Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Camelia Ungureanu | -- | 2988 | 2024-01-18 10:57:04 | | | |

| 2 | Sirius Huang | Meta information modification | 2988 | 2024-01-19 01:35:24 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ungureanu, C.; Răileanu, S.; Zgârian, R.; Tihan, G.; Burnei, C. Gel-Based Membranes. Encyclopedia. Available online: https://encyclopedia.pub/entry/54034 (accessed on 08 February 2026).

Ungureanu C, Răileanu S, Zgârian R, Tihan G, Burnei C. Gel-Based Membranes. Encyclopedia. Available at: https://encyclopedia.pub/entry/54034. Accessed February 08, 2026.

Ungureanu, Camelia, Silviu Răileanu, Roxana Zgârian, Grațiela Tihan, Cristian Burnei. "Gel-Based Membranes" Encyclopedia, https://encyclopedia.pub/entry/54034 (accessed February 08, 2026).

Ungureanu, C., Răileanu, S., Zgârian, R., Tihan, G., & Burnei, C. (2024, January 18). Gel-Based Membranes. In Encyclopedia. https://encyclopedia.pub/entry/54034

Ungureanu, Camelia, et al. "Gel-Based Membranes." Encyclopedia. Web. 18 January, 2024.

Copy Citation

Gel-based membranes, a fusion of polymer networks and liquid components, have emerged as versatile tools in a variety of technological domains thanks to their unique structural and functional attributes. Historically rooted in basic filtration tasks, advancements in synthetic strategies have increased the mechanical strength, selectivity, and longevity of these membranes.

gel

membrane

biomedical applications

water treatment

energy storage

1. Introduction

The concept of membranes can be traced back to ancient civilizations, where simple forms of filtration using natural materials like sand, gravel, and charcoal were employed to purify water [1]. The 19th century saw the birth of dialysis; in 1861, Thomas Graham described the process of separating dissolved substances using “parchment or some analogous membrane” [2]. In the early 20th century, researchers began to use cellulose-based materials to make membranes. In the 1960s, the development of asymmetric cellulose acetate membranes led to the commercialization of the reverse osmosis process, a significant breakthrough for desalination and water purification. Around the same time, ultrafiltration membranes were developed using new polymer materials, enhancing their ability to separate macromolecules. In the latter half of the 20th century, there was significant interest in gas separation [3]. Membranes became a focus for separating gases such as oxygen and nitrogen from air. With the advancement of nanotechnology, new materials like zeolites, metal-organic frameworks (MOFs), and carbon-based materials (e.g., graphene oxide) started being explored for membrane fabrication. Membranes began to be designed not just for separation but also for additional functions such as catalysis, sensing, and antimicrobial activity. Given the increasing concerns over environmental pollution, there was a rising interest in membranes for wastewater treatment, desalination, and other sustainable applications [4][5].

The exploration of membranes for separation processes began with traditional materials like ceramics and polymers. As technology advanced, researchers sought materials that offered more flexibility, adaptability, and specificity. The development of hydrogels, comprising polymer chains crosslinked in a way to retain significant amounts of water, provided a foundation for a new type of membrane. When these hydrogels were further engineered to have controlled pore sizes and mechanical stability, they emerged as viable membrane materials [6][7][8].

The main advantages of the gel-based membranes are their adaptability to different environments due to their tunable nature, better selectivity due to controlled pore sizes, enhanced flux because of their higher water content, and improved biocompatibility, which makes them ideal for biological and medical applications [9][10]. As the search for efficient, adaptable, and sustainable materials in separation technologies intensifies, gel-based membranes have emerged as a beacon of innovation, bridging the gap between functionality and environmental responsibility. The importance of gel-based membranes can be found in multiple areas, such as biomedical applications, water treatment, environmental remediations and energy, durability and stability, sensing and detection, and economic and environmental impact [11][12].

