| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Madan Verma | -- | 3639 | 2024-01-15 12:01:44 | | | |

| 2 | Peter Tang | Meta information modification | 3639 | 2024-01-16 03:05:54 | | |

Video Upload Options

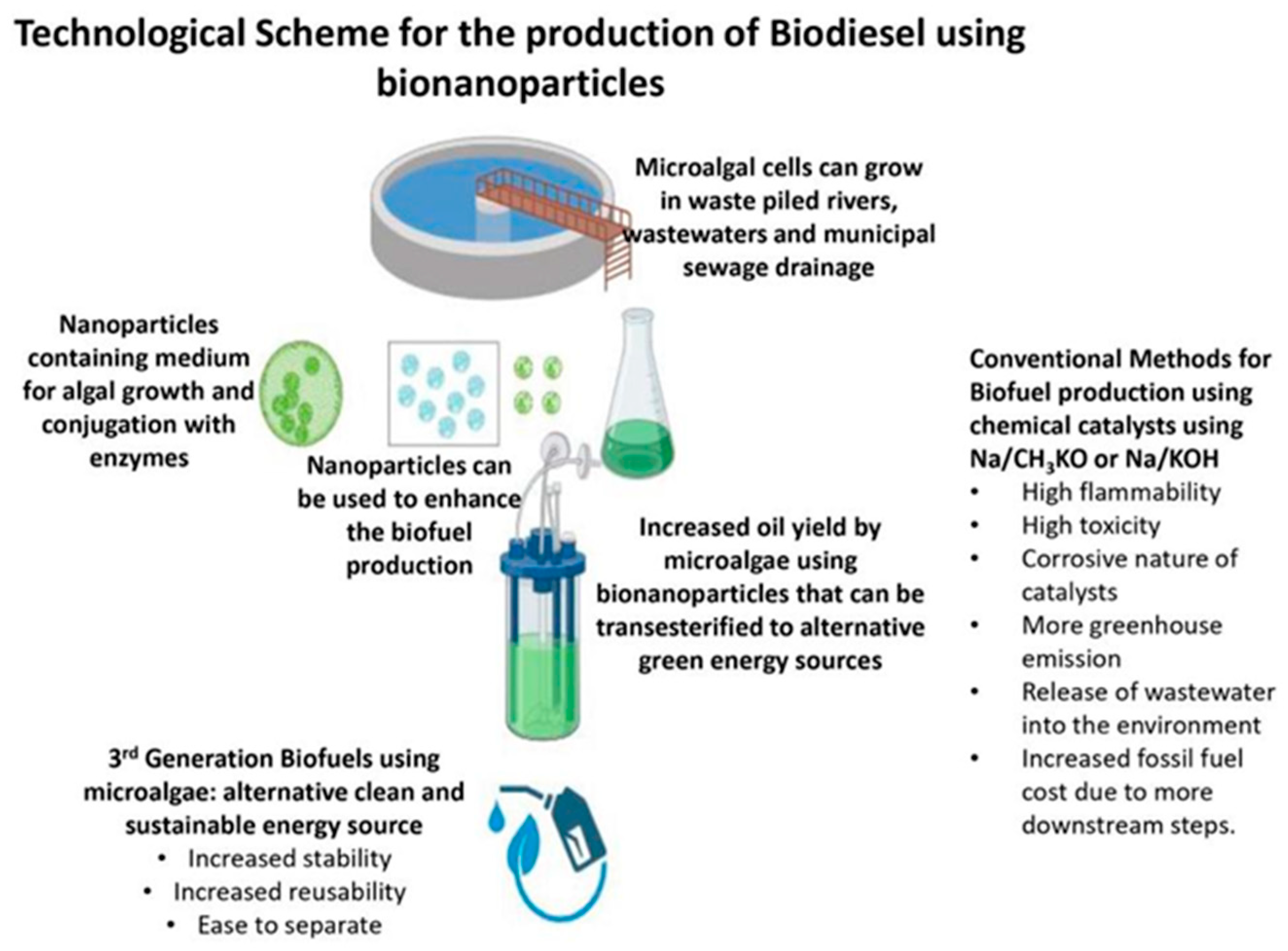

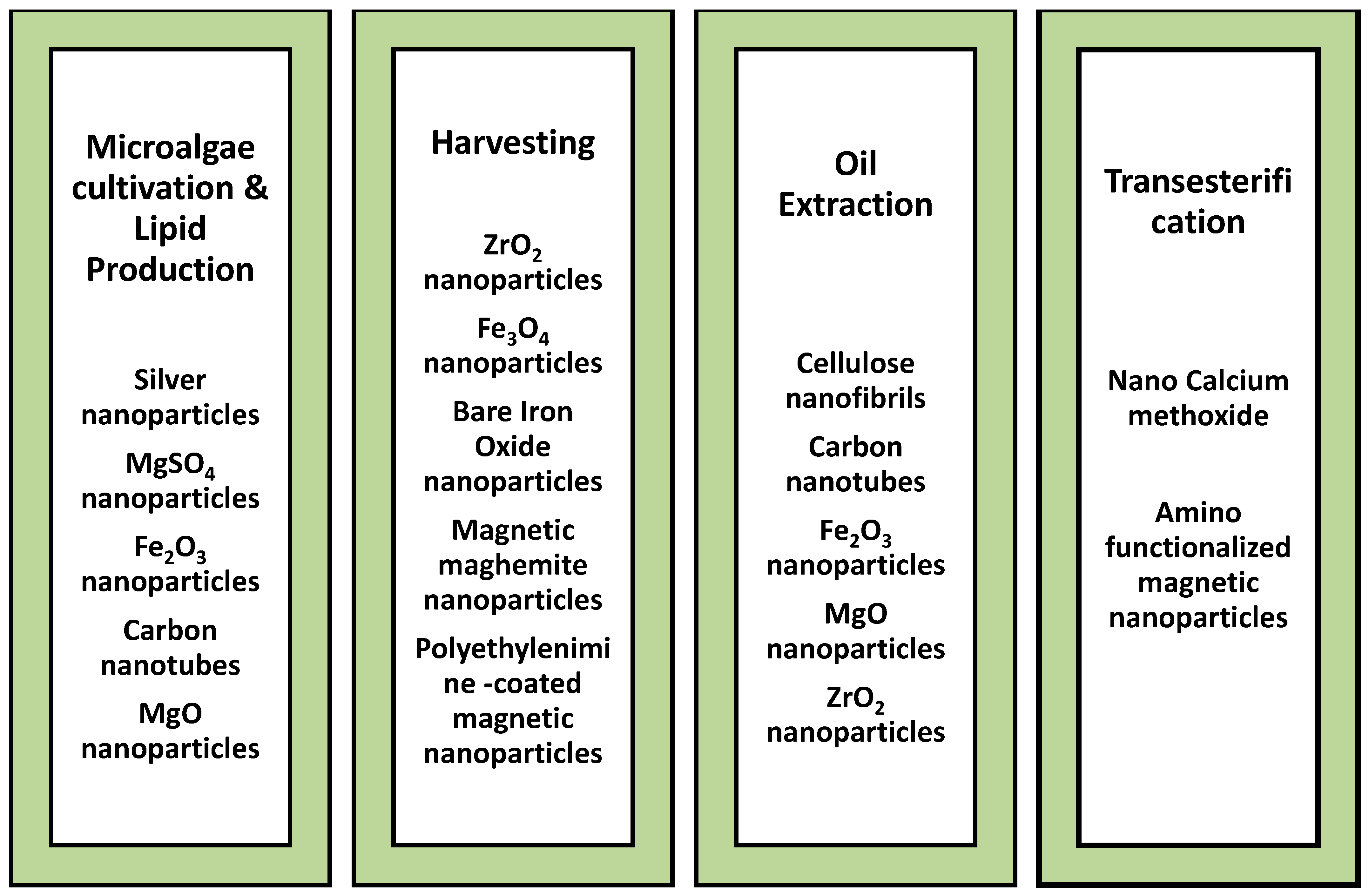

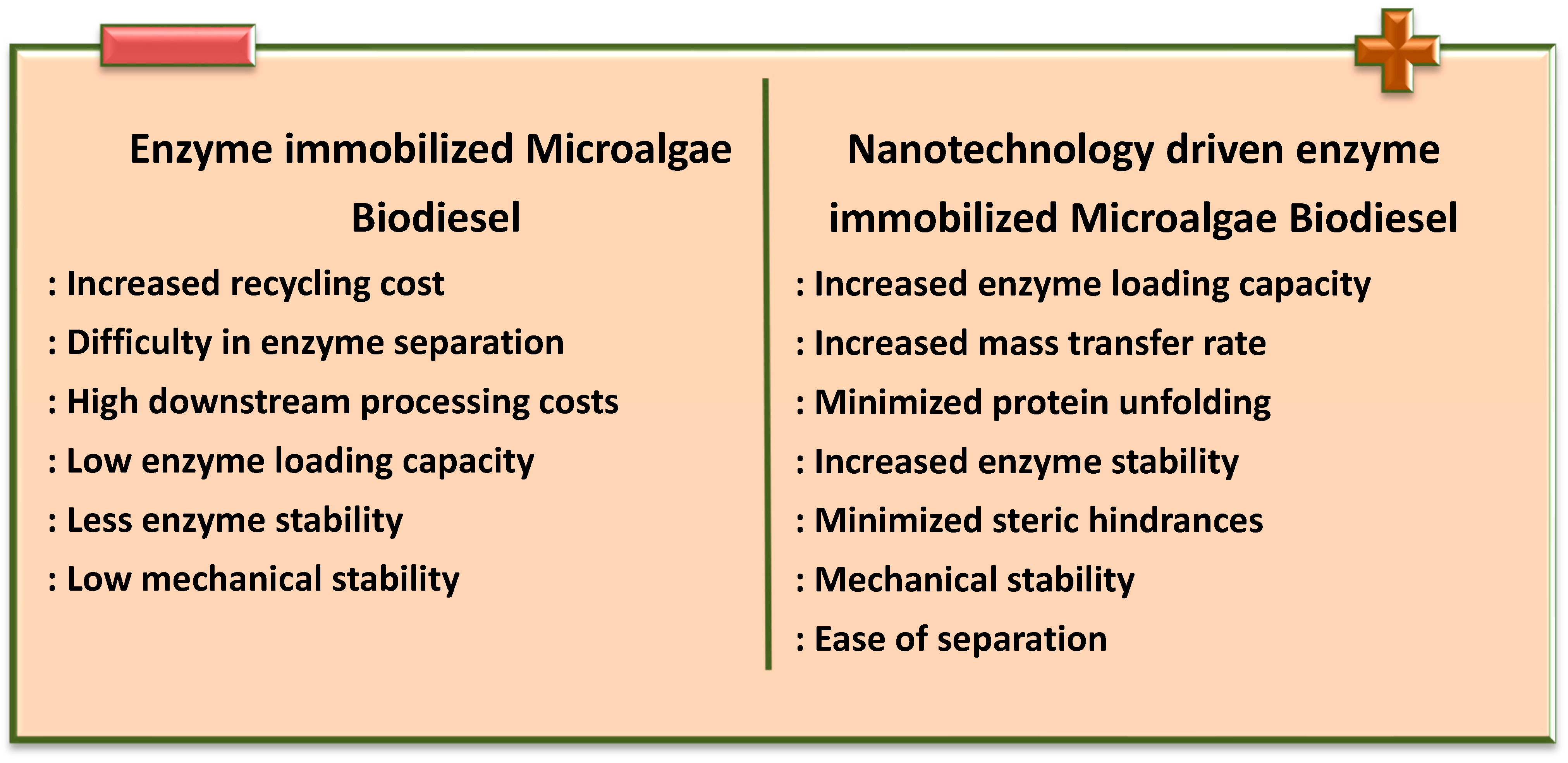

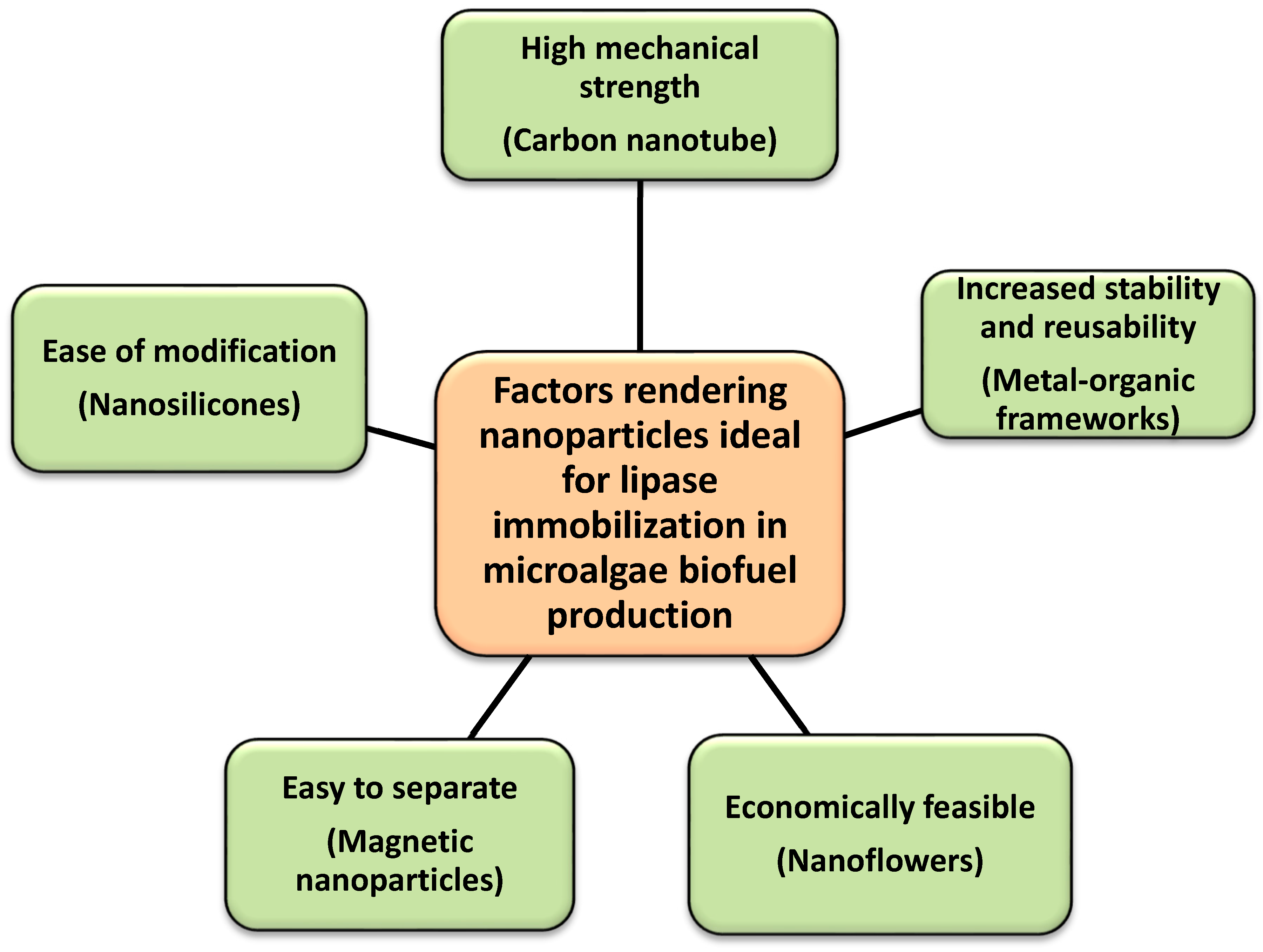

Immense use of fossil fuels leads to various environmental issues, including greenhouse gas emissions, reduced oil reserves, increased energy costs, global climate changes, etc. These challenges can be tackled by using alternative renewable fuels such as biodiesel. Many studies reported that biodiesel production from microalgae biomass is an environment-friendly and energy-efficient approach, with significantly improved fuel quality in terms of density, calorific value and viscosity. Biodiesel is produced using the transesterification process and the most sustainable method is utilizing enzymes for transesterification. Lipase is an enzyme with excellent catalytic activity, specificity, enantio-selectivity, compatibility and stability and hence it is applied in microalgae biodiesel production. But, difficulty in enzymatic