1. Introduction

The energy sector plays a crucial role in the growth of national economies as a production factor oriented to integrate innovation solutions to reduce energy generation costs and improve the quality of the carriers used for delivering energy to end-users and as a growth factor to support and facilitate the pursuit of the decarbonization targets defined by the national and European strategic agendas

[1]. Renewable Energy Source (RES), energy efficiency, and flexibility in final energy use are among the priority measures to foster sustainable development of an energy system as a whole

[2][3]. The development of RES integrated with high-efficiency systems is essential since they are usually characterized by low environmental impacts and contribute to increasing the penetration of distributed generation and cogeneration systems within traditional networks. Furthermore, renewable technologies can also be seen as the main driver for accelerating the development of smart grids and Energy Communities (ECs)

[4][5][6][7].

The renewable energy supply chain, although characterized by different levels of technological maturity and economic competitiveness, generally requires industrial research, innovation, and competitive development efforts: (i) to reduce CAPital EXpenditure (CAPEX) and OPerating Expenditure (OPEX) costs related to the implementation of the energy technologies involved; (ii) to optimize performance and increase the system’s efficiency and reliability; (iii) to develop hybridization and RES integration solutions for the combined generation of electricity and heat with the aid of distributed energy storage systems; (iv) to develop and implement advanced control logic and management systems

[8].

Among the various renewable technologies for electricity production, systems based on solar energy, including photovoltaic (PV) systems and concentrating solar power (CSP) systems, are the most widely used

[9]. Currently, PV systems are dominating the market for solar energy production, accounting for approximately 98% of new annual installations of solar-based systems on a global scale

[10]. In 2021, PV systems with a total capacity of 848.4 GW and CSP systems for 6.4 GW were installed. Overall, over the last decade, the solar technology sector has seen growth of 719%, with installed capacity increasing from 104.3 GW in 2012 to 854.8 GW in 2021

[11][12]. Furthermore, over the same period, the installed capacity of CSP increased by 149% globally

[11]. Unlike PV technology, which directly converts solar energy into electricity, CSP systems concentrate direct normal irradiance (DNI) onto a receiver through mirrors or lenses

[13], allowing the conversion of concentrated solar radiation into thermal energy at high temperatures, which is then transformed into mechanical energy by means of a thermodynamic cycle. Mechanical energy is thus converted into electricity

[14][15].

Despite the countless benefits related to RES integration, this brings new challenges to energy systems, such as the risk of imbalance between energy generation and demand, sudden changes in flows in transmission lines with a need for expensive and time-consuming upgrades, and, moreover, withdrawal of conventional generation systems with consequent demands for new solutions and innovation to support grid service provision

[16]. A potential solution that limits the huge intermittence and fluctuation in power generation from RES and makes it usable, even when the primary resource (e.g., wind and sun) is not available, is the CSP technology integrated with long-term thermal energy storage (TES)

[17]. In fact, predictability, the reliability of production, and dispatchability are achievable thanks to the integration with thermal storage, high efficiency in terms of costs, low use of critical raw materials, and the potential employment of recyclable materials with low environmental impact represent the main advantages of CSP technology.

The CSP systems can be broadly classified into two main categories: line-focusing and point-focusing

[18]. Line-focusing systems, such as linear parabolic systems and linear Fresnel reflectors, use long, curved mirrors to concentrate solar radiation onto a receiver tube positioned along the focal line. The receiver tube contains a heat transfer fluid (HTF) that is heated up by concentrated solar radiation, and the resulting thermal energy is then used to generate steam and supply a turbine to produce electricity. On the other hand, point-focusing systems, including dish-Stirling systems and solar towers, concentrate solar radiation on a single point or a small area. Dish-Stirling systems use a paraboloid-shaped collector to reflect and concentrate the direct solar radiation incident on the focal point where the power conversion unit (PCU) is installed. This is achieved through a biaxial solar tracking system, which can maintain continuous alignment between the focal axis and the direction of the sun’s rays, following the apparent position of the sun in the sky during the day. The PCU includes the receiver, the engine for the conversion of thermal energy into mechanical energy (e.g., through a Stirling engine or a microturbine), and the electric generator for converting mechanical energy into electrical energy. The receiver permits the most elevated temperature level of the thermodynamic cycle to be kept up by managing heat to the hot chamber of the Stirling engine, whereas a cooling system removes the heat from the cold chamber, wasting it through the environment, to preserve the level of the lower temperature of the cycle

[18]. Solar tower systems are characterized by a series of mirrors or heliostats that reflect incident solar irradiance onto a central receiver located at the top of a tower. The receiver absorbs concentrated radiation and transfers the resulting thermal energy to an HTF. The latter is then used to produce steam and generate electricity.