2. Fundamental Properties of Gel-Based Membranes

Understanding the composition and structure of gel-based membranes is crucial as these factors directly influence their performance in various applications. The versatility in design and adaptability of these membranes comes from the ability to tweak these fundamental properties, which can lead to their widespread utilization in diverse technological fields [9]. Most gel-based membranes are made from a polymeric backbone. This could be natural polymers like agarose, chitosan, and alginate, or synthetic polymers like polyvinyl alcohol (PVA), polyacrylamide (PAM), and polyethylene glycol (PEG). To provide stability and determine the mechanical properties of the gel, crosslinking agents are added. Examples include glutaraldehyde for PVA or N,N’-methylenebisacrylamide for PAM. Depending on the intended use, specific functional monomers can be added to the gel composition, providing specialized properties like increased hydrophilicity, ionic conductivity, or reactive sites for further modifications [13][14][15]. To tailor specific properties or enhance functionality, various additives can be integrated, such as nanoparticles, salts, or organic solvents. At the microscopic level, gel-based membranes exhibit a porous network structure [16][17]. The size and distribution of these pores are crucial determinants of the membrane’s selectivity and permeability. Due to the high water content, these membranes usually exist in a swollen state, where water molecules are trapped within the polymeric matrix. This makes them highly hydrophilic, which in turn affects their permeability and rejection characteristics. The density and nature of the cross-linking play pivotal roles in determining the mechanical strength and flexibility of the membrane [18][19]. A higher cross-linking density usually leads to a stiffer but less swellable membrane. Advanced gel-based membranes might have multiple layers or a composite structure, each layer offering a specific function. For instance, a composite membrane might have a highly selective skin layer and a supportive and mechanically robust sublayer. Gel-based membranes have distinct characteristics that set them apart from other conventional membrane types [20][21]. Due to their gelatinous nature, these membranes exhibit a high degree of swelling, allowing them to retain significant amounts of water. This feature not only enhances their hydrophilicity but also improves their permeation characteristics, especially in aqueous environments [22]. The properties of gel-based membranes, such as pore size, mechanical strength, and chemical functionality, can be easily tailored during the synthesis process by varying the type of monomer, cross-linking agent, and polymerization conditions [23][24]. Some gel-based membranes have the unique ability to heal themselves after being damaged, owing to their dynamic cross-linked network [25][26]. Also, gel-based membranes can be engineered to respond to external stimuli such as pH, temperature, or ionic strength. This responsive behavior can be leveraged for controlled substance release or selective separation applications [27][28]. Unlike rigid ceramic membranes or certain polymeric membranes, gel-based membranes are inherently soft and flexible, which can reduce the risk of fracturing under mechanical stress [29][30]. Despite their soft nature, many gel-based membranes exhibit remarkable stability under various thermal and chemical conditions, especially when designed with specific cross-linkers or additives [31][32]. Also, the high water content and hydrophilic nature of gel-based membranes can reduce the affinity of foulants to the membrane surface, leading to decreased fouling tendencies in applications like water purification [33][34]. Some gel-based membranes, especially those integrated with specific nanoparticles or dyes, can showcase tunable optical properties, which are useful in sensing and detection applications [35]. These distinct properties make gel-based membranes versatile and adaptable to a plethora of applications. Their ability to combine the strengths of both polymeric and ceramic membranes, along with their unique features, underpins their growing significance in the field of advanced separation and filtration technologies.

3. Advances in Gel-Based Membrane Technology

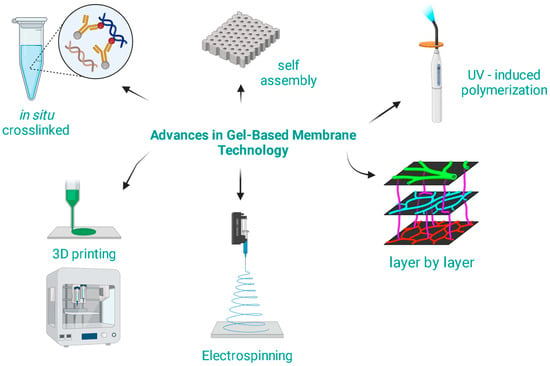

The modern synthesis techniques are not only more efficient but also allow for greater tunability and specificity of the membrane properties [36][37][38]. Some key advances in the synthesis methods for gel-based membranes are presented in Figure 1.

Figure 1. Advances in gel-based membrane technology.

- (a)

-

Interfacial polymerization involves the reaction of two immiscible solutions at their interface, leading to the formation of a thin, dense polymeric layer [33]. By adjusting the monomers and conditions, one can tailor the properties of the resulting gel-based membrane. Yuan et al. [34] introduced a novel method for creating thin film composite nanofiltration membranes to tackle global water shortages exacerbated by population growth and water pollution. This technique utilized hydrogel-assisted interfacial polymerization, which incorporated piperazine monomers within a hydrogel that acted as the aqueous phase. This approach facilitated a more uniform polymerization process at the interface, slowed the diffusion of piperazine monomers, and enhanced the mechanical robustness of the resulting polyamide selective layer. Furthermore, the underlying principles contributing to the high permeance were investigated through theoretical simulations of the hydrogel-assisted interfacial polymerization. Significantly, the production method for these hydrogel-thin film composite membranes was straightforward, suggesting potential for cost-effective and scalable manufacturing, which is crucial for widespread application in addressing water scarcity challenges [39][40].

- (b)

-

Electrospinning allows for the creation of membranes with high porosity and adjustable fiber diameters. By applying a high voltage to a polymer solution, fibers can be drawn and deposited on a substrate, resulting in nanofibrous gel-based membranes [41][42]. Al-Baadani et al. [41] explored polycaprolactone/gelatin (PCL/Gel) composite membranes, assessing their biocompatibility and controlled drug release capabilities for the first time. Gelatin enhanced osteoblast adhesion and differentiation, while polycaprolactone improved mechanical durability. The study found that adjusting the amount and size of PCL fibers can control the degradation of gelatin and the release patterns of hydrophilic drugs or proteins. Lower PCL content led to a quick dissolution of gelatin fibers and a rapid drug release within one week. Conversely, higher PCL levels slowed the release rate, extending the duration to over two weeks, which could be beneficial for bone regeneration applications. The findings indicate that PCL/Gel composite membranes fabricated via co-electrospinning could be an effective method for creating customizable drug delivery systems that support bone healing.

