Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Donatela Saric | -- | 3887 | 2024-01-02 14:08:40 | | | |

| 2 | Rita Xu | Meta information modification | 3887 | 2024-01-03 02:37:43 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Šarić, D.; Sole, A.S. Gloss Measurements. Encyclopedia. Available online: https://encyclopedia.pub/entry/53324 (accessed on 08 February 2026).

Šarić D, Sole AS. Gloss Measurements. Encyclopedia. Available at: https://encyclopedia.pub/entry/53324. Accessed February 08, 2026.

Šarić, Donatela, Aditya Suneel Sole. "Gloss Measurements" Encyclopedia, https://encyclopedia.pub/entry/53324 (accessed February 08, 2026).

Šarić, D., & Sole, A.S. (2024, January 02). Gloss Measurements. In Encyclopedia. https://encyclopedia.pub/entry/53324

Šarić, Donatela and Aditya Suneel Sole. "Gloss Measurements." Encyclopedia. Web. 02 January, 2024.

Copy Citation

The appearance of a surface depends on four main appearance attributes, namely color, gloss, texture, and translucency. Gloss is an important attribute that people use to understand surface appearance, right after color.

gloss

appearance

gloss perception

1. Introduction

Visual appearance is the result of the interaction between the physical properties of an object, the illuminating characteristics of the light, and the human visual system. The main appearance attributes are considered color, gloss, texture, and translucency [1][2]. Visual appearance plays a crucial role in our perception of the world around us. The appearance of an object provides us with information about its identity and function but also influences our emotional and behavioral responses toward the observed object. The study of the visual appearance of objects has been a central topic in psychology, neuroscience, computer vision, design, and more. When light strikes a surface and reflects, it can result in different types of reflection, depending on the surface properties. A perfectly polished mirror reflects light uniformly at the same angle in the opposite direction, called the specular direction. High-gloss surfaces also produce concentrated, coherent reflection in the specular direction, and it creates highlights on glossy surfaces. In contrast, rough or irregular surfaces cause diffuse reflection, scattering incident light in various directions. Unlike the focused reflections of specular and mirror reflection, diffuse reflection results in soft, nondirectional light scattering. In most cases, the reflected light consists of diffuse and specular reflection. From the specular reflection, researchers obtain gloss information, and from the diffuse reflection, color information.

From that, it can be noted that the appearance of an object is a complex and multidimensional phenomenon that can be difficult to quantify objectively. However, the measurement of appearance is crucial for many industries. There are various methods and techniques for measuring appearance, ranging from subjective evaluation by human observers to objective measurements using advanced imaging and analytical techniques. The subjective evaluation of appearance involves the assessment of visual properties by human observers. This type of evaluation is typically performed using a visual inspection or rating system, where trained or untrained observers rate the appearance of objects on a scale or using descriptive terms. While subjective evaluation can provide valuable information about the perceived appearance of objects, it is highly dependent on individual perception and can be influenced by factors such as lighting, background, and other parts of the setup of the psychophysical experiment. On the other hand, objective measurements of appearance involve the use of advanced imaging and analytical techniques to quantify the visual properties of objects. These techniques can provide precise and standardized measurements of color, gloss, translucency, and texture, but a measurement of any appearance attribute needs to take the underlying dimensionality into consideration. Numerous studies have demonstrated that color perception can be effectively described using three dimensions. However, when it comes to describing gloss, the dimensionality remains uncertain and difficult to define [3][4][5].

Gloss is usually considered to be the second important appearance attribute, right after color [6]. It gives us information about the object’s properties, such as surface shape, solidity, moisture (wet or dry), roughness, position in the environment, etc. Additionally, gloss is a second-order attribute, which means we do not have receptors for gloss on our retina; instead, researchers get the color information of the surface, and the information is further reconstructed in our brain as a mat or glossy surface. According to ISO 2813, gloss is an “optical property of a surface, characterized by its ability to reflect light specularly” [7]. The CIE (Commission Internationale de l’Eclairage) definition of gloss is that gloss is a “mode of appearance by which reflected highlights of objects are perceived as superimposed on the surface due to the directionally selective properties of the surface.” [8]. With this CIE definition from 1987, gloss was no longer considered a purely physical property of a material; instead, the CIE defined gloss as a perception that can be quantified and associated with the geometrical properties of a surface. In the work from Chadwick and Kentridge, a comprehensive exploration of the factors and mechanisms contributing to gloss perception is described [9].