Several factors may influence the performance of CSP systems, such as the outside air temperature, the level of DNI, and the fouling factor of the reflective surface

[19]. Among these, the DNI level is the factor having the greatest influence on the manufacturability of a CSP system and essentially depends on the geographical location of the installed plant. The regions of the Sun Belt, North Africa (MENA), South Africa, the Middle East, Australia, Chile, and south-western Europe offer the most favorable conditions for the installation of CSP systems, thanks to the abundance of direct solar radiation. All operational, non-operational, and CSP projects under construction are located in these areas, as indicated by Solar Power and Chemical Energy Systems (SolarPACES)

[20].

The Italian SOLARGRID Project (Thermodynamic and Photovoltaic Solar Systems with Storage for co-generation and network flexibility)

[21] is collocated in this context. The main goal of the project is indeed to achieve a technical–economical optimization and improved competitiveness of CSP and thermodynamic solar technology based on the use of parabolic trough and linear Fresnel systems by means of technological improvements on solar tracking systems, as well as the identification of improved solutions for CSP technology based on the use of centralized “beam-down” tower systems with fluidized-beds TES, in order to improve the energy performance, with a key focus on system optics. The SOLARGRID project also aims at maximizing research implications in concrete industrialization and market activities to translate the demand for innovative technologies and components into development opportunities and competitive growth for the national industry, thereby helping support a cost-effective energy transition and encouraging the creation of new business models. Developed in the framework of the SOLARGRID project, the main contribution of this work is to comprehensively discuss the key benefits and challenges related to the use of CSP technology by presenting innovative industrial solutions and methodologies aiming at the improvement of the technical performance and the reduction of the levelized cost of electricity (LCOE) of CSP. A detailed critical analysis of the CSP technology is first presented, focusing attention on the main technical and technological solutions, their implementation and development status, and key issues and challenges to address for massive deployment. Then, the advantages deriving from the development of innovative industrial solutions for CSP components and systems are presented by exploring the enhancement of flexibility and the increased reliability achieved by coupling CSP and PV technologies, the proposed new concept related to the STEM technologies of Magaldi Power S.p.A., the advanced parabolic trough collector realized by Eni S.p.A., and the new linear Fresnel reflector (LFR) concept developed by IDEA S.r.l. All these innovative solutions aim to reduce the LCOE and improve the technical performance of CSP, making them competitive with other renewable technologies for electrical and thermal energy production.

2. Analysis of Concentrated Solar Power Technology and Future Perspectives

2.1. Line-Focusing CSP Systems

2.1.1. Linear Parabolic Systems

Linear parabolic collectors consist of a concentrator that has a linear parabolic profile, with reflective surfaces that follow the sun, through a rotation mechanism on a single axis, to focus the solar radiation on a receiver tube positioned along the focus of the parabola. The solar energy absorbed by the receiver tube is transferred to a working fluid that is an HTF.

The HTF most used in these systems is synthetic oil, which has a maximum operating temperature of approximately 400 °C, which limits the conversion efficiency of the power generation cycle. For this reason, researchers and industry have developed advanced HTFs capable of reaching higher temperatures (up to 600 °C). One example is the use of molten salts. This “second generation” of the HTF is expected to lead to significant improvements in average conversion efficiency and further reductions of energy production cost. Although some demonstration plants have already been built with these “second generation” HTFs, more operational experience is still needed

[22].

The existing CSP plants represent 78% (approximately 4900 MW) of the total installed and operational capacity. PT technology can be considered “mature” as several manufacturers are available for building entire plants or subsystems. There is good experience (at least 20 years) in the procurement, design, construction, and operational management of these systems, and good functional reliability has been achieved

[20][22][23].

Most of the PT solar plants currently in operation are designed to produce electricity. These plants have sizes from 15 to 100 MWe, an average overall efficiency of 14–16% (in terms of the ratio between net electrical energy produced and input solar energy), and a maximum operating temperature of 390 °C due to the stability limits of the HTF (synthetic oil). Most of these systems are sized to store high quantities of thermal energy using TES systems based on double tanks of molten salts.

