Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Peter Čerin | -- | 2876 | 2024-01-31 09:30:13 | | | |

| 2 | Jason Zhu | Meta information modification | 2876 | 2024-03-01 11:32:20 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Čerin, P.; Beškovnik, B. Development of Port Communication Systems. Encyclopedia. Available online: https://encyclopedia.pub/entry/54572 (accessed on 05 March 2026).

Čerin P, Beškovnik B. Development of Port Communication Systems. Encyclopedia. Available at: https://encyclopedia.pub/entry/54572. Accessed March 05, 2026.

Čerin, Peter, Bojan Beškovnik. "Development of Port Communication Systems" Encyclopedia, https://encyclopedia.pub/entry/54572 (accessed March 05, 2026).

Čerin, P., & Beškovnik, B. (2024, January 31). Development of Port Communication Systems. In Encyclopedia. https://encyclopedia.pub/entry/54572

Čerin, Peter and Bojan Beškovnik. "Development of Port Communication Systems." Encyclopedia. Web. 31 January, 2024.

Copy Citation

The efficient and sustainable operation of container terminals (CTs) plays a key role in global trade and in ensuring the sustainable functioning of transport chains. While larger container terminals utilise port communication systems (PCSs), smaller container terminals often face challenges when implementing similar systems due to resource constraints and unique operational characteristics.

port community system

container terminal

terminal operating system

blockchain

1. Introduction

A container terminal (CT) is an important part of the logistics chain where various operational processes are carried out to ensure the handling and temporary storage of containers [1]. The main operational processes of a CT take place on the sea side of the terminal, on the surface of the terminal and on the land side of the container terminal [2]. The coordination between the operational processes ensures efficient operation of the entire system, which also has a positive effect on the operation of intermodal transport chains [3]. The growth in container traffic, which is expected to increase by 12% per year until 2028, places an increasing technical and technological burden on CTs [4]. This increased burden has a direct impact on the environment. In particular, the proportion of CO2 emissions caused by the means of transport used to handle and transport containers is increasing [5]. The container ships remain in the system for longer, further impacting the environment through greenhouse gas (GHG) emissions, noise and light pollution. The European Emissions Reduction Directive also obliges the transport sector to comply with the directive and the measures it contains to reduce its carbon footprint [6].

The operation of CT depends on the functioning of the port system, which is composed of different stakeholders such as shipowners, freight forwarders, land carriers, public institutions, terminals, insurance companies, shipping agents, etc. Depending on the requirements of the process and the roles of the parties involved, information relevant to the movement of goods through the port system is exchanged between the parties [7]. In the age of digitalisation, port systems use an IT solution for the exchange of information that ensures the electronic exchange of data between stakeholders in real time. The rapid exchange of information is reflected in the efficiency of operational processes within the port system and increases the competitive advantage of the system in terms of the speed at which a container can move through the system [8]. Modern digital technologies are enabling the development of advanced port communication systems (PCSs) that allow stakeholders to exchange data paperless and in real time, even if they use different information systems. This is a development phase based on smart processes, which makes it possible to lay the foundations for the introduction of automation and business analytics to support decision-making and business optimisation [9].

In smaller CTs, the degree of automation of operational processes is lower. Such systems also have difficulties in obtaining timely information, which is essential for planning operations at the berth, in the marshalling yard and on the transhipment tracks. The timeliness of data delivery depends on how communication between stakeholders is handled, in particular whether it is supported by a regulated channel via a single communication point or whether stakeholders exchange data directly with each other [10][11].

2. Port of Koper and Container Terminal

The Port of Koper is a complex port system comprising 12 different terminals, all of which are operated by the company Luka Koper Ltd. (Koper, Slovenia). These terminals are divided into 5 profit centers based on their operational and technological characteristics. Technically, technologically and developmentally, CTs stands out the most. It is one of the largest and most important CTs in the Adriatic, although it is considered relatively small on a global scale. The terminal’s infrastructure on the seaside includes an operational berth with a length of 694.5 m and a maximum permissible draught of 14.5 m. This enables the berthing and handling of container ships with a capacity of up to 15,500 TEU. The terminal’s storage area covers 270,000 square meters. Access to the terminal from the hinterland is ensured via three truck entrances and 1.27 km of rail handling tracks. The terminal’s superstructure for loading and unloading containers on the seaside consists of Super Post-Panamax cranes (4 units), post-Panamax cranes (4 units) and Panamax cranes (3 units). The equipment on the land side of the terminal consists of Rubber-Tired Gantry (RMG) cranes (4 cranes), transtainers (27 cranes) and container handlers (40 cranes) [12].

