Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Roi Peretz | -- | 2228 | 2024-01-29 10:03:54 | | | |

| 2 | Jessie Wu | + 1 word(s) | 2229 | 2024-01-30 02:38:26 | | | | |

| 3 | Jessie Wu | Meta information modification | 2229 | 2024-01-30 02:40:37 | | | | |

| 4 | Jessie Wu | Meta information modification | 2229 | 2024-01-30 02:41:12 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Or-Chen, D.; Gerchman, Y.; Mamane, H.; Peretz, R. Recycled Paper Sludge for Energy Applications. Encyclopedia. Available online: https://encyclopedia.pub/entry/54474 (accessed on 07 February 2026).

Or-Chen D, Gerchman Y, Mamane H, Peretz R. Recycled Paper Sludge for Energy Applications. Encyclopedia. Available at: https://encyclopedia.pub/entry/54474. Accessed February 07, 2026.

Or-Chen, Dafna, Yoram Gerchman, Hadas Mamane, Roi Peretz. "Recycled Paper Sludge for Energy Applications" Encyclopedia, https://encyclopedia.pub/entry/54474 (accessed February 07, 2026).

Or-Chen, D., Gerchman, Y., Mamane, H., & Peretz, R. (2024, January 29). Recycled Paper Sludge for Energy Applications. In Encyclopedia. https://encyclopedia.pub/entry/54474

Or-Chen, Dafna, et al. "Recycled Paper Sludge for Energy Applications." Encyclopedia. Web. 29 January, 2024.

Copy Citation

Recycled paper sludge (RPS), a paper production by-product, is an excellent lignocellulosic biomass source for bioethanol production due to its high cellulose content and negative cost. Converting RPS to bioethanol aligns with circular economy (CE) concepts and is key in achieving Agenda 2020 for America’s forest, wood, and paper industries. Paper is a well-explored material, including its production process, waste product, and properties.

bioethanol

waste management

waste-to-energy

circular economy

paper-mill wastes

1. Waste-to-Energy (WtE)

Another category of paper mill sludge (PMS) management is waste-to-energy (WtE), which groups several methods [1]. Thermal processes, like pyrolysis, provide an option for thermally upgrading the PMS to higher calorific value fuels. The bio-oils and charcoal produced from paper sludge pyrolysis have the potential to provide marketable feedstock and sources of energy. Charcoal derived from biomass was traditionally used as metallurgical fuel and is also being considered as a soil amendment and fertilizer replacement. The bio-gas product of waste pyrolysis has sufficient calorific energy and can be combusted to provide the required internal heat of pyrolysis, thus closing the circular process and reducing the external heat supply [2][3]. Other thermal processes include combustion incineration, steam reforming, wet oxidation, gasification, and more [4].

2. Bioethanol Production from Lignocellulosic Biomass

Ethanol (or EtOH, C2H6O) is a colorless liquid with a slight odor, soluble in water, flammable, and volatile. Ethanol, unlike fossil fuels, is a renewable energy source produced through the fermentation of sugars. As a high-octane fuel (98), it has replaced lead as an octane enhancer in petrol. Blending ethanol with gasoline fuel benefits the engine, burns more completely, and reduces polluting emissions [5]. Ethanol can also be used as a fuel for power generation, such as in solid oxide fuel cells, and as an ingredient in the chemicals industry [6][7].

Bioethanol is produced from natural matter. first-generation bioethanol feedstock is mainly edible food crops such as rice, corn, sugarcane, and vegetable oils like soybean oil and olive oil. Production of first-generation bioethanol has its disadvantages, competing with the food supply and land utilization. However, this form of biofuel is commercially available and known for its yield and production process [8].

Second-generation bioethanol refers to ethanol produced from nonedible feedstocks such as woody biomass, herbaceous biomass, solid waste, and animal fat. Compared to the first generation, the amount of energy that can be produced per land area is much bigger. Some drawbacks, however, are higher capital costs in production due to sophisticated processing equipment and lower energy density vs. first-generation bioethanol [9].