2. Gloss Measurements

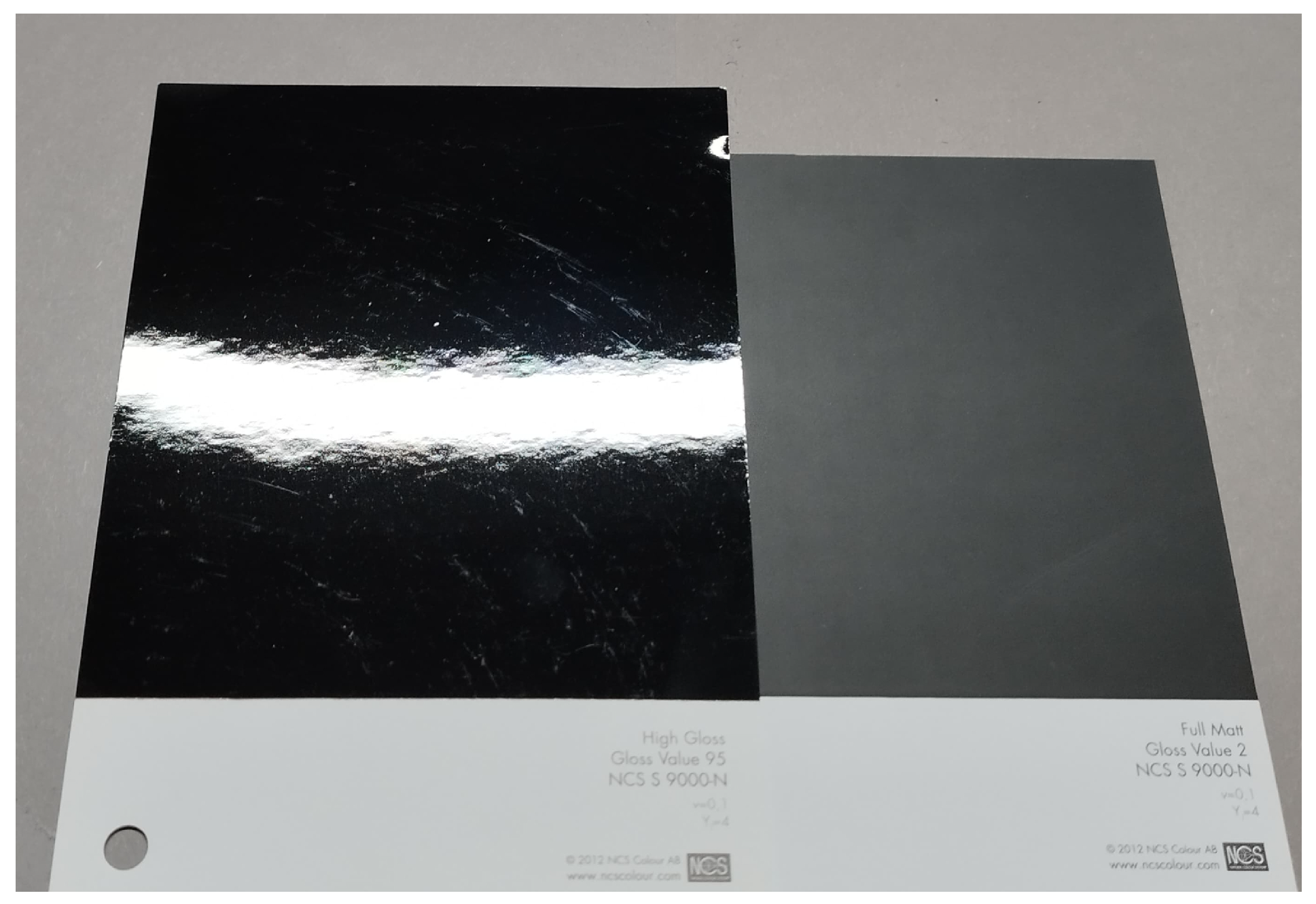

The concept of gloss has long captivated researchers and professionals in various fields, including material science, surface engineering, graphic design, etc. Over the years, various methods have been developed to measure and quantify gloss, providing valuable insights into the physical and perceptual aspects of gloss. In this chapter, researchers explore the different approaches to gloss measurement, divided into two categories: physical gloss measurements and perceptual gloss measurements. By examining these two perspectives, researchers can gain a comprehensive understanding of gloss and its multifaceted nature. In Figure 1 two samples with the same color and different glossiness are shown.

Figure 1. Samples with the same color and different specular gloss (95 GU on the left and 6 GU on the right) measured at a 60° incidence angle.

2.1. Physical Gloss Measurements

For decades, optical instruments have been utilized by various industries to assess different properties of surface gloss, and they continue to be employed to this day. This demonstrates their effectiveness in tasks such as quality control and the detection of defects or anomalies in production processes. Specular glossmeters are optical instruments that are used to measure the specular gloss of a surface. Specular gloss refers to the amount of light that is reflected from a surface in a mirror-like manner, as opposed to diffuse reflection, which scatters light in many directions. Specular gloss is a ratio of the luminous flux reflected from the specimen to that reflected by a glass surface with a refractive index of 1.567 at a wavelength of 587.6 nm in the specular direction and is indicated as Gloss Unit (GU) [7].

