Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Md. Jannatul Ferdaus | -- | 5298 | 2024-01-29 10:39:43 | | | |

| 2 | Rita Xu | Meta information modification | 5298 | 2024-01-29 10:46:32 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ferdaus, M.J.; Barman, B.; Mahmud, N.; Da Silva, R.C. Oleogels as a Promising Alternative in Meat Products. Encyclopedia. Available online: https://encyclopedia.pub/entry/54478 (accessed on 07 February 2026).

Ferdaus MJ, Barman B, Mahmud N, Da Silva RC. Oleogels as a Promising Alternative in Meat Products. Encyclopedia. Available at: https://encyclopedia.pub/entry/54478. Accessed February 07, 2026.

Ferdaus, Md. Jannatul, Bishal Barman, Niaz Mahmud, Roberta Claro Da Silva. "Oleogels as a Promising Alternative in Meat Products" Encyclopedia, https://encyclopedia.pub/entry/54478 (accessed February 07, 2026).

Ferdaus, M.J., Barman, B., Mahmud, N., & Da Silva, R.C. (2024, January 29). Oleogels as a Promising Alternative in Meat Products. In Encyclopedia. https://encyclopedia.pub/entry/54478

Ferdaus, Md. Jannatul, et al. "Oleogels as a Promising Alternative in Meat Products." Encyclopedia. Web. 29 January, 2024.

Copy Citation

The surge in chronic diseases is closely linked to heightened levels of saturated and trans fatty acids in processed foods, particularly meat products. Addressing this concern, various strategies have been employed to alleviate the impact of these detrimental fats. Among these, oleogels have emerged as a novel and promising approach in the food industry.

oleogels

meat products

substitution

saturated fat

1. Introduction

Dietary fats constitute an essential macronutrient crucial for good health, serving as the most concentrated energy source compared to carbohydrates or proteins [1]. In processed food products, fats significantly enhance organoleptic features such as texture, mouthfeel, and flavor. This macronutrient is broadly categorized into saturated fatty acids (SFAs) and unsaturated fatty acids (UFAs) [2]. Saturated fats exhibit saturation with hydrogen molecules and lack double or triple bonds in their chemical structure. While they serve particular purposes, research has indicated that an excess of saturated fats can contribute to cardiovascular diseases (CVDs) and is recommended to be restricted to below 10% of daily energy intake [3].

Meat products, favored by consumers for their rich content of protein, fat, minerals, carbon polymers, vitamins, and palatable taste, are not without drawbacks. The notable issue lies in their high-fat content, predominantly saturated fat and trans fatty acids, which contribute to desirable functionality, texture, flavor, and mouthfeel [4]. Recognizing the adverse health effects of saturated fat, particularly trans fatty acids, food producers, including those in the meat processing industry, actively strive to reduce these levels. Traditionally, hydrogenated fats are utilized in meat product industries due to the susceptibility of unsaturated plant oils to rancidity during processing [4]. Hydrogenation involves reinforcing chemical bonds, resulting in oils adopting a solid phase, with potential trans fat formation in partial hydrogenation [5].