The architecture of the PT solar field is similar for all the installations. Usually, the solar field has a square plan, and in its center, there is a TES and power block. The solar field is composed of different strings of solar collectors. Every string is linked with a power block and TES through a pipe loop connected with all solar strings. Every string is composed of two or more lines of solar collectors with a length ranging between 300 and 400 m. Each line is made up of 3–4 solar collectors. Each solar collector consists of a series of aligned manufactured modules, generally 4 m long, supported by pylons. The central pylon is equipped with a tracking system to move the PT and follow the sun’s position with respect to the horizon line. The collector movement system can be hydraulic or electromechanical and is controlled through optical pointing devices or software tools aimed at calculating the position of the sun at any moment. In large systems, each collector is typically 100 m long, with an opening to the order of 6 m. Recently, collectors up to 190 m long, with an opening greater than 8 m, have been introduced in power generation plants. In PT systems aiming at producing process heat, the dimensions are generally smaller (lengths of 50 m and openings of 2–3 m).

PT collectors (PTC) had a strong development in the 1980–1990 years, with the construction of nine plants for a total power of 354 MW in the California desert. The construction of new thermodynamic solar plants based on PT technology came to a halt until 2000 when a new development program on an industrial scale began in Spain, which led to the construction of 45 PTC CSP plants for a total installed power capacity of about 1.8 GW (2.3 GW total CSP).

PT systems are suitable for a hybrid operation called integrated solar combined cycle (ISCC), where the steam generated by the solar source is fed into a thermal power plant, which also uses fossil fuels (usually natural gas) to generate steam. Examples of operational CSP and ISCC plants are the 25 MW-Hassi R’mel in Algeria, the 20 MW-Al Kuraymat in Egypt, and the 20 MW-Ain Beni Mathar in Morocco (the other three ISCC plants are currently under construction, namely two in Saudi Arabia and one in Mexico)

[22]. The main benefits of PT systems are essentially related to the simple design of optical systems, that also guarantee high concentration ratios, and to the possibility of assimilating commercial CSP systems to parabolic collectors that use oil as the HTF to other types of industrial plants, thus taking advantage of existing industrial supply chains. Currently, the minimal annual level of DNI required for a CSP plant to become profitable is 1800–2000 kWh/m

2 per year, while for the process heat generation, a significantly lower threshold DNI is requested (1200–1300 kWh/m

2), which explains the development of some applications in certain northern countries, such as Denmark (Aalborg 2020)

[24] and Belgium (Oostende, ADPO, Port of Antwerp).

With specific reference to Italy, the suitable geographical areas for large-scale CSP applications for power generation—considering the current installation costs and the optimal conditions for their use—are limited only to a limited part of the national territory as Sicily, southern Puglia, and part of Sardinia

[25]. Disused industrial areas or exhausted landfills represent the best conditions for installation, as these systems represent a useful way to redevelop the environment. In this context, the capacity of solar thermal power plants to bulk store the collected solar energy at low cost is an asset for their future deployment. In 2011, the Italian potential of CSP technology was estimated at 600 MW

[26], but to date, only 5 MW have been installed. More factors have contributed to not reaching the goal set in 2011. The Italian stakeholders have individuated two key factors as the reason why the CSP did not spread to Italy as expected. The first problem was the lag between the release of the ministerial decrees with incentives for solar thermodynamic and the actual complex authorization process. A problem that started with the first decrees of 2008 and continued in 2012 with the lack of authorizations, mostly at the regional level. The 2016 decree, which allowed incentives for large CSP plants through auctions, was not successful, as the auctions had to close in 3–4 months and no investor, even though this time with the authorizations in hand, had enough time to investigate on the return of investment in power plants with the CSP technology. Furthermore, the decree provided for the payment of a high deposit via bank guarantee, to be paid only to participate in the auction. The second factor that has blocked the sector is linked to the distrust of local communities in accepting the technology. Policies related to climate change and objectives related to the implementation of the European Green Deal may represent a new opportunity for PTC system technology in Italy and Europe.

The CSP plants, coupled with thermal storage, can play a key role by supporting a smart integration of RES. On the other hand, the large-scale CSP plants can help to cope with grid and flexibility issues on a broader level. In detail, the CSP systems, coupled with long-term TES, represent a better solution for a power grid characterized by variable electrical loads than a power grid characterized by constant electrical demand. This is because CSP plants can be designed to feed an optimized average load profile derived from the interpolation of the valleys and peaks of the load profile. This allows for reducing the solar multiple (and therefore the size of the mirror field) and the capacity of the TES, resulting in a lower cost compared to a scenario with constant demand. This characteristic can enhance coupling PTC–CSP plants with other RES like PV and/or Wind.