recovery, high enzyme cost and minimal reaction rate are some of its drawbacks that have to be addressed. In this aspect, the nanotechnological approach of lipase immobilization in producing microalgae biodiesel is a promising way to increase production yield and it is due to the adsorption efficiency, economic benefit, recyclability, crystallinity, durability, stability, environmental friendliness and catalytic performance of the bio-nanoparticles used. Through increasing post-harvest biomass yield, absorption of CO2 and photosynthesis in the photobioreactor, the use of nanoparticle immobilized lipase during the generation of biodiesel from microalgae has the potential to also remove feedstock availability constraints.

1. Introduction

2. Microalgae Biodiesel Production

3. Effect of Nanoparticles on Microalgae Biodiesel Production

4. Enzyme Immobilization and Nanotechnology-Driven Microalgae Biodiesel Production

5. Effect of Nanoparticle-Immobilized Lipase Enzyme on Biodiesel Production

6. Reuse and Recovery of Lipase Nanoparticles

7. Challenges in Large-Scale Commercialization and the Proposed Strategies to Overcome

References

- Aghabeigi, F.; Nikkhah, H.; Zilouei, H.; Bazarganipour, M. Immobilization of lipase on the graphene oxides magnetized with NiFe2O4 nanoparticles for biodiesel production from microalgae lipids. Process Biochem. 2023, 126, 171–185.

- Mintz-Habib, N. Biofuels, Food Security, and Developing Economies; Routledge: London, UK, 2016.

- Liu, L.; Wu, Y.; Wang, Y.; Wu, J.; Fu, S. Exploration of environmentally friendly marine power technology-ammonia/diesel stratified injection. J. Clean. Prod. 2022, 380, 135014.

- Collotta, M.; Champagne, P.; Mabee, W.; Tomasoni, G. Wastewater and waste CO2 for sustainable biofuels from microalgae. Algal Res. 2018, 29, 12–21.

- Gumba, R.E.; Saallah, S.; Misson, M.; Ongkudon, C.M.; Anton, A. Green biodiesel production: A review on feedstock, catalyst, monolithic reactor, and supercritical fluid technology. Biofuel Res. J. 2016, 3, 431–447.

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C. Second generation biofuels: High-efficiency microalgae forbiodiesel production. Bioenergy Res. 2008, 1, 20–43.

- Yadav, G.; Dubey, B.K.; Sen, R. A comparative life cycle assessment of microalgae production by CO2 sequestration from flue gas in outdoor raceway ponds under batch and semi-continuous regime. J. Clean. Prod. 2020, 258, 120703.