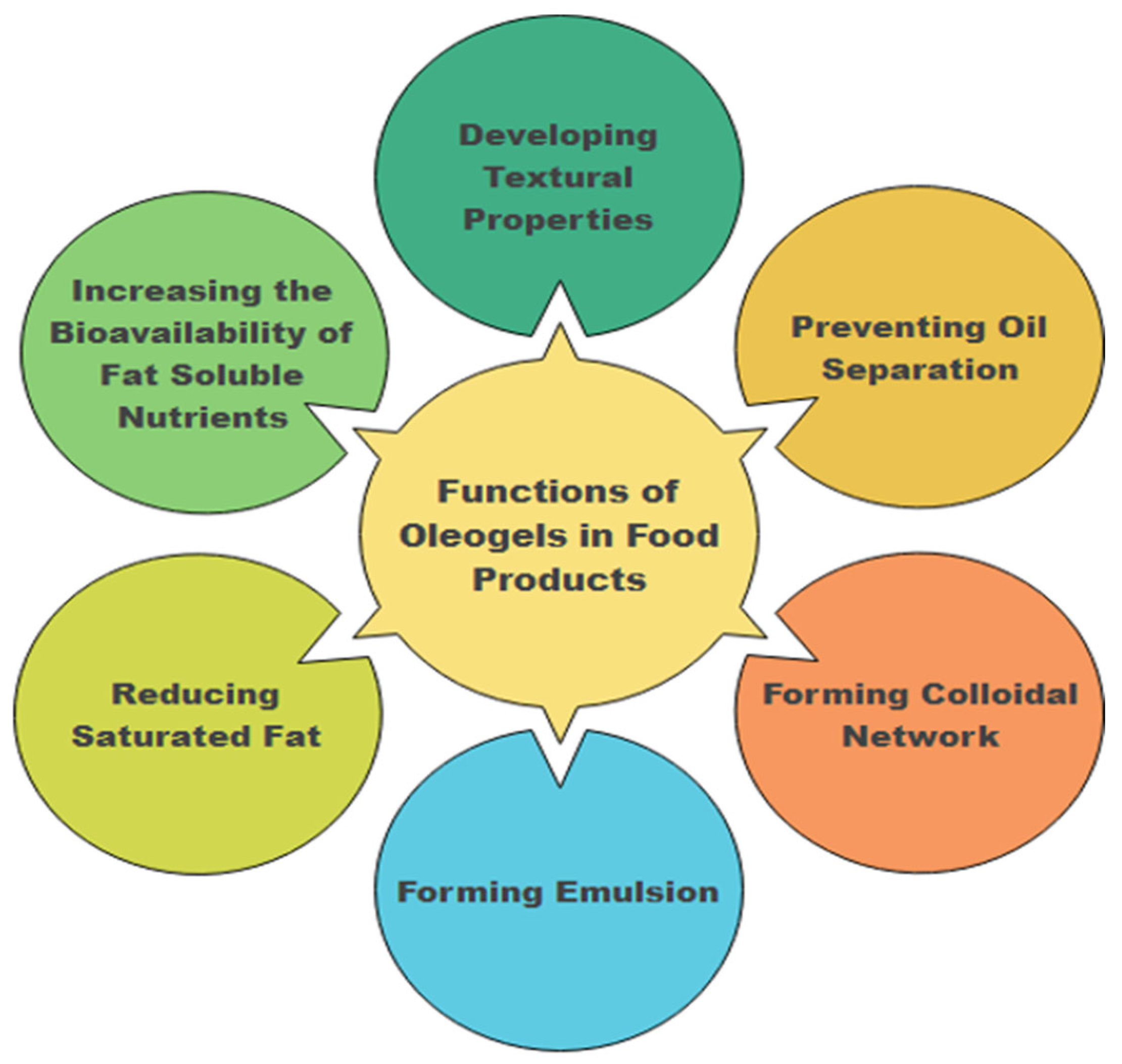

Recently, food technologists have explored oleogels as a distinctive alternative to hydrogenated oils or animal fats. Oleogels transform unsaturated-rich plant-based oils into solid-like systems, representing a novel strategy. This transformation is deemed a healthier substitute for saturated and trans fats while meeting consumer expectations for functional and sensory qualities [6]. By incorporating natural waxes, glycerides, alcohols, ethylcellulose, and phytosterols—termed oleogelators—oleogels restructure plant oils, creating a gel network in the oil phase and effectively entrapping liquid oils. The resulting state is semi-solid, firm, spreadable, and viscoelastic, commonly referred to as oleogel [2]. In addition, besides lowering the saturated fatty acids percentage in foods, oleogels also have other functions in foods but not limited to developing textural properties, increasing bioavailability of nutrients, preventing oil separation, forming colloidal network, and forming emulsion (Figure 1).

Figure 1. Different functions of oleogels in food products.

2. What Is Oleogel?

Oleogels, also known as organogels, provide a method for transforming organic oil into a solid or semi-solid substance by entrapping them into a thermo-reversible gel structure (oleogelators). By self-assembling or crystallizing to form a wide range of structures, oleogelators may capture liquid oil and keep it from flowing by creating a three-dimensional network structure and gelatinizing the entire system. Oleogels are created using a variety of oleogelators, each of which results in a unique phase transition mechanism, taking place on the nano- and micro-scales and inducing a new set of macroscopic properties [7]. Many gels only need a minimal quantity of oleogelators and are often characterized as bulk-like fat products since they include a lot of liquid oil, sometimes even >97% [2]. Oleogels’ ability to substitute solid fat in food items and enhance the nutritional value of food products is the motivating factor behind the study and development of these food ingredients. Oleogel can benefit things from low-saturated fatty acids while maintaining their solid features. To substitute solid fats or perform other desired activities, such as controlled release and high bioavailability, a good oleogel should have changeable physical and chemical characteristics for edible purposes [8]. It is vital to choose an appropriate oleogelator to produce qualified food-grade oleogel. A good oleogelator for food applications should have natural sources. Different edible ingredients, including glycerol, fatty acids, organic waxes, and monostearate, have recently been investigated as oleogelators. Research has revealed that a mono-component oleogel cannot realistically imitate the characteristics of conventional solid fats; however, a combination of oleogelators can produce a more desired oleogel with a stronger network [2][9]. Barroso et al. (2020) showed that at 5 and 25 °C, multicomponent gels composed of sunflower wax, glycerol monostearate, and berry wax demonstrated solid-like properties. Notably, the mono-component oleogel consisting of sunflower wax displayed more liquid-like characteristics at both temperatures [9].

Research indicates that a mono-component oleogel, while exhibiting some desirable properties, faces challenges in replicating the multifaceted characteristics of conventional solid fats. Hence, the primary hurdle in developing oleogels for food applications is creating a specific crystal network to meet the required solid fat properties, achieving the requisite structural complexity and stability that saturated fats inherently possess [2].

The oleogelators play a crucial role in controlling the network structure and resultant properties of oleogels. Mono-component gels often lack the intricate network and crystalline arrangements found in saturated fats, leading to suboptimal textural attributes and performance in certain applications. The adverse results observed may include inferior mouthfeel, compromised stability under varying conditions, and challenges in mimicking the specific melting profiles characteristic of saturated fats. Thus, recent research has shifted towards utilizing combinations of oleogelators [2][9].

Recent studies have underscored the significance of employing a combination of oleogelators to address these challenges [3][5][9]. The synergistic interaction between different edible ingredients, each contributing unique structural elements and functionalities, has been found to enhance the overall performance of oleogels. This approach, involving a blend of oleogelators, has shown promise in achieving a more desirable and robust oleogel structure that closely mimics the characteristics of saturated fats. The combination of oleogelators has the potential to strengthen the interfacial bonds, consequently bolstering the oleogels’ resilience to drying, enhancing gel strength, elevating oil binding capacity, and fortifying thermal stability [5].

Oleogels (cellulose derivatives) are thermo-reversible because they can go through the sol–gel transition several times with only the warming and re-cooling of the solution. Different external conditions, including pH, light, and solvent changes, are needed for other oleogels that usually are not employed in food systems to stimulate self-assembly. In apolar liquid, very efficient oleogelators may produce gels at concentrations as low as 0.5 wt%. The capacity to form oleogels at low concentrations is attractive for the food industry [10]. Although oleogels are still being developed for food applications, the cosmetics and pharmaceutical sectors have extensively researched them.

