Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Paulo Santos | -- | 7035 | 2024-01-23 10:19:39 | | | |

| 2 | Mona Zou | Meta information modification | 7035 | 2024-01-23 11:05:53 | | | | |

| 3 | Mona Zou | -141 word(s) | 6894 | 2024-03-01 09:50:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Santos, P.; Cervantes, G.C.; Zaragoza-Benzal, A.; Byrne, A.; Karaca, F.; Ferrández, D.; Salles, A.; Bragança, L. Circular Material Usage Strategies and Principles in Buildings. Encyclopedia. Available online: https://encyclopedia.pub/entry/54241 (accessed on 08 February 2026).

Santos P, Cervantes GC, Zaragoza-Benzal A, Byrne A, Karaca F, Ferrández D, et al. Circular Material Usage Strategies and Principles in Buildings. Encyclopedia. Available at: https://encyclopedia.pub/entry/54241. Accessed February 08, 2026.

Santos, Paulo, Génesis Camila Cervantes, Alicia Zaragoza-Benzal, Aimee Byrne, Ferhat Karaca, Daniel Ferrández, Adriana Salles, Luís Bragança. "Circular Material Usage Strategies and Principles in Buildings" Encyclopedia, https://encyclopedia.pub/entry/54241 (accessed February 08, 2026).

Santos, P., Cervantes, G.C., Zaragoza-Benzal, A., Byrne, A., Karaca, F., Ferrández, D., Salles, A., & Bragança, L. (2024, January 23). Circular Material Usage Strategies and Principles in Buildings. In Encyclopedia. https://encyclopedia.pub/entry/54241

Santos, Paulo, et al. "Circular Material Usage Strategies and Principles in Buildings." Encyclopedia. Web. 23 January, 2024.

Copy Citation

Building construction accounts for a significant proportion of global greenhouse gas emissions, raw material extraction, and waste production. Applying circular economy (CE) principles in the building construction industry would considerably reduce these values. However, uptake by the industry is relatively slow, which is largely attributed to sectoral barriers, including limitations in knowledge and experience.

circular economy

buildings

circular materials

strategies

principles

1. Introduction

The EU has agreed to reduce greenhouse gas emissions by 55% (of 1990 levels) by 2030 and to become carbon neutral by 2050 [1]. The construction industry is a critical sector because it accounts for 5–12% of total greenhouse gas emissions through material extraction, construction product manufacture, and building work. This includes the production of cement, aluminum, steel, brick, and glass, which contributes approximately 9% of global energy related CO2 emissions [2].

Furthermore, the sector is a lead consumer of raw materials, accounting for approximately 50% of global extracted material [3], including finite resources such as cement and metals. Mineral aggregates, such as sand and gravel, which are extensively used in buildings and construction as concrete, asphalt, and glass, are the largest extracted material group in the world [4]. Scarcity of supply, high demand, and resulting increasing prices have led to illegal extraction activities, including that of river sand [5]. Natural alluvial sand is essentially a nonrenewable resource consumed in the making of materials such as concrete and plaster, leading to a global sand crisis and research into alternative substitutes [6][7]. In addition to this, the European Commission (EC) has defined a list of “Critical Raw Materials”. These materials and minerals are crucial to Europe’s economy and need to be maintained to meet growing demands in expanding sectors such as renewable energy and digital technologies [8]. Examples include coking coal, which is used in steelmaking [9], and bauxite used in aluminum production [10]. The European Commission (EC) proposed the Critical Raw Materials Act [11] in 2023, intending to make the European Union (EU) more competitive and sovereign by boosting the research and development of alternative materials and more sustainable mining and production. This is a consideration in building design and also for demolition and waste management because many of these materials are already locked inside existing buildings.

Despite stringent financial penalties, illegal disposal practices, such as fly-tipping of CDW, persist (Figure 1). The EU has, therefore, made the management of CDW a priority [12]. The Waste Framework Directive (WFD) 2008/98/EC [13] set a mandatory recovery target of 70% recovery rate by weight for CDW by 2020. These recovery efforts encompass various activities, including the preparation of nonhazardous CDW for reuse, recycling, and other material recovery operations, inclusive of backfilling [14].

Figure 1. Illegal dumping of construction and demolition waste (CDW) in Romania (Source: Mihai [15]).

2. Principles and Strategies for the Circular Use of Materials in Construction Operations

This section is devoted to examining the principles and strategies related to the circular utilization of materials within the construction industry. It begins by outlining strategies aimed at prolonging the lifespan of materials and addressing end-of-life considerations. Subsequently, collaborative approaches and business models designed to promote a circular economy in the construction sector are discussed. The assessment and illustration of technological innovations for circular material usage follow. A comprehensive review of the primary obstacles and facilitators influencing circular material usage in the building sector is then provided. Finally, exemplars of best practices in circular economy within the construction industry, specifically about material usage, are presented as “case studies”.

2.1. Extending Product Lifespan and End-of-Life Strategies

Frequently, the economy is saturated with items that have been created without considering the question: What are the implications for this product at the conclusion of its lifecycle [16]? Hence, it is crucial to establish, during the design phase, the end-of-life strategies that will enhance the circular economy (CE) of construction products and materials. The construction industry is undergoing a gradual and progressive shift towards CE, as determined and affirmed by Charef et al. [17]. Indeed, the building industry is beginning to adopt circular strategies, as illustrated by the work of Nußholz et al. [18]. In their study, they examined 65 real-world cases of new construction, renovation, and demolition projects in Europe, considering the circular solutions employed, the extent of their application in buildings, and the reported potential for decarbonization.

Several researchers developed and made use of disruptive technologies to foster the circular building industry. Setaki and Timmeren [19] delineated how disruptive, frequently digital technologies have the potential to facilitate a CE in the building industry, particularly during the construction and demolition phases, which are recognized as the two most wasteful stages in the building cycle. Furthermore, in the realm of additive manufacturing, Tavares et al. [20] conducted a comprehensive review outlining the assessment of advantages and obstacles associated with additive manufacturing in the context of the circular economy. They also introduced a proposed framework. Moreover, there is a rising trend in employing artificial intelligence to improve the integration of systemic circular practices within the construction industry, as recently examined by Oluleye et al. [21].

As stated by Marsh et al. [22], the construction CE principles could be congregated as follows:

-

Minimization of material usage through design and specification;

-

Creation of long-lasting designs to enhance durability;

-

Emphasis on maintenance, repair, and refurbishing;

-

Adoption of practices for reuse and remanufacturing;

-

Incorporation of recycling methods.

A fundamental principle of the circular economy is to maximize the utilization duration of products and materials, as emphasized by Figge et al. [23]. This involves designing for longevity to prolong the time items remain in use [22]. The objective is to maximize the period of use for products and materials, encouraging practices such as reuse, refurbishment, remanufacturing, and recycling. Prolonging the lifespan of products preserves their value and diminishes the necessity for extracting and processing new resources. Nevertheless, Kirchherr et al. [24] stated “that the CE is most frequently depicted as a combination of reduce, reuse and recycle activities”. They also observed that the term “recover” is frequently added to the previously mentioned CE activities, thereby establishing a 4Rs framework instead of the traditional 3Rs.

In addition to enhancing the durability of materials and products, it is crucial to promote their repairability. Moreover, there should be the incorporation of a remanufacturing process, with a focus on upgrading the product to its highest value whenever feasible.

Given the numerous available possibilities and potential approaches for addressing the circular economy in existing buildings, it is highly pertinent to assess the recoverable value of in situ building materials. Mollaei et al. [25] established a new computational tool to “choose the optimal combination of reuse, recycling and disposal options for those materials”, considering “cost, value, duration, environmental impacts, and building component precedence in demolition and deconstruction activities”.

According to Marsh et al. [22], the principles and strategies of CE can be organized into three primary groups, categorized by the lifecycle stage, as outlined in Table 2. It is worth noting that numerous other strategies could be defined and incorporated into this table, such as the recovery of products/materials from a building’s end-of-life for subsequent reuse, remanufacturing, or recycling. Another instance could involve the recovery of thermal energy from the combustion of a material (e.g., plastic or rubber). Both examples mentioned above pertain to the end-of-use lifecycle stage.

