Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ansheng Cao | -- | 2213 | 2024-01-30 02:30:50 | | | |

| 2 | Camila Xu | Meta information modification | 2213 | 2024-01-30 02:45:53 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Wang, J.; Cao, A.; Cui, T.; Wu, Z.; Li, Z.; Lin, L.; Li, H.; Long, Y. Large Section Bifurcated Small Clear Distance Tunnel. Encyclopedia. Available online: https://encyclopedia.pub/entry/54503 (accessed on 07 February 2026).

Wang J, Cao A, Cui T, Wu Z, Li Z, Lin L, et al. Large Section Bifurcated Small Clear Distance Tunnel. Encyclopedia. Available at: https://encyclopedia.pub/entry/54503. Accessed February 07, 2026.

Wang, Jianxiu, Ansheng Cao, Tao Cui, Zhao Wu, Zonghai Li, Lihua Lin, Huboqiang Li, Yanxia Long. "Large Section Bifurcated Small Clear Distance Tunnel" Encyclopedia, https://encyclopedia.pub/entry/54503 (accessed February 07, 2026).

Wang, J., Cao, A., Cui, T., Wu, Z., Li, Z., Lin, L., Li, H., & Long, Y. (2024, January 30). Large Section Bifurcated Small Clear Distance Tunnel. In Encyclopedia. https://encyclopedia.pub/entry/54503

Wang, Jianxiu, et al. "Large Section Bifurcated Small Clear Distance Tunnel." Encyclopedia. Web. 30 January, 2024.

Copy Citation

A bifurcated tunnel refers to the intersection of one tunnel with another, including the intersection of auxiliary tunnel inclined shafts, vertical shafts, or transverse tunnels with the main tunnel, as well as the intersection of hydropower tunnels and working tunnels.

bifurcated small clear distance tunnel

construction monitoring

monitoring scheme

middle rock pillar

1. Introduction

With the continuous and accelerating development of social modernization, conventional modes of tunnel design and construction are often unable to meet requirements due to various factors. In particular, the design of tunnels must take into account the influence of many boundary conditions. The advent of bifurcated tunnels has alleviated many problems faced in tunnel design and has also helped in subsequent design and construction [1][2].

A bifurcated tunnel refers to the intersection of one tunnel with another, including the intersection of auxiliary tunnel inclined shafts, vertical shafts, or transverse tunnels with the main tunnel, as well as the intersection of hydropower tunnels and working tunnels. With the combination of a large span tunnel and a small clear distance tunnel, the bifurcated tunnel presents higher requirements for design and construction technology [3][4].

Scholars have conducted extensive and effective research on bifurcated tunnels. Lu et al. [5] studied the maximum ceiling temperature and longitudinal temperature distribution of bifurcated tunnels with different bifurcated angles under longitudinal ventilation conditions. Chen et al. [6] used numerical simulation methods to study the critical wind speed in fire scenarios where the fire source is located before and after the fork of the bifurcated tunnel. Wang et al. [7] conducted numerical simulations of bifurcated tunnels to determine the ventilation distribution ratio. Zhang et al. [8] analyzed the deformation characteristics and control measures of the surrounding rock in the large arch section of the bifurcated tunnel of the Miaoya tunnel on the Huurongxi Expressway by monitoring the surrounding rock deformation. Tan et al. [9], for the Liantang tunnel with a maximum span of 30.1 m and a minimum spacing of 1.05 m, proposed the reverse expansion excavation method and the sectional controlled blasting excavation method. Peng et al. [10] proposed a new nonlinear reinforcement analysis method for the design of reinforced concrete lining and anchor reinforcement systems for the fork of a long-span tailwater tunnel with complex three-dimensional geometry. Cao et al. [11] studied the stability criterion of the surrounding rock in a multiarch section with a small clear distance using theoretical analysis and calculated the internal stress and corresponding ultimate strength of the middle rock pillar under different burial depths and widths according to the stability criterion. Li et al. [12], relying on the Xiamen Haicang Evacuate Channel project, monitored and analyzed the blasting vibration velocity and surrounding rock acoustic velocity of the middle rock pillar by employing blasting vibration measurement and acoustic testing on-site, optimized the original blasting scheme, and explored the vibration propagation and damage evolution law of the middle rock pillar under cyclic blasting. Qing et al. [1] used numerical simulation methods to compare and analyze the deformation of the surrounding rock of small clear distance tunnels using the beach cut method, CD method, and double side heading method. Wang et al. [13] conducted a 1:10 scale physical shaking table test model for a tunnel with a small clear distance and shallow deviation to study the type, direction, and peak acceleration of seismic waves that greatly influence the dynamic response characteristics of the tunnel.