The CT co-operates with all major container shipping lines such as Maersk, MSC, Evergreen, CMA-CGM, etc., which call at the port regularly with weekly services. The terminal has established regular direct services with a weekly frequency to the Far and Middle East, the Red Sea and feeder services to the major Mediterranean hub ports. An integral part of the logistics hub are logistics and forwarding companies that are part of the port community and co-operate with CTs, especially with regard to the administrative representation of cargo owners.

In the last twenty years, the CT has increased its annual container throughput from 0.12 million TEU to 1 million TEU. Approximately 50 container ships (feeders and mother vessels), 14,000 trucks, and 550 railway compositions enter the system every month via the regular rail connections. The growth in throughput is putting increasing strain on the existing infrastructure and requires additional optimisation in handling operations. At the current operating level, the terminal’s capacity is reaching its limits, which is reflected in traffic congestion in the surrounding port areas and waiting times for container ships anchored outside the port. One challenge for the terminal is managing container flows in the direction of import, in particular determining the correct storage block for each container. This leads to additional movements of containers and handling equipment at the terminal, which has a direct impact on CO2 emissions, the terminal’s productivity and the associated operating costs. The terminal endeavours to obtain high quality data from stakeholders in order to better plan processes. This requires updates to the PCSs and the implementation of modern technological IT solutions.

The development process of digitalisation in the CT has been ongoing for 20 years and is directly proportional to the growth in throughput. The development process involves all stakeholders within the port community, as some user requirements are interconnected. When designing the system architecture, the possible future integration into global logistics chains was taken into account in order to improve the competitiveness of the terminal on the global logistics market. The aim of the further business digitalisation development is to establish a PCSs system that acts as a unified platform and ensures greater efficiency in the execution of processes, better traceability and control of container movements, optimisation of terminal capacity, improved communication between stakeholders in the port and a reduction of the carbon footprint.

3. Operational Processes and Interaction with PCSs

3.1. Announcement of the Arrival of a Container Ship

The flow of containers through the port is outbound (containers arrive at the terminal by land and are loaded onto the ship) and inbound (containers arrive by ship and are loaded onto trucks or railway waggons). The ship notification process covers container movements in the inbound direction and involves stakeholders from three defined groups. Firstly, these are the container lines and/or their ship agents, then CTs and finally the public authorities. All these stakeholders are involved in the process based on the ship’s arrival notification and require a wide range of mandatory information. This includes ship data, crew data, cargo characteristics and cargo owners’ information about the ship, E.T.A and E.T.D, coordination of work plans on the ship, etc. Data about the ship is exchanged via the PCSs between the shipping agent and the port or CT, and additionally with pilots and tugs. The exchange of freight data (ship cargo manifest), which the shipping agent provides to the authorities, is supported electronically and also processed via the PCSs system. Data exchange outside the PCSs system includes communication with the national single window (NEO), where advance notifications of arriving ships are sent to public institutions. Shipping agents also use NEO to send the necessary documents to the authorities. Outside the PCSs, communication also takes place between the CT and the container lines in order to obtain the list of containers (bapli) on the arriving ship. This data is exchanged via structured messages. The analysis of the existing information support for the container ship announcement process has shown that all processes and parties involved are well supported.

3.2. Discharging/Loading a Container Ship

The most complex and operationally demanding process is the unloading and loading of a ship, which occasionally takes place simultaneously on the same container ship. All four groups of stakeholders are involved in this process and exchange a lot of information. Shipping agents give instructions for the unloading of containers and indicate the type of land transport and the final destination of the container. This enables a more efficient grouping of containers in the storage area. Freight forwarders provide information about containers in the export direction. Based on this information, the CT draws up a work plan (unloading and/or loading the ship), while public authorities play a role in the release of containers/cargo. INVOCCs are involved in the operational process and take over the dispatch and/or delivery of containers in the “ship–terminal” relationship and vice versa. The aim of each container line is to carry out unloading and loading operations as quickly as possible and to minimise the time the ship spends at berth.