- (c)

-

Layer-by-Layer (LbL) assembly uses the alternate deposition of positively and negatively charged polymers, building up multi-layered structures. The method allows for the precise control of membrane thickness and functionality. LbL techniques can help in crafting multilayered membranes, where each layer can cater to a specific separation requirement, offering improved overall selectivity. In a review paper, Liu et al. [43] focused on multi-layered hydrogels, which are preferred materials for biomedical applications due to their organized functional layers. It compiled recent advancements in multi-layered hydrogels, categorizing them based on their fabrication techniques such as layer-by-layer self-assembly, stepwise, photo-polymerization, and sequential electrospinning. The review also examined the morphology of these hydrogels and their various biomedical uses. It concluded by addressing the current challenges faced in the development of multi-layered hydrogels and suggested that 3D printing technology may offer innovative solutions for designing these materials, potentially broadening their biomedical applications.

- (d)

-

During in situ cross-linking, the membrane is formed by introducing cross-linking agents directly into the polymer solution or gel, triggering cross-linking in place. This can provide enhanced mechanical stability and tailor the swelling behavior of the gel-based membrane [44][45]. Leone et al. [39] studied the production of such hydrogels designed for wound healing, particularly in treating complex blast injuries. In situ-forming hydrogels are emerging as versatile biomaterials for patient-specific biomedical applications like cell therapy and drug delivery. Researchers developed bionanocomposite hydrogels by integrating oxidized polysaccharides (which have aldehyde groups), chitosan (rich in amine groups), and nanostructured zinc oxide. They thoroughly examined the physicochemical properties of these components, their cytotoxicity towards HaCat skin cells, and the release profile of zinc ions on synthetic skin models. The hydrogels formed rapidly in situ, exhibited no toxicity at functional levels for HaCat cells, and successfully released Zn2+ ions, indicating the potential to promote wound healing.

- (e)

-

UV-induced polymerization uses ultraviolet light to initiate polymerization and cross-linking within the gel precursor. It offers rapid synthesis and the potential for spatial control over membrane properties [46][47]. Siccardi et al. [41] introduced a novel approach using UV-induced, solvent-free radical copolymerization to create a solid polymer electrolyte with enhanced properties. Solid polymer electrolytes offer a safer alternative for lithium metal batteries, but their practical use is hindered by low ionic conductivity and poor cyclability at room temperature. When activated with a small amount of liquid electrolyte, these polymers demonstrated high thermal resistance, good lithium-ion conductivity, and a wide electrochemical window. The polymers exhibited excellent interfacial stability, enabling stable lithium metal plating and stripping at room temperature. This research led to a significant advancement toward developing safer, room-temperature operable, self-healing quasi-solid-state lithium metal batteries.

- (f)

-

With the self-assembly method, some gel-based systems can spontaneously organize into structured networks through non-covalent interactions like hydrogen bonding, electrostatic forces, or π-π stacking. This bottom-up approach can lead to membranes with highly ordered nanostructures [48][49]. Braun et al. [43] investigated the self-assembly of the hydrogel-forming peptide, revealing the microscopic steps of its formation. By applying theoretical models of linear polymerization to kinetic data, it was discovered that peptide fibril formation is predominantly driven by fibril-catalyzed secondary nucleation. Furthermore, the peptide’s self-assembly processes exhibited enzyme-like saturation, indicating that they are not simply chemical reactions but are regulated in a manner like biological systems. The study quantified the rates of these processes at various concentrations and the evolution of these rates throughout the assembly. This novel mechanistic approach, distinct from traditional material science methods, could lead to more a sophisticated design and application of self-assembling hydrogels in medicine.

- (g)

-

Microfluidic fabrication allows for the controlled synthesis of gel particles or fibers with uniform sizes and shapes. When these are used to fabricate membranes, they can offer highly reproducible transport properties [50][51]. Correa et al. [44] explored the biofabrication of stable, aligned collagen hydrogels within microfluidic devices, aiming to improve tissue and organ models for extended culture times. Collagen-alginate microgels were created by cross-linking with calcium ions within a microfluidic channel, using a chitosan membrane to allow ion diffusion without convection. These gels formed rapidly into isolated structures and their growth was self-regulating. By adjusting the calcium concentration and the flow rate of the collagen-alginate solution, gel thickness could be precisely controlled between 30 and 200 μm. Less calcium and higher flow rates resulted in more compressed gels, especially further from the pores. The study also showed that the gels allowed size-dependent diffusion of molecules, making them suitable for on-chip models that require the invasion of a dense extracellular matrix, cancer growth, and targeted drug delivery. This demonstrates the potential of controlled physicochemical parameters for collagen gel formation in microfluidic applications.

- (h)

-

Incorporation of nanomaterials: Modern synthesis methods have adapted to integrate various nanomaterials like metal nanoparticles, carbon nanotubes, or graphene oxide into the gel matrix. This enhances the functional properties of the membrane, from improved mechanical strength to specialized separation characteristics [52][53].

