and the Sun. It is considered non-toxic, odorless, colorless, highly combustible, and unpolluted. Also, it is an energy carrier [1]; it scarcely exists by itself and should be generated from compounds that contain it. Hydrogen is versatile; it can be produced from varied resources, and it is used in a wide range of applications. It can be converted into electricity using conversion devices like fuel cells [2]. The main advantages of hydrogen are its high electrochemical reactivity, theoretical energy density, safe combustion products, and unbounded availability. However, hardness storage, low density under normal circumstances, and explosion hazards represent the main impediments to the use of hydrogen in fuel cells. Many sources could be used to generate hydrogen, like water, fossil fuels, and renewable energy. According to its production method, hydrogen can be classified as follows [3]:

- -

-

Gray hydrogen: fossil fuels are used to produce hydrogen, like natural gas and oils; this kind of hydrogen releases a large amount of CO2 into the air during its production process.

- -

-

Blue hydrogen: hydrogen is produced using fossil fuels, and it is accompanied by carbon-capture storage technology to decrease carbon dioxide emissions.

- -

-

Green hydrogen: hydrogen is generated by electrolysis powered by renewable energy, such as solar, wind, geothermal, nuclear, and waste energy. It is considered to be a clean technology to generate hydrogen.

- -

-

Brown hydrogen: this type of hydrogen is considered to be the most affordable and the most harmful to the environment due to the thermal coal that is used in the generation process.

- -

-

Turquoise hydrogen: hydrogen is fabricated using methane pyrolysis technology that yields solid carbon.

- -

-

Yellow hydrogen: this refers to the hydrogen generated by electrolysis using solar energy.

- -

-

White hydrogen: this type of hydrogen is geological, which is established in underground deposits and formed via fracking. Presently, there are procedures to harness and exploit it.

Hydrogen energy is versatile in terms of its usage and generation. Currently, it is used in the production of methanol and ammonia, the fabrication of vitamins and pharmaceutical products, and the hydrogeneration process of liquid oils. Also, hydrogen is used to extract sulfur and nitrogen compounds in refinery processes [4]. It is used to produce steel by replacing coking coal and to generate fuel for transportation. Moreover, some companies are planning to use hydrogen to heat and cool buildings and to generate power to minimize GHG emissions and improve efficiency.

Hydrogen energy is anticipated to be a sustainable fuel for the future. Recently, the development of hydrogen technologies has gained more international interest and attention due to the significant role that hydrogen can play in increasing energy security and economic sustainability. Hence, hydrogen energy can sustainably cope with the global growth in energy demand. In addition, hydrogen energy can be used to generate and store energy and to deal with the intermittent nature of renewable energy sources [5]. Also, hydrogen can contribute to decarbonization in many sectors, including chemical, transportation, and steel production, and therefore, it can enhance air quality, boost energy security, minimize oil reliance, and cope with climate change. Moreover, hydrogen can be produced from plastic waste materials through several thermo–catalytic processes; therefore, it is considered to be a solid waste treatment [6].

The neutral carbon characteristic of hydrogen depends on the cleanliness of its generation method, the feedstock used, and the energy used in its generation process [7]. Therefore, it is essential to determine the hydrogen origin before considering it as a green energy source. The kind of feedstock and energy and the desired end-use purity determine the specified technology and hydrogen generation method.

2. Economics of Hydrogen Generation

2.1. Cost of Hydrogen Based on Hydrogen Types

An analysis of the hydrogen-based energy system has been conducted [8]. The findings pointed out that the global future energy system will be established mainly on electricity and hydrogen. The cost of hydrogen relies on technologies used to generate hydrogen and the feedstock used. Among the different types of hydrogen (colors), the lowest cost of hydrogen generation is gray hydrogen, with a price range from 0.88 to 2.31 USD/kg of H2 [9]. The cost of blue hydrogen is higher owing to the necessity to use devices/systems to capture and store carbon, and it ranges between 1.32 and 3.30 USD/kg of H2 [10]. The generation cost of green hydrogen through electrolysis is the most expensive, and it ranges from 2.42 to 9.01 US USD/kg of H2 [9][10].