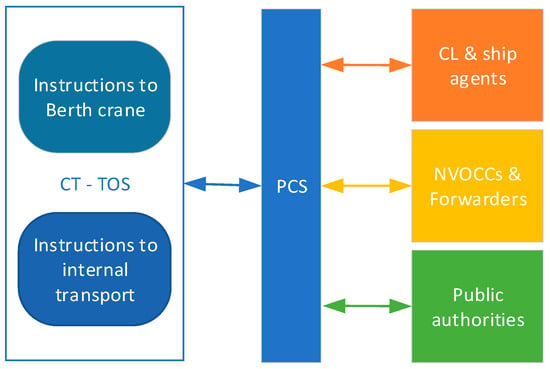

According to the data received, CTs and the stakeholders in the port community cover these processes sufficiently through the PCSs to ensure smooth operations. The TOS dictates the execution of all operations in the loading and unloading process in a way that sends work instructions to shore cranes and internal transport vehicles that transport containers in the “yard–ship–yard” relationship (Figure 1). Each completed manipulation is recorded in real time via the PCSs system in the form of a message, which is then transmitted to the NVOCC or the port forwarder.

Figure 1. Data exchange architecture in the operational process of discharging/loading a container ship in CT. Source: Authors.

3.3. Arrival and Departure of a Container to CT by Truck Gate

Efficient operational planning for the arrival and departure of containers by land plays a crucial role in the pre-notification process. This process regulates the occupancy of the port area as well as the internal and external routes. Prior to the announcement, the forwarder uses the IT system to compile a range of data about the container and cargo, which is then sent to the PCSs in the form of a “hashtag” message. The PCSs system identifies the type of message, checks which operational process it is intended for and sends the message to the TOS. The TOS forwards the pre-notification via the PCSs system to the customs office information system, which identifies the goods based on the attached information about the customs procedure.

Before entering the port/CT, the trucking company selects a free entry slot in the VBS on the basis of the advertised slots. These slots are planned daily by CT within the VBS system. When a full container is delivered, the information is also forwarded to the customs authorities, who check the required transport and commercial documents before the container enters the port.

Different procedures are used for the arrival of full containers by rail. Before a full train composition enters the port/CT area, the railway operator and CT exchange information about the list of containers and cargo via the PCS. The information received on the list of railway waggons is then forwarded to the TOS via the PCS. The CT then creates a work plan that is optimised with an algorithm that takes into account all the information from the pre-announcement and the list exchanged with the railway operator. The customs office in the customs information system confirms the authorisation for the container to enter the port. As unloading and loading takes place simultaneously on the railway waggons, the internal transport vehicles transport the containers on the relation “handling tracks–terminal–handling tracks” route. The TOS sends handling instructions to internal transport vehicles and RMG cranes, including information about the container number and location at the terminal as well as the waggon number onto which the container is loaded or unloaded.

3.4. Container Storage Area

The central part of the CT is the container storage area, where the containers are temporarily stored before they leave the terminal and where additional tasks are carried out. The additional tasks include the provision of containers for cargo inspections in accordance with the instructions of public authorities, the loading and/or unloading of containers with additional cargo, etc.

The TOS plays a crucial role in managing the processes in the storage area of the terminal. Specifically, the TOS uses algorithms to assign a specific storage location to each container, which is determined on the basis of information received from the PCSs. Key information includes data on the owner of the container, the destination and the intended means of transport by which the container is to be dispatched from the terminal. The TOS records every movement of the container within the terminal, with the basic container movements being sent via the PCS in the form of a “hashtag” message to the stakeholders involved. This includes the arrival of the container, the movement of the container from the CT to a delivery point that has been ordered as additional work, and the movement when the container is dispatched from the terminal.

4. PCS Architecture

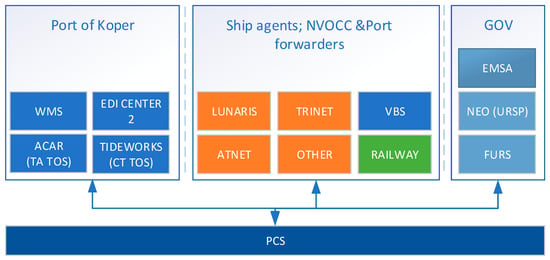

The research of existing PCS architecture illustrates its complexity, which is due to the historical development of different IT solutions within the Koper port system (Figure 2). Each group of stakeholders, depending on the nature of their involvement in the execution of the operational process of cargo movement through the port, has specific data requirements that are crucial for the coordinated and efficient execution of their tasks and decisions in the logistics chain. Port terminals need accurate information on ship arrivals, the sequence of containers and their destinations in order to plan unloading and loading operations, while NVOCCs and port forwarders need data on container availability, customs procedures and delivery times in order to organise transport on time. Public institutions need information on the content of containers, customs documents and all regulatory requirements to fulfil their regulatory tasks and conduct oversight. By each group of stakeholders requesting and sharing specific data, a higher level of coordination in the execution of processes is achieved, increasing the efficiency and safety of cargo movements in the port.

Figure 2. PCS architecture in the port community of the Port of Koper. Source: Authors.