- (i)

-

3D Printing techniques are being explored to create gel-based membranes with intricate structures, customizable geometries, and multi-functional regions [54][55]. Tayebi et al. [49] highlighted the creation of scaffolds designed for the cultivation of full-thickness oral mucosa, representing a type of heterogeneous tissue. By exploring these dimensions, the paper provided insights into the nuanced production of biologically relevant models using 3D printing technology, which holds potential for advancing tissue engineering and regenerative medicine. Biological membranes, while seemingly two-dimensional, possess intricate structures extending into the third dimension. Three-dimensional printing, particularly through layer-by-layer assembly, emerged as a sophisticated technique for crafting models that embody this complexity. Nonetheless, printing certain hydrogels like gelatin can be challenging due to their unique rheological properties. The authors tackled these challenges by analyzing the complexities of 3D printing gelatin, proposing a reproducible method to surmount the associated experimental hurdles, and detailing the design specifications and fabrication process for 3D printed gelatin membranes.

These modern synthesis methods underscore the versatility and adaptability of gel-based membrane technology. By leveraging these techniques, researchers can design membranes for specific applications with unprecedented precision, paving the way for innovations across diverse industrial domains.

The advancements in gel-based membrane technology have ushered in significant enhancements in mechanical strength, selectivity, and longevity. The density and nature of cross-linking have been optimized to provide higher mechanical robustness [56]. For instance, dual cross-linking, involving both physical and chemical bonds, can significantly boost strength [57]. The introduction of nanofillers like silica nanoparticles, carbon nanotubes, or graphene oxide can reinforce the gel matrix, leading to improved tensile strength and toughness [58]. Creating hybrid structures by incorporating both organic and inorganic components can marry the flexibility of polymers with the rigidity of inorganic materials, leading to enhanced mechanical properties [59]. Advanced synthesis methods allow for precise control over pore sizes, enabling high selectivity based on the size of molecules or ions. The introduction of specific functional groups or ligands can enhance selectivity based on chemical interactions, such as hydrogen bonding, electrostatic attractions, or even affinity-based separations [60]. Incorporation of hydrophilic groups or zwitterionic components can provide antifouling properties, reducing membrane fouling and thereby extending its lifespan for applications. Chemical modifications or the inclusion of stabilizing agents can render the membranes more resistant to harsh conditions like extreme pH, high temperatures, or aggressive solvents [61]. Some modern gel-based membranes are imbued with self-healing capabilities, where minor damage can be auto-repaired, thus prolonging their operational lifespan [62][63]. The addition of protective coatings or layers can shield the membrane from mechanical abrasions, aggressive chemicals, or microbial attacks, thereby extending its durability [64]. The development of efficient cleaning-in-place (CIP) and maintenance protocols has further bolstered the longevity of gel-based membranes in industrial applications [65].

These enhancements in mechanical strength, selectivity, and longevity underline the commitment of researchers and industries to optimize gel-based membrane technology. Such improvements ensure that these membranes can meet the rigorous demands of contemporary applications while maintaining operational efficiency over extended periods. Incorporating nanoparticles or functional groups into membranes has provided an avenue to tailor membrane properties to specific needs [66]. This customizable approach ensures that the resultant membranes are not only more efficient but also versatile in handling a wide range of applications. For example, by incorporating metal and metal oxide nanoparticles like silver (Ag), gold (Au), titanium dioxide (TiO2), and zinc oxide (ZnO), they can impart antimicrobial properties, improve thermal stability, and enhance mechanical strength [67][68][69]. Also, incorporating magnetic nanoparticles is useful in applications where remote actuation or controlled movement is required, like in drug delivery or targeted separations. Nanoparticles can add size-exclusion properties or even specific affinity interactions that can enhance the selectivity of membranes [70]. Certain nanoparticles can improve the porosity and hydrophilicity of the membranes, leading to improved permeation rates [71]. Incorporating groups like -OH, -COOH, or -NH2 can also enhance the hydrophilicity of the membrane, reducing fouling and improving water flux. Zwitterionic Groups have both positive and negative charges, which can greatly reduce protein or microbial fouling due to their unique surface properties [72].

Functional groups like epoxy, carboxyl, or amine can allow for further modifications, tethering of other molecules, or even specific interactions with target substances [73].

The introduction of charged moieties (like sulfonic or quaternary ammonium groups) can enhance the ionic selectivity of the membrane, useful in processes like desalination or ion exchange [74]. Functional groups that have a specific affinity for certain contaminants (e.g., chelating agents for heavy metal capture) can be introduced into membranes to provide selectivity based on chemical interactions [75].

The integration of nanoparticles and functional groups into water treatment membranes has set a new benchmark for efficiency, selectivity, and sustainability. These advanced membranes not only ensure cleaner water but also promise more energy-efficient and eco-friendly water treatment solutions. Gel-based membranes, with their unique properties and adaptability, hold great potential in revolutionizing water treatment processes, providing both efficiency and sustainability [76].