Table 2. CE strategies/principles organized by lifecycle stage (Source: adapted from Marsh et al. [22]).

| Lifecycle Stage | CE Strategies/Principles |

|---|---|

| Design stage | - Reduction of material usage through design and specification |

| - Design for increased longevity | |

| In-service | - Maintenance |

| - Repair | |

| - Refurbishing | |

| End-of-use | - Reuse |

| - Remanufacturing | |

| - Recycling |

The actual subsection will primarily address strategies aimed at prolonging the lifespan of products and explore the existing end-of-life approaches to promote circular material usage in construction activities.

2.1.1. Extending Product Lifespan

- -

-

Increasing durability through maintenance, repair, and refurbishment

Maintenance, repair, and refurbishment represent in-service strategies to decelerate resource flows by prolonging the technical lifespan of products and components [22]. Maintenance entails universal upkeep, and preventive measures aim to prevent damage to building components, such as the application of protective coatings. Repair and refurbishment involve addressing limited damage to a component or replacing a damaged component entirely with a new one [22].

Designers should consider how their product aligns with either technical or biological cycles after use, ensuring that the product is created with the subsequent path in mind. In the case of products intended for technical cycles, it is advantageous for them to be easily repairable and maintainable, simple to disassemble, and constructed with modular components that can be replaced [26]. They should possess sufficient durability to endure the wear and tear caused by numerous users. Additionally, they should be crafted from materials that can be easily recycled.

The optimal solution would involve utilizing self-healing materials to prolong their lifespan and, in the extreme, create “immortal” products or components, as investigated by Haines-Gadd et al. [27].

2.1.2. End-of-Life Strategies

- -

-

Remanufacturing and Upgrading

In the processes aimed at enhancing durability mentioned earlier, when the product becomes unusable, its components should, whenever feasible, undergo remanufacturing and upgrading [28]. Upgrading and remanufacturing are strategies employed at the end of a product’s use, aiming to decelerate resource flows by incorporating still-functional components from end-of-use products into new products. In his research work, Atta [28] outlined how digital technologies play a role in facilitating the adoption of circular service-based models centered around remanufacturing in contemporary construction practices.

Plans for upgrading and remanufacturing building components should be anticipated during the design phase. Van Stijn and Gruis [29] established an integral design software for circular buildings components (CBC), named “CBC-generator” 2.0. This software is a parameter-based “three-tiered design tool, consisting of a technical, industrial and business model generator”, in which the designers can choose and compare various design alternatives.

- -

-

Reuse, Reverse Logistics, and Take-Back Programs

These are also strategies employed at the end of use. Indeed, the most efficient method for preserving the highest value of products is through maintenance and reuse. Take a window, for instance: its value is greater as a functional window than as a collection of individual components and materials (such as PVC or aluminum from the frame, glass, etc.). Therefore, the initial stages in the technical cycle focus on maintaining products intact to maximize their potential value. This may encompass business models centered on sharing, allowing users access to a product rather than ownership, and facilitating broader usage over time (e.g., renting equipment during the construction phase). It might involve reuse through resale or recurring cycles of maintenance, repair, and refurbishment.

Reverse logistics (RL), defined as a series of activities conducted after the sale of a product to recapture value and conclude the product’s lifecycle, plays a crucial role in promoting the circular economy in the construction sector [30]. It usually entails sending a product back to the manufacturer or distributor or redirecting it for servicing, refurbishment, or recycling. In the context of construction, RL is described as “the movement of products and materials from salvaged buildings to a new construction site” [30]. This approach promotes material reuse, as well as the processes of deconstruction and disassembly.

In a more recent study, Ding et al. [31] conducted a review on forward and reverse logistics for the circular economy in construction, concluding that “while similar methods and CE strategies are used in forward logistics (FL) and RL, RL operations require more integration between supply chain actors to close the loop for CE in construction”.

A take-back program essentially involves a brand reclaiming or repurchasing its own materials or products. These items are either cleaned, repaired, and subsequently resold by the brand at a discounted rate, dismantled and repurposed in other collections, or recycled through alternative methods. The construction industry is also beginning to adopt this strategy [32][33].

A market for secondhand building products and materials already exists, encompassing items like windows and doors (see Figure 2), lumber, flooring, furniture, masonry, tiles, stones, sheathing boards, appliances, architectural/decorative elements, lighting, heating, and cooling devices, electrical components, plumbing, etc., which are available for commercialization and reuse [34][35][36].

Figure 2. Instances of preowned building products available for reuse that are being exchanged on online platforms: (a) window [35]; (b) door [36] (Source: reproduced with permissions from seconduse.com [35] and rotordc.com [36]).

- -

-

Material Recovery

Material recovery pertains to the process of reclaiming and reutilizing materials from construction and demolition waste (CDW). This involves the identification of valuable materials within the “waste” stream, salvaging them for reuse or resale [37]. The activities involved in material recovery typically include deconstruction, which requires the careful disassembly of structures to preserve valuable components. Recovered materials may encompass lumber [38][39], cross-laminated timber [40], bricks [41], and other items that can be repurposed in upcoming construction projects. The primary aim of material recovery is to decrease waste generation, conserve resources, and minimize the environmental impact associated with the extraction of new raw materials.

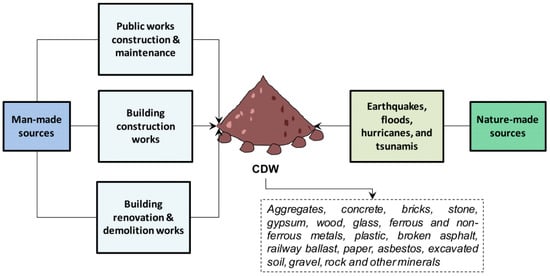

It is important to acknowledge that CDW can originate from various sources, whether human-made or natural, as depicted in Figure 3. Concerning the human-made sources of CDW, these authors categorize them into three groups: (1) public works construction and maintenance; (2) building construction works; and (3) building renovation and demolition works. The key constituents of this CDW, encompassing the natural sources, are also outlined in the illustration (Figure 3), including aggregates, concrete, bricks, stone, wood, glass, metals, plastic, etc.

Figure 3. Categorization of construction and demolition waste (CDW) based on its source of origin (Source: dos Reis et al. [42]).

In their study, [43] assessed the dynamics at a local scale to enhance the sustainable management of CDW. Their findings emphasized the importance of investing in local solutions to optimize logistics and address cost issues, fostering cooperation among stakeholders, and enhancing the market for recycled aggregates. Furthermore, they underscored the necessity of providing support in the form of information, awareness, and training, with a focus on promoting good practices onsite and implementing oversight procedures. While material recovery concentrates on salvaging and reusing intact components or materials, recycling involves breaking down waste materials to generate new products or raw materials, as will be elaborated on next.

- -

-

Material Recycling

Recycling serves as an end-of-use strategy aimed at closing resource loops by reprocessing materials for use in another product, thereby preventing both waste generation and the extraction of raw materials [22]. Components that cannot undergo remanufacturing can be disassembled into their constituent materials and recycled. Although recycling is ideally considered as a last resort due to the potential loss of embedded value in products and components, it is crucial as the final step in ensuring that materials remain within the economy and do not become waste [16].

Recycling entails converting waste materials into new products or raw materials, which can subsequently be utilized for diverse purposes. Within the construction sector, recycling typically denotes the transformation of CDW into reusable materials. This process may include activities such as crushing, grinding, or shredding waste materials like concrete, asphalt, metal, and wood to produce recycled aggregates [43], crushed concrete, or other materials capable of substituting virgin materials in construction projects.

Numerous studies have explored the feasibility and effectiveness of new recycled materials derived from CDW, including cement [44], concrete [45], mortars [46], plasters [47], gypsums [48], plastics [49][50], insulation materials [51], bricks [52][53], soil reinforcement [54], and fire-resistant materials [55].

In addition to CDW, other waste sources are being recycled and investigated for utilization in the construction sector and the building environment, including concrete [56], mortars [57], plasters [47][58], gypsum [48], thermal break strips made of recycled tire rubber [59][60] and rubber–cork composites [59][60], plastics [61], and insulation materials such as silica–aerogel composites and recycled tire rubber [62][63].