The integrated CSP–PTC/PV systems coupled with molten salt storage systems allow solar energy to be injected into the grid in a flexible and programmable way to follow the demand curve, thus minimizing the effects of the fluctuations of the renewable source on the management of the power grid and maximizing coverage of the load from solar source

[27]. This characteristic allows integrated CSP–PTC/PV systems to be considered a technical solution particularly suitable for Italy. Several analyses have shown that hybrid CSP/PV plants with a size of 50 MW built in peninsular Italy would be able to satisfy almost 70% of the hourly electricity load

[28]. With the same load profile considered, the integration between PV and CSP allows a greater share of the demand to be satisfied (compared to a pure CSP system) by reducing the cost of the energy produced (i.e., LCOE) from 10% to 30%. This is possible because the addition of a relatively simple and low-cost specific component, such as PVs, reduces the size of the more expensive components of the CSP section, such as the solar field and the power block. Additionally, the possibility of converting the excess PV production into heat through the electrical resistors of the TES, though thermodynamically inefficient, is successful from an economic point of view in increasing the dispatchability of PVs. In fact, the latter allows for exploiting the TES already present, which is also less expensive, instead of the battery characterized by high specific cost. Moreover, in the hybridization between CSP and wind and between CSP and PVs, wind is of particular interest since the trends of wind speed and solar radiation are not synchronous but, on the contrary, tend to be complementary

[29].

The production of carbon-free heat for industrial, civil, and thermochemical applications is increasingly being considered by the scientific community as the very field of application of CSP technology for countries such as Italy, where the DNI does not reach high levels for long seasonal periods. Also, in this application, the coupling of CSP with thermal storage is fundamental. There are several hundred large solar thermal systems serving industries around the world. In these applications, PTC systems are mainly used for preheating feed water in steam boilers

[30]. Moreover, in small-scale PTC systems, they can play an important role by feeding the users for thermal purposes in the building sector, as well as by producing industrial process heat for district heating, often enhanced with TES.

In this sector, among the new applications, the mini-CSP and the PTC–CST systems devoted to the co-production of electrical and thermal energy-serving ECs are of high interest. The mini-CSP refers to the use of thermodynamic solar technologies in small thermal or cogeneration applications (1 MW or slightly more), with smaller collectors, lower temperature of the HTF (no more than 350 °C), and the possibility of installation on the buildings’ roofs and industrial plants. These systems can find convenient applications in the industrial field to produce or process heat or in the tertiary sector for air conditioning purposes

[31]. The PTC systems can be conveniently used to feed users that need low-temperature heat (<80 °C) and electricity. In this case, the PTC systems are coupled to Organic Rankine Cycle (ORC) or steam turbines, where the heat is the by-product of the thermodynamic process used in the power block. The use of PTC systems to directly feed users for thermal purposes is convenient only when the required temperature is higher than 120 °C

[32].

In Italy, the food industries, agricultural product processing, and the chemical and petrochemical sectors, in which the use of heat at temperatures between 100 and 400 °C is expected, seem to be the most promising applications for CST systems based on linear PT systems. In these sectors, the technological challenge lies in the development of modular, expandable, and integrable concentrated solar technologies and in the identification of proper management and operation strategies to ensure stable operation of the process and reduced operating and maintenance costs

[30].

The analysis of the cost of heat production from CST plants located in central and peninsular Italy for different thermal levels

[33] shows that the cost of heat, in terms of Levelized Cost Of Heat (LCOH), currently stands on average between 5 and 7 c€/kWh

th (considering an average solar field cost of 200 €/m

2). The DNI characteristic of the installation sites significantly affects the final cost of the heat produced, with percentage variations in the LCOH ranging between 10 and 50%. The cost item with the greatest impact on the LCOH is the supply of the solar field (25–35%), followed by thermal storage, which represents 15% of the LCOH

[33]. The integration of storage systems with CST plants determines an increase in CAPEX between 50 and 200%, depending on the hours of storage, and an increase in LCOH of approximately 5–20%

[33]. These higher costs are compensated by the possibility of better integration of the CST systems with industrial processes. In this sense, the presence of the storage allows for increasing both the production hours and the stability of the thermal levels of the heat produced.

In Italy, a potential and promising application sector of PTC systems that has not been developed yet is the cooling sector of large buildings. All solar cooling systems are built using single-effect absorption machines. The use of double-effect absorption machines, and therefore of medium-temperature solar collectors, has the notable advantage of requiring a smaller collecting surface (about 40% compared to the single-effect machine and flat-plate solar collector solution)

[32]. The development of medium-temperature solar collectors, which are also small, modular, and integrated with the roofing surface of buildings, could foster the creation of solar cooling systems by positioning the PTC collectors on otherwise unused spaces.