As one of the three pillars of the new Austrian tunnel construction concept, monitoring and measurement play crucial roles in ensuring tunnel construction safety. Careful on-site monitoring and measurement enable construction teams to understand the response dynamics of the ground and tunnel and make necessary adjustments to design parameters and construction sequences based on feedback data to ensure safe and smooth construction. Monitoring technology and information management are directly related to the safety and quality of tunnel construction [14]. Over the years, both theoretical systems and equipment technology have made significant progress. For instance, Wu et al. [15] developed an automatic tunnel monitoring and early warning system based on geostationary technology satellites, enabling information management and the early warning and forecasting of tunnel monitoring and measurement data. Lin et al. [16] conducted tunnel monitoring at the Qiyueshan tunnel site, analyzed the deformation characteristics and development trends of the tunnel surrounding rock by processing and evaluating the measurement data of tunnel section arch settlement and surrounding displacement, and revised and optimized tunnel design and construction accordingly. Wei et al. [17] described the construction process of the tunnel opening excavation monitoring and measurement system in a mountainous area based on the actual situation of the tunnel opening excavation monitoring and measurement in a mountainous area of Chongqing. The portal stability analysis method and monitoring information feedback process based on multisource data were analyzed. Xiong et al. [18] analyzed the deformation and mechanical characteristics of the surrounding rock and initial support of the plateau wetland tunnel in the construction process of the Bodhisattva Hill wetland tunnel and introduced monitoring and measurement projects and methods in the construction process of the new Austrian method. Furthermore, Xiong et al. [19] presented a tunnel monitoring method based on distributed fiber sensing, which provides hundreds of strain and temperature sensing points within the structure, offering new information about the tunnel lining behavior. Chen et al. [20] evaluated the applicability of two noncontact measurement methods for monitoring a series of small model tunnels, while Shi et al. [21] introduced BOTDR, a newly developed strain measurement and monitoring technology, and analyzed its feasibility in TST strain monitoring through the BOTDR monitoring results of a tunnel in Nanjing. Luo et al. [22] conducted a comparative test of three-dimensional coordinate measurement, RDM, and traditional measurement at the tunnel construction site, while Sakai et al. [23] proposed a prediction method based on monitoring the roadway crown dip angle along the roadway axis and applied it in field tests. Additionally, Du et al. [24] developed and proposed the CNU-TS-1 mobile tunnel monitoring system based on an in-depth study of tunnel monitoring methods. This method can effectively obtain the cross-section of the tunnel and eliminate the control measurement that depends on design data.

Zhang et al. [25] conducted finite element calculation and analysis on the stability of surrounding rock at the overpass of the upper and lower reaches of the Fengze Street tunnel and emphasized the importance of mastering the mechanical dynamics of surrounding rock and support, timely feedback adjustment of construction methods and supporting parameters, and on-site monitoring projects. Wu et al. [26] introduced the field measurement results of deformation at the fork of the Y-shaped fork of the mainline tunnel and branch tunnel of Guangzhou Rail transit line 3 during construction. Bai et al. [27] provided a detailed description of the on-site monitoring and measurement method of deformation in the bifurcation section of the Shanghai Metro Line 2 tunnel and Metro Line 1 tunnel during the construction process of shield tunneling. Finally, Yang et al. [28] carried out on-site monitoring and measurement during the construction of the Nanjing Xuanwuhu tunnel and subway bifurcation section.