2.2. Collaborative Approaches and Business Models

This section includes some of the innovations that are currently affecting business models linked to construction and which promote the integration of circular economy criteria in this industrial sector.

2.2.1. Circular Supply Chains and Networks

The literature addressing CE in the construction sector includes the design of circular supply chains to improve the management of natural resources and reduce the volume of waste generated [64]. Policymakers have referred to these circular supply chains as a key activity to move toward sustainable and environmentally friendly economic growth [65]. In the linear model, construction products at the end of their use are considered waste, and their management becomes a challenge for cities [66]. It is known that in the demolition processes, about 40% of the total mass of raw materials extracted during the execution/production phase is lost, making the construction industry one of the most polluting on a global scale [2]. For this reason, the CE includes as a goal “closing the loop” in the flow of raw materials and resources used in construction throughout the useful life of buildings [24][31] because it is at this point that the supply chain represents a value proposition in the redesign of the execution process [67][68].

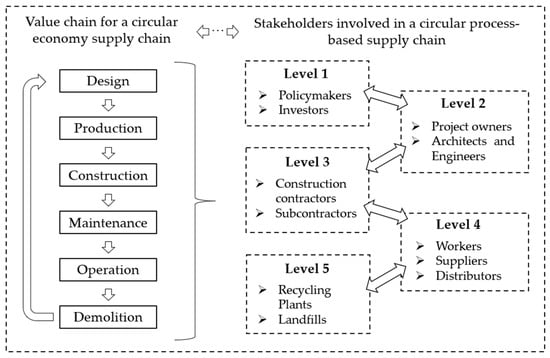

To provide an overview, Figure 4 schematically shows the relationship between stakeholders and the different stages included in the supply chain.

Figure 4. Complete supply chain cycle and stakeholders involved (Source: authors based on Chen et al. [64]).

Therefore, as shown in Figure 4, it is necessary to make a combined effort on the part of all stakeholders included in the network generated in the process of supplying construction materials to advance toward the integration of the CE in the sector [69]. In this regard, the establishment of agile communication channels that enhance transparency in the agreements and allow CDW to be recovered, create value from them, or correctly dispose of them [31][70] is particularly relevant. This is the only way to achieve an eco-industrial symbiosis and incorporate the reverse logistics stage in the manufacture of building products, redesigning current distribution processes and improving warehouse management to increase the level of service [31][71]. In turn, a greater recirculation of construction products would favor the creation of a controlled market for CDW, which, together with strategies that impute the environmental costs derived from the distribution process to the final product, would make it possible to boost its demand [72].

Finally, the importance of separating CDW at the point of origin should be emphasized. A selective sorting of waste at the initial stage of the recycling or reuse process would significantly improve the management process of these secondary raw materials [73]. This would reduce costs by reducing the work of intermediate processing and sorting plants, obtaining more homogeneous products, and improving the traceability of samples [74]. At the same time, this separation at the starting point would mitigate the environmental impact by reducing the number of trips to the landfill and the volume of occupation at the deposit points [46].

2.2.2. Sharing Economy and Product-as-a-Service Models

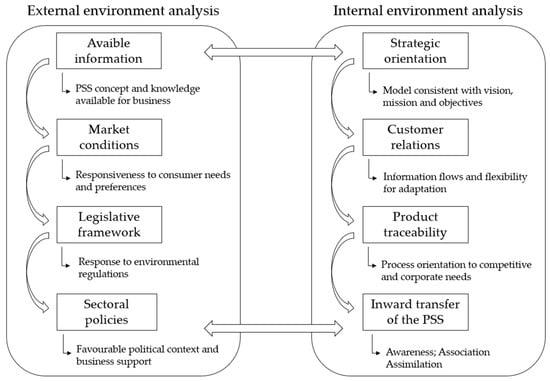

The strategies used at the industrial level to promote value creation have evolved in recent years as a result of globalization processes and the dizzying technological development that has taken place in recent decades [75]. Sharing economy business models aim to create a service around a product, technology, or equipment in such a way as to enhance its reuse and share it among the different stakeholders [76]. This initiative has also affected the construction sector, which, through the development of new information channels, allows stakeholders to use and share goods to move toward a model based on product–service systems (PSS) [77]. This adds complexity because companies are forced to introduce innovations in their manufacturing process and increase the level of interaction in the development phases to enable these business models [78][79]. By transmitting the value of the product to its use and linking its functionality to its use, manufacturers are forced to understand its complete lifecycle and the needs of the customer in depth, sometimes requiring a redesign of activities [79].

Certain factors (external and internal) have been found to condition the incorporation of these business models in the construction sector (Figure 5), and it is necessary to raise consumer awareness to promote the acceptance of this product or service model.

Figure 5. Internal and external determinants of product-as-a-service models (Source: authors based on Cook et al. [78]).

Several authors have worked on the implications of implementing this business model to different products to advance in this “servitization” process. Thus, the researchers find examples linked to construction machinery and construction equipment [75][79], prefabricated building products [80], or building components [81]. In the cases in which it has been implemented added environmental benefit is obtained thanks to the greater ease of product recovery [82]. It is worth noting that the promotion and proliferation of online platforms has made it possible, among other things, to share geographic location, know the demand and available resources in real time, and provide new opportunities for business collaboration [83]. This makes it possible to promote a more democratic organization and reduce information asymmetries between the parties involved [84]. In short, this collaborative economy model allows companies to have high value-added resources available without the need to purchase them with the large initial outlay that this action entails, thus reducing the volume of waste generated as a result of disuse [80].

2.2.3. Extended Product Responsibility

Extended product responsibility (EPR) was first defined at the beginning of the century by Lindhqvist [85] as a strategy to protect the environment and is intended to ensure that any product manufacturer takes responsibility for its entire lifecycle, incorporating the stages of recovery, recycling, collection, and disposal. As a result of this definition, other related actions have arisen, such as the extension of the useful life of products, which goes against the traditional linear model, where the benefit lies in individual mass consumption and preventing products from remaining for long periods of time [86].

This approach would make it possible to change the current production models related to the construction industry, so that the companies involved should include in their activities a plan for collection and management of the resource once it has been consumed [14]. Some secondary raw materials, as in the case of plastics, are leading the way in the development of these business models [87], as well as household appliances or air conditioning equipment commonly used in homes [88]. However, complex civil infrastructures or constructed buildings, conceived as unique products made onsite, hinder the implementation of these models. In this sense, it is possible to think of an EPR localized to the main raw materials used in the elaboration of constructive systems; however, the useful life of this is rarely less than 50 years, and it becomes difficult to manage the final management of these products [89].

In this sense, it is necessary to review the current initiatives and regulations in force to address the problems related to CDW generated and implement the “polluter pays” principle as far as possible [90]. Thus, through a solid legislative framework, companies can be encouraged to incorporate CE criteria in their manufacturing process, moving toward eco-efficient design and including the final stages of recycling, recovery, and revaluation of the manufactured product [91][92].

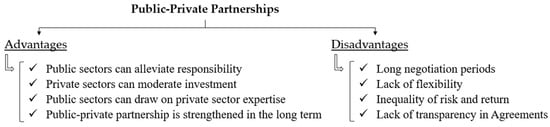

2.2.4. Public–Private Partnerships and Policy Implications

Public–private partnerships (PPPs) have become a very useful tool in the construction industry, seeking to leverage the expertise of private companies supported by public resources [93]. These relationships are established with a medium- to long-term temporary objective and with the intention of moving toward a more sustainable design of the sector. These relationships are, therefore, based on mutual trust between the organizations involved, which allows the sharing of resources and capabilities and must, therefore, be coordinated in decision-making [94]. In this sense, there is a shared responsibility and, therefore, these agreements cannot always be considered favorable. Figure 6 shows the advantages and disadvantages of these agreements, as stated by Bao et al. [95].

Figure 6. Advantages and disadvantages of public–private partnerships in the construction sector (Source: authors).

However, although PPPs are already established for tasks related to the development of construction infrastructures or the design, execution, and development of facilities [96][97], in the area of waste management, moving toward a circular economy model in the EU is still a pending task, and there is still a long way to go. For this reason, managers and environmental policymakers in the Union are moving toward the development of an international legal framework that will allow for the proliferation of such agreements in the construction sector [98]. Despite this, the changes brought about to date have not been as efficient as could be desired, although it is true that the path has been set by policymakers to create resilient infrastructures that make these collaboration models attractive to companies and serve to maintain solid support from the public administrations that back the agreements [99].