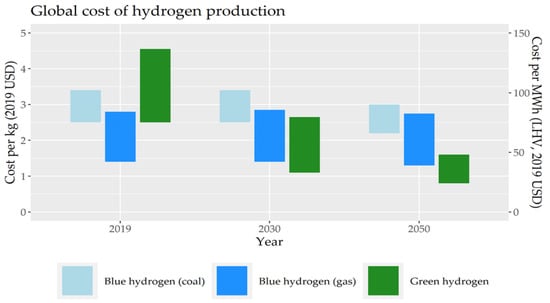

Figure 1 displays the cost of blue hydrogen, generated with coal and gas, and green hydrogen in 2019 and a future estimation of their costs [11]. It can be noticed that the cost of blue hydrogen generated with gas is the lowest, and the cost of green hydrogen is the highest. Blue hydrogen is 2–3 times cheaper than green hydrogen. Nevertheless, the cost of green hydrogen is projected to drop significantly, by up to 60%, to reach a minimum value of 1.5 USD/kg by 2050. Many issues affect the cost of green hydrogen, such as the renewable electricity price, operating hours, and the electrolyzer investment cost [12]. Innovation and enhanced efficiency are required to maximize the electrolyzer’s ability to reach multi-gigawatt (GW) levels. The drop in electricity price and the investment cost of electrolysis facilities are fundamental to producing a competitive green hydrogen.

Figure 1. The global cost of hydrogen generation [11].

2.2. Cost of Hydrogen Generated Based on the Technologies Used

Currently, the most predominately used and economical technology for hydrogen generation is the steam reformation of methane. Around half of all global hydrogen is generated using steam reformation, with a generation cost of 7 USD/GJ. Partial oxidation of hydrogen showed a competitive price for hydrogen generation. Nevertheless, a carbon capture and storage system should be integrated to minimize the greenhouse gases generated by thermochemical technologies, and in this case, a rise in hydrogen price by 25–30% must be considered [13].

Gasification and pyrolysis of biomass are among the thermochemical technologies used to generate hydrogen. The cost of hydrogen generation by gasification and pyrolysis is costly, about three times greater than the cost of hydrogen generated by steam reformation technology. Therefore, these technologies are generally not deemed as cost-competitive for steam reformation. The cost of hydrogen generated by gasification and pyrolysis of biomass ranges from 10 to 14 USD/GJ and from 8.9 to 15.5 USD/GJ, respectively. The generation cost depends on different factors, including the equipment, accessibility, and cost of raw materials [1].

Generating hydrogen using water electrolysis is considered to be the simplest and most efficient process without byproducts. However, the generation of hydrogen through water electrolysis is costly due to the cost of electricity needed to split the water and the cost of water. Decreasing the electricity prices and increasing the operating hours are crucial for hydrogen generation through electrolysis [14].

An economic analysis of the different hydrogen generation technologies has been carried out [15]. Results demonstrated that the most economical technology is the generation of gray hydrogen. In addition, the study indicated that alternative technologies could be economically competitive in the future. Gasification and pyrolysis have the potential to be competitive over time [16]. Also, results showed that hydrogen-generated power by solar energy is the most ecofriendly process. The main technologies to generate hydrogen by 2030 will be steam reformation of natural gas and catalyzed biomass gasification. In addition, coal gasification and electrolysis will be used to a limited extent. Hydrogen production using solar energy is arguable in a given context and is questionable but also possible. The use of solar energy will most likely rise by 2050 [1].

A comparative study of the different hydrogen generation technologies in terms of efficiency and cost has been performed [9]. Findings showed that hydrogen generation based on fossil fuels is not in phase with the transition toward a sustainable energy future. Also, the study pointed out that in the case of the generation of blue hydrogen, substantial fugitive methane emissions happen, which is not taken into consideration in most studies. Moreover, the study discussed the possibility of decreasing the cost of electrolysis in the future. The introduction of a global hydrogen market is viewed as an important key player since it would enable countries with suitable circumstances for renewable energy generation to generate hydrogen at lower costs [17].