- Liu, L.; Tang, Y.; Liu, D. Investigation of future low-carbon and zero-carbon fuels for marine engines from the view of thermal efficiency. Energy Rep. 2022, 8, 6150–6160.

- Meher, L.C.; Sagar, D.V.; Naik, S.N. Technical aspects of biodiesel production by transesterification—A review. Renew. Sust. Energy Rev. 2006, 10, 248–268.

- Baadhe, R.R.; Potumarthi, R.; Gupta, V.K. Lipase-Catalyzed Biodiesel Production: Technical Challenges. In Bioenergy Research: Advances and Applications; Elsevier: Amsterdam, The Netherlands, 2014; pp. 119–129.

- Cavalcante, F.T.; Neto, F.S.; de Aguiar Falcão, I.R.; da Silva Souza, J.E.; de Moura Junior, L.S.; da Silva Sousa, P.; Rocha, T.G.; de Sousa, I.G.; de Lima Gomes, P.H.; de Souza, M.C.; et al. Opportunities for improving biodiesel production via lipase catalysis. Fuel 2021, 288, 119577.

- Aybastıer, O.; Demir, C. Optimization of immobilization conditions of Thermomyces lanuginosus lipase on styrene–divinylbenzene copolymer using response surface methodology. J. Mol. Catal. B Enzym. 2010, 63, 170–178.

- Borrelli, G.; Trono, D. Recombinant Lipases and Phospholipases and Their Use as Biocatalysts for Industrial Applications. Int. J. Mol. Sci. 2015, 16, 20774–20840.