A local industry capable of producing the components for PT plants and, in general, a strong supply chain makes a country more attractive for the installation of CSP plants. The need to reduce CO2 emissions in highly urbanized areas, where installation sites are usually not available for the construction of large-scale CSP, is pushing research in the direction of developing medium-, small- or even micro-PTC solutions. They aim to optimize distributed generation, making an important contribution to Solar Heat for Industrial Processes (SHIP) solutions (heat at medium temperature for industrial processes) as well as positive energy districts in residential applications or heat and cooling solutions. Moreover, the growing interest in renewable energy communities could represent a new stimulus for the development of solutions based on linear concentration solar technologies for the harnessing of thermal energy in a heat and power cascade in urban areas.

The analysis elaborated on the potential barriers to the development of CST technology in Europe

[33][34], highlighting that a mix of complementary policy measures is required to either activate drivers or mitigate barriers to CSP deployment in the future. The adoption of long-term targets, ensuring predictable changes in the remuneration for new plants, and avoiding retroactive changes for existing plants are considered by key stakeholders as essential elements for the CSP deployment

[34][35]. The improvement of the performance and the cost reduction are important key drivers for their deployment. Some of the key Research and Development (R&D) actions identified to foster the enhancement of the diffusion of the PTC technology are listed in

Table 1 [36]:

Table 1. Key R&D actions identified to foster the spread of the PTC technology.

| Key R&D Actions |

Expected Improvements for the PTC Technology |

| Thin, low-cost mirrors with high (95%) reflectivity and low focal deviation |

Increase in efficiency by up to 3% |

| High-absorptance coating |

Increase in efficiency by up to 4%. |

| Employment of alternative HTFs (e.g., molten salts, chlorite) |

Increase in overall efficiency |

| New mirror supports (stamped steel, aluminum, composites) and foundations |

Reduction of costs |

| Special coatings |

Reduction of cleaning and washing needs |

| Innovative robotic systems and module layout |

Reduction of cleaning costs and installation costs. |

On the other hand, policies to encourage public–private partnerships, the cooperation between the industrial sector and the Research, Development, and Deployment (RD&D) sector on deployment projects, and support for collaboration at national and international levels are considered by key stakeholders as essential to remove or mitigate specific barriers (“proven technology,” “cost reductions,” and “technology risk”) and activate related drivers

[34]. All these measures would also support “local manufacturing capabilities.”

2.1.2. Linear Fresnel reflectors

A typical linear Fresnel collector essentially includes two subsystems represented by the primary optical system and the secondary receiver. The primary optic system includes (i) the primary mirrors realizable in glass, metal, and plastic film; (ii) the mirror support, fabricable in metal, composite material, and structural sandwich; (iii) the mechatronic tracking system. The latter can include either linear actuators or specially designed geared motor systems, together with an astronomical type of control system based on solar sensors or a combination of astronomical tracking and pointing systems. The secondary receiver includes the secondary mirror, usually made of metal reflective sheets and the tubular absorber.

LFR systems, in their decades-long evolution, have explored numerous combinations of the above solutions. Numerous design concepts have been analyzed and proposed, and some of them have progressed to engineering design and prototyping. The first significant linear Fresnel collector was patented and prototyped by Giovanni Francia in Italy in 1964. This pioneering installation was not followed by significant industrial developments until the 2000s, characterized by a general revival of interest in CSP technologies. The first decade of the century saw the testing of the Solarmundo prototype in Belgium, the demonstration of the FRES DEMO project at the Plataforma Solar de Almeria (PSA) in Spain, the FERA collector prototype (CSP-F Solar) installed in Italy, and the German Mirroxx LFR system

[37].

In the following decade, some LFR collectors were perfected for high-temperature applications. In particular, Novatec Solar (now Frenell) and Areva Solar represented the leaders in this type of application. The Novatec/Frenell system uses vacuum receiver tubes with a secondary reflector to reach temperatures up to 550 °C, while Areva Solar (formerly Ausra) installed a receiver assembly that includes multiple unevacuated steel receiver tubes

[38]. SkyFuel has also made efforts to develop high-temperature LFR collectors using its ReflecTech reflective film technology in DOE-funded activities

[39]. These players are joined by France’s SunCNIM with a collector usable for CSP and SHIP applications tested in a pilot plant

[40].