2.3. Technological Innovations for Circular Material Usage

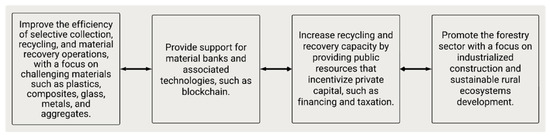

CE aims to enhance productivity in the construction industry through investments in technology and digitalization. In the study by Ferrer et al. [100], the importance of establishing efficient networks for recycling, reusing, and recovering construction materials is highlighted, as illustrated in Figure 7. These networks play a crucial role in achieving several key objectives related to CE [100].

Figure 7. Fundamentals in circular material usage (Source: authors based on Ferrer et al. [100]).

To promote reindustrialization and sustainability in the construction sector, innovation ecosystems advocate for the implementation of research, development, and innovation (R + D + i), as well as knowledge transfer instruments. These instruments focus on various areas, including 4.0 technologies, recycling and recovery of challenging materials and components (such as plastics, composites, and waste), productivity enhancements in component manufacturing and recovery through 3D printing, robotics, artificial intelligence (AI), and internet of things (IoT), as well as the development of new long-lasting materials and material traceability technologies like blockchain [100].

2.3.1. Recycling Technologies

The resource recovery approach, which serves as a business model and a catalyst for the CE, primarily emphasizes the reclamation of materials or energy from waste. Examples include the recycling of steel and fibers, as well as the use of recycled aggregates in construction or other industries. The adoption of CE principles relies on the establishment of industrial and energy symbiosis between complementary sectors [100].

In the construction industry, the adoption of disassembly and recycling best practices is crucial to revalue construction waste, which is often considered as “low value” material. By employing testing methods for disassembly, treatment, and recycling, the recovery and reuse of materials can be optimized, leading to more efficient resource utilization in the production process. Implementing advanced recycling technologies allows the construction industry to reduce waste, decrease the extraction of virgin resources, and promote a more sustainable approach to material management [30]. These technologies enable the transformation of waste into valuable resources, fostering the development of a CE. Recycled steel, fibers, and aggregates find applications in various sectors, including construction, creating a closed-loop system in which materials are continuously reused and recycled [21]. This approach not only reduces the environmental impact of resource extraction but also contributes to the development of a more resource-efficient and less wasteful economy, as highlighted by the European Environment Agency [101].

2.3.2. Revolutionizing Material Sorting and Separation Systems

Intelligent sorting and separation systems play a crucial role in advancing the principles of the CE by improving the efficiency and effectiveness of waste management and resource recovery processes [100]. These systems leverage cutting-edge technologies like AI, machine learning, computer vision, and robotics to accurately identify, sort, and segregate different types of materials. This enables appropriate recycling, reuse, or recovery, promoting sustainable practices.

By automating the sorting process, these systems enhance the purity and quality of recovered materials, increasing their value for subsequent reuse or recycling. They also optimize resource allocation by dynamically adjusting parameters like conveyor speed and sensor settings, maximizing efficiency while minimizing waste [102]. Additionally, these systems detect and eliminate contaminants, improving the quality of recovered materials and reducing the risk of cross-contamination [103].

Moreover, intelligent sorting systems reduce the need for manual labor, increase throughput capacity, and enable the processing of larger volumes of waste due to their exceptional accuracy and speed. Furthermore, they generate valuable data on waste composition, quantity, and quality. This data-driven approach facilitates informed decision-making, process optimization, and the development of innovative recycling technologies.

By integrating into circular supply chains, these systems facilitate the efficient recovery and reintroduction of recycled materials, closing the loop in the CE. As technology continues to advance, intelligent sorting systems are expected to contribute significantly to resource efficiency, waste reduction, and sustainable material utilization.

2.3.3. The Transformational Power of Digitalization and Blockchain Applications

The delivery of a sustainable and circular built environment requires the promotion of a guaranteed system for components and spare parts, along with digital traceability through a European passport and associated documentation. These measures ensure transparency and accountability in the construction industry, as emphasized by Ferrer et al. [100]. Furthermore, financial aid for investments by industrialized and sustainable construction companies is proposed as a complementary measure. This includes support for technologies such as modular design, building information modeling (BIM), internet of things (IoT) digitalization, 3D printing, and cutting-edge robotics. Additionally, the establishment of components’ banks and material passports is suggested as a means to promote public–private collaboration and drive innovation in the industry. These initiatives aim to encourage sustainable practices and foster the transition toward a circular economy, as highlighted by Ferrer et al. [100].

In terms of material circularity, the utilization of blockchain technology for material passports addresses the issue of low transparency and traceability in the construction industry. This solution allows for improved tracking of materials such as fiber plates, steels, coatings, and facades [104]. The integration of collaborative design and manufacturing technologies, such as BIM and the internet of things (IoT), benefits from the availability of these new technologies. Thus, by integrating design, production, and delivery systems, including just-in-time (JIT) delivery, construction sites can operate more efficiently and effectively.

2.3.4. Robotic Deconstruction

Technological advancements in deconstruction have brought about innovative tools and techniques that enable the dismantling and repurposing of buildings and structures in a more efficient, sustainable, and profitable manner. These innovations are designed to reduce waste, minimize environmental impact, and enhance safety throughout deconstruction [104].

In this regard, robotic systems have emerged as a promising solution for deconstruction, offering improved efficiency and sustainability in the construction industry. Traditional demolition methods often pose significant risks and have adverse environmental effects, particularly in densely populated urban areas, as highlighted by [105].

In Japan, alternative approaches have been developed to address the legal, economic, and ecological requirements of deconstruction. These include the utilization of single-task construction robots (STCRs) and the establishment of semiautomated onsite factories. These methods aim to streamline the deconstruction process while meeting the specific needs of the project [104]. By implementing these technological innovations, the construction industry can achieve more efficient and environmentally friendly deconstruction practices, contributing to overall sustainability and safety [21].

However, the implementation of traditional industrial robots in a deconstruction environment presents challenges, particularly in terms of human–robot interaction and collaboration. To address these challenges, the efficient collaboration between humans and robots is carefully considered when designing deconstruction STCRs. Moreover, the adoption of the robot-oriented design method can enhance the efficiency of the deconstruction system’s operation [105].

To evaluate the effectiveness of robot-assisted, systemized deconstruction, Leder et al. [104] proposed a framework that includes performance indicators that can be adjusted based on the perspectives of stakeholders. Overall, the use of robots in deconstruction provides a scalable and sustainable solution for the industry, offering improved efficiency and environmental outcomes [104].

2.3.5. Emerging Materials and Sustainable Manufacturing Processes

Innovation in materials, sustainable design, and the development of alternative technologies can play a crucial role in mitigating supply risks. These advancements can help reduce the ecological footprint and increase material recovery, ultimately improving the safety and competitiveness of production processes. While solutions to these challenges are within reach, global scenarios continue to present increasing complexity and competition for natural resources, as highlighted by Morató et al. [106]. Industrialized systems exhibit lower durations and footprints of carbon dioxide (CO2), water, and material consumption. The environmental impact of circular and sustainable industrialized construction can vary depending on different modelling scenarios of recycling percentages, as identified by Ferrer et al. [100]. This suggests that by incorporating circular and sustainable practices, such as increased recycling, the duration and environmental impact of construction processes can be further reduced.

2.4. Barriers and Enablers of Circular Material Usage

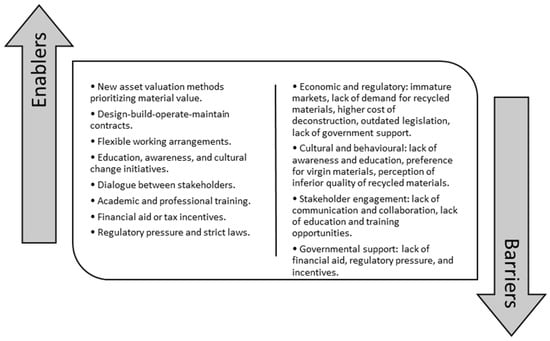

It is critical to identify the barriers and enablers to understand the circular material usage strategies and principles in construction activities. This could be achieved by collecting stakeholders’ opinions, particularly the ones who are the implementers of CE in the sector.