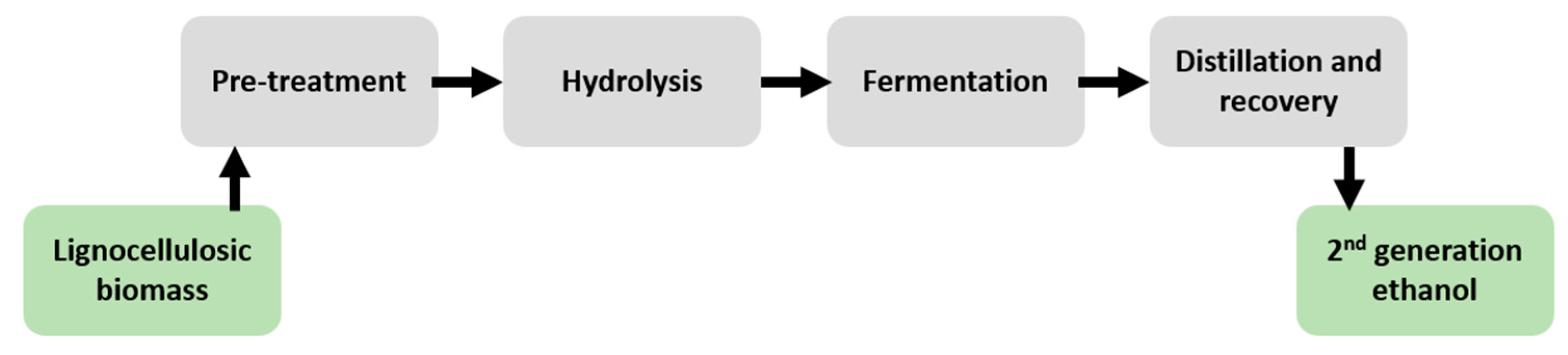

The conversion of lignocellulosic biomass into bioethanol generally starts with feedstock preparation that involves cleaning and size reduction. This is done by milling, grinding, or chopping and is crucial for the removal of impurities and increasing surface area; however, this step is energy-consuming [10]. The process is followed by four steps: pretreatment for the degradation of the lignocellulosic matrix, hydrolysis of cellulose in the lignocellulosic materials to fermentable reducing sugars, fermentation of the sugars to ethanol, and lastly, distillation and recovery of the produced ethanol (Figure 1).

Figure 1. Stages in second-generation bioethanol production.

Pre-treatment is needed to reduce the lignin and hemicellulose amount, as they hinder hydrolysis by impeding the access of cellulase enzymes to cellulose [11][12]. The pre-treatment should also reduce cellulose crystallinity and increase its porosity or surface area, which can significantly improve hydrolysis. In addition to being cost-effective, it is required to prevent the loss of carbohydrates and the formation of hydrolysis-inhibiting by-products [13][14]. This process has been intensively studied as it is a major technical and economical bottleneck in the bioconversion of lignocellulos to bioethanol, accounting for 40% of total costs [15], hence enabling scaling up production [16][17]. During pre-treatment, inhibitory compound may be generated. These compounds have a negative effect on enzymes and microorganisms, affecting catalytic processes and reducing ethanol production yield. Table 1 presents current industrial pre-treatment methods.

| Pre-Treatment Method | Advantages | Disadvantages |

|---|---|---|

| Steam explosion |

|

|

| Ozonolysis |

|

|

| Ammonia fiber Explosion |

|

|

| Organosolv |

|

|

| Concentrated acid |

|

|

| Diluted acid |

|

|

Hydrolysis is usually catalyzed by cellulase enzymes, and fermentation is carried out by yeast or bacteria. Factors that have been identified to affect the hydrolysis of cellulose include the porosity (accessible surface area) of the feedstock, cellulose fiber crystallinity, and lignin and hemicellulose content [21].

Ethanol is produced by fermenting soluble sugars using a variety of microorganisms. The fermentation is conducted in anaerobic conditions, with the maximum theoretical yield being 0.51 kg of ethanol and 0.49 kg of CO2 per kg of glucose [22]. There are several possibilities for the integration of hydrolysis and fermentation steps. These include separate hydrolysis and fermentation (SHF), simultaneous saccharification and fermentation (SSF), and consolidated bioprocessing (CBP) [23]. SHF consists of two separate hydrolysis and fermentation steps. In SSF, both steps are conducted simultaneously in the same vessel. In this method, soluble sugars are immediately fermented into ethanol, improving both enzymatic hydrolysis efficiency and ethanol yield. In CBP, enzymes are produced alongside hydrolysis and fermentation in a single step [24].

Generally, at the end of the fermentation step, the bioethanol value stands at 5% wt. This is a lower value compared to first-generation ethanol, which stands at 12% wt. The ethanol broth is distilled in a stripper column to reach a 20% wt. concentration and then further concentrated in a rectifier column to no higher than 95.6% wt. ethanol in water. Distillation is an energy-demanding step, accounting for 60–80% of the total separation cost of bioethanol from water [24].

3. Paper Wastes as a Lignocellulosic Material

Paper wastes are considered a good lignocellulosic biomass source for bioethanol production because of their high cellulose content (Table 2). Paper is usually recycled 3–4 times [25], and after that, most fibers become too short and incompatible for papermaking. Using such fibers may negatively affect paper product properties; therefore, they are rejected as waste. Since the recovery of recycled paper cannot solely be in the papermaking market, RPS may also be used for ethanol production, as the process waste is beneficial [26].