Different standards recommend different angles of measurement, reflecting different use cases and demonstrating the complexity of the problem. The American Society for Testing and Materials (ASTM) has played a significant role in the development of gloss measurement. Their technical work has led to the development of a widely adopted standard, also known as the ASTM Method [7][10]. However, it has been observed that there is a lack of correlation between the visually assessed gloss data and the measured gloss data across the entire range [11]. The complexity of gloss lies in the relation between the physical stimulus and perceived gloss, which is complex and still not fully understood [12]. While specular glossmeters provide a single-value measurement (one dimension) of the specular gloss of a surface, these instruments have certain limitations that make them inapplicable for the soft metrology of surface gloss. Soft metrology encompasses measurement techniques and models designed to quantitatively assess properties influenced by human perception, involving any of the five senses (sight, smell, sound, taste, and touch) [13]. For instance, the limited dynamic range of glossmeters compromises their ability to accurately characterize surfaces, especially for very mat samples, where the read-out is dominated by diffusely reflected light [14][15]. Thus, gloss measurements with one-dimensional glossmeters are suitable for measuring gloss differences between samples, rather than for providing an absolute scale for gloss. However, it is worth considering the possibility of mathematically transforming these measured gloss values into a perceptual uniform gloss scale to enable an absolute glossiness comparison. However, for more complex surfaces and luxurious objects where there is a need for more extensive research, it becomes necessary to consider multiple dimensions. In such cases, the Bidirectional Reflectance Distribution Function (BRDF) is used in order to capture the comprehensive characterization of their gloss [16].

2.1.1. BRDF

The BRDF, or Bidirectional Reflectance Distribution Function, is a mathematical function used to describe how light is reflected from a surface in different directions [17]. The BRDF describes the ratio of the light reflected from a surface in a particular direction to the light incident on the surface in a particular direction. In other words, it describes how the surface reflects light in different directions, considering the angle of incidence and the angle of reflection. The BRDF is a function of four variables: the incident angle, the viewing angle, the wavelength of the light, and the polarization of the light [18][19][20]. BRDF measurements in general provide a complete angular distribution of how light is reflected from the surface in all directions. This includes both the specular reflection and the diffuse reflection components. BRDF measurements allow for a more thorough understanding of how light interacts with a surface and can be used to model the surface’s appearance under a wider range of lighting conditions. BRDF measurements with defined subsets, i.e., angle combinations (deduced from different use cases), are commonly used in research and development for material characterization, as well as in industries such as aerospace, automotive, and semiconductor manufacturing. In these industries, BRDF measurements can be used to optimize surface treatments and coatings, ensure uniformity and consistency in surface properties, and improve the accuracy of simulations used for product design and testing. However, BRDF measurements are typically more complex and time- and money-consuming than specular gloss measurements [14][17][21][22]. From the BRDF, important parameters can be computed, like color, specular reflection, specular peak, distinctness-of-image gloss, image clarity, specular peak, luminous flux, haze, and some other parameters that are not part of any standard (instead, companies develop their own parameters for appearance description).

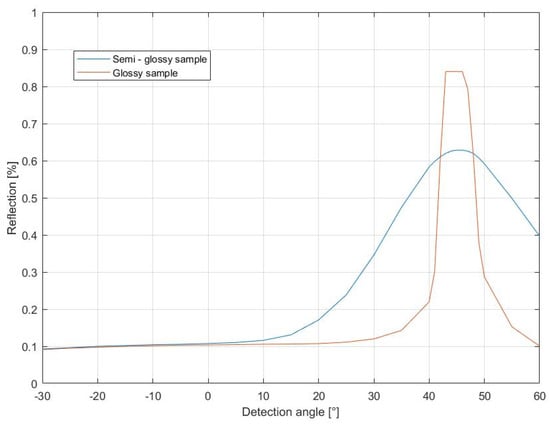

In Figure 2, two BRDF measurements are shown. The measured samples are mat and glossy 2.5D printed samples. The samples were measured with the incidence angle at 45° at the wavelength of 580 nm. For easier interpretation of the reflection distributions, the reflection scale is logarithmic. From the height of the specular peak, researchers can notice which BRDF curve represents which object. The specular peak is the most important component of gloss. For different materials, the specular peak is strongly dependent on the refractive index (n). The higher the refractive index, the higher the specular peak. The size of the peak from a measured surface also depends on the angle of incidence. The peak increases when the incidence angle increases [6]. The specular reflection will be bigger when illuminating the object under a grazing angle (e.g., 85°). Therefore, ISO 2813 standard recommends three incidence angles, 20°, 60°, and 85° geometries [7]. The 60° geometry is used for intercomparing the gloss of most specimens. The 20° geometry is advantageous for comparing specimens that have a 60° gloss higher than 70 GUs (Gloss Units), whereas the 85° geometry is used for comparing specimens for sheen or near-grazing shininess. It is mostly applied when the 60° geometry gloss is lower than 10 GUs.

Figure 2. Example of BRDF measurements of two 2.5D printed color patches with the same color and different glossiness. The BRDF measurements were taken