3. Oleogel Applications in Meat Product

Modifying processed meat’s quantities and lipid profiles, pivotal sources of dietary fat, can enhance the nutritional quality of the Western diet [11]. Reformulation, a critical approach involving removing, reducing, adding, or replacing various components, stands out as a key method for crafting healthier meat products. Through reformulation, key objectives in fat content improvement include reducing total fat and energy content, lowering cholesterol, and modifying fatty acid profiles [7][12]. While technological methods often replace animal fat to optimize fatty acid profiles, challenges arise in maintaining essential product qualities (mouthfeel, juiciness, texture, bite, heat transmission) associated with the solid animal fat in meat products. This poses a significant technological challenge when attempting to reduce or substitute animal fat with liquid oils [13]. Despite numerous experiments and efforts to enhance the fat content of meat products and find alternatives to animal fat, the use of technical methods to replace non-meat fat with animal fat has been extensively explored. Some previous studies have explored diverse avenues, including using various vegetable oils, marine oils (from fish and algae), or combinations to partially substitute animal fat in fresh, cooked, and fermented meat products [14][15]. Notably, there is limited research on using oleogels for developing healthier, lipid-rich meat products.

3.1. Burgers

Since it enhances the meat’s flavor, texture, and juiciness, animal fat is crucial in burgers. The fat gives the burger moisture, which keeps it moist and tasty while cooking. The fat also helps keep the beef together, preventing the patty from disintegrating [16]. The type of animal fat utilized can also impact the burger’s flavor. For instance, beef fat has a distinctive flavor that might improve the taste of the meat. It is crucial to remember that consuming too much animal fat can have adverse health effects [1], so eating burgers in moderation is preferable as part of a healthy diet.

Gómez-Estaca et al. (2019) aimed to evaluate the sustainability of oleogels derived from ethyl cellulose (EC) and beeswax (BW) obtained through a blend of olive, linseed, and fish oils [15]. These oleogels were explored as alternatives to conventional fats in low-fat, polyunsaturated fatty acid (PUFA)-enriched pork burgers. The oleogelation process involved EC contributing to a “polymeric network” and beeswax functioning within a “crystal particle system,” resulting in a semi-solid phase. Compared to the control group, where the developed oleogels entirely replaced traditional pork back fat, the low-fat pork burgers exhibited a notably softer texture without significant changes in optical properties. Moreover, the reformulated burgers demonstrated substantial improvements in the fatty acid profile, presenting a remarkable 3.6-fold increase in the PUFA/SFA ratio and a significant 23-fold reduction in the n-6/n-3 ratio compared to the control group. The oleogels’ stability was maintained for at least one month when stored at 3 ± 1 °C. Sensory acceptability assessments indicated that burgers made with beeswax oleogels consistently received high ratings, while those prepared with EC scored below the neutral rating threshold. In conclusion, the findings suggest that these oleogels have the potential to produce healthier fresh pork burgers with an improved fatty acid profile.

In a study by Moghtadaei et al., 2018, the objective was to develop beef burgers with varying levels of animal fat substitution using oleogel and assess their physicochemical properties [17]. Sesame oil oleogels were synthesized with beeswax (BW) at 5%, 7.5%, and 10% concentrations. Subsequently, 0%, 25%, and 50% of animal fat in beef burgers was replaced with the oleogel. Various characteristics of both control and formulated burger samples were analyzed to assess the impact of oleogel addition. The results revealed that as the level of animal fat replacement increased with the oleogel, the moisture content increased while the fat content decreased. Higher moisture content in food products is associated with lower oil absorption during frying, potentially explaining the reduced fat content in burgers with a 50% oleogel replacement. In raw burgers, the hardness decreased as the level of animal fat was substituted due to the smaller size of fat globules. The addition of BW oleogel significantly reduced the lightness of raw burgers. Cooking loss was most pronounced in burgers produced with animal fat, but cooking loss decreased as the replacement level increased. An increasing oleogel concentration in the burger correlated with a 1.5% reduction in fat absorption. In the oxidative stability test, the sample produced with animal fat exhibited the lowest TBARs value, and as the oleogel concentration increased, TBARs values rose. Sensory evaluation results indicated that panelists could not detect differences in texture and color among the burgers; however, they preferred the flavor of burgers produced with BW oleogel. This comprehensive study provides valuable insights into beef burgers’ physicochemical attributes and sensory aspects, incorporating oleogel as an animal fat substitute.

A previous study by Gómez-Estaca et al. (2020) examined how household activities, including refrigerated storage and cooking, impact the quality attributes of reduced-fat PUFA-enriched pork burgers [18]. Beyond household activities, they explored the influence of an oleogelation system involving an olive–linseed–fish oil blend and the integration of curcumin (CU) as an antioxidant, focusing on health implications. A comparative analysis with a control sample composed of pork back fat revealed that samples formulated with BW, BW-CU, EC, and EC-CU exhibited elevated levels of PUFA and MUFA. Furthermore, these formulated samples demonstrated significantly reduced levels of SFA, resulting in a higher PUFA/SFA ratio and a noteworthy decrease in the n-6/n-3 ratio—notably, the oleogel-incorporated samples delivered approximately twice the calories of the control counterparts. The utilization of oleogel contributed to a softer texture in the burgers compared to the control. Overall, the sensory attributes of burgers incorporating BW oleogel were deemed satisfactory and showed less lipid oxidation on storage.