Table 2. Paper sources’ composition.

| Source | Cellulose | Hemicellulose | Lignin | References |

|---|---|---|---|---|

| Newspaper | 40–69 | 25–40 | 18–30 | [27][28][29] |

| Kraft paper | 57.3 | 9.9 | 20.8 | [23] |

| Corrugated cardboard | 53–57 | 10–13 | 21–22 | [27] |

| Office and copy paper | 57–63 | 16–21 | 0–6.5 | [27][29] |

| Paper towel | 53 | 13 | 18 | [27] |

| Paperboard SBB a | 64 | 20 | 5 | [27] |

| Paperboard SUB b | 43 | 12.5 | 24.3 | [27] |

| Bleached softwood kraft pulp | 82 | 16 | 0.6 | [30][31] |

| Bleached hardwood kraft pulp | 70–81 | 17–27 | 0.8–3 | [30][31] |

| Unbleached kraft pulp | 72 | 20 | 3–7 | [32][33] |

| Chemi-thermomechanical pulp (CTM) | 54 | 25 | 19–21 | [30][31] |

| Municipal solid waste (MSW) | 15 | 10 | 8.5–15 | [34][35] |

| Waste paper | 40–80 | 5–20 | 1–10 | [28][36][37] |

| Paperboard mill sludge (PMS) | 23.4–37 | 8.6–33 | 16.5–24.5 | [31][38][39] |

a SBB, solid bleached board; b SUB, solid unbleached board.

Both RPS and other PMS may have a negative cost impact from a circular economy standpoint, as they are an environmental burden and typically landfilled by default. PMS and RPS were evaluated and demonstrated as bioethanol feedstock, presenting successful conversion (Table 3). The integral utilization of lignocellulosic biomass, namely paper sludge, has been considered within the bio-refinery concept and can be evaluated by circular economy monitors for environmental, economic, and even social aspects. The common evaluation methodology is the life cycle assessment (LCA), standardized in the ISO 14040 series [32].

Table 3. Paper products and paper waste conversion to ethanol.

| Lignocellulosic Source | Pre-Treatment | Ethanol Yield (L/Dry Ton Feedstock) |

References |

|---|---|---|---|

| Recycled paper sludge (RPS) | Ozonation | 120 | [40] |

| Recycled paper sludge (RPS) | Sterilization (autoclaving with Sodium Azide) | 93–112 | [41] |

| Copy paper | None | 287 | [37] |

| Copier paper | None | 198 | [42] |

| Virgin pulp PS | None | 241 | [43] |

| Corrugated recycle PS | None | 214 | [43] |

| Newspaper | Oxidative lime: 1.875% w/w Ca(OH), 7.1 bar (absolute) O2, 140 °C, 3 h | 290 | [44] |

| Office paper | Diluted acid: 0.5% w/w H2SO4, 220 °C | 419 | [45] |

| Recycled paper sludge (RPS) | Ash removal (TAPPI, 1995) | 289–332 | [46][47] |

| Waste office paper | Diluted acid: 1% v/v H2SO4, 50 °C, 3 h | 206 | [48] |

4. Paper Sludge as a Source of Ethanol

Several PS valorization routes have already been suggested and explored. Many different products have already been produced from sludge, including: nanocellulose [49], lactic acid [50], cellulase [51], isoprene [52], microbial lipids [53], and building materials supplement [54]. In addition, various WtE routes have also been suggested for a variety of energy products, including: hydrogen [55], bio-gas from anaerobic digestion (AD) [56], butanol through acetone-butanol-ethanol fermentation [57], bio-oil [58], bio-methanol through gasification [59], and bioethanol. These solutions have yet to be found sustainable, resulting in PS being landfilled for the most part. The conversion of sludge to ethanol holds several economic benefits, and even negative costs, since using PS to produce other products reduces landfilling and shipping costs, environmental fees, and eliminates purchasing costs without the need to purchase the original source material. In addition, other by-products from the papermaking process, like kraft pulp and Spent sulfite liquor, have also been suggested for ethanol production, [24]. Table 4 shows different studies on bioethanol production from papermaking process waste by-products.