2. Monitoring Scheme of Large Section Bifurcated Small Clear Distance Tunnel

2.1. Monitoring Items

The necessary survey items for tunnel construction in this section include advanced geological prediction, geological and support status observation, vault settlement, and peripheral convergence monitoring and measurement. The selected measurement items include monitoring the displacement of the surrounding rock, the pressure between supports, and the internal force of steel supports.

2.1.1. Advanced Geology Prediction

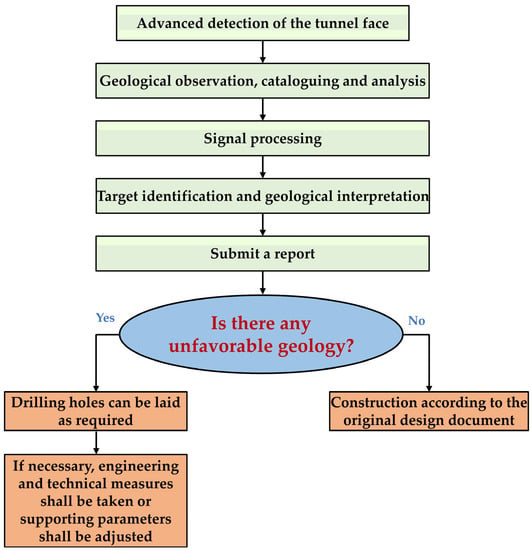

Tunnel construction is greatly affected by terrain, hydrogeology, and tunnel burial depth, among other factors. Building tunnels in unfavorable geological conditions is extremely challenging, and local collapse and large deformation are prone to occur during construction. Advanced geological prediction can effectively predict unfavorable geological conditions and ensure the safety of tunnel construction. Common unfavorable geology includes loose formations, karst caves, collapses, faults, groundwater, fracture zones, and gas formations. The methods of tunnel advanced geological prediction mainly include geological methods, geophysical prospecting methods, and drilling methods. The geological method predicts the possible types and scales of unfavorable geological conditions developed in a tunnel based on lithology, occurrence, structure, and other characteristics. The geophysical prospecting method uses the characteristics of seismic waves reflected in the inhomogeneous geological body to predict geological conditions in front of the tunnel. The drilling method identifies the lithology of the stratum in front of the tunnel face through horizontal drilling, determines the grade and thickness of the surrounding rock, and explores the characteristics of the carbonate karst cave and the occurrence conditions of groundwater in the rock stratum. In the research section, advanced geological forecasting work was performed to provide information on the surrounding rock as the basis for excavation and support. Figure 1 shows the advanced geological prediction process. When advanced geological prediction detects fault fracture zones, abundant groundwater, developed rock veins, uneven weathering of tuff, and hard rock bursts, the geological condition can be judged as being unfavorable geology.

Figure 1. Advanced geological prediction process.

2.1.2. Geological and Support Status Observation

Geological observation was divided into two parts: observation inside the tunnel and observation outside of the tunnel. The observation inside the tunnel mainly observes the excavation working face, which should be carried out once after each excavation, including the development of joint fissures, the stability of the working face, water gushing, and whether the floor was raised. When the geological conditions were basically unchanged, it could be performed once a day. Observation outside of the tunnel includes observation of the surface condition of the entrance, surface settlement, stability of the slope and invert, and surface water penetration. After observation, the geological sketch map of the excavation face should be drawn. In the process of observation, if geological conditions deteriorate and abnormal phenomena occur in the initial support, the construction person in charge shall be instructed to adopt emergency measures and ensure uninterrupted monitoring. The completed area was observed once a day, including the condition of the shotcrete, bolt, and steel frame and whether the construction quality complied with the specified requirements.