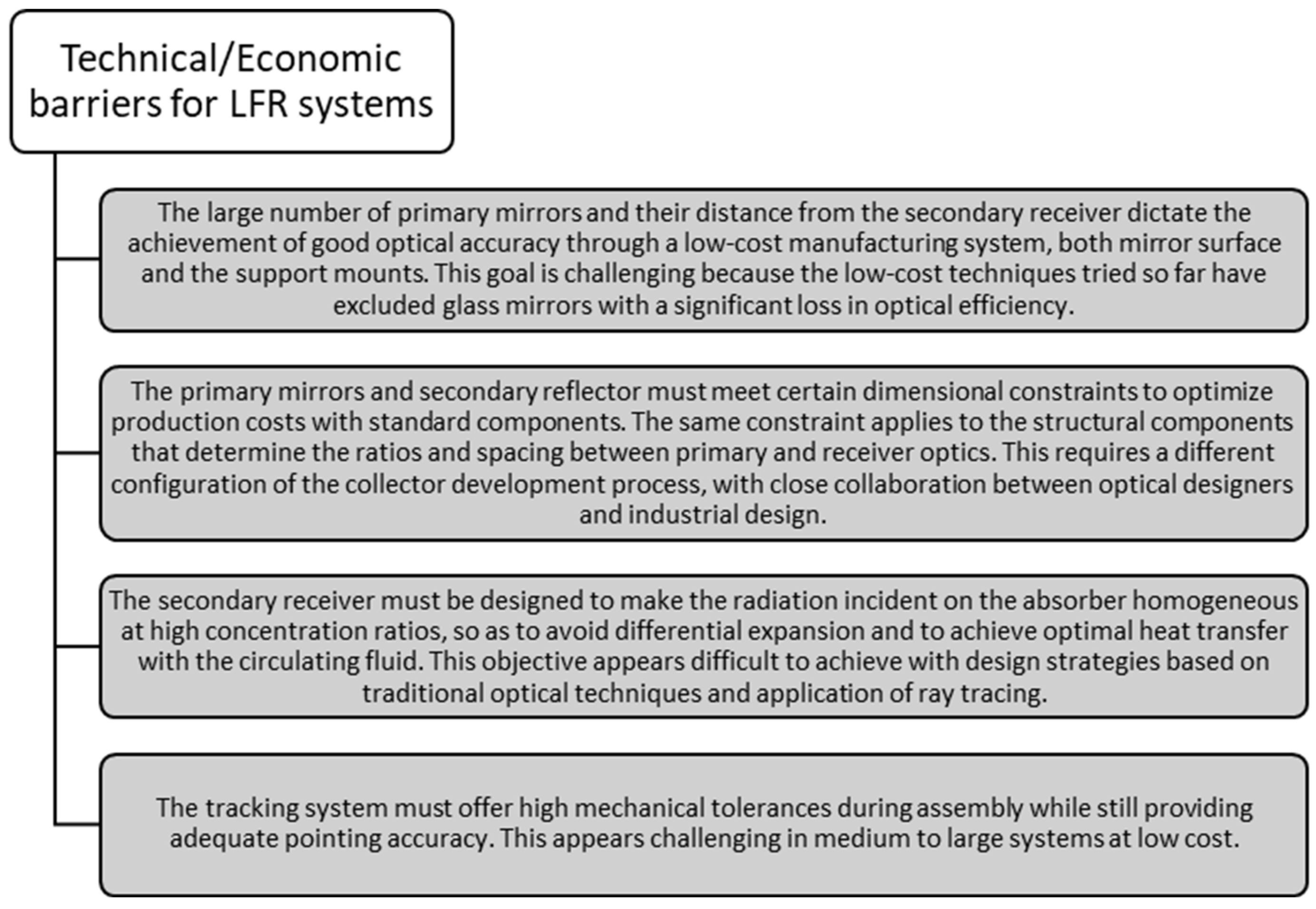

Compared to parabolic systems, linear Fresnel collectors suffer from lower optical efficiency. However, linear Fresnel technology offers the ability to increase the concentration ratio, and therefore the receiver temperature, by increasing the aperture area of the reflector without substantially changing the design requirements of the system. For this reason, the LFR poses no difficulty, either structurally or mechanically, in attempting to maximize the geometric concentration ratio of the collector (i.e., the ratio of the mirror aperture to the receiver aperture) to achieve higher output temperatures. Finally, the drive system can be shared between mirrors of the same module, or it is possible to exploit coupling between adjacent modules to reduce the number of mechatronic components. However, there are still several technical/economic barriers to the deployment of this technology that require further investment in research and development, as indicated in Figure 1.

Figure 1. Technical/Economic barriers identified for LFR systems.

2.2. Point-Focusing CSP Systems

2.2.1. Dish-Stirling Systems

Compared to other CSP technologies, dish-Stirling systems as point-focusing CSP have some advantages that make them an attractive choice for solar power generation. One of them is the high geometric concentration factor. The paraboloid shape of the reflector allows the concentration of incident solar radiation on a small focal point, with the consequent increase in both the energy density concentrated there and the upper limit of the operating temperature range. This explains how, in terms of energy efficiency, dish-Stirling solar concentrators hold the record for the efficiency of converting solar energy into electricity under nominal conditions

[19]. Another advantage of dish-Stirling systems is the modular design. In fact, these systems can be built in a modular way, guaranteeing a high degree of flexibility and adaptability to energy generation on various scales

[41]. Furthermore, dish-Stirling systems have a low level of land occupation compared to other solar technologies thanks to their high concentration efficiency

[42]. Finally, dish-Stirling systems can be used for a wide range of applications, such as cogeneration integrated with heating, ventilation, and air conditioning technologies in residential buildings, combined with thermal energy storage, or hybridized with other RES. They are also suitable for electricity generation in remote rural areas and for the production of desalinated water

[43].