The first and most critical finding during our closer inspection of the existing literature is that the CE concept is multifaceted and that barriers and enablers have a primary focus on the use of materials and products and their technical specifications, including their compositions and origins. Charef et al. [107] identified and classified barriers into six different categories. The first category, economic barriers, refers to those that are related to market constraints, such as lack of financial resources or funding. The second category, sociological barriers, addresses cultural or psychological obstacles that can impede progress. The third category, political barriers, involves obstacles that arise due to government policies or regulations. The fourth category, organizational barriers, includes obstacles that involve stakeholders, such as a lack of support or resistance from key players. The fifth category, technological barriers, pertains to issues related to technology, such as outdated equipment or inadequate infrastructure. Finally, the sixth category, environmental barriers, concerns ecological impact and any obstacles that may arise due to environmental factors. Similarly, Ababio and Lu [108] also identified five distinct categories of barriers in this field. These categories are as follows: social and cultural barriers, political and legislative barriers, financial and economic barriers, technological barriers, and framework- and theory-related barriers.

The second critical general issue is that while significant research has been conducted on the barriers, including obstacles and challenges, that hinder the development of circular economy practices, relatively little attention has been given to the factors that, as enablers, facilitate and promote CE initiatives. For instance, Ababio and Lu [108] did not classify enablers but discussed them within selected themes. Therefore, this research addresses the importance of conducting more studies and research on CE enablers to identify the key drivers that can accelerate the transition. Generally, enablers are related to building design and construction technologies and innovations, internal and external policies and legislations, professional training and education, stakeholders’ awareness, financing options, and market creation.

After providing the justifications above, the researchers decided to concentrate this section of the present report on the barriers associated with material usage that the literature addresses. They are discussed in four categories and summarized in Figure 8.

Figure 8. Summary of barriers and enablers of circular material usage (Source: authors).

2.4.1. Legislative and Economic Barriers

Insufficient and immature markets are the most common economic barriers to the implementation of circular economy practices in the construction sector, and they are mostly associated with the low demand for reused and recycled materials [109][110][111]. The construction industry is often criticized for its inflexibility in adopting innovative practices due to the perceived risk of losing profits [107][110].

The construction industry faces a major challenge in adopting CE practices: the higher cost of resources associated with deconstruction compared to demolition. Virgin materials are less expensive than recycled ones, and recycling costs more than CDW disposal. Unfortunately, the COVID-19 pandemic has further worsened these challenges by halting economic development and increasing the use of single-use materials. Implementing CE practices in construction requires significant investments, such as renewing equipment [111]. Moreover, outdated legislation and the lack of standardized guides related to design and procurement procedures are other leading major regulatory barriers to CE development [107][112]. The lack of government and public institutional support are critical barriers to CE adoption [107][113].

The construction industry can benefit greatly from the integration of CE practices. To achieve this, it is important to adopt new business models and methods of evaluating assets that prioritize the material value. One way to do this is by making long-term investments that support the CE business case through the use of whole-life costing. This involves considering all the costs of a product or service over its entire lifespan, from design and production to disposal or recycling. By implementing CE practices, businesses can also transform their existing business models into product-as-a-service contracts (PSS). This approach involves providing a product or service to customers as a subscription or on a pay-per-use basis rather than selling it outright. This can help to reduce waste and improve resource efficiency because the manufacturer retains ownership of the product and is responsible for its maintenance and repair [114]. The adoption of CE practices can also lead to the development of new revenue streams. For example, businesses can recover and sell valuable materials from waste streams, creating a new source of income. Ababio and Lu [108] highlighted that enablers have been commonly identified, including design-build-operate-maintain contracts and their variations. Furthermore, Torgautov et al. [112] suggested to stakeholders that implementing circular economy practices can offer more flexible working arrangements.

2.4.2. Cultural and Behavioral Challenges

The construction industry faces many obstacles when adopting innovative practices, particularly those related to CE and sustainability. The industry is known for conservatism and reluctance to embrace new ideas that challenge established attitudes, customs, and beliefs. These cultural and behavioral issues pose significant challenges to adopting sustainable practices. One primary cultural challenge is the need for more awareness among construction stakeholders regarding CE and sustainability practices. Many stakeholders are unfamiliar with these concepts and, therefore, need to understand their potential benefits. This lack of awareness can lead to a reluctance to invest in sustainable practices. Another cultural challenge is the inherent risk aversion in the construction industry. This risk aversion can make it difficult to adopt innovative practices, particularly when there is a perceived risk that they may not work as intended. As a result, many stakeholders may be hesitant to invest in new technologies or processes that are not proven. There is also a preference for virgin construction materials over reused and recycled products. This preference is often reinforced by ingrained beliefs that circular economy practices are not feasible. Many construction stakeholders believe that using recycled materials may compromise the quality and safety of construction projects [107][113].

The literature highlights that the perceptions of various stakeholders toward incorporating CE practices in construction significantly impact their adoption. The reluctance of contractors to use recycled or refurbished materials in their projects stems from concerns about the potential decline in the quality of their work. They fear that using such materials may adversely impact the durability and reliability of the structures they construct [107][113][115].

Similarly, customers may not prefer buildings made using old materials due to the perception that they may not be aesthetically pleasing or may lack modern features. Furthermore, the quality of reclaimed materials is often viewed as inferior to virgin materials, which further fuels skepticism about the feasibility of CE practices [112].

2.4.3. Stakeholder Engagement and Awareness

Addressing existing cultural and behavioral barriers is essential to facilitating the widespread adoption of CE practices in the construction industry. This can be achieved through various initiatives, including training, education, awareness-raising activities, and cultural change through work culture. By doing so, stakeholders can work toward creating a CE, which would benefit the industry and the environment.

Open and honest communication between different groups of stakeholders can increase awareness of important issues, challenge assumptions and biases, and ultimately lead to a shift in attitudes and behaviors. It allows people to share their perspectives, experiences, and concerns and encourages active listening and empathy. Through dialogue, individuals can gain a deeper understanding of complex issues, build trust and respect, and work towards finding common ground. Dialogue is a powerful enabler for promoting CE [108]. This can involve open and honest communication between stakeholders, including industry professionals, academics, and government officials. Through dialogue, stakeholders can better understand each other’s perspectives and work collaboratively toward finding solutions to industry challenges.

Academic engagement and professional workshops are also essential enablers for promoting CE [108]. These educational opportunities give stakeholders ideas and knowledge to address industry challenges and help them to be equipped with the skills and expertise needed to implement CE practices.

2.4.4. Governmental Support and Incentives

The global construction industry needs more adequate policies, laws, and frameworks to adopt circular practices and business models. Government support, such as financial aid or tax incentives, is needed to make it more economically feasible to invest in circular models. This, in turn, discourages their adoption. The absence of regulatory pressure and strict laws fails to establish the necessary urgency for circularity. As a result, the required behavioral changes in the construction industry are not taking place. This pressing issue needs to be addressed so that the construction industry can move towards a more sustainable and circular future [115].

Circular buildings are gaining popularity as we move towards a more sustainable future due to their environmental benefits. Circular buildings are designed to promote the idea of “building as a material bank” [110], which means that the materials used in the construction of the building can be stored and reused when the building is no longer needed. This approach minimizes waste and reduces the construction industry’s carbon footprint. However, designing circular buildings requires careful planning because they need to be easily deconstructed and reconstructed. This is because circular buildings are designed to be disassembled, and all materials are recycled or reused at the end of their useful life. Therefore, the design of circular buildings should prioritize using modular components and materials that can be easily separated and recycled. While the benefits of circular buildings are clear, some challenges need to be addressed. One of the main challenges is the cost, as circular buildings are generally more expensive to construct than traditional buildings. However, governmental support and incentives for circular buildings’ long-term economic and environmental benefits can offset this cost.

The circular economy in the construction industry is a complex issue requiring all stakeholders’ involvement, including governments, investors, designers, constructors, and users. The transition towards circular practices requires a significant change in mindset and approach and the adoption of new technologies and systems. Nonetheless, the benefits of circularity in the construction industry are far-reaching, including reduced waste and carbon emissions, increased resource efficiency, and improved social and economic outcomes. Therefore, all stakeholders must collaborate and work toward a more sustainable future for the construction industry.