References

- Malik, S.; Khyalia, P.; Singh Laura, J. Chapter 7—Conventional methods and materials used for water treatment in rural areas. In Water Resources Management for Rural Development; Madhav, S., Srivastav, A.L., Chibueze Izah, S., Hullebusch, E.v., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 79–90.

- Ling, G.N. Chapter 6—Colloid, the Brain Child of a Chemist. In Life at the Cell and Below-Cell Level. The Hidden History of a Fundamental Revolution in Biology; Pacific Press: New York, NY, USA, 2001; pp. 29–34.

- Linder, C.; Kedem, O. History of Nanofiltration Membranes from 1960 to 1990. In Nanofiltration; Wiley: Hoboken, NJ, USA, 2021; pp. 1–34.

- Kujawa, J.; Al-Gharabli, S.; Muzioł, T.M.; Knozowska, K.; Li, G.; Dumée, L.F.; Kujawski, W. Crystalline porous frameworks as nano-enhancers for membrane liquid separation—Recent developments. Coord. Chem. Rev. 2021, 440, 213969.

- Căprărescu, S.; Zgârian, R.G.; Tihan, G.T.; Purcar, V.; Eftimie Totu, E.; Modrogan, C.; Chiriac, A.-L.; Nicolae, C.A. Biopolymeric Membrane Enriched with Chitosan and Silver for Metallic Ions Removal. Polymers 2020, 12, 1792.

- Ulbricht, M. Advanced functional polymer membranes. Polymer 2006, 47, 2217–2262.

- Kaliaraj, G.S.; Shanmugam, D.K.; Dasan, A.; Mosas, K.K.A. Hydrogels—A Promising Materials for 3D Printing Technology. Gels 2023, 9, 260.

- Atia, G.A.N.; Shalaby, H.K.; Ali, N.G.; Morsy, S.M.; Ghobashy, M.M.; Attia, H.A.N.; Barai, P.; Nady, N.; Kodous, A.S.; Barai, H.R. New Challenges and Prospective Applications of Three-Dimensional Bioactive Polymeric Hydrogels in Oral and Craniofacial Tissue Engineering: A Narrative Review. Pharmaceuticals 2023, 16, 702.

- Thang, N.H.; Chien, T.B.; Cuong, D.X. Polymer-Based Hydrogels Applied in Drug Delivery: An Overview. Gels 2023, 9, 523.

- Radu, E.R.; Voicu, S.I.; Thakur, V.K. Polymeric Membranes for Biomedical Applications. Polymers 2023, 15, 619.

- Rando, G.; Sfameni, S.; Plutino, M.R. Development of Functional Hybrid Polymers and Gel Materials for Sustainable Membrane-Based Water Treatment Technology: How to Combine Greener and Cleaner Approaches. Gels 2023, 9, 9.

- Burratti, L.; Prosposito, P.; Venditti, I. Functionalized Gels for Environmental Applications. Gels 2023, 9, 818.

- Hussain, S.; Maktedar, S.S. Structural, functional and mechanical performance of advanced Graphene-based composite hydrogels. Results Chem. 2023, 6, 101029.

- Varghese, S.A.; Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J. Chapter 2—Natural polymers and the hydrogels prepared from them. In Hydrogels Based on Natural Polymers; Chen, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 17–47.

- Talebian, S.; Mehrali, M.; Taebnia, N.; Pennisi, C.P.; Kadumudi, F.B.; Foroughi, J.; Hasany, M.; Nikkhah, M.; Akbari, M.; Orive, G.; et al. Self-Healing Hydrogels: The Next Paradigm Shift in Tissue Engineering? Adv. Sci. 2019, 6, 1801664.

- Baskaran, K.; Ali, M.; Gingrich, K.; Porter, D.L.; Chong, S.; Riley, B.J.; Peak, C.W.; Naleway, S.E.; Zharov, I.; Carlson, K. Sol-gel derived silica: A review of polymer-tailored properties for energy and environmental applications. Microporous Mesoporous Mater. 2022, 336, 111874.

- Das, A.; Ringu, T.; Ghosh, S.; Pramanik, N. A comprehensive review on recent advances in preparation, physicochemical characterization, and bioengineering applications of biopolymers. Polym. Bull. 2023, 80, 7247–7312.

- Sahu, A.; Dosi, R.; Kwiatkowski, C.; Schmal, S.; Poler, J.C. Advanced Polymeric Nanocomposite Membranes for Water and Wastewater Treatment: A Comprehensive Review. Polymers 2023, 15, 540.

- Nafti Mateur, M.; Gonzalez Ortiz, D.; Jellouli Ennigrou, D.; Horchani-Naifer, K.; Bechelany, M.; Miele, P.; Pochat-Bohatier, C. Porous Gelatin Membranes Obtained from Pickering Emulsions Stabilized with h-BNNS: Application for Polyelectrolyte-Enhanced Ultrafiltration. Membranes 2020, 10, 144.