Despite these advantages, dish-Stirling systems are the least widespread and least mature technologically among CSP technologies

[17], as found through the analysis of data collected by SolarPACES. The limited adoption of dish-Stirling systems on a global scale can essentially be attributed, on the one hand, to the high initial cost associated with the complex design of the technology and components of the Stirling engine and, on the other hand, to the difficulty of integrating such systems with TES

[44]. These factors make dish-Stirling systems less economically sustainable, preventing their widespread market diffusion. Certainly, the combined action of technological development associated with the adoption by national governments of a dedicated incentive scheme could trigger an economy of scale, such as making CSP systems competitive with other, currently more mature technologies by pushing for their diffusion.

Technological development could involve the recovery of low-temperature thermal energy on the cold side of the Stirling engine, which could be used to satisfy the winter heating needs of buildings (space heating)

[45]. For this purpose, when the dish-Stirling system operates in a cogeneration setting, it is necessary to resolve the problem of temporal misalignment that exists between the annual period of maximum thermal energy production (summer) and the period in which greater thermal energy is required of the served user (winter). The solution consists of integrating the dish-Stirling system with a seasonal thermal energy storage system, Seasonal Thermal Energy Storage (STES)

[46]. In this context, geothermal systems can be considered a promising source of residential heating thanks to their high thermal storage efficiency

[47], for example, by installing a solar-assisted geothermal heat pump as described in

[48][49].

The HTF, usually a solution of water and glycol, flows along the vertical exchanger, loading and unloading the soil and creating a radial temperature gradient which allows for reducing heat losses towards the outside or, better, towards the portion of thermally undisturbed soil surrounding the storage volume. The BTES system can also be thermally isolated on the upper boundary surface to limit the influence of external climatic conditions and minimize heat losses to the external environment

[50]. Among the aforementioned sensible TES, BTES systems are the most suitable to be coupled with the cogenerative dish-Stirling type CSP technology due to the low temperature at which it is possible to recover the heat, the relative ease of installation, the moderate investment necessary to create the geothermal field

[51] and the medium-high value of the thermal storage efficiency. The losses of thermal energy to the external environment are, in fact, limited due to the low enthalpy that characterizes the storage process and, therefore, the low temperature of the HTF used. BTES are already widely used worldwide

[52].

2.2.2. Solar Tower Systems

Among the various technologies to produce clean energy through CSP, Solar Power Tower (SPT) plants are considered a promising technology and, in 2020, account for 15% of operational plants

[53]. The technology is characterized by a heliostat field and a central receiver on the top of the tower, where the HTF is heated. High temperatures can be reached in the solar receiver, ensuring high cycle efficiency. An SPT uses a large number of heliostats, having a dual-axis control system (one for the vertical axis and the other for the horizontal axis), whose total collecting area can reach extensive dimensions, even hundreds of thousands of m

2. As far as the heliostat field and its symmetry are concerned, there are two types of layouts: polar or 360° (surrounding) fields. Heliostats are spaced appropriately to limit shading phenomena. The distance between each heliostat increases as it moves away from the tower. The capturing surface of the individual heliostat is between 40 and 70 m

2. The heliostats reflect the solar radiation on the focal point, which is fixed in time and space, in the solar receiver located at the top of the tower. The height of the tower depends on the solar field: the greater the number of heliostats, the higher the position of the focal point, up to more than a hundred meters. The solar radiation receiver can be of different types characterized by a configuration with external solar radiation collection or with cavities. The concentrated solar energy incident on the receiver is converted to thermal energy, which is carried by the HTF passing through the receiver. The thermal energy of the HTF is transferred to the working fluid of the power cycle, thereby generating electricity.