Table 4. Ethanol production from papermaking process waste by-products.

| Raw Material | Ethanol Production (g/L) | Yield (%) | References |

|---|---|---|---|

| Recycled paper sludge | 14.9 | 9.44 | [40] |

| Recycled paper sludge | 5.6–6.3 | 67.9–76.8 | [41] |

| Virgin pulp sludge | 34.2 | 66.9 | [44] |

| Primary sludge | 25–30 | 94.5–95.7 | [60] |

| Primary sludge | 30.7–58.8 | 90 | [61] |

| Primary sludge | 37.2 | 23.5 | [62] |

| Kraft pulp | 30–38 | 16.8–20.2 | [63] |

| Kraft pulp | 5.88 | 4.5 | [64] |

| Kraft pulp | N/A | 12–20 | [65] |

| Spent sulfite liquor | 8.1 | 49 | [66] |

| Spent sulfite liquor | 9 | 25 | [67] |

A large amount of water is required in the papermaking process for both the reaction media and for use as wash water. Depending on the type of raw material input and the process conditions, there is great variability in PS properties, such as organic content, ash content, and pH [24]. In addition, there is a large variation in the chemical composition of the PS produced in different pulp mills. Previous work showed differences in the chemical composition of 37 PS samples that originated from different mills, depending on the feed material and the upstream processing in papermaking [44].

Although PS shows great promise, a major barrier in PS conversion to ethanol is its high ash content. The ash, mostly CaCO3, absorbs enzymes and increases sludge pH levels and suppresses enzymatic activity. Acidic treatments can be used for neutralization to minimize this limitation [68]. Moreover, high ash content limits the total solid load, eventually increasing processing costs. PS also has high water-holding capacity and viscosity, resulting in inefficient mixing and poor mass transfer [24].

5. Economic Aspects of Circular Economy in the Paper Industry

Paper waste management poses a major economic burden on paper and cardboard producers and recyclers. This burden has dramatically increased in recent years, due to the increase in e-commerce and shipments and the growing need for cardboard boxes and containers [49]. These challenges are also accompanied by major fluctuations in paper and cardboard prices, initially started by a major reduction of more than 300% in cardboard prices, due to the high-volume importation of cheap cardboard from China in recent years, which left the paper recycling sector “in a crisis situation” [69]. A more recent case study in Catalonia, Spain, showed a major drop of 73% in paper and cardboard prices from 74.5 € to 20 € during 2018–2019 [70]. Recently, cardboard prices have been moving up, which is explained by the end of inventory hoarding that characterized the post-pandemic recovery. However, it is too soon to determine if these price increases will stay and be repeated [71].

Furthermore, the necessity for waste handling and shipments to landfills/treatment sites, as mostly practiced, contributes substantially to the economic burden of the paper industry. The necessity for the paper and carboard industry to shift toward a CE is demonstrated by the cost of unit cargo for truck shipments that can be estimated to range between 40–180 USD/ton of waste (for a 1000 km distance), according to the truck fullness ratio and additional tax fees [72]. A recent publication by the Ministry of Land, Infrastructure, Transport and Tourism of Japan issued a transportation rate of 7.63 USD/km for a 20-ton truck (with a volume capacity of 75 m3) [73]. This has led to several works evaluating full life cycle assessments (LCAs) in the paper industry, analyzing water and raw materials and end waste-products for the possibility of further use, thus increasing economic feasibility [74][75][76]. Moreover, PS valorization into valuable energy products holds high potential for environmental benefits. A case study conducted on a virgin pulp mill has shown that the use of PS bioenergy for ethanol and bio-gas production has the potential to reduce energy demand by 10%, while reclaiming 82% of the water from the PS. As a result, greenhouse gas emissions (GHGs) will be reduced by three times, and solids suitable for land spreading will be produced as well [77]. To date, carbon taxes and emissions trading system (ETSs) cover 20% of global emissions. Since these tools increasingly take central places in GHG emissions regulations, this approach can be much more beneficial economically, saving high carbon fees [78].

Integration of ethanol production may transform P&P mills into biorefineries, allowing them to diversify production and increase profitability. For example, several works have assessed the techno-economic potential for repurposing kraft mills into ethanol production plants [79][80]. Although sulfite pulps correspond to only 2% of annual wood pulps [24], additional papers have suggested the conversion of sulfite mills into integrated biorefineries [81][82]. Bioethanol production integration into existing paper mills can maximize the use of raw material and reduce operational costs. The economics for the conversion of PS to ethanol in kraft pulping mills were evaluated to be a low-cost opportunity, due to the negative cost of feedstock material and the simplicity of the process [83]. Nevertheless, industrial-scale production of ethanol from PS and from lignocellulosic material is limited due to high capital investment and technical risks [24].

References

- Oladejo, J.; Shi, K.; Luo, X.; Yang, G.; Wu, T. A review of sludge-to-energy recovery methods. Energies 2019, 12, 60.

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308.

- Strezov, V.; Evans, T.J. Thermal processing of paper sludge and characterisation of its pyrolysis products. Waste Manag. 2009, 29, 1644–1648.

- Thompson, G.; Swain, J.; Kay, M.; Forster, C.F. The treatment of pulp and paper mill effluent: A review. Bioresour. Technol. 2001, 77, 275–286.