- Hou, Y.; Ma, S.; Hao, J.; Lin, C.; Zhao, J.; Sui, X. Construction and Ion Transport-Related Applications of the Hydrogel-Based Membrane with 3D Nanochannels. Polymers 2022, 14, 4037.

- Sikdar, P.; Uddin, M.M.; Dip, T.M.; Islam, S.; Hoque, M.S.; Dhar, A.K.; Wu, S. Recent advances in the synthesis of smart hydrogels. Mater. Adv. 2021, 2, 4532–4573.

- Ho, T.-C.; Chang, C.-C.; Chan, H.-P.; Chung, T.-W.; Shu, C.-W.; Chuang, K.-P.; Duh, T.-H.; Yang, M.-H.; Tyan, Y.-C. Hydrogels: Properties and Applications in Biomedicine. Molecules 2022, 27, 2902.

- Foudazi, R.; Zowada, R.; Manas-Zloczower, I.; Feke, D.L. Porous Hydrogels: Present Challenges and Future Opportunities. Langmuir 2023, 39, 2092–2111.

- Morteza, B.; Naimeh, M.; Mehdi, M. An Introduction to Hydrogels and Some Recent Applications. In Emerging Concepts in Analysis and Applications of Hydrogels; Sutapa Biswas, M., Ed.; IntechOpen: Rijeka, Croatia, 2016; Chapter 2.

- Devi, V.K.A.; Shyam, R.; Palaniappan, A.; Jaiswal, A.K.; Oh, T.-H.; Nathanael, A.J. Self-Healing Hydrogels: Preparation, Mechanism and Advancement in Biomedical Applications. Polymers 2021, 13, 3782.

- Quan, L.; Xin, Y.; Wu, X.; Ao, Q. Mechanism of Self-Healing Hydrogels and Application in Tissue Engineering. Polymers 2022, 14, 2184.

- Li, J.; Mooney, D.J. Designing hydrogels for controlled drug delivery. Nat. Rev. Mater. 2016, 1, 16071.

- Kaner, P.; Bengani-Lutz, P.; Sadeghi, I.; Asatekin, A. Responsive filtration membranes by polymer self-assembly. Technology 2016, 04, 217–228.

- Hamoudi, L.; Akretche, D.E.; Hadadi, A.; Amrane, A.; Mouni, L. Comparative Study of Ceramic Membranes Developed on Different Algerian Natural Clays for Industrial-Effluent Filtration. Minerals 2023, 13, 273.

- National Research Council. Polymer Science and Engineering: The Shifting Research Frontiers. In 3. Manufacturing: Materials and Processing; The National Academies Press: Washington, DC, USA, 1994.

- Parhi, R. Cross-Linked Hydrogel for Pharmaceutical Applications: A Review. Adv. Pharm. Bull. 2017, 7, 515–530.

- Mashabela, L.T.; Maboa, M.M.; Miya, N.F.; Ajayi, T.O.; Chasara, R.S.; Milne, M.; Mokhele, S.; Demana, P.H.; Witika, B.A.; Siwe-Noundou, X.; et al. A Comprehensive Review of Cross-Linked Gels as Vehicles for Drug Delivery to Treat Central Nervous System Disorders. Gels 2022, 8, 563.

- Shahkaramipour, N.; Tran, T.N.; Ramanan, S.; Lin, H. Membranes with Surface-Enhanced Antifouling Properties for Water Purification. Membranes 2017, 7, 13.

- Ahmed, M.A.; Amin, S.; Mohamed, A.A. Fouling in reverse osmosis membranes: Monitoring, characterization, mitigation strategies and future directions. Heliyon 2023, 9, e14908.

- Quazi, M.Z.; Hwang, J.; Song, Y.; Park, N. Hydrogel-Based Biosensors for Effective Therapeutics. Gels 2023, 9, 545.

- Ciolacu, D.E.; Nicu, R.; Ciolacu, F. Cellulose-Based Hydrogels as Sustained Drug-Delivery Systems. Materials 2020, 13, 5270.

- Rabiee, N.; Sharma, R.; Foorginezhad, S.; Jouyandeh, M.; Asadnia, M.; Rabiee, M.; Akhavan, O.; Lima, E.C.; Formela, K.; Ashrafizadeh, M.; et al. Green and Sustainable Membranes: A review. Environ. Res. 2023, 231, 116133.

- Owens, G.J.; Singh, R.K.; Foroutan, F.; Alqaysi, M.; Han, C.-M.; Mahapatra, C.; Kim, H.-W.; Knowles, J.C. Sol–gel based materials for biomedical applications. Prog. Mater. Sci. 2016, 77, 1–79.

- Ma, Z.-Y.; Xue, Y.-R.; Xu, Z.-K. Alginate Hydrogel Assisted Controllable Interfacial Polymerization for High-Performance Nanofiltration Membranes. Membranes 2021, 11, 435.

- Yuan, S.; Zhang, G.; Zhu, J.; Mamrol, N.; Liu, S.; Mai, Z.; Van Puyvelde, P.; Van der Bruggen, B. Hydrogel assisted interfacial polymerization for advanced nanofiltration membranes. J. Mater. Chem. A 2020, 8, 3238–3245.