- Cipolatti, E.P.; Manoel, E.A.; Fernandez-Lafuente, R.; Freire, D.M.G. Support engineering: Relation between development of new supports for immobilization of lipases and their applications. Biotechnol. Res. Innov. 2017, 1, 26–34.

- Da Fonseca, A.M.; Colares, R.P.; de Oliveira, M.M.; de Souza, M.C.; de Castro Monteiro, R.R.; dos Santos Araújo, R.; Amorim, A.V.; dos Santos, J.C.; Alcócer, J.C.; de Oliveira Pinto, O.R. Enzymatic biocatalyst using enzymes from Pineapple (Ananas comosus) peel immobilized in hydrogel beads. Rev. Eletrônica Gest. Edu Tecnol. Ambient. 2019, 23, 32.

- Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 11 November 2023).

- Voegele, E. IEA Expects Global Biofuels Production to Rebound in 2021. Available online: http://biodieselmagazine.com/articles/2517259/iea-expects-global-biofuelsproduction-to-rebound-in-2021 (accessed on 7 October 2023).

- Yang, X.; Liu, K.; Han, X.; Xu, J.; Bian, M.; Zheng, D.; Xie, H.; Zhang, Y.; Yang, X. Transformation of waste battery cathode material LiMn2O4 into efficient ultra-low temperature NH3-SCR catalyst: Proton exchange synergistic vanadium modification. J. Hazard. Mater. 2023, 459, 132209.

- Nwokoagbara, E.; Olaleye, A.K.; Wang, M. Biodiesel from microalgae: The use of multi-criteria decision analysis for strain selection. Fuel 2015, 159, 241–249.

- Velasquez-Orta, S.; Lee, J.; Harvey, A. Alkaline in situ transesterification of Chlorella vulgaris. Fuel 2012, 94, 544–550.

- Maceiras, R.; Rodrı, M.; Cancela, A.; Urrejola, S.; Sanchez, A. Macroalgae: Raw material for biodiesel production. Appl. Energy 2011, 88, 3318–3323.

- Tran, D.T.; Yeh, K.L.; Chen, C.L.; Chang, J.S. Enzymatic transesterification of microalgal oil from Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized Burkholderia lipase. Bioresour. Technol. 2012, 108, 119–127.

- Johnson, M.B.; Wen, Z. Development of an attached microalgal growth system for biofuel production. Appl. Microbiol. Biotechnol. 2010, 85, 525–534.

- Xu, H.; Miao, X.; Wu, Q. High quality biodiesel production from a microalga Chlorella protothecoides by heterotrophic growth in fermenters. J. Biotechnol. 2006, 126, 499–507.

- Ali, M.; Sultana, R.; Tahir, S.; Watson, I.A.; Saleem, M. Prospects of microalgal biodiesel production in Pakistan—A review. Renew. Sust. Energy Rev. 2017, 80, 1588–1596.

- Kokkinos, K.; Karayannis, V.; Moustakas, K. Optimizing microalgal biomass feedstock selection for nanocatalytic conversion into biofuel clean energy, using fuzzy multi-criteria decision-making processes. Front. Energy Res. 2021, 8, 622210.

- Grima, E.; Belarbi, E.; Fernandez, F.A.; Medina, A.; Chisti, Y. Recovery of microalgal biomass and metabolites: Process options and economics. Biotechnol. Adv. 2003, 20, 491–515.

- Chanquia, S.N.; Vernet, G.; Kara, S. Photobioreactors for cultivation and synthesis: Specifications, challenges, and perspectives. Eng. Life Sci. 2022, 22, 712–724.

- Rodolfi, L.; Zittelli, G.C.; Bassi, N.; Padovani, G.; Biondi, N.; Bonini, G. Microalgae for oil: Strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol. Bioeng. 2008, 102, 100–112.

- Khalekuzzaman, M.; Alamgir, M.; Islam, M.B.; Hasan, M. A simplistic approach of algal biofuels production from wastewater using a Hybrid Anaerobic Baffled Reactor and Photobioreactor (HABR-PBR) System. PLoS ONE 2019, 14, e0225458.

- Narala, R.; Garg, S.; Sharma, K.K.; Thomas-Hall, S.R.; Deme, M.; Li, Y.; Peer, M.S. Comparison of microalgae cultivation in Photobioreactor, open raceway pond, and a two-stage hybrid system. Front. Energy Res. 2016, 4, 29.

- Benemann, J.R.; Oswald, W.J. Systems and economic analysis of microalgae ponds for conversion of CO2 to biomass. STIN 1994, 95, 19554.

- Mathimani, T.; Mallick, N. A comprehensive review on harvesting of microalgae for biodiesel–Key challenges and future directions. Renew. Sustain. Energy Rev. 2018, 91, 1103–1120.

- Ljubic, A.; Safafar, H.; Jacobsen, C. Recovery of microalgal biomass and metabolites from homogenized, swirl flash-dried microalgae. J. Appl. Phycol. 2019, 31, 2355–2363.

- Kumar, D.; Korstad, J.; Singh, B. Life cycle assessment of algal biofuels. In Algae and Environmental Sustainability; Springer: New Delhi, India, 2015; pp. 165–181.