References

- European Commission COM. 640 Final, The European Green Deal 2019; European Commission: Brussels, Belgium, 2019.

- UNEP. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UNEP: Nairobi, Kenya, 2022.

- European Commission COM. 98 Final, A New Circular Economy Action Plan for a Cleaner and More Competitive Europe 2020; European Commission: Brussels, Belgium, 2020.

- Bisht, A. Conceptualizing Sand Extractivism: Deconstructing an Emerging Resource Frontier. Extr. Ind. Soc. 2021, 8, 100904.

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; zu Ermgassen, S.O.S.E.; Liu, J.; Jaeger, J.A.G.; Winter, M.; Lambin, E.F. Sustainability of the Global Sand System in the Anthropocene. One Earth 2021, 4, 639–650.

- Gallagher, L.; Peduzzi, P. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Geneva, Switzerland, 2019.

- Zadeh, A.A.; Peng, Y.; Puffer, S.M.; Garvey, M.D. Sustainable Sand Substitutes in the Construction Industry in the United States and Canada: Assessing Stakeholder Awareness. Sustainability 2022, 14, 7674.

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; EU: Luxembourg, 2020.

- Baruya, P. Coking Coal—The Strategic Raw Material; Technical Report CCC/306; IEA Clean Coal Centre: London, UK, 2020.

- Szczepański, M. Briefing: Critical Raw Materials for the EU—Enablers of the Green and Digital Recovery; European Parliamentary Research Service; European Union: Brussels, Belgium, 2020.

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Establishing a Framework for Ensuring a Secure and Sustainable Supply of Critical Raw Materials and Amending Regulations (EU) 168/2013, (EU) 2018/858, 2018/1724 and (EU) 2019/1020; European Union: Belgium, Brussels, 2023.

- European Commission. Construction and Demolition Waste. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en (accessed on 7 November 2023).

- European Parliament; Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Union: Brussels, Belgium, 2008.

- Moschen-Schimek, J.; Kasper, T.; Huber-Humer, M. Critical Review of the Recovery Rates of Construction and Demolition Waste in the European Union—An Analysis of Influencing Factors in Selected EU Countries. Waste Manag. 2023, 167, 150–164.

- Mihai, F.-C. Construction and Demolition Waste in Romania: The Route from Illegal Dumping to Building Materials. Sustainability 2019, 11, 3179.

- Ellen Macarthur Foundation. Available online: https://ellenmacarthurfoundation.org/ (accessed on 8 July 2023).

- Charef, R.; Lu, W.; Hall, D. The Transition to the Circular Economy of the Construction Industry: Insights into Sustainable Approaches to Improve the Understanding. J. Clean. Prod. 2022, 364, 132421.

- Nußholz, J.; Çetin, S.; Eberhardt, L.; De Wolf, C.; Bocken, N. From Circular Strategies to Actions: 65 European Circular Building Cases and Their Decarbonisation Potential. Resour. Conserv. Recycl. Adv. 2023, 17, 200130.

- Setaki, F.; van Timmeren, A. Disruptive Technologies for a Circular Building Industry. Build. Environ. 2022, 223, 109394.

- Tavares, T.M.; Ganga, G.M.D.; Filho, M.G.; Rodrigues, V.P. The Benefits and Barriers of Additive Manufacturing for Circular Economy: A Framework Proposal. Sustain. Prod. Consum. 2023, 37, 369–388.

- Oluleye, B.I.; Chan, D.W.M.; Antwi-Afari, P. Adopting Artificial Intelligence for Enhancing the Implementation of Systemic Circularity in the Construction Industry: A Critical Review. Sustain. Prod. Consum. 2023, 35, 509–524.

- Marsh, A.T.M.; Velenturf, A.P.M.; Bernal, S.A. Circular Economy Strategies for Concrete: Implementation and Integration. J. Clean. Prod. 2022, 362, 132486.

- Figge, F.; Thorpe, A.S.; Givry, P.; Canning, L.; Franklin-Johnson, E. Longevity and Circularity as Indicators of Eco-Efficient Resource Use in the Circular Economy. Ecol. Econ. 2018, 150, 297–306.

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232.

- Mollaei, A.; Bachmann, C.; Haas, C. Estimating the Recoverable Value of In-Situ Building Materials. Sustain. Cities Soc. 2023, 91, 104455.

- Zhuang, G.L.; Shih, S.G.; Wagiri, F. Circular Economy and Sustainable Development Goals: Exploring the Potentials of Reusable Modular Components in Circular Economy Business Model. J. Clean. Prod. 2023, 414, 137503.

- Haines-Gadd, M.; Charnley, F.; Encinas-Oropesa, A. Self-Healing Materials: A Pathway to Immortal Products or a Risk to Circular Economy Systems? J. Clean. Prod. 2021, 315, 128193.

- Atta, N. Remanufacturing Towards Circularity in the Construction Sector: The Role of Digital Technologies. In Technological Imagination in the Green and Digital Transition; Springer International Publishing: Cham, Switzerland, 2023; pp. 493–503. ISBN 978-3-031-29515-7.

- van Stijn, A.; Gruis, V. Towards a Circular Built Environment: An Integral Design Tool for Circular Building Components. Smart Sustain. Built Environ. 2020, 9, 635–653.

- Hosseini, M.R.; Rameezdeen, R.; Chileshe, N.; Lehmann, S. Reverse Logistics in the Construction Industry. Waste Manag. Res. 2015, 33, 499–514.

- Ding, L.; Wang, T.; Chan, P.W. Forward and Reverse Logistics for Circular Economy in Construction: A Systematic Literature Review. J. Clean. Prod. 2023, 388, 135981.

- Antwi-Afari, P.; Ng, S.T.; Hossain, M.U. A Review of the Circularity Gap in the Construction Industry through Scientometric Analysis. J. Clean. Prod. 2021, 298, 126870.

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and Drivers in a Circular Economy: The Case of the Built Environment. Procedia CIRP 2019, 80, 619–624.

- Rebuydeal.Com. Available online: https://www.rebuydeal.com/en/buy-sell-second-hand/115/building-materials (accessed on 15 July 2023).

- Seconduse.Com. Available online: https://www.seconduse.com/inventory/categories/windows/ (accessed on 15 July 2023).

- Rotordc.Com. RotorDC—Deconstruction and Consulting, Photography by Pascal BROZE (2021162-20). 2022. Available online: https://rotordc.com/aboutus-1 (accessed on 7 November 2023).

- Oluleye, B.I.; Chan, D.W.M.; Saka, A.B.; Olawumi, T.O. Circular Economy Research on Building Construction and Demolition Waste: A Review of Current Trends and Future Research Directions. J. Clean. Prod. 2022, 357, 131927.

- Ghobadi, M.; Sepasgozar, S.M.E. Circular Economy Strategies in Modern Timber Construction as a Potential Response to Climate Change. J. Build. Eng. 2023, 77, 107229.

- Ahn, N.; Dodoo, A.; Riggio, M.; Muszynski, L.; Schimleck, L.; Puettmann, M. Circular Economy in Mass Timber Construction: State-of-the-Art, Gaps and Pressing Research Needs. J. Build. Eng. 2022, 53, 104562.

- Llana, D.F.; González-Alegre, V.; Portela, M.; Íñiguez-González, G. Cross Laminated Timber (CLT) Manufactured with European Oak Recovered from Demolition: Structural Properties and Non-Destructive Evaluation. Constr. Build. Mater. 2022, 339, 127635.

- Cobîrzan, N.; Balog, A.-A.; Thalmaier, G.; Nasui, M.; Munteanu, C.; Babota, F. Microscopical and Macroscopical Analysis of Recovered Bricks for Assessing Their Reusability in Masonry Buildings. Procedia Manuf. 2020, 46, 144–149.

- dos Reis, G.S.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700.

- Ramos, M.; Martinho, G.; Vasconcelos, L.; Ferreira, F. Local Scale Dynamics to Promote the Sustainable Management of Construction and Demolition Waste. Resour. Conserv. Recycl. Adv. 2023, 17, 200135.