2.1.3. Vault Settlement and Peripheral Convergence

Vault subsidence and peripheral convergence measurements should be performed on the same section with the same measurement frequency. In the case of abnormal displacement, a large number of measurement frequencies should be added. The measuring points were arranged according to the technical specifications for the construction of highway tunnels (JTG/T 3360-2020) [29], as shown in Table 1. The vault subsidence was measured using the level, the level ruler, and the hook steel ruler, and the peripheral convergence was measured using the convergence meter.

Table 1. Monitoring items and monitoring methods.

| Measurement Items | Peripheral Convergence | Vault Settlement | ||||||

|---|---|---|---|---|---|---|---|---|

| Methods and tools | Convergence meter | The level, the level ruler, and the hook steel ruler | ||||||

| The layout of measuring points | One section every 10 ~ 20 m, and 1 ~ 3 pairs of measuring points for each section | One section every 10 ~ 20 m | ||||||

| Construction period | 1 to 15 days | 16 days to 1 month | 1 month to 3 months | More than 3 months | 1 to 15 days | 6 days to 1 month | 1 month to 3 months | More than 3 months |

| Measurement interval | Once or twice a day | Once every two days | Once or twice a week | One to three times per month | Once or twice a day | Once every two days | Once or twice a week | One to three times per month |

In the informatization construction method, the monitoring data should be sorted out and fed back to the construction in time. According to the monitoring scheme, the management of the monitoring data is shown in Table 2.

Table 2. Monitoring data management.

| Management Level | Managed Displacement | Construction State |

|---|---|---|

| III | U0<Un3U0<Un3 | Normal construction |

| II | Un3≤U0<2Un3Un3≤U0<2Un3 | Strengthen monitoring |

| I | 2Un3≤U02Un3≤U0 | Take measures to strengthen support |

Note: U0 is the measured displacement value, and Un is the allowable displacement value.

2.2. Layout of Monitoring Points

2.2.1. Advanced Geology Prediction

Advanced GPR detection was adopted in the section with complex geological conditions of grade IV and V surrounding rock. It can accurately judge the geological surrounding rock conditions in front of construction and improve the quality and safety of construction. GPR is an electronic piece of equipment that penetrates underground objects using high-frequency electromagnetic waves. The GPR transmitters emit a pulse electromagnetic wave signal. When this signal meets targets such as karst caves and faults in the rock stratum, it generates a reflection signal. The reflected signal is inputted to the receiver through the receiving antenna and displayed by the oscilloscope after amplification. Based on the presence or absence of reflected signals by the oscilloscope, it can determine whether there is a target to be measured. Based on the arrival time of the reflected signal, the distance of the target can be calculated. The layout of its survey line is shown in Figure 2.

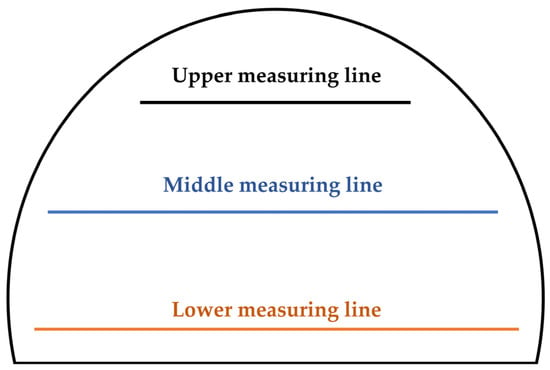

Figure 2. Layout of advanced geological prediction measuring line.

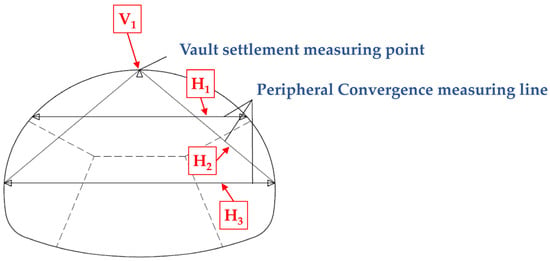

2.2.2. Vault Settlement and Peripheral Convergence

The installation of measuring points for the vault settlement and the peripheral convergence ensured that the first reading was taken within 12 h after the excavation and before the next cycle of excavation, and they were installed within the range of 2 m from the excavation face. When the displacement speed and displacement were too large and a large number of cracks occurred in the primary lining support, it was necessary to strengthen the monitoring and support measures. Based on the performance of the primary lining support, the timing of the secondary lining support should be considered to bear the confining pressure. The arrangement of measuring points is shown in Figure 3.