- Deborah, L.; Vidia, P.; Michael, J.; Michael, C.; Tal, M.; Charles, H.; Jefferson, W. Quantitative Uncertainty Analysis of Life Cycle Assessment for Algal Biofuel Production. Environ. Sci. Technol. 2013, 47, 687–694.

- Ahmad, A.L.; Yasin, N.M.; Derek, C.J.C.; Lim, J.K. Comparison of harvesting methods for microalgae Chlorella sp. and its potential use as a biodiesel feedstock. Environ. Technol. 2014, 35, 2244–2253.

- Şirin, S.; Trobajo, R.; Ibanez, C.; Salvadó, J. Harvesting the microalgae Phaeodactylum tricornutum with polyaluminum chloride, aluminium sulphate, chitosan and alkalinity-induced flocculation. J. Appl. Phycol. 2012, 24, 1067–1080.

- Fuad, N.; Omar, R.; Kamarudin, S.; Harun, R.; Idris, A.; Azlina, W.W. Effective use of tannin based natural biopolymer, AFlok-BP1 to harvest marine microalgae Nannochloropsis. J. Environ. Chem. Eng. 2018, 6, 4318–4328.

- Newkirk, G.M.; de Allende, P.; Jinkerson, R.E.; Giraldo, J.P. Nanotechnology approaches for chloroplast biotechnology advancements. Front. Plant Sci. 2021, 12, 691295.

- Shurair, M.; Almomani, F.; Bhosale, R.; Khraisheh, M.; Qiblawey, H. Harvesting of intact microalgae in single and sequential conditioning steps by chemical and biological based–flocculants: Effect on harvesting efficiency, water recovery and algal cell morphology. Bioresour. Technol. 2019, 281, 250–259.

- Xu, Y.; Milledge, J.J.; Abubakar, A.; Swamy, R.; Bailey, D.; Harvey, P. Effects of centrifugal stress on cell disruption and glycerol leakage from Dunaliella salina. Microalgae Biotechnol. 2015, 1, 20–27.

- Stephenson, A.L.; Kazamia, E.; Dennis, J.S.; Howe, C.J.; Smith, S.A.; Scott, A.G. Life-cycle assessment of potential algal biodiesel production in the United Kingdom: A comparison of raceways and air-lift tubular bioreactors. Energy Fuels 2010, 24, 4062–4077.

- Pattarkine, M.V.; Pattarkine, V.M. Nanotechnology for algal biofuels. In The Science of Algal Fuels. Cellular Origin, Life in Extreme Habitats and Astrobiology; Gordon, R., Seckbach, J., Eds.; Springer: Dordrecht, The Netherlands, 2012; Volume 25.

- Yang, J.; Li, X.; Hu, H.; Zhang, X.; Yu, Y.; Chen, Y. Growth and lipid accumulation properties of a freshwater microalga, Chlorella ellipsoidea YJ1, in domestic secondary effluents. Appl. Energy 2011, 88, 3295–3299.

- Chen, L.; Liu, T.; Zhang, W.; Chen, X.; Wang, J. Biodiesel production from algae oil high in free fatty acids by two-step catalytic conversion. Bioresour. Technol. 2012, 111, 208–214.

- Zhang, Y.; Dubé, M.A.; McLean, D.D.; Kates, M. Biodiesel production from waste cooking oil: Process design and technological assessment. Bioresour. Technol. 2003, 89, 1–16.

- Yu, V.; Xu, V.; Xiao, R. Lipases from the genus Rhizopus: Characteristics, expression, protein engineering and application. Prog. Lipid Res. 2016, 64, 57–68.

- Mota, G.F.; de Sousa, I.G.; de Oliveira, A.L.; Cavalcante, A.L.; da Silva Moreira, K.; Cavalcante, F.T.; da Silva Souza, J.E.; de Aguiar Falcão, Í.R.; Rocha, T.G.; Valério, R.B.; et al. Biodiesel production from microalgae using lipase-based catalysts: Current challenges and prospects. Algal Res. 2022, 62, 102616.

- Chintagunta, A.D.; Ray, S.; Banerjee, R. An integrated bioprocess for bioethanol and biomanureproduction from pineapple leaf waste. J. Clean. Prod. 2017, 165, 1508–1516.

- Kim, J.; Jia, H.; Wang, P. Challenges in biocatalysis for enzyme-based biofuel cells. Biotechnol. Adv. 2006, 24, 296–308.

- Bin Rashid, A. Utilization of nanotechnology and nanomaterials in biodiesel production and property enhancement. J. Nanomater. 2023, 2023, 1–4.

- Zhu, L.-D.; Hiltunen, E.; Li, Z. Using magnetic materials to harvest microalgal biomass: Evaluation of harvesting and detachment efficiency. Environ. Technol. 2019, 40, 1006–1012.

- Li, X.; Liu, B.; Lao, Y.; Wan, P.; Mao, X.; Chen, F. Efficient magnetic harvesting of microalgae enabled by surface-initiated formation of iron nanoparticles. Chem. Eng. J. 2021, 408, 127252.

- Almomani, F. Algal cells harvesting using cost-effective magnetic nanoparticles. Sci. Total Environ. 2020, 720, 137621.

- Bharte, S.; Desai, K. Harvesting Chlorella species using magnetic iron oxide nanoparticles. Phycol. Res. 2019, 67, 128–133.