The results of the analysis indicate that different information solutions are used for communication via the PCS, enabling separate data exchange for each group of processes. Various business-to-business (B2B) portals such as Lunaris, Trinet and Atnet are used to announce the arrival of cargo and transport vehicles, while the VBS is responsible for announcing and coordinating the arrival of road vehicles. The announcement of railway waggons is handled separately, supported by the exchange of messages between the PCS and the railway companies’ system. The announcement of the arrival of ships, which requires advance notification of data to public institutions, is supported by the NEO system. The container lines and/or their agents use NEO to transmit the required documents to the public authorities. The management of the status of goods in import, export and transit is handled via communication between the PCS and the eTaxes solution (FURS system), which establishes a link with the national tax office. The customs service is also part of this system. The CT manages the processes via the communication between the PCS and TOS. Information related to the cargo reporting process initiated by the port forwarders is sent via the PCS to the TOS, where it is then utilised and shaped by the operators for further processes related to the operational execution of cargo handling processes.

The study of the interaction between the PCS and TOS in CT has shown that the necessary data is exchanged for the execution of important operational processes, such as the announcement of the arrival of ships, the announcement of the arrival of containers by road and rail, the release of containers for free circulation and the ordering of additional work for containerised cargo. However, there are several different B2B solutions and a large set of structured messages, which illustrates the complexity of the architecture.

The standards and message formats for exchange between the various stakeholders within the PCSs system vary depending on the time period in which the solution was introduced. Proprietary message standards developed for communication with the PCSs are often used in the port community. The messages exchanged between the systems have a predefined structure and are not bound to a specific standard. Their format is often in the form of “hashtags” and “Extended Markup Language (XML)”. The EC2 solution for data exchange between container carriers, the PCS and TOS, is an exception. Messages in EDIFACT format are used for EC2. With EC2, full integration between CT and the container lines has been achieved, which has a positive effect on the timely delivery of container data for arrivals and departures. Information arrives in the TOS which allows the CT to create more accurate lists of manipulations and organise operational processes more efficiently.

References

- Song, D. A Literature Review, Container Shipping Supply Chain: Planning Problems and Research Opportunities. Logistics 2021, 5, 41.

- Brinkmann, B. Operations Systems of Container Terminals: A Compendious Overview. In Handbook of Terminal Planning; Springer: Cham, Switzerland, 2011.

- Steenken, D.; Voss, S.; Stahlbock, R. Container terminal operation and operations research—A classification and literature review. OR Spectr. 2004, 26, 3–49.

- Placek, M. Container Shipping—Statistics & Facts. Statista. 2023. Available online: https://www.statista.com/topics/1367/container-shipping (accessed on 7 October 2023).

- Giuffrida, N.; Stojaković, M.; Twrdy, E.; Ignaccolo, M. The Importance of Environmental Factors in the Planning of Container Terminals: The Case Study of the Port of Augusta. Appl. Sci. 2021, 11, 2153.

- European Commission. Reducing Emissions from the Shipping Sector. Available online: https://climate.ec.europa.eu/eu-action/transport/reducing-emissions-shipping-sector_it#eu-action (accessed on 7 October 2023).

- Caldeirinha, V.; Felicio, J.A.; Sena Salvador, A.; Nabais, J.; Pinho, T. The impact of port community systems (PCS) characteristics on performance. Res. Transp. Econ. 2020, 80, 100818.

- Jović, M.; Aksentijević, S.; Plentaj, B.; Tijan, E. Port Community System Business Models. In Proceedings of the 34th Bled eConference Digital Support from Crisis to Progressive Change, Bled, Slovenia, 27–30 June 2021.

- Heilig, L.; Stahlbock, R.; Voß, S. From Digitalization to Data-Driven Decision Making in Container Terminals. In Handbook of Terminal Planning: Operations Research/Computer Science; Springer: Cham, Switzerland, 2020.

- Aloini, D.; Benevento, E.; Stefanini, A.; Zerbino, P. Process fragmentation and port performance: Merging SNA and text mining. Int. J. Inf. Manag. 2019, 51, 101925.

- Sfiroera, E.; Alafodimos, C.; Papoutsidakis, M.; Papachristos, D. New Trends in Port Community Systems and Fundamental Descriptions. Int. J. Comput. Appl. 2019, 178, 20–25.

- Port of Koper. About Port of Koper. Available online: https://www.luka-kp.si/en/ (accessed on 15 October 2023).

More

Information

Subjects:

Transportation Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

643

Revisions:

2 times

(View History)

Update Date:

01 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No