Figure 3. The layout of vault settlement and peripheral convergence measuring points.

References

- Jiang, Q.; Song, S.G.; Li, T.; Wang, K.; Gu, R.H. Study on surrounding rock stability of small clear-distance twin highway tunnel with eight lanes. Geotech. Geol. Eng. 2019, 37, 593–598.

- Chen, L.F.; Mao, P.F.; Zhang, Y.C.; Xing, S.S.; Li, T. Experimental study on smoke characteristics of bifurcated tunnel fire. Tunn. Undergr. Space Technol. 2020, 98, 103295.

- Chen, C.K.; Nie, Y.L.; Zhang, Y.L. Experimental investigation on the influence of ramp slope on fire behaviors in a bifurcated tunnel. Tunn. Undergr. Space Technol. 2020, 104, 103522.

- Wang, X.; Wang, M.N.; Qin, P.C.; Yan, T.; Chen, J.; Deng, T.; Yu, L.; Yan, G.F. An experimental study on the influence of local loss on ventilation characteristic of dividing flow in urban traffic link tunnel. Build. Environ. 2020, 174, 106793.

- Lu, X.L.; Weng, M.C.; Liu, F.; Wang, F.; Han, J.Q.; Cheung, S.C. Effect of bifurcation angle and fire location on smoke temperature profile in longitudinal ventilated bifurcated tunnel fires. Tunn. Undergr. Space Technol. 2022, 127, 104610.

- Chen, C.K.; Jiao, W.B.; Lei, P.; Zhang, Y.L.; Zhao, X.L. Numerical simulation analysis on influence of fire source position on critical wind velocity of bifurcated tunnel fire. J. Saf. Sci. Technol. 2022, 18, 93–99.

- Wang, F.F.; Ren, Q.Q.; Zou, P.; Niu, J.Y.; Meng, Z.H.; Li, A.B.; Liu, Z.Y.; Hu, W.J.; Ma, Z. Acceleration and displacement dynamic response laws of a shallow-buried bifurcated tunnel. J. Vibroeng. 2019, 21, 1015–1029.

- Zhang, Q.S.; Li, S.C.; Li, L.P. Study of blasting dynamic effect and site monitoring of large-span shallow part of bifurcated tunnel. Chin. J. Rock Mech. Eng. 2008, 27, 1462–1468.

- Tan, Z.S.; Zhou, Z.L.; Kong, H.; Zhao, B.J.; Zhao, J.P. Single excavation face method for super large span bifurcated tunnels. Geotech. Eng. 2021, 174, 406–418.

- Peng, L.; Zhou, Y.E.; Liu, H.Y.; Chen, W. Reinforcement design and stability analysis for large-span tailrace bifurcated tunnels with irregular geometry. Tunn. Undergr. Space Technol. 2013, 38, 189–204.

- Cao, S.D.; Xie, Y.L.; Tang, W.; Wang, W.; Zhou, Q.R.; Guo, A.P. Research on construction methods for ultralarge y-shaped tunnel sections. Math. Probl. Eng. 2021, 2021, 9969208.

- Li, X.G.; Zhou, X.Q.; Yang, H.P.; Fu, X.Q.; Yu, J. Blasting Vibration Control and Damage Determination of Interlaid Rock in a Tunnel with Large Spans and Short Distances. Tunn. Constr. 2022, 42, 406–413.

- Wang, F.F.; Jiang, X.L.; Niu, J.Y. The large-scale shaking table model test of the shallow-bias tunnel with a small clear distance. Geotech. Geol. Eng. 2017, 35, 1093–1110.