- Al-Baadani, M.A.; Hii Ru Yie, K.; Al-Bishari, A.M.; Alshobi, B.A.; Zhou, Z.; Fang, K.; Dai, B.; Shen, Y.; Ma, J.; Liu, J.; et al. Co-electrospinning polycaprolactone/gelatin membrane as a tunable drug delivery system for bone tissue regeneration. Mater. Des. 2021, 209, 109962.

- Zeugolis, D.I.; Khew, S.T.; Yew, E.S.Y.; Ekaputra, A.K.; Tong, Y.W.; Yung, L.-Y.L.; Hutmacher, D.W.; Sheppard, C.; Raghunath, M. Electro-spinning of pure collagen nano-fibres—Just an expensive way to make gelatin? Biomaterials 2008, 29, 2293–2305.

- Liu, G.; Ding, Z.; Yuan, Q.; Xie, H.; Gu, Z. Multi-Layered Hydrogels for Biomedical Applications. Front. Chem. 2018, 6, 439.

- Xiangdong, B.; Aiye, L. In Situ-Forming Cross-linking Hydrogel Systems: Chemistry and Biomedical Applications. In Emerging Concepts in Analysis and Applications of Hydrogels; Sutapa Biswas, M., Ed.; IntechOpen: Rijeka, Croatia, 2016; Chapter 6.

- Leone, F.; Firlak, M.; Challen, K.; Bonnefin, W.; Onida, B.; Wright, K.L.; Hardy, J.G. In Situ Crosslinking Bionanocomposite Hydrogels with Potential for Wound Healing Applications. J. Funct. Biomater. 2019, 10, 50.

- Nair, J.R.; Chiappone, A.; Destro, M.; Jabbour, L.; Meligrana, G.; Gerbaldi, C. UV-Induced Radical Photo-Polymerization: A Smart Tool for Preparing Polymer Electrolyte Membranes for Energy Storage Devices. Membranes 2012, 2, 687–704.

- Siccardi, S.; Amici, J.; Colombi, S.; Carvalho, J.T.; Versaci, D.; Quartarone, E.; Pereira, L.; Bella, F.; Francia, C.; Bodoardo, S. UV-cured self-healing gel polymer electrolyte toward safer room temperature lithium metal batteries. Electrochim. Acta 2022, 433, 141265.

- Zhi, K.; Wang, J.; Zhao, H.; Yang, X. Self-assembled small molecule natural product gel for drug delivery: A breakthrough in new application of small molecule natural products. Acta Pharm. Sin. B 2020, 10, 913–927.

- Braun, G.A.; Ary, B.E.; Dear, A.J.; Rohn, M.C.H.; Payson, A.M.; Lee, D.S.M.; Parry, R.C.; Friedman, C.; Knowles, T.P.J.; Linse, S.; et al. On the Mechanism of Self-Assembly by a Hydrogel-Forming Peptide. Biomacromolecules 2020, 21, 4781–4794.

- Correa, S.O.; Luo, X.; Raub, C.B. Microfluidic fabrication of stable collagen microgels with aligned microstructure using flow-driven co-deposition and ionic gelation. J. Micromech. Microeng. 2020, 30, 085002.

- De Geest, B.G.; Urbanski, J.P.; Thorsen, T.; Demeester, J.; De Smedt, S.C. Synthesis of Monodisperse Biodegradable Microgels in Microfluidic Devices. Langmuir 2005, 21, 10275–10279.

- Herrera-Ruiz, A.; Tovar, B.B.; García, R.G.; Tamez, M.F.L.; Mamidi, N. Nanomaterials-Incorporated Chemically Modified Gelatin Methacryloyl-Based Biomedical Composites: A Novel Approach for Bone Tissue Engineering. Pharmaceutics 2022, 14, 2645.

- Bokov, D.; Turki Jalil, A.; Chupradit, S.; Suksatan, W.; Javed Ansari, M.; Shewael, I.H.; Valiev, G.H.; Kianfar, E. Nanomaterial by Sol-Gel Method: Synthesis and Application. Adv. Mater. Sci. Eng. 2021, 2021, 5102014.

- Zhang, X.N.; Zheng, Q.; Wu, Z.L. Recent advances in 3D printing of tough hydrogels: A review. Compos. Part B 2022, 238, 109895.

- Tayebi, L.; Rasoulianboroujeni, M.; Cui, Z.; Ye, H. 3D-printed thick structured gelatin membrane for engineering of heterogeneous tissues. Mater. Lett. 2018, 217, 39–43.

- Bashir, S.; Hina, M.; Iqbal, J.; Rajpar, A.H.; Mujtaba, M.A.; Alghamdi, N.A.; Wageh, S.; Ramesh, K.; Ramesh, S. Fundamental Concepts of Hydrogels: Synthesis, Properties, and Their Applications. Polymers 2020, 12, 2702.