- Sahoo, P.; Dwivedi, A.; Tuppad, S.M.; Gupta, S. Sequestration and Utilization of Carbon Dioxide to Improve Engineering Properties of Cement-Based Construction Materials with Recycled Brick Powder: A Pathway for Cleaner Construction. Constr. Build. Mater. 2023, 395, 132268.

- Bergonzoni, M.; Melloni, R.; Botti, L. Analysis of Sustainable Concrete Obtained from the By-Products of an Industrial Process and Recycled Aggregates from Construction and Demolition Waste. Procedia Comput. Sci. 2023, 217, 41–51.

- Ferrández, D.; Saiz, P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Towards a More Sustainable Environmentally Production System for the Treatment of Recycled Aggregates in the Construction Industry: An Experimental Study. Heliyon 2023, 9, e16641.

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Morón, C. New Lightened Plaster Material with Dissolved Recycled Expanded Polystyrene and End-of-Life Tyres Fibres for Building Prefabricated Industry. Case Stud. Constr. Mater. 2023, 18, e02178.

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Morón, C. Recovery of End-of-Life Tyres and Mineral Wool Waste: A Case Study with Gypsum Composite Materials Applying Circular Economy Criteria. Materials 2023, 16, 243.

- Sormunen, P.; Deviatkin, I.; Horttanainen, M.; Kärki, T. An Evaluation of Thermoplastic Composite Fillers Derived from Construction and Demolition Waste Based on Their Economic and Environmental Characteristics. J. Clean. Prod. 2021, 280, 125198.

- Ahmed, N. Utilizing Plastic Waste in the Building and Construction Industry: A Pathway towards the Circular Economy. Constr. Build. Mater. 2023, 383, 131311.

- Özçelikci, E.; Oskay, A.; Bayer, İ.R.; Şahmaran, M. Eco-Hybrid Cement-Based Building Insulation Materials as a Circular Economy Solution to Construction and Demolition Waste. Cem. Concr. Compos. 2023, 141, 105149.

- Seco, A.; Omer, J.; Marcelino, S.; Espuelas, S.; Prieto, E. Sustainable Unfired Bricks Manufacturing from Construction and Demolition Wastes. Constr. Build. Mater. 2018, 167, 154–165.

- dos Reis, G.S.; Cazacliu, B.G.; Cothenet, A.; Poullain, P.; Wilhelm, M.; Sampaio, C.H.; Lima, E.C.; Ambros, W.; Torrenti, J.M. Fabrication, Microstructure, and Properties of Fired Clay Bricks Using Construction and Demolition Waste Sludge as the Main Additive. J. Clean. Prod. 2020, 258, 120733.

- Islam, S.; Islam, J.; Robiul Hoque, N.M. Improvement of Consolidation Properties of Clay Soil Using Fine-Grained Construction and Demolition Waste. Heliyon 2022, 8, e11029.

- Giannopoulou, I.; Robert, P.M.; Sakkas, K.M.; Petrou, M.F.; Nicolaides, D. High Temperature Performance of Geopolymers Based on Construction and Demolition Waste. J. Build. Eng. 2023, 72, 106575.

- He, X.; Li, W.; Su, Y.; Zheng, Z.; Fu, J.; Zeng, J.; Tan, H.; Wu, Y.; Yang, J. Recycling of Plastic Waste Concrete to Prepare an Effective Additive for Early Strength and Late Permeability Improvement of Cement Paste. Constr. Build. Mater. 2022, 347, 128581.

- Thwe Win, T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of Polypropylene Fibers Extracted from Recycled Surgical Face Masks in Cement Mortar. Constr. Build. Mater. 2023, 391, 131845.

- Álvarez, M.; Santos, P.; Lopes, P.; Abrantes, D.; Ferrández, D. Performance Characterisation of a New Plaster Composite Lightened with End-of-Life Tyres’ Recycled Materials for False Ceiling Plates. Materials 2022, 15, 5660.

- Santos, P.; Mateus, D. Experimental Assessment of Thermal Break Strips Performance in Load-Bearing and Non-Load-Bearing LSF Walls. J. Build. Eng. 2020, 32, 101693.

- Santos, P.; Mateus, D.; Ferrandez, D.; Verdu, A. Numerical Simulation and Experimental Validation of Thermal Break Strips’ Improvement in Facade LSF Walls. Energies 2022, 15, 8169.

- Paihte, P.L.; Lalngaihawma, A.C.; Saini, G. Recycled Aggregate Filled Waste Plastic Bottles as a Replacement of Bricks. Mater. Today Proc. 2019, 15, 663–668.

- Lamy-Mendes, A.; Dora, A.; Pontinha, R.; Santos, P.; Durães, L. Aerogel Composites Produced from Silica and Recycled Rubber Sols for Thermal Insulation. Materials 2022, 15, 7897.

- Rodrigues Pontinha, A.D.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241.

- Chen, Q.; Feng, H.; Garcia de Soto, B. Revamping Construction Supply Chain Processes with Circular Economy Strategies: A Systematic Literature Review. J. Clean. Prod. 2022, 335, 130240.

- Amir, S.; Salehi, N.; Roci, M.; Sweet, S.; Rashid, A. Towards Circular Economy: A Guiding Framework for Circular Supply Chain Implementation. Bus. Strategy Environ. 2023, 32, 2684–2701.

- Yuan, F.; Shen, L.Y.; Li, Q.M. Emergy Analysis of the Recycling Options for Construction and Demolition Waste. Waste Manag. 2011, 31, 2503–2511.

- Roci, M.; Salehi, N.; Amir, S.; Shoaib-ul-Hasan, S.; Asif, F.M.A.; Mihelič, A.; Rashid, A. Towards Circular Manufacturing Systems Implementation: A Complex Adaptive Systems Perspective Using Modelling and Simulation as a Quantitative Analysis Tool. Sustain. Prod. Consum. 2022, 31, 97–112.

- Vegter, D.; van Hillegersberg, J.; Olthaar, M. Supply Chains in Circular Business Models: Processes and Performance Objectives. Resour. Conserv. Recycl. 2020, 162, 105046.

- Ahmed, R.R.; Zhang, X. Multi-Stage Network-Based Two-Type Cost Minimization for the Reverse Logistics Management of Inert Construction Waste. Waste Manag. 2021, 120, 805–819.

- Petrunya, Y.Y.; Pasichnyk, T.O. Impact of Modern Technologies on Logistics and Supply Chain Management. Mark. Manag. Innov. 2018, 9, 130–139.

- Seroka-Stolka, O.; Ociepa-Kubicka, A. Green Logistics and Circular Economy. Transp. Res. Procedia 2019, 39, 471–479.

- Munaro, M.R.; Tavares, S.F. A Review on Barriers, Drivers, and Stakeholders towards the Circular Economy: The Construction Sector Perspective. Clean. Responsible Consum. 2023, 8, 100107.

- Sáez, P.V.; Porras-Amores, C.; Del Río Merino, M. New Quantification Proposal for Construction Waste Generation in New Residential Constructions. J. Clean. Prod. 2015, 102, 58–65.

- Pallewatta, S.; Weerasooriyagedara, M.; Bordoloi, S.; Sarmah, A.K.; Vithanage, M. Reprocessed Construction and Demolition Waste as an Adsorbent: An Appraisal. Sci. Total Environ. 2023, 882, 163340.

- Ruvald, R.; Bertoni, A.; Askling, C.J. A Role for Physical Prototyping in Product-Service System Design: Case Study in Construction Equipment. Procedia CIRP 2019, 83, 358–362.

- Guerra, B.C.; Shahi, S.; Molleai, A.; Skaf, N.; Weber, O.; Leite, F.; Haas, C. Circular Economy Applications in the Construction Industry: A Global Scan of Trends and Opportunities. J. Clean. Prod. 2021, 324, 129125.

- Tseng, M.L.; Lin, S.; Chen, C.C.; Calahorrano Sarmiento, L.S.; Tan, C.L. A Causal Sustainable Product-Service System Using Hierarchical Structure with Linguistic Preferences in the Ecuadorian Construction Industry. J. Clean. Prod. 2019, 230, 477–487.