Further, Moghtadaei et al. (2021) conducted a study investigating the partial substitution of animal fat with ethyl cellulose (EC) oleogel in beef burgers [19]. The oleogels, essential for substitution, were formed by combining sesame oil with EC. Compared to animal fats, EC oleogel exhibited higher concentrations of linoleic and linolenic acids, lower levels of palmitic and stearic acids, and an absence of myristic acid. As the EC oleogel content increased in the burger samples, the moisture content increased while the fat content decreased. EC oleogel seemed to create more fat globules, engaging additional proteins surrounding them. Cooked burgers with oleogel substitution demonstrated a roughly two-fold decrease in saturated fat content compared to control samples without animal fat replacement. However, oxidative stability was reduced in oleogel-incorporated samples. The study revealed that the hardness of raw beef burgers with EC oleogel was lower than those prepared with animal fat. Interestingly, an alternative hard behavior was observed in cooked samples, attributed to hydrogen bond breakage during temperature elevation, enabling additional protein interaction and resulting in a firmer texture. Sensory acceptability tests, encompassing color, taste, and texture, indicated that burgers produced with EC oleogels received higher ratings. The panelists favored beef burgers with a higher oleogel concentration (50%). This research suggests that oleogels hold the potential for substituting animal fat in meat products, enhancing textural qualities while reducing overall fat content.

3.2. Sausages and Frankfurters

Sausage, a popular meat product commonly prepared with pork and fat, is frequently consumed as a breakfast item. The composition and texture of sausage products heavily depend on fat as a key ingredient, exerting a profound influence on their sensory attributes. Fat, muscle tissue, and water are pivotal in determining emulsion stability in meat sausages. Consequently, understanding the potential impact of variations in fat quality is imperative for assessing and maintaining the overall quality of sausage products.

Barbut et al. (2016) explored the potential of structuring canola oil to replace animal fat in breakfast sausages while preserving textural and sensory properties [14]. This study aimed to evaluate the impact of substituting pork back fat with linseed oleogel on the key quality parameters of Frankfurters. An oleogel was created by incorporating 8% (w/w) beeswax into the linseed oil phase as a pork fat substitute in frankfurter sausage. Three sausage batches were produced: a control batch with pork back fat and two with 25% and 50% of pork back fat replaced by oleogel, respectively. Oleogels were prepared using canola oil, EC (8, 10, 12, and 14%), and sorbitan monostearate (SMS) (1.5% and 3%). The sausages underwent testing for texture profile, cooking loss, color assessment, microstructure, and sensory properties. Pork breakfast sausages produced with SMS-free oleogels exhibited lower objective hardness and springiness ratings but comparable cohesiveness to controls containing pork fat and canola oil. However, incorporating SMS into the oleogels resulted in accurate hardness values closely resembling those of the pork fat control treatment. This indicates that utilizing oleogels holds promising potential for improving the texture of sausages in the meat industry. Furthermore, creating tougher oleogels allows the customization of hardness qualities, considering various manufacturing-related parameters. This study underscores the viability of oleogels as a valuable tool for enhancing the textural attributes of sausages.

The investigation by Wolfer et al. in 2018 aimed to assess the influence of substituting pork back fat with soybean oil oleogel, structured with varying levels of rice bran wax, on the sensory characteristics of Frankfurter-type sausages [20]. The introduction of soybean-based oleogel elevated polyunsaturated fatty acids (PUFA) levels, particularly linoleic and α-linolenic acids. Notably, despite soybean oil’s limited n-3 fatty acid content, it improved the n-6/n-3 fatty acid ratio in the oleogel system. Frankfurters with oleogels exhibited increased puncture resistance, which can be attributed to oleogels’ ability to maintain structural integrity during manufacturing. This results in larger fat globules requiring higher energy input for reshaping. Oleogel-formulated samples demonstrated uniform hardness values, except those introduced later displayed elevated hardness. The 10% rice bran wax (RBW) oleogel-integrated sample exhibited extensive lipid oxidation, possibly accelerated during the prolonged heating needed for wax dissolution—a crucial step in 10% RBW. Distinct “Plastic” or “Grassy” sensory attributes were noted in 10% RBW oleogel samples, while higher oleogel content correlated with increased chewiness and hardness. The study highlighted oleogel technology as a viable alternative to animal-derived fats in processed meat products. Oleogel integration, replacing traditional fats, yielded Frankfurters with satisfactory technical attributes and notably enhanced nutritional composition, evidenced by the favorable fatty acid profile in oleogel-infused sausages.

In a study conducted by Franco et al. in 2019, linseed oil was structured with beeswax (BW) to create an oleogel aimed at assessing the impact of substituting pork back fat on the physicochemical, nutritional, and sensory characteristics of Frankfurter sausages [21]. Two replacement levels, 25% and 50%, were examined. Both replacements exhibited a significant reduction in cholesterol levels. Across all batches, MUFA, SFA, and PUFA consistently dominated the fatty acid profile. Particularly noteworthy was the substantial decrease in SFA content, specifically palmitic and stearic acids, indicating an overall improvement in the fatty acid profile. The 25% and 50% replacements demonstrated a PUFA increase of approximately 19% and 51%, respectively. The 50% replacement reduced the n-6/n-3 ratio from 14.92 to 1.61 and increased the PUFA/SFA ratio from 0.47 to 0.78 compared to the control. Moreover, the incremental inclusion of oleogel intensified the yellow coloration of the reformulated sausages. Textural metrics, including hardness, were nearly identical to the control. In sensory evaluations between the 25% and 50% replacements, the control sample was preferred, with panelists attributing this preference to superior visual, olfactory, and gustatory qualities linked to lower lipid oxidation levels than the reformulated counterparts. While the incorporation of linseed oleogels did not yield significant improvements in color and specific sensory attributes, a notable enhancement was observed in the fatty acid composition of the restructured product. Further research is imperative to refine strategies for mitigating lipid oxidation and optimizing sensory attributes in food formulations utilizing linseed oleogels.