- Verma, M.L.; Naebe, M.; Barrow, C.J.; Puri, M. Enzyme immobilisation on amino-functionalised multi-walled carbon nanotubes: Structural and biocatalytic characterisation. PLoS ONE 2013, 8, e73642.

- Shamsudin, M.I.; Tan, L.S.; Tsuji, T. Enzyme immobilization technology in biofuel production: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1051, 012056.

- Santos, S.; Puna, J.; Gomes, J. A review on bio-based catalysts (immobilized enzymes) used for biodiesel production. Energies 2020, 13, 3013.

- Verma, M.L.; Puri, M.; Barrow, C.J. Recent trends in nanomaterials immobilized enzymes for biofuel production. Crit. Rev. Biotechnol. 2016, 36, 108–119.

- Hwang, E.T.; Gu, M.B. Enzyme stabilization by nano/microsized hybrid materials. Eng. Life Sci. 2013, 13, 49–61.

- Verma, M.L.; Azmi, W.; Kanwar, S.S. Microbial lipases: At the interface of aqueous and non-aqueous media. Acta Microbiol. Immunol. Hung. 2008, 55, 265–293.

- Chandel, H.; Wang, B.; Verma, M.L. Microbial lipases and their applications in the food industry. In Value-Addition in Food Products and Processing Through Enzyme Technology; Elsevier: Amsterdam, The Netherlands, 2022; ISSN 978-0-323-89929-1.

- Bartha-Vari, J.-H.; Moisa, M.E.; Bencze, L.C.; Irimie, F.-D.; Paizs, C.; Toșa, M.I. Efficient Biodiesel Production Catalyzed by Nanobioconjugate of Lipase from Pseudomonas fluorescens. Molecules 2020, 25, 651.

- Zhong, L.; Feng, Y.; Wang, G.; Wang, Z.; Bilal, M.; Lv, H.; Jia, S.; Cui, J. Production and use of immobilized lipases in/on nanomaterials: A review from the waste to biodiesel production. Int. J. Biol. Macromol. 2020, 152, 207–222.

- Verma, M.L. Biotechnological applications of lipases in flavour and fragrance ester production. In Microbial Technology for the Welfare of Society. Microorganisms for Sustainability; Arora, P., Ed.; Springer: Singapore, 2019; ISBN 978-981-13-8843-9.

- Singh, N.; Dhanya, B.S.; Verma, M.L. Nano-immobilized biocatalysts and their potential biotechnological applications in bioenergy sector. Mater. Sci. Energy Technol. 2020, 3, 808–824.

- Verma, M.L.; Rao, N.M.; Barrow, C.J.; Puri, M. Suitability of recombinant lipase immobilised on functionalised magnetic nanoparticles for fish oil hydrolysis. Catalysts 2019, 9, 420.

- Zhang, X.L.; Yan, S.; Tyagi, R.D.; Surampalli, R.Y. Biodiesel production from heterotrophic microalgae through transesterification and nanotechnology application in the production. Renew. Sustain. Energy Rev. 2013, 26, 216–223.

- Ngo, T.P.; Li, A.; Tiew, K.W.; Li, Z. Efficient transformation of grease to biodiesel using highly active and easily recyclable magnetic nanobiocatalyst aggregates. Bioresour. Technol. 2013, 145, 233–239.

- Sakai, S.; Liu, Y.; Yamaguchi, T.; Watanabe, R.; Kawabe, M.; Kawakami, K. Production of butyl-biodiesel using lipase physically-adsorbed onto electrospun polyacrylonitrile fibers. Bioresour. Technol. 2010, 101, 7344–7349.

- Huang, J.; Wang, J.; Huang, Z.; Liu, T.; Li, H. Photothermal technique-enabled ambient production of microalgae biodiesel: Mechanism and life cycle assessment. Bioresour. Technol. 2023, 369, 128390.

- Amini, Z.; Ilham, Z.; Ong, H.C.; Mazaheri, H.; Chen, W.H. State of the art and prospective of Lipase- catalyzed transesterification reaction for biodiesel production. Energy Convers. Manag. 2017, 141, 339–353.

- Netto, C.G.; Toma, H.E.; Andrade, L.H. Superparamagnetic nanoparticles as versatile carriersand supporting materials for enzymes. J. Mol. Catal. B Enzym. 2013, 85, 71–92.

- Xie, W.; Zang, X. Covalent immobilization of Lipase onto aminopropyl-functionalizedhydroxyapatite-encapsulated-γ-Fe2O3 nanoparticles: A magnetic biocatalyst for interesterification of soybean oil. Food Chem. 2017, 227, 397–403.

- Knothe, G. Analyzing biodiesel: Standards and other methods. J. Am. Oil Chem. Soc. 2006, 83, 823–833.

- Shaw, S.Y.; Chen, Y.J.; Ou, J.J.; Ho, L. Preparation and characterization of Pseudomonas putida esterase immobilized on magnetic nanoparticles. Enzym. Microb. Technol. 2006, 39, 1089–1095.

- Tang, L.; Cheng, J. Nonporous silica nanoparticles for nanomedicine application. Nano Today 2013, 8, 290–312.