- Al-Hasan, M. Effect of ethanol-unleaded gasoline blends on engine performance and exhaust emission. Energy Convers. Manag. 2003, 44, 1547–1561.

- Douvartzides, S.; Coutelieris, F.; Tsiakaras, P. Exergy analysis of a solid oxide fuel cell power plant fed by either ethanol or methane. J. Power Sources 2004, 131, 224–230.

- Ruan, R.; Zhang, Y.; Chen, P.; Liu, S.; Fan, L.; Zhou, N.; Ding, K.; Peng, P.; Addy, M.; Cheng, Y.; et al. Biofuels: Introduction. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels, 2nd ed.; Pandey, A., Larroche, C., Dussap, C.G., Gnansounou, E., Khanal, S.K., Ricke, S., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 3–43.

- Acheampong, M.; Ertem, F.C.; Kappler, B.; Neubauer, P. In pursuit of Sustainable Development Goal (SDG) number 7: Will biofuels be reliable? Renew. Sustain. Energy Rev. 2017, 75, 927–937.

- Halder, P.; Azad, K.; Shah, S.; Sarker, E. Prospects and technological advancement of cellulosic bioethanol ecofuel production. In Advances in Eco-Fuels for a Sustainable Environment; Azad, K., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 211–236.

- Sebayang, A.H.; Masjuki, H.H.; Ong, H.C.; Dharma, S.; Silitonga, A.S.; Mahlia, T.M.I.; Aditiya, H.B. A perspective on bioethanol production from biomass as alternative fuel for spark ignition engine. RSC Adv. 2016, 6, 14964–14992.

- Ximenes, E.; Kim, Y.; Mosier, N.; Dien, B.; Ladisch, M. Deactivation of cellulases by phenols. Enzym. Microb. Technol. 2011, 48, 54–60.

- Zheng, Y.; Pan, Z.; Zhang, R. Overview of biomass pretreatment for cellulosic ethanol production. Int. J. Agric. Biol. Eng. 2009, 2, 51–68.

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93.

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11.

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 2017, 122, 724–745.

- Banerjee, G.; Scott-Craig, J.S.; Walton, J.D. Improving enzymes for biomass conversion: A basic research perspective. Bioenergy Res. 2010, 3, 82–92.

- Minami, E.; Saka, S. Comparison of the decomposition behaviors of hardwood and softwood in supercritical methanol. J. Wood Sci. 2003, 49, 73–78.

- Rosen, Y.; Mamane, H.; Gerchman, Y. Short ozonation of lignocellulosic waste as energetically favorable pretreatment. Bioenergy Res. 2019, 12, 292–301.

- Rosen, Y.; Maskennikov, A.; Trabelcy, B.; Gerchman, Y.; Mamane, H. Short ozonation for effective removal and detoxification of fermentation inhibitors resulting from thermal pretreatment. Renew. Energy 2022, 189, 1407–1418.

- Alvira, P.; Tomás-Pejó, E.; Ballesteros, M.; Negro, M.J. Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 2010, 101, 4851–4861.

- Peretz, R.; Gerchman, Y.; Mamane, H. Ozonation of tannic acid to model biomass pretreatment for bioethanol production. Bioresour. Technol. 2017, 241, 1060–1066.

- Muller, C.; Scapini, T.; Rempel, A.; Abaide, E.R.; Camargo, A.F.; Nazari, M.T.; Tadioto, V.; Bonatto, C.; Tres, M.V.; Zabot, L.M.; et al. Challenges and opportunities for third-generation ethanol production: A critical review. Eng. Microbiol. 2023, 3, 100056.

- Hawaguchi, H.; Hasunuma, T.; Ogino, C.; Kondo, A. Bioprocessing of bio-based chemicals produced from lignocellulosic feedstocks. Curr. Opin. Biotechnol. 2016, 42, 30–39.

- Branco, R.H.R.; Serafim, L.S.; Xavier, A.M.R.B. Second generation bioethanol production: On the use of pulp and paper industry wastes as feedstock. Fermentation 2019, 5, 4.

- Zhang, Z.; Macquarrie, D.J.; de Bruyn, M.; Budarin, V.L.; Hunt, A.J.; Gronnow, M.J.; Fan, J.; Shuttleworth, P.S.; Clark, J.H.; Matharu, A.S. Low-temperature microwave-assisted pyrolysis of waste office paper and the application of bio-oil as an Al adhesive. Green Chem. 2015, 17, 260–270.

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Waste paper: An underutilized but promising source for nanocellulose mining. Waste Manag. 2020, 102, 281–303.

- Gonzalez-Estrella, J.; Asato, C.M.; Jerke, A.C.; Stone, J.J.; Gilcrease, P.C. Effect of structural carbohydrates and lignin content on the anaerobic digestion of paper and paper board materials by anaerobic granular sludge. Biotechnol. Bioeng. 2017, 114, 951–960.