In a thorough investigation conducted by Da Silva et al. in 2019, the focus was placed on a comprehensive analysis of Bologna-type sausages, specifically exploring the strategic replacement of pork back fat with high oleic sunflower oil (HOSO) oleogel at varying levels [22]. The preparation of the oleogel itself involved a meticulous blend of pork skin, water, and HOSO in a balanced ratio of 1.5:1.5:1, resulting in an ingeniously crafted oleogel with elevated protein content and a substantial presence of monounsaturated fatty acids (MUFA). The principal outcome of this innovative substitution strategy was a noteworthy reduction in the sausages’ fat content. Increasing levels of HOSO oleogel substitution correlated with a significant decrease in fat levels, with all substituted samples exhibiting an approximate 10% reduction in cholesterol levels—a commendable enhancement. Beyond compositional changes, the substitution of pork back fat induced alterations in textural properties. This transformation was attributed to collagen converting into gelatin, solidifying upon cooling and contributing to a firmer texture in the modified sausages. Crucially, the modified sausages demonstrated lower readings of TBARS, indicating reduced malondialdehyde levels. This was attributed to the decreased lipid content in these samples, coupled with a reduced proportion of polyunsaturated fatty acids (PUFA) in the lipid composition. Notably, at substitution levels of 75% and 100%, there was a discernible reduction in stearic acid concentration. Furthermore, when employing pork back fat substitutions of 50%, 75%, and 100%, a significant decrease of over 30% in saturated fatty acid (SFA) content was observed. Sensory evaluations revealed that substitutions of 25% and 50% of pork back fat with HOSO oleogel did not yield significant differences in sensory characteristics compared to the control group. In conclusion, this study emphasizes that substituting 50% of pork back fat with HOSO oleogel represents a pivotal threshold for enhancing Bologna-type sausage’s nutritional and technological attributes.

In a previous study conducted by Igenbayev et al., 2023, the viability of substituting traditional pork fat in semi-smoked sausages with a sunflower oil oleogel, structured using a blend of beeswax and monoglyceride in a 2:1 ratio, was thoroughly assessed [23]. The formulated oleogel exhibited a total fatty acid content of approximately 62.61% polyunsaturated fatty acids (PUFA), with linoleic acid constituting around 99.3% of the total PUFA content. The replacement of pork fat with oleogel significantly reduced stearic acid in the lipid-formulated semi-smoked sausages, reaching over a two-fold decrease with a 10% and 7% substitution, respectively. Additionally, the incorporation of oleogels led to a substantial 3.5-fold increase in the linoleic acid content of the pork fat-substituted sausages. Notably, the former exhibited superior sensorial attributes when comparing sausages with 7% pork fat substitution using oleogels to their 10% counterparts. The study elucidated the impact of beeswax’s hydrophobic properties on juiciness, monoglycerides’ influence on lipid distribution within the sausage matrix, and the potential instability of the matrix when 10% oleogel was incorporated, affecting overall appeal. These findings underscore that substituting pork fat with oleogel can significantly alter the fatty acid composition of sausages, thereby influencing their nutritional profile. Consequently, the study concludes that the strategic incorporation of oleogel as a partial replacement for pork fat is a scientifically sound approach to enhancing the nutritional quality of sausages, resulting in improved fatty acid profiles and sensory attributes. This approach promotes the overall healthful characteristics of the sausages.

The impact of substituting pork back fat with an oleogel derived from peanut oil (PO) structured by ethyl cellulose (EC) was explored by Shao et al. (2023) in Harbin red sausages [24]. Comparative analyses were conducted on traditional pork back fat and oleogel-substituted samples across various parameters. The modified samples consistently displayed a notable reduction in total lipid content, with the 50% substitution variant registering the lowest total fat level. As the percentage of oleogel substitution increased, there was a consistent decline in saturated fatty acid (SFA) content and a significant rise in unsaturated fatty acid (UFA) content, peaking at approximately 22% in the 50% substitution sample. Moreover, the polyunsaturated fatty acid (PUFA)-to-SFA ratio in oleogel-incorporated samples demonstrated a favorable shift, ranging from 20% to 50%, indicating a positive impact on fatty acid composition. A discernible reduction in hardness was observed with increasing oleogel substitution, notably in the 40% and 50% substitution variants. However, 10% to 30% substitution levels effectively maintained the desired texture profile of Harbin red sausages. While elevated lipid oxidation levels were evident compared to the control sample, attributed to a heightened unsaturated fat content, it is noteworthy that samples with 10%, 20%, and 30% pork back fat substitution exhibited significantly reduced malondialdehyde values compared to those with 45% and 50% substitution, indicating a favorable effect on oxidative stability.

In conclusion, Harbin red sausages reformulated with PO oleogel, substituting 10–30% of pork fat, demonstrated consumer satisfaction comparable to the original while simultaneously enhancing nutritional and health attributes. These improvements were achieved without compromising texture or sensory qualities. In summary, using an EC-based oleogel presents a promising avenue for producing healthier and more nutrient-rich Harbin red sausages [24].