- Carrico, J.D.; Tyler, T.; Leang, K.K. A comprehensive review of select smart polymeric and gel actuators for soft mechatronics and robotics applications: Fundamentals, freeform fabrication, and motion control. Int. J. Smart Nano Mater. 2017, 8, 144–213.

- Ganguly, S.; Das, P.; Bose, M.; Das, T.K.; Mondal, S.; Das, A.K.; Das, N.C. Sonochemical green reduction to prepare Ag nanoparticles decorated graphene sheets for catalytic performance and antibacterial application. Ultrason. Sonochem. 2017, 39, 577–588.

- Sachot, N.; Engel, E.; Castano, O. Hybrid Organic-Inorganic Scaffolding Biomaterials for Regenerative Therapies. Curr. Org. Chem. 2014, 18, 2299–2314.

- Shi, Y.; Zhang, J.; Pan, L.; Shi, Y.; Yu, G. Energy gels: A bio-inspired material platform for advanced energy applications. Nano Today 2016, 11, 738–762.

- Amira, A.; Huu, D.; Ali, L. Applications of Biomimetic and Bioinspired Membranes. In Biomimetic and Bioinspired Membranes for New Frontiers in Sustainable Water Treatment Technology; Amira, A., Huu, D., Ali, L., Eds.; IntechOpen: Rijeka, Croatia, 2017; Chapter 8.

- Wei, Z.; Yang, J.H.; Zhou, J.; Xu, F.; Zrínyi, M.; Dussault, P.H.; Osada, Y.; Chen, Y.M. Self-healing gels based on constitutional dynamic chemistry and their potential applications. Chem. Soc. Rev. 2014, 43, 8114–8131.

- Xu, C.; Zhan, W.; Tang, X.; Mo, F.; Fu, L.; Lin, B. Self-healing chitosan/vanillin hydrogels based on Schiff-base bond/hydrogen bond hybrid linkages. Polym. Test. 2018, 66, 155–163.

- Ray, P.; Chakraborty, R.; Banik, O.; Banoth, E.; Kumar, P. Surface Engineering of a Bioartificial Membrane for Its Application in Bioengineering Devices. ACS Omega 2023, 8, 3606–3629.

- Chung, M.M.S.; Arbour, A.J.; Huang, J.-Y. Microbubble-Assisted Cleaning-in-Place Process for Ultrafiltration System and Its Environmental Performance. Membranes 2023, 13, 424.

- Liu, S.; Low, Z.-X.; Hegab, H.M.; Xie, Z.; Ou, R.; Yang, G.; Simon, G.P.; Zhang, X.; Zhang, L.; Wang, H. Enhancement of desalination performance of thin-film nanocomposite membrane by cellulose nanofibers. J. Membr. Sci. 2019, 592, 117363.

- Khdary, N.H.; Almuarqab, B.T.; El Enany, G. Nanoparticle-Embedded Polymers and Their Applications: A Review. Membranes 2023, 13, 537.

- Ng, L.Y.; Mohammad, A.W.; Leo, C.P.; Hilal, N. Polymeric membranes incorporated with metal/metal oxide nanoparticles: A comprehensive review. Desalination 2013, 308, 15–33.

- Salim, S.H.; Al-Anbari, R.H.; Haider, A.J. Polymeric Membrane with Nanomaterial’s for Water Purification: A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 779, 012103.

- Sadeghi, A.; PourEskandar, S.; Askari, E.; Akbari, M. Polymeric Nanoparticles and Nanogels: How Do They Interact with Proteins? Gels 2023, 9, 632.

- Khraisheh, M.; Elhenawy, S.; AlMomani, F.; Al-Ghouti, M.; Hassan, M.K.; Hameed, B.H. Recent Progress on Nanomaterial-Based Membranes for Water Treatment. Membranes 2021, 11, 995.

- Li, M.; Zhuang, B.; Yu, J. Functional Zwitterionic Polymers on Surface: Structures and Applications. Chem. Asian J. 2020, 15, 2060–2075.

- Basinska, T.; Gadzinowski, M.; Mickiewicz, D.; Slomkowski, S. Functionalized Particles Designed for Targeted Delivery. Polymers 2021, 13, 2022.

- Stenina, I.; Golubenko, D.; Nikonenko, V.; Yaroslavtsev, A. Selectivity of Transport Processes in Ion-Exchange Membranes: Relationship with the Structure and Methods for Its Improvement. Int. J. Mol. Sci. 2020, 21, 5517.

- Darban, Z.; Shahabuddin, S.; Gaur, R.; Ahmad, I.; Sridewi, N. Hydrogel-Based Adsorbent Material for the Effective Removal of Heavy Metals from Wastewater: A Comprehensive Review. Gels 2022, 8, 263.

- Kolya, H.; Kang, C.-W. Next-Generation Water Treatment: Exploring the Potential of Biopolymer-Based Nanocomposites in Adsorption and Membrane Filtration. Polymers 2023, 15, 3421.

More

Information

Subjects:

Others

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

819

Revisions:

2 times

(View History)

Update Date:

19 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No