The advantage of SPTs is represented by the possibility of obtaining a high concentration ratio, referring to the ratio between the flux concentrated on the receiver and the ambient flux coming from the sun, ranging from 200 to 1000. Consequently, temperatures up to 1000 °C could be potentially reached with suitable HTFs. The high temperature leads to an increase in the power cycle efficiency. As a result, high overall solar-to-electric conversion efficiency can be achieved

[54]. It can be highlighted that thermal efficiency (solar to mechanical) is estimated between 30% and 40% for this technology. This kind of system presents overall plant peak efficiency (solar to electric) values in the interval of 23–35%, while its annual solar to electric efficiency varies from 20% to 35%

[55]. The fact that the latest SPTs give better LCOE

[56][57] stands out, as they have a bigger potential for cost decrease and better performance when employing TES. The space for improvement of this concept is higher, and there are more plants currently under construction and development than the rest of the CSP technologies, thanks to their technical advantages

[53][55].

The main HTFs used are water, molten salts, and, more recently, air and granular particles. Commercial-scale installations are generally equipped with absorber tubes or volumetric absorbers, which may be inside the cavity or arranged externally. Typically, the materials used for the construction of the receiver are ceramic materials or metals that are stable at high temperatures. SPTs are often coupled with TES systems, typically realized through two tanks, one for the hot fluid and one for the cold fluid. To date, there are countless studies presenting the potential of other types of HTFs, such as gas and/or solid particles

[58] and advanced molten salts, to evaluate the possibility of improving the performances of SPT systems based on conventional molten salts.

In this context, the Generation 3 CSP Systems (Gen3 CSP), a funding program by the USA Department of Energy (DOE), builds on prior research for high-temperature concentrating SPT technologies

[59]. The project is led by Sandia National Laboratories. Gen3 CSP focused on developing integrated assembly designs with TES to reach high operating temperatures using solid particles.

The first SPT plants in operation saw Spain lead the way: the PS10 plant, the first to supply electricity to the grid, started up in 2007, and later in 2009, the PS20 was also operational. In 2011, the GEMASOLAR plant with a 20 MW turbine and 15 h energy storage was put into operation in Spain. Plants start-up in the USA began with the Sierra SunTower plant in 2009, the Ivanpah in 2014, and the Crescent Dunes in 2015. The Ivanpah plant, with its 377 MW turbine, is one of the largest power plants in the world

[17][60]. Crescent Dunes plant used an external cylindrical receiver with molten salts as HTF and incorporated a 10 h storage. Also, in China, several SPT plants are taking shape and going into operation; for instance, in 2013, the 10 MW Supcon and in 2018, the 50 MW Supcon. Other plants are under construction and/or development, such as the Golmud 100 MW. The Sundrop project realized in 2016 in Australia enabled seawater desalination and electricity generation through SPTs. Moreover, SPT plants are being developed in the MENA region. The Noor-III commercial plant located in Morocco started operation in 2018 with 150 MW and 7 h of storage capacity, while the 100 MW DEWA SPT plant has been in operation in Dubai since 2023. Another region of the world with high insolation is Chile, which has vast desert areas for the construction of SPT plants, and to date, Cerro Dominador is in operation

[61].

2.3. Key Takeaways of the CSP Technologies Analyzed

This part briefly summarized the key takeaways of the CSP technologies analyzed in detail in the previous part through Table 1.

Table 1. Key takeaways of all CSP technologies which analyzed.

| Technology |

Linear Parabolic Systems |

Linear Fresnel Reflectors |

Dish-Stirling Systems |

Solar Tower Systems |

| Capacity range [MW] |

10–250 |

5–250 |

0.01–1 |

10–100 |

| Capacity installed [MW] |

4800 (1200 under construction) |

20 (10 under construction) |

Several prototypes |

1200 (300 under construction and 1300 under development) |

| Annual solar to electric efficiency (%) |

14–16 |

8–10 |

16–29 |

20–35 |

| Concentration ratio |

70–90 |

35–170 |

<3000 |

200–1000 |

| Land use factor (%) |

25–40 |

60–80 |

20–25 |

20–25 |

| Development status |

Commercially proven |

Recently commercial |

Prototype tests |

Semi-commercial |

| Benefits |

Proven reliability and durability.

Simple design of optical systems that also guarantee acceptable concentration ratios.

Possibility of assimilating commercial CSP systems to parabolic collectors that use oil as the HTF to other types of industrial plants, thus taking advantage of existing industrial supply chains |

High concentration ratio.

Simple structure.

Direct steam generation proven |

Highest concentration ratio.

High modularity and high efficiency of the power cycle.

Low level of land occupation.

Wide range of applications. |

Very high concentration ratio.

High efficiency of power cycle and potential options for powering gas turbines and combined cycles |

| Drawbacks |

Limited HTF temperature. |

Lower optical efficiency as compared to other CSP technologies.

Storage for direct steam generation is still in the R&D stage |

Not commercially proven.

High cost related to the complex design and components.

Difficulty of integration with TES |

High installation and maintenance costs |