3.3. Patties

Martins et al. (2019) conducted a study to substitute animal fat with sterol-based oleogels in pork patties [25]. The researchers utilized a 60:40 (w/w) oryzanol/sitosterol ratio mixed with linseed oil to create sterol-based oleogels. These oleogels, containing an 8% (w/w) concentration of structuring agents, were employed in all experiments. The combination of oryzanol and sitosterol oleogelators follow a self-assembly system inside the liquid phase to make oleogels. However, three sets of patties were prepared: a control set (H-Co) and two sets with partial replacement of subcutaneous pork fat with sterol-based oleogels at proportions of 25% (H-25) and 75% (H-75). The physicochemical characteristics and sensory attributes of the patties were systematically analyzed. The inclusion of oleogel, ranging from 25% to 75% of the total fat content, impacted the hardness of the samples. A discernible trend indicated a decrease in hardness with an increase in the percentage of fat replacement. The study demonstrated statistically significant variations in n6/n3 ratios due to different treatments, resulting in an elevation of the healthier cholesterol fraction in the final product when substituting pork fat with sterol-based oleogels. In the sensory evaluation, acceptance and preference tests were conducted to measure consumer appeal. The findings revealed a clear preference for the control patty samples among consumers. However, patties with less oleogel (H-25) received favorable ratings from the sensory panel in acceptance and preference tests. These results underscored the feasibility of incorporating oleogels as effective fat replacers in patty manufacturing.

Canola oil was structurally modified through the incorporation of hydroxypropyl methylcellulose (HPMC), leading to the development of oleogels, which were subsequently assessed as a viable alternative to animal fats in the production of saturated fat-reduced meat patties [26]. These HPMC oleogels exhibited behavior like an elastic gel, displaying solid fat contents independent of temperature variations. Notably, they demonstrated superior resistance to oxidative processes compared to canola oil, particularly under accelerated storage conditions. Several noteworthy improvements were observed after substituting beef tallow in the meat patty formulation with HPMC oleogels at 50% and 100% replacement levels. Firstly, the cooking loss of the patties saw a significant reduction, contributing to enhanced moisture retention and overall product quality. Additionally, the texture of the meat patties became notably softer, enhancing their palatability. Furthermore, incorporating HPMC oleogels in the meat patties positively impacted the nutritional profile. Saturated fatty acid levels in the resulting meat patties containing HPMC oleogels were substantially reduced, decreasing to only 15% compared to the beef tallow-based counterparts, which contained a much higher saturated fat content of 42%. Importantly, these findings highlight that the utilization of HPMC oleogels as a replacement for traditional animal fats not only improves the healthfulness of meat products by reducing saturated fat content but also manages to preserve their sensory attributes, ensuring a pleasurable culinary experience.

The objective of a study by Agregán et al. (2019) was to assess the efficacy of Fucus vesiculosus extracts in prolonging the shelf life of pork patties formulated with linseed oil oleogels and packaged under modified atmosphere conditions during refrigerated storage [27]. The oleogel utilized in this investigation comprised linseed oil and a combination of two structuring agents (γ-oryzanol and β-sitosterol). Both structuring agents were dispersed by stirring until complete solubilization, along with the linseed oil, at a temperature of 80 °C for 30 min. Subsequently, the mixture was allowed to cool at room temperature until the gel formation occurred. Pork patties with linseed oil oleogel as a fat replacer were supplemented with Fucus vesiculosus extract (FVE) at 250 mg, 500 mg, or 1000 mg/kg concentrations. Additionally, patties containing butylated hydroxytoluene (BHT) at a concentration of 200 mg/kg, a conventional synthetic antioxidant, were included, and patties without any antioxidant (CO) were included as the control group. The physicochemical properties and sensory attributes of the pork patty formulations incorporating seaweed-based ingredients were compared with control samples formulated with oleogels, antioxidants, or BHT. Containing FVE at 1000 mg/kg concentration into pork patties effectively safeguarding the samples against oxidation. Notably, the treatment with FVE at 500 mg/kg yielded the highest sensory scores for odor in the cooked product, indicating its potential as an optimal concentration for enhancing the overall sensory attributes of the seaweed-based pork patties.

The study conducted by Gao et al. (2021) aimed to assess the physical attributes of oleogel derived from a combination of beeswax and rapeseed oil [28]. Additionally, the research investigated the storage characteristics of beef heart patties wherein all conventional beef fat was substituted with beeswax and rapeseed oil oleogel. To create the rapeseed oil oleogels, five distinct concentrations of beeswax (2.5%, 5%, 7.5%, 10%, and 12.5% w/w) were utilized. The process involved heating the oil and wax mixture in a water bath at 90 °C and stirring it at a consistent speed of 200 r/min for 45 min. The resulting oleogels were examined for their physical properties, revealing that the 10% beeswax oleogel, when cooled at 4 °C, achieved a gel state with higher L* values than those cooled at 25 °C. Consequently, the 10% beeswax oleogel at 4 °C was chosen to replace beef fat in beef heart patties. Two patties were prepared: one with 15% beef fat (control) and the other with 15% oleogel. Subsequently, the patties were vacuum-packed and stored at 4 °C. Samples were extracted for analysis at intervals of 0, 3, 5, 7, and 14 days of storage. The incorporation of 10% beeswax rapeseed oil oleogels (cooled at 4 °C) resulted in a significant enhancement in the fatty acid composition, including a reduction in saturated fatty acids (SFA) from 54.08 to 8.34 and an increase in polyunsaturated fatty acids (PUFA) from 8.88 to 34.37 g/100 g of patties. Moreover, it led to improvements in cooking loss and the nutrient ratio of the beef heart patties. However, these oleogels were observed to decrease the oxidative stability and hardness of the patties during cold storage. In conclusion, the authors determined that adding oleogels positively influenced beef heart patties’ fatty acid profiles and nutritional indices. Nonetheless, further enhancements in the texture and oxidative stability of the patties were deemed necessary [28].