- Babaki, M.; Yousefi, M.; Habibi, Z.; Mohammadi, M.; Yousefi, P.; Mohammadi, J.; Brask, J. Enzymatic production of biodiesel using lipases immobilized on silica nanoparticles as highly reusable biocatalysts: Effect of water, t-butanol and blue silica gel contents. Renew. Energy 2016, 91, 196–206.

- Jun, S.H.; Lee, J.; Kim, B.C.; Lee, J.E.; Joo, J.; Park, H.; Lee, J.H.; Lee, S.M.; Lee, D.; Kim, S. Highly efficient enzyme immobilization and stabilization within meso-structured onion-like silica for biodiesel production. Chem. Mater. 2012, 24, 924–929.

- Arumugam, A.; Thulasidharan, D.; Jegadeesan, G.B. Process optimization of biodiesel production from Hevea brasiliensis oil using lipase immobilized on spherical silica aerogel. Renew. Energy 2018, 116, 755–761.

- Bilal, M.; Adeel, M.; Rasheed, T.; Iqbal, H.M. Multifunctional metal–organic frameworks-based biocatalytic platforms: Recent developments and future prospects. J. Mater. Res. Technol. 2019, 8, 2359–2371.

- Lyu, F.; Zhang, Y.; Zare, R.N.; Ge, J.; Liu, Z. One-pot synthesis of protein-embedded metal–organic frameworks with enhanced biological activities. Nano Lett. 2014, 14, 5761–5765.

- Goyanes, S.; Rubiolo, G.; Salazar, A.; Jimeno, A.; Corcuera, M.; Mondragon, I. Carboxylation treatment of multiwalled carbon nanotubes monitored by infrared and ultraviolet spectroscopies and scanning probe microscopy. Diam. Relat. Mater. 2007, 16, 412–417.

- Jiang, W.; Wang, X.; Yang, J.; Han, H.; Li, Q.; Tang, J. Lipase-inorganic hybrid nanoflower constructed through biomimetic mineralization: A new support for biodiesel synthesis. J. Colloid. Interface Sci. 2018, 514, 102–107.

- Verma, M.L.; Barrow, C.J.; Puri, M. Nanobiotechnology as a novel paradigm for enzyme immobilization and stabilisation with potential applications in biofuel production. Appl. Microbiol. Biotechnol. 2013, 97, 23–39.

- Pico, E.A.; Lopez, C.; Cruz-Izquierdo, Á.; Munarriz, M.; Iruretagoyena, F.J.; Serra, J.L.; Llama, M.J. Easy reuse of magnetic crosslinked enzyme aggregates of lipase B from Candida antarctica to obtain biodiesel from Chlorella vulgaris lipids. J. Biosci. Bioeng. 2018, 126, 451–457.

- Duraiarasan, S.; Razack, S.A.; Manickam, A.; Munusamy, A.; Syed, M.B.; Ali, M.Y.; Ahmed, G.M.; Mohiuddin, M.S. Direct conversion of lipids from marine microalga C. salina to biodiesel with immobilized enzymes using magnetic nanoparticle. J. Environ. Chem. E 2016, 4, 1393–1398.

- He, S.; Feng, Y.; Ren, H.; Zhang, Y.; Gu, N.; Lin, X. The impact of iron oxide magnetic nanoparticles on the soil bacterial community. J. Soils Sediments 2011, 11, 1408–1417.

- Toh, P.Y.; Yeap, S.P.; Kong, L.P.; Ng, B.W.; Chan, D.J.C.; Ahmad, A.L.; Lim, J. Magnetophoretic removal of microalgae from fishpond water: Feasibility of high gradient and low gradient magnetic separation. Chem. Eng. J. 2012, 211–212, 22–30.

- Yan, X.H.; Xue, P. Tailoring magnetic mesoporous silica spheres-immobilized lipase for kinetic resolution of methyl 2-bromopropionate in a co-solvent system. Res. Chem. Intermed. 2018, 44, 4295–4306.

- Olabi, A.G.; Alami, A.H.; Alasad, S.; Aljaghoub, H.; Sayed, E.T.; Shehata, N.; Rezk, H.; Abdelkareem, M.A. Emerging technologies for enhancing microalgae biofuel production: Recent progress, barriers, and limitations. Fermentation 2022, 8, 649.

- Xu, H.; Lee, U.; Coleman, A.M.; Wigmosta, M.S.; Wang, M. Assessment of algal biofuel resource potential in the United States with consideration of regional water stress. Algal Res. 2019, 37, 30–39.

- Mirzajanzadeh, M.; Tabatabaei, M.; Ardjmand, M.; Rashidi, A.; Ghobadian, B.; Barkhi, M.; Pazouki, M. A novel soluble nano-catalysts in diesel–biodiesel fuel blends to improve diesel engines performance and reduce exhaust emissions. Fuel 2015, 139, 374–382.

- Kamilli, K.; Ofner, J.; Zetzsch, C.; Held, A. Formation of halogen-induced secondary organic aerosol (XOA). In Proceedings of the EGU General Assembly 2013 (EGU2013-11969), Vienna, Austria, 7–12 April 2013; Available online: https://ui.adsabs.harvard.edu/abs/2013EGUGA..1511969K/abstract (accessed on 11 November 2023).