- Li, C.X.; Wang, M.F.; Gao, X.K.; Bin, Y. Research on on-site monitoring and measurement technology of tunnel. IOP Conf. Ser. Earth Environ. Sci. 2020, 455, 012154.

- Wu, S.L.; Deng, H.L.; Chen, K.J.; Zhu, M.; Huang, D.H.; Fu, S.Y. Automatic warning system of Tunnel monitoring and application. Adv. Mater. Resear. 2013, 779–780, 457–462.

- Lin, C.J.; Zhou, L.; Li, S.C.; Xu, Z.H.; Li, L.P.; Wu, J.; Zhang, Y.H. Tunnel Monitoring and Measurement Case Study in Qiyueshan Tunnel. In Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering, Guangzhou, China, 27–28 June 2015.

- Wei, S.Y.; Li, C.A.; Jiang, J.; Li, C.; Lu, P.F. Research and Practice of Monitoring Measurement Security Technology of Portal Excavation for Mountain Tunnel. In Proceedings of the International Conference on Architectural Engineering and Civil Engineering, Petaling Jaya, Malaysia, 8–9 May 2017.

- Xiong, J.; Wang, Z.Z. Monitoring and Analysis of High Altitude Wetland Tunnel. In Proceedings of the International Symposium on Multi-Field Coupling Theory of Rock and Soil Media and Its Applications, Chengdu, China, 10–12 October 2010; pp. 714–718.

- Buchmayer, F.; Monsberger, C.M.; Lienhart, W. Advantages of tunnel monitoring using distributed fibre optic sensing. J. Appl. Geophys. 2021, 15, 1–12.

- Chen, H.M.; Smith, M.; Yu, H.S.; Kokkas, N. Monitoring deformation of small scale model tunnels under load testing. Emp. Surv. Rev. 2014, 46, 417–425.

- Shi, B.; Xu, H.Z.; Chen, B.; Zhang, D.; Ding, Y.; Cui, H.L.; Gao, J.Q. A Feasibility Study on the Application of Fiber-Optic Distributed Sensors for Strain Measurement in the Taiwan Strait Tunnel Project. Mar. Georesour. Geotec. 2003, 21, 333–343.

- Luo, Y.B.; Chen, J.X.; Xi, W.Z.; Zhao, P.Y.; Li, J.Z.; Qiao, X.; Liu, Q. Application of a Total Station with RDM to Monitor Tunnel Displacement. J. Perform. Constr. Fac. 2017, 31, 04017030.

- Sakai, K.; Tani, T.; Aoki, T.; Ohtsu, H. Inclination monitoring at tunnel crown to predict change in ground stiffness ahead of excavation face—ScienceDirect. Tunn. Undergr. Space Technol. 2020, 104, 103516.

- Du, L.M.; Zhong, R.F.; Sun, H.; Zhu, Q.; Zhang, Z. Study of the Integration of the CNU-TS-1 Mobile Tunnel Monitoring System. Sensors 2018, 18, 420.

- Zhang, Y.j.; Liu, Y.P. 3D finite element analysis for stability of surrounding rockmass at grade separation section of up tunnel and down tunnel. Rock Soil Mech. 2002, 23, 511–515.

- Wu, H. Summary of tunnel construction technology in overlapping section of main and branch lines. West-China Explor. Eng. 2005, 17, 210–212.

- Bai, T.H.; You, X.D.; Li, W.Y. The protection technology of shield crossing the subway operation tunnel in super close distance. Chin. J. Undergr. Space Eng. 1999, 19, 2–6.

- Yang, L.; Su, Q.; Wu, B. Key Construction Technologies Adopted in the Nanjing XuanwuLake Tunnel Project. Constr. Technol. 2003, 32, 1–3.

- Ministry of Transport of the People’s Republic of China. Technical Specifications for Construction of Highway Tunnel: JTG/T 3660-2020; People’s Communications Press: Beijing, China, 2020.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

820

Revisions:

2 times

(View History)

Update Date:

30 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No