- Cook, M.; Gottberg, A.; Angus, A.; Longhurst, P. Receptivity to the Production of Product Service Systems in the UK Construction and Manufacturing Sectors: A Comparative Analysis. J. Clean. Prod. 2012, 32, 61–70.

- Zhang, D.; Hu, D.; Xu, Y.; Zhang, H. A Framework for Design Knowledge Management and Reuse for Product-Service Systems in Construction Machinery Industry. Comput. Ind. 2012, 63, 328–337.

- Li, C.Z.; Chen, Z.; Xue, F.; Kong, X.T.R.; Xiao, B.; Lai, X.; Zhao, Y. A Blockchain- and IoT-Based Smart Product-Service System for the Sustainability of Prefabricated Housing Construction. J. Clean. Prod. 2021, 286, 125391.

- Ness, D.; Xing, K.; Kim, K.; Jenkins, A. An ICT-Enabled Product Service System for Reuse of Building Components. IFAC-PapersOnLine 2019, 52, 761–766.

- Räisänen, J.; Ojala, A.; Tuovinen, T. Building Trust in the Sharing Economy: Current Approaches and Future Considerations. J. Clean. Prod. 2021, 279, 123724.

- Fraccascia, L.; Yazan, D.M. The Role of Online Information-Sharing Platforms on the Performance of Industrial Symbiosis Networks. Resour. Conserv. Recycl. 2018, 136, 473–485.

- Thierer, A.; Koopman, C.; Hobson, A.; Kuiper, C. How the Internet, the Sharing Economy, and Reputational How the Internet, the Sharing Economy, and Reputational Feedback Mechanisms Solve the “Lemons Problem” Feedback Mechanisms; University of Miami School of Law Institutional Repository: Miami, FL, USA, 2016; Volume 70.

- Lindhqvist, T. Extended Producer Responsibility in Cleaner Production: Policy Principle to Promote Environmental Improvements of Product Systems; Lund University: Lund, Sweden, 2000.

- Kasuga, A. Evolution of Fib Model Codes: Mastering Challenges and Encountering New Ones. Struct. Concr. 2023, 24, 4336–4340.

- Leal Filho, W.; Saari, U.; Fedoruk, M.; Iital, A.; Moora, H.; Klöga, M.; Voronova, V. An Overview of the Problems Posed by Plastic Products and the Role of Extended Producer Responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558.

- Jang, Y.C. Waste Electrical and Electronic Equipment (WEEE) Management in Korea: Generation, Collection, and Recycling Systems. J. Mater. Cycles Waste Manag. 2010, 12, 283–294.

- Xu, J.; Ye, M.; Lu, W.; Bao, Z.; Webster, C. A Four-Quadrant Conceptual Framework for Analyzing Extended Producer Responsibility in Offshore Prefabrication Construction. J. Clean. Prod. 2021, 282, 124540.

- Campbell-Johnston, K.; Calisto Friant, M.; Thapa, K.; Lakerveld, D.; Vermeulen, W.J.V. How Circular Is Your Tyre: Experiences with Extended Producer Responsibility from a Circular Economy Perspective. J. Clean. Prod. 2020, 270, 122042.

- Ferrão, P.; Ribeiro, P.; Silva, P. A Management System for End-of-Life Tyres: A Portuguese Case Study. Waste Manag. 2008, 28, 604–614.

- Deutz, P. Producer Responsibility in a Sustainable Development Context: Ecological Modernisation or Industrial Ecology? Geogr. J. 2009, 175, 274–285.

- Zhang, X.; Yousaf, H.M.A.U. Green Supply Chain Coordination Considering Government Intervention, Green Investment, and Customer Green Preferences in the Petroleum Industry. J. Clean. Prod. 2020, 246, 118984.

- Xie, Y.; Zhao, Y.Q.; Chen, Y.H.; Allen, C. Green Construction Supply Chain Management: Integrating Governmental Intervention and Public–Private Partnerships through Ecological Modernisation. J. Clean. Prod. 2022, 331, 129986.

- Bao, Z.; Lu, W.; Chi, B.; Yuan, H.; Hao, J. Procurement Innovation for a Circular Economy of Construction and Demolition Waste: Lessons Learnt from Suzhou, China. Waste Manag. 2019, 99, 12–21.

- Munoz-Jofre, J.; Hinojosa, S.; Mascle-Allemand, A.L.; Temprano, J. A Selectivity Index for Public-Private Partnership Projects in the Urban Water and Sanitation Sector in Latin America and the Caribbean. J. Environ. Manag. 2023, 335, 117564.

- Tang, L.Y.; Shen, Q.; Cheng, E.W.L. A Review of Studies on Public-Private Partnership Projects in the Construction Industry. Int. J. Proj. Manag. 2010, 28, 683–694.

- Azarian, M.; Shiferaw, A.T.; Laedre, O.; Wondimu, P.A.; Stevik, T.K. Project Ownership in Public-Private Partnership (PPP) Projects of Norway. Procedia Comput. Sci. 2023, 219, 1838–1846.

- Ampratwum, G.; Osei-Kyei, R.; Tam, V.W.Y. Exploring the Concept of Public-Private Partnership in Building Critical Infrastructure Resilience against Unexpected Events: A Systematic Review. Int. J. Crit. Infrastruct. Prot. 2022, 39, 100556.

- Ferrer, J.; Herrería, N.; Remón, A.; Armas, R.; Rivera, T.D.; Ramos, I.; Sartori, T.; Isla, M.; Morató, J.; Villanueva, B. Proyecto Economía Circular España—Acelerando La Transición En El Sector de Construcción. 2022.

- European Environment Agency (EEA). Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; Briefing No. 14/2019; European Environment Agency (EEA): Copenhagen, Denmark, 2019.

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital Concrete: A Review. Cem. Concr. Res. 2019, 123, 105780.

- Debnath, B.; Siraj, M.T.; Rashid, K.H.O.; Mainul Bari, A.B.M.; Karmaker, C.L.; Al Aziz, R. Analyzing the Critical Success Factors to Implement Green Supply Chain Management in the Apparel Manufacturing Industry: Implications for Sustainable Development Goals in the Emerging Economies. Sustain. Manuf. Serv. Econ. 2023, 2, 100013.

- Leder, S.; Menges, A. Architectural Design in Collective Robotic Construction. Autom. Constr. 2023, 156, 105082.

- Lee, S.; Pan, W.; Linner, T.; Bock, T. A Framework for Robot Assisted Deconstruction: Process, Sub-Systems and Modelling. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining: Connected to the Future, Oulu, Finland, 15–18 June 2015.

- Morató, J.; Jiménez, L.M. Informe COTEC—Situación y Evolución de La Economía Circular En España; Fundación Cotec Para La Innovación: Madrid, Spain, 2021.

- Charef, R.; Morel, J.C.; Rakhshan, K. Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review. Sustainability 2021, 13, 12989.

- Ababio, B.K.; Lu, W. Barriers and Enablers of Circular Economy in Construction: A Multi-System Perspective towards the Development of a Practical Framework. Constr. Manag. Econ. 2023, 41, 3–21.

- Hosseini, M.R.; Chileshe, N.; Rameezdeen, R.; Lehmann, S. Reverse Logistics for the Construction Industry: Lessons from the Manufacturing Context. Int. J. Constr. Eng. Manag. 2014, 3, 75–90.

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77.

- Tleuken, A.; Tokazhanov, G.; Jemal, K.M.; Shaimakhanov, R.; Sovetbek, M.; Karaca, F. Legislative, Institutional, Industrial and Governmental Involvement in Circular Economy in Central Asia: A Systematic Review. Sustainability 2022, 14, 8064.

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Borucki, C.; Karaca, F. Performance Assessment of Construction Companies for the Circular Economy: A Balanced Scorecard Approach. Sustain. Prod. Consum. 2022, 33, 991–1004.

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current State and Barriers to the Circular Economy in the Building Sector: Towards a Mitigation Framework. J. Clean. Prod. 2020, 276, 123250.

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212.

- Wuni, I.Y. Mapping the Barriers to Circular Economy Adoption in the Construction Industry: A Systematic Review, Pareto Analysis, and Mitigation Strategy Map. Build. Environ. 2022, 223, 109453.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

3 times

(View History)

Update Date:

01 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No