The cost breakdown of different technologies used to generate hydrogen is displayed in Table 1. The highest investment cost is recorded for PEM electrolysis, with a value of 3163 (USD/kW), and the lowest is for the SMR technology. Steam reformation and steam reformation with CCUS have the highest operating time and the lowest energy price.

Table 1. Cost breakdown of gray, blue, and green hydrogen [17].

| Alkaline Electrolysis | PEM | SMR | SMR with CCUS | |

|---|---|---|---|---|

| Investment cost (USD/kW) | 2836 | 3163 | 1090 | 1939 |

| O&M (USD/kW) | 42.54 | 48 | 51.27 | 57.82 |

| Efficiency (LHV) | 64 | 66 | 76 | 69 |

| Operating hours | 3000 | 3000 | 8322 | 8322 |

| Energy price (USD/kW) | 0.044 | 0.044 | 0.033 | 0.033 |

References

- Mazloomi, K.; Gomes, C. Hydrogen as an energy carrier: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033.

- Stambouli, A.B.; Traversa, E. Fuel cells, an alternative to standard sources of energy. Renew. Sustain. Energy Rev. 2002, 6, 295–304.

- Kochanek, E. The role of hydrogen in the visegrad group approach to energy transition. Energies 2022, 15, 7235.

- Ramachandran, R.; Menon, R.K. An overview of industrial uses of hydrogen. Int. J. Hydrogen Energy 1998, 23, 593–598.

- Ehteshami, S.M.M.; Chan, S. The role of hydrogen and fuel cells to store renewable energy in the future energy network–potentials and challenges. Energy Policy 2014, 73, 103–109.

- Al-Fatesh, A.S.; AL-Garadi, N.Y.; Osman, A.I.; Al-Mubaddel, F.S.; Ibrahim, A.A.; Khan, W.U.; Alanazi, Y.M.; Alrashed, M.M.; Alothman, O.Y. From plastic waste pyrolysis to Fuel: Impact of process parameters and material selection on hydrogen production. Fuel 2023, 344, 128107.

- Navarro, R.M.; Pena, M.; Fierro, J. Hydrogen production reactions from carbon feedstocks: Fossil fuels and biomass. Chem. Rev. 2007, 107, 3952–3991.

- Ball, M.; Weeda, M. The hydrogen economy–vision or reality? Int. J. Hydrogen Energy 2015, 40, 7903–7919.

- Longden, T.; Beck, F.J.; Jotzo, F.; Andrews, R.; Prasad, M. ‘Clean’hydrogen?—Comparing the emissions and costs of fossil fuel versus renewable electricity based hydrogen. Appl. Energy 2022, 306, 118145.

- Noussan, M.; Raimondi, P.; Scita, R.; Hafner, M. The role of green and blue hydrogen in the energy transitionda technological and geopolitical perspective. Sustainability 2021, 13, 298.

- IEA. The Future of Hydrogen; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 20 August 2023).

- De León, C.M.; Ríos, C.; Brey, J. Cost of green hydrogen: Limitations of production from a stand-alone photovoltaic system. Int. J. Hydrogen Energy 2022, 48, 11885–11898.

- Yu, J.; Takahashi, P. Biophotolysis-based hydrogen production by cyanobacteria and green microalgae. Commun. Curr. Res. Educ. Top. Trends Appl. Microbiol. 2007, 1, 79–89.

- Rosen, M.A.; Koohi-Fayegh, S. The prospects for hydrogen as an energy carrier: An overview of hydrogen energy and hydrogen energy systems. Energy Ecol. Environ. 2016, 1, 10–29.

- Bartels, J.R.; Pate, M.B.; Olson, N.K. An economic survey of hydrogen production from conventional and alternative energy sources. Int. J. Hydrogen Energy 2010, 35, 8371–8384.

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611.

- Ajanovic, A.; Sayer, M.; Haas, R. The economics and the environmental benignity of different colors of hydrogen. Int. J. Hydrogen Energy 2022, 47, 24136–24154.

More

Information

Subjects:

Energy & Fuels

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

663

Revisions:

2 times

(View History)

Update Date:

07 Feb 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No