3.4. Pâté

The primary aim of an experiment by Martins et al. (2020) was to investigate the impact of substituting pork back fat with linseed beeswax-based oleogel on the physicochemical and nutritional characteristics of pâté [29]. The rationale behind this substitution was to identify a viable alternative for reducing saturated fat content in pâté formulations. Additionally, the study assessed the sensory attributes associated with the pâté samples. To create the beeswax-based oleogel, linseed oil was structured with 8% (w/w) of a gelator, and this process was replicated for all fat replacement experiments. Beeswax was introduced into the linseed oil under stirring at 80 °C (above the wax melting point) for a minimum of 30 min. Subsequently, the resultant gels were allowed to cool at room temperature until complete gel formation occurred, requiring a minimum of 48 h. Pâté samples were formulated with pork fat replacement levels set at 30% and 60%. The incorporation of linseed oil in the form of an oleogel contributed to an elevation in polyunsaturated fatty acids (PUFAs). Consequently, the omega-3 intake potential of pâtés with oleogel incorporation was augmented, thereby enhancing the health profile of a product traditionally not regarded as a source of health benefits. The n-6/n-3 ratio analysis revealed that substituting pork back fat with oleogel yielded a pâté with a more favorable nutritional profile than the control. Furthermore, a discernible reduction in hardness and adhesivity was observed in pâtés with oleogel incorporation. In the sensory analysis, the collated data suggested that the control and sample containing 30% oleogel received the highest appreciation, with combined scores for “liked” and “liked a lot,” reaching 7 and 6, respectively. The overall score for the 30% oleogel replaced pâté sample remained notably positive, considering its proximity to the control sample results [29].

A study by Gómez-Estaca et al., 2019, focused on structuring a more healthful lipid mixture comprising olive, linseed, and fish oils using two distinct oleogelators, namely EC and beeswax [15]. The aim was to assess the suitability of these structured lipid mixtures as functional ingredients for pork liver pâtés, with a comprehensive analysis of their physicochemical, sensory, and nutritional attributes. The researchers initiated the experiment by preparing a mixture of olive oil, linseed oil, and fish oil, combined with EC (11 g/100 g oleogel) and sorbitan monostearate (3.67 g/100 g oleogel). This mixture was then heated in Pyrex beakers within a thermostatic bath set at 170 °C under continuous stirring. After reaching a temperature of 160 °C, the mixture was allowed to stand for 10 min. Notably, the beeswax oleogel demonstrated a more rigid, ordered, brittle structure with a melting point of around 55 °C. In contrast, the EC oleogel exhibited a softer, more deformable structure with high conformational flexibility and thermal stability. Subsequently, five pâtés with a reduced fat content of 15% were formulated, with a control batch prepared using pork back fat as the primary fat source. The experimental pork liver pâtés were successfully formulated by either total or partial substitution of back fat with beeswax oleogel or EC oleogels. These reformulated products exhibited an optimal fatty acid profile, characterized by a high PUFA/SFA ratio and a low n-6/n-3 ratio, indicating their potential health benefits. Significantly, the technological behavior of the reformulated products did not significantly deviate from the control sample, including characteristics such as color and texture. Beeswax oleogel had no discernible impact on sensory parameters, while EC oleogel exhibited a negative effect directly correlated with the substitution level. Nevertheless, all samples received ratings near “neutral” on the sensory scale. Due to their composition and favorable technological and sensory properties, the developed ingredients emerge as promising candidates for producing healthier pork liver pâtés [15].

References

- Forouhi, N.G.; Krauss, R.M.; Taubes, G.; Willett, W. Dietary Fat and Cardiometabolic Health: Evidence, Controversies, and Consensus for Guidance. BMJ 2018, 361, k2139.

- Silva, R.C.D.; Ferdaus, M.J.; Foguel, A.; Da Silva, T.L.T. Oleogels as a Fat Substitute in Food: A Current Review. Gels 2023, 9, 180.

- Abdolmaleki, K.; Alizadeh, L.; Nayebzadeh, K.; Hosseini, S.M.; Shahin, R. Oleogel Production Based on Binary and Ternary Mixtures of Sodium Caseinate, Xanthan Gum, and Guar Gum: Optimization of Hydrocolloids Concentration and Drying Method. J. Texture Stud. 2020, 51, 290–299.

- Vieira, S.A.; McClements, D.J.; Decker, E.A. Challenges of Utilizing Healthy Fats in Foods. Adv. Nutr. 2015, 6, 309S–317S.

- Winkler-Moser, J.K.; Anderson, J.; Felker, F.C.; Hwang, H. Physical Properties of Beeswax, Sunflower Wax, and Candelilla Wax Mixtures and Oleogels. J. Am. Oil Chem. Soc. 2019, 96, 1125–1142.

- Martins, A.J.; Vicente, A.A.; Cunha, R.L.; Cerqueira, M.A. Edible Oleogels: An Opportunity for Fat Replacement in Foods. Food Funct. 2018, 9, 758–773.

- Ferdaus, M.J.; Blount, R.J.S.; Silva, R.C.D. Assessment of Natural Waxes as Stabilizers in Peanut Butter. Foods 2022, 11, 3127.

- Pinto, T.C.; Martins, A.J.; Pastrana, L.; Pereira, M.C.; Cerqueira, M.A. Oleogel-Based Systems for the Delivery of Bioactive Compounds in Foods. Gels 2021, 7, 86.

- Barroso, N.G.; Okuro, P.K.; Ribeiro, A.P.B.; Cunha, R.L. Tailoring Properties of Mixed-Component Oleogels: Wax and Monoglyceride Interactions Towards Flaxseed Oil Structuring. Gels 2020, 6, 5.

- Wijarnprecha, K.; Aryusuk, K.; Santiwattana, P.; Sonwai, S.; Rousseau, D. Structure and Rheology of Oleogels Made from Rice Bran Wax and Rice Bran Oil. Food Res. Int. 2018, 112, 199–208.