- Schmitt, E.; Bura, R.; Gustafson, R.; Cooper, J.; Vajzovic, A. Converting lignocellulosic solid waste into ethanol for the State of Washington: An investigation of treatment technologies and environmental impacts. Bioresour. Technol. 2012, 104, 400–409.

- Singh, Y.D.; Satapathy, K.B. Conversion of lignocellulosic biomass to bioethanol: An overview with a focus on pretreatment. Int. J. Eng. Technol. 2018, 15, 17–43.

- He, M.; Yang, G.; Chen, J.; Ji, X.; Wang, Q. Production and characterization of cellulose nanofibrils from different chemical and mechanical pulps. J. Wood Chem. Technol. 2018, 38, 149–158.

- Lahtinen, P.; Liukkonen, S.; Pere, J.; Sneck, A.; Kangas, H. A Comparative study of fibrillated fibers from different mechanical and chemical pulps. BioResources 2014, 9, 2115–2127.

- Borrega, M.; Sixta, H. Purification of cellulosic pulp by hot water extraction. Cellulose 2013, 20, 2803–2812.

- Koshijima, T.; Watanabe, T. Association between Lignin and Carbohydrates in Wood and Other Plant Tissues; Springer: Berlin/Heidelberg, Germany, 2003.

- Faruk, O.; Sain, M. Lignin in Polymer Composites, Lignin in Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2016.

- Malakahmad, A.; Ahmad Basri, N.E.; Md Zain, S. Production of renewable energy by transformation of kitchen waste to biogas, case study of Malaysia. In Proceedings of the IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA), Langkawi, Malaysia, 25–28 September 2011; pp. 219–223.

- Prasetyo, J.; Park, E.Y. Waste paper sludge as a potential biomass for bio-ethanol production. Korean J. Chem. Eng. 2013, 30, 253–261.

- Nishimura, H.; Tan, L.; Sun, Z.; Tang, Y.; Kida, K.; Morimura, S. Efficient production of ethanol from waste paper and the biochemical methane potential of stillage eluted from ethanol fermentation. Waste Manag. 2016, 48, 644–651.

- Farghaly, A.; Elsamadony, M.; Ookawara, S.; Tawfik, A. Bioethanol production from paperboard mill sludge using acid-catalyzed bio-derived choline acetate ionic liquid pretreatment followed by fermentation process. Energy Convers. Manag. 2017, 145, 255–264.

- Lin, Y.; Wang, D.; Wang, T. Ethanol production from pulp & paper sludge and monosodium glutamate waste liquor by simultaneous saccharification and fermentation in batch condition. Chem. Eng. J. 2012, 191, 31–37.

- Peretz, R.; Mamane, H.; Wissotzky, E.; Sterenzon, E.; Gerchman, Y. Making cardboard and paper recycling more sustainable: Recycled paper sludge for energy production and water-treatment applications. Waste Biomass Valorization 2020, 12, 1599–1608.

- Schroeder, B.G.; Zanoni, P.R.S.; Magalhaes, W.L.E.; Hansel, F.A.; Tavares, L.B.B. Evaluation of biotechnological processes to obtain ethanol from recycled paper sludge. J. Mater. Cycles Waste Manag. 2017, 19, 463–472.

- Mussatto, S.I. Biomass Fractionation Technologies for a Lignocellulosic Feedstock Based Biorefinery; Elsevier: Amsterdam, The Netherlands, 2016.

- Elliston, A.; Collins, S.R.A.; Wilson, D.R.; Roberts, I.N.; Waldron, K.W. High concentrations of cellulosic ethanol achieved by fed batch semi simultaneous saccharification and fermentation of waste-paper. Bioresour. Technol. 2013, 134, 117–126.

- Boshoff, S.; Gottumukkala, L.D.; van Rensburg, E.; Görgens, J. Paper sludge (PS) to bioethanol: Evaluation of virgin and recycle mill sludge for low enzyme, high-solids fermentation. Bioresour. Technol. 2016, 203, 103–111.

- Wang, L.; Sharifzadeh, M.; Templer, R.; Murphy, R.J. Bioethanol production from various waste papers: Economic feasibility and sensitivity analysis. Appl. Energy. 2013, 111, 1172–1182.

- Robus, C.L.L.; Gottumukkala, L.D.; Rensburg, V.; Johann, F.G. Feasible process development and techno-economic evaluation of paper sludge to bioethanol conversion: South African paper mills scenario. Renew. Energy 2016, 92, 333–345.

- TAPPI, Forming Handsheets for Physical Tests of Pulp (Reaffirmation of T 205 sp-02). 2006. Available online: https://www.tappi.org/content/sarg/t205.pdf (accessed on 11 July 2006).

- Rocha, J.M.T.S.; Alencar, B.R.A.; Mota, H.G.; Gouveia, E.R. Enzymatic hydrolysis of waste office paper for ethanol production by spathaspora passalidarum. Cellul. Chem. Technol. 2016, 50, 243–246.

- Maslennikov, A.; Peretz, R.; Vadivel, V.K.; Mamane, H. Recycled Paper Sludge (RPS)-Derived Nanocellulose: Production, Detection and Water Treatment Application. Appl. Sci. 2022, 12, 3077.

- Marques, S.; Matos, C.T.; Girio, F.M.; Roseiro, J.C.; Santos, J.A.L. Lactic acid production from recycled paper sludge: Process intensification by running fed-batch into a membrane-recycle bioreactor. Biochem. Eng. J. 2017, 120, 63–72.

- Adu, C.; Jolly, M.; Kumar Thakur, V. Exploring new horizons for paper recycling: A review of biomaterials and biorefinery feedstocks derived from wastepaper. Curr. Opin. Green Sustain. Chem. 2018, 13, 21–26.

- Duncan, S.M.; Alkasrawi, M.; Gurram, R.; Almomani, F.; Wiberley-Bradford, A.E.; Singsaas, E. Paper mill sludge as a source of sugars for use in the production of bioethanol and isoprene. Energies 2020, 13, 4662.

- Annamalai, N.; Sivakumar, N.; Oleskowicz-popiel, P. Enhanced production of microbial lipids from waste office paper by the oleaginous yeast Cryptococcus curvatus. Fuel 2018, 217, 420–426.

- Frias, M.; Vegas, I.; Virgil de la Villa, R.; Gimenez, R.G. Recycling of waste paper sludge in cements: Characterization and behavior of new eco-efficient matrices. In Integrated Waste Management; InTech Open: London, UK, 2011; pp. 302–318.

- Namdarimonfared, M.; Zilouei, H.; Tondro, H. Biological hydrogen production from paper mill effluent via dark fermentation in a packed bed biofilm reactor. Fuel 2023, 338, 127231.

- Kolbl, S.; Forte-Tavcer, P.; Stres, B. Potential for valorization of dehydrated paper pulp sludge for biogas production: Addition of selected hydrolytic enzymes in semi-continuous anaerobic digestion assays. Energy 2017, 126, 326–334.

- Gogoi, H.; Nirosha, V.; Jayakumar, A.; Prabhu, K.; Maitra, M.; Panjanathan, R. Paper mill sludge as a renewable substrate for the production of acetone-butanol-ethanol using Clostridium sporogenes NCIM 2337. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 39–44.

- Reckamp, J.M.; Garrido, R.A.; Satrio, J.A. Selective pyrolysis of paper mill sludge by using pretreatment processes to enhance the quality of bio-oil and biochar products. Biomass.-Bioenergy 2014, 71, 235–244.

- Shi, T.; Liu, Y.; Yang, A.; Sun, S.; Shen, W.; Ren, J. Developing a novel gasification-based sludge-to-methanol utilization process and exergy-economic-environmental (3E) analysis. Energy Convers. Manag. 2022, 260, 115600.

- Gurram, R.N.; Al-Shannag, M.; Lecher, N.J.; Duncan, S.M.; Singsaas, E.L.; Alkasrawi, M. Bioconversion of paper mill sludge to bioethanol in the presence of accelerants or hydrogen peroxide pretreatment. Bioresour. Technol. 2015, 192, 529–539.

- Romani, A.; Del-Rio, P.G.; Rubira, A.; Jose Perez, M.; Garrote, G. Co-valorization of discarded wood pinchips and sludge from the pulp and paper industry for production of advanced biofuels. Ind. Crops Prod. 2024, 209, 117992.

- Prasetyo, J.; Naruse, K.; Kato, T.; Boonchird, C.; Harashima, S.; Park, E.Y. Bioconversion of paper sludge to biofuel by simultaneous saccharification and fermentation using a cellulase of paper sludge origin and thermotolerant Saccharomyces cerevisiae TJ14. Biotechnol. Biofuels Bioprod. 2011, 4, 35.

- Monrroy, M.; García, J.R.; Mendonça, R.T.; Baeza, J.; Freer, J. Kraft pulping of Eucalyptus globulus as a pretreatment for bioethanol production by simultaneous saccharification and fermentation. J. Chil. Chem. Soc. 2012, 57, 1113–1117.

- Ko, C.-H.; Wang, Y.-N.; Chang, F.-C.; Chen, J.-J.; Chen, W.-H.; Hwang, W.-S. Potentials of lignocellulosic bioethanols produced from hardwood in Taiwan. Energy 2012, 44, 329–334.

- Buzała, K.P.; Kalinowska, H.; Małachowska, E.; Przybysz, P. The utility of selected kraft hardwood and softwood pulps for fuel ethanol production. Ind. Crop. Prod. 2017, 108, 824–830.

- Xavier, A.M.R.B.; Correia, M.F.; Pereira, S.R.; Evtuguin, D.V. Second-generation bioethanol from eucalypt sulphite spent liquor. Bioresour. Technol. 2010, 101, 2755–2761.

- Johansson, E.; Xiros, C.; Larsson, C. Fermentation performance and physiology of two strains of Saccharomyces cerevisiae during growth in high gravity spruce hydrolysate and spent sulphite liquor. BMC Biotechnol. 2014, 14, 47.

- Wang, W.; Kang, L.; Lee, Y.Y. Production of cellulase from Kraft paper mill sludge by Trichoderma Reesei Rut C-30. Appl. Biochem. Biotechnol. 2010, 161, 382–394.

- EURACTIVE. EU Paper Recyclers ‘in Crisis’ as China Waste Import Ban Bites. 2019. Available online: https://www.euractiv.com/section/circular-economy/news/eu-paper-recyclers-in-crisis-as-china-waste-import-ban-bites/ (accessed on 27 August 2019).

- Rendon, M.; Espluga-Trenc, J.; Verd, J.M. Assessing the functional relationship between the formal and informal waste systems: A case-study in Catalonia (Spain). Waste Manag. 2021, 131, 483–490.

- The Wall Street Journal. What Cardboard Prices Tell Us about the State of the Economy. 2023. Available online: https://www.wsj.com/business/the-rising-price-of-cardboard-a-positive-sign-for-the-economy-08908d0f (accessed on 13 December 2023).

- Sahin, B.; Yilmaz, H.; Ust, Y.; Guneri, A.F.; Gulsun, B. An approach for analysing transportation costs and a case study. Eur. J. Oper. Res. 2009, 193, 1–11.

- Wu, W.; Hasagawa, T.; Fujimori, S.; Takahashi, K.; Oshiro, K. Assessment of bioenergy potential and associated costs in Japan for the 21st century. Renew. Energy 2020, 162, 308–321.

- Peretz, R.; Sterenzon, E.; Gerchman, Y.; Vadivel, V.V.; Luxbacher, T.; Mamane, H. Nanocellulose production from recycled paper mill sludge using ozonation pretreatment followed by recyclable maleic acid hydrolysis. Carbohydr. Polym. 2019, 216, 343–351.

- Simoes, F.; Rios-Devila, F.J.; Paiva, H.; Maljaee, H.; Morais, M.; Ferreira, V.M. Sustainability evaluation using a life cycle and circular economy approach in precast concrete with waste incorporation. Appl. Sci. 2021, 11, 11617.

- Liuzzi, S.; Rubino, C.; Martellotta, F.; Stefanizzi, P. Sustainable materials from waste paper: Thermal and acoustical characterization. Appl. Sci. 2023, 13, 4710.

- Donkor, K.O.; Gottumukkala, L.D.; Diedericks, D.; Gorgens, J.F. An advanced approach towards sustainable paper industries through simultaneous recovery of energy and trapped water from paper sludge. J. Environ. Chem. Eng. 2021, 9, 105471.

- Haites, E. Carbon taxes and greenhouse gas emissions trading systems: What have we learned? Clim. Policy 2018, 18, 955–966.

- Phillips, R.B.; Jameel, H.; Chang, H.M. Integration of pulp and paper technology with bioethanol production. Biotechnol. Biofuels 2013, 6, 13.

- Wu, S.; Jameel, H.; Chang, H.M.; Phillips, R. Techno-economic analysis of the optimum softwood lignin content for the production of bioethanol in a repurposed kraft mill. BioResources 2014, 9, 6817–6830.

- Rueda, C.; Marinova, M.; Paris, J.; Ruiz, G.; Coz, A. Technoeconomic assessment of different biorefinery approaches for a spent sulfite liquor. J. Chem. Technol. Biotechnol. 2016, 91, 2646–2653.

- Petersen, A.M.; Daful, A.G.; Görgens, J.F. Technical, economic, and greenhouse gas reduction potential of combined ethanol fermentation and biofuel gasification-synthesis at sulphite pulping mills. Energy Fuels 2016, 30, 7387–7399.

- Fan, Z.; Lynd, L.R. Conversion of paper sludge to ethanol, II: Process design and economic analysis. Bioprocess. Biosyst. Eng. 2007, 30, 35–45.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

767

Revisions:

4 times

(View History)

Update Date:

30 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No