- Rakhra, V.; Galappaththy, S.L.; Bulchandani, S.; Cabandugama, P.K. Obesity and the Western Diet: How We Got Here. Mo. Med. 2020, 117, 536–538.

- Mahmud, N.; Islam, J.; Oyom, W.; Adrah, K.; Adegoke, S.C.; Tahergorabi, R. A Review of Different Frying Oils and Oleogels as Alternative Frying Media for Fat-Uptake Reduction in Deep-Fat Fried Foods. Heliyon 2023, 9, e21500.

- Ren, Y.; Huang, L.; Zhang, Y.; Li, H.; Zhao, D.; Cao, J.; Liu, X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods 2022, 11, 1950.

- Barbut, S.; Wood, J.; Marangoni, A. Quality Effects of Using Organogels in Breakfast Sausage. Meat Sci. 2016, 122, 84–89.

- Gómez-Estaca, J.; Herrero, A.M.; Herranz, B.; Álvarez, M.D.; Jiménez-Colmenero, F.; Cofrades, S. Characterization of Ethyl Cellulose and Beeswax Oleogels and Their Suitability as Fat Replacers in Healthier Lipid Pâtés Development. Food Hydrocoll. 2019, 87, 960–969.

- Serdaroğlu, M.; Nacak, B.; Karabıyıkoğlu, M. Effects of Beef Fat Replacement with Gelled Emulsion Prepared with Olive Oil on Quality Parameters of Chicken Patties. Korean J. Food Sci. Anim. Resour. 2017, 37, 376–384.

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H. Production of Sesame Oil Oleogels Based on Beeswax and Application as Partial Substitutes of Animal Fat in Beef Burger. Food Res. Int. 2018, 108, 368–377.

- Gómez-Estaca, J.; Pintado, T.; Jiménez-Colmenero, F.; Cofrades, S. The Effect of Household Storage and Cooking Practices on Quality Attributes of Pork Burgers Formulated with PUFA- and Curcumin-Loaded Oleogels as Healthy Fat Substitutes. LWT 2020, 119, 108909.

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H.; Sharifimehr, S. Physicochemical Properties of Beef Burger after Partial Incorporation of Ethylcellulose Oleogel Instead of Animal Fat. J. Food Sci. Technol. 2021, 58, 4775–4784.

- Wolfer, T.L.; Acevedo, N.C.; Prusa, K.J.; Sebranek, J.G.; Tarté, R. Replacement of Pork Fat in Frankfurter-Type Sausages by Soybean Oil Oleogels Structured with Rice Bran Wax. Meat Sci. 2018, 145, 352–362.

- Franco, D.; Martins, A.; López-Pedrouso, M.; Purriños, L.; Cerqueira, M.; Vicente, A.; Pastrana, L.; Zapata, C.; Lorenzo, J. Strategy towards Replacing Pork Backfat with a Linseed Oleogel in Frankfurter Sausages and Its Evaluation on Physicochemical, Nutritional, and Sensory Characteristics. Foods 2019, 8, 366.

- Da Silva, S.L.; Amaral, J.T.; Ribeiro, M.; Sebastião, E.E.; Vargas, C.; De Lima Franzen, F.; Schneider, G.; Lorenzo, J.M.; Fries, L.L.M.; Cichoski, A.J.; et al. Fat Replacement by Oleogel Rich in Oleic Acid and Its Impact on the Technological, Nutritional, Oxidative, and Sensory Properties of Bologna-Type Sausages. Meat Sci. 2019, 149, 141–148.

- Igenbayev, A.; Ospankulova, G.; Amirkhanov, S.; Aldiyeva, A.; Temirova, I.; Amirkhanov, K. Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages. Appl. Sci. 2023, 13, 5312.

- Shao, L.; Bi, J.; Li, X.; Dai, R. Effects of Vegetable Oil and Ethylcellulose on the Oleogel Properties and Its Application in Harbin Red Sausage. Int. J. Biol. Macromol. 2023, 239, 124299.

- Martins, A.J.; Silva, P.; Maciel, F.; Pastrana, L.M.; Cunha, R.L.; Cerqueira, M.A.; Vicente, A.A. Hybrid Gels: Influence of Oleogel/Hydrogel Ratio on Rheological and Textural Properties. Food Res. Int. 2019, 116, 1298–1305.

- Oh, I.; Lee, J.; Lee, H.G.; Lee, S. Feasibility of Hydroxypropyl Methylcellulose Oleogel as an Animal Fat Replacer for Meat Patties. Food Res. Int. 2019, 122, 566–572.

- Agregán, R.; Barba, F.J.; Gavahian, M.; Franco, D.; Khaneghah, A.M.; Carballo, J.; Ferreira, I.C.; Da Silva Barretto, A.C.; Lorenzo, J.M. Fucus Vesiculosus Extracts as Natural Antioxidants for Improvement of Physicochemical Properties and Shelf Life of Pork Patties Formulated with Oleogels. J. Sci. Food Agric. 2019, 99, 4561–4570.

- Gao, Y.; Li, M.; Zhang, L.; Wang, Z.; Yu, Q.; Han, L. Preparation of Rapeseed Oil Oleogels Based on Beeswax and Its Application in Beef Heart Patties to Replace Animal Fat. LWT 2021, 149, 111986.

- Martins, A.J.; Lorenzo, J.M.; Franco, D.; Pateiro, M.; Domínguez, R.; Munekata, P.E.S.; Pastrana, L.M.; Vicente, A.A.; Cunha, R.L.; Cerqueira, M.A. Characterization of Enriched Meat-Based Pâté Manufactured with Oleogels as Fat Substitutes. Gels 2020, 6, 17.

More

Information

Subjects:

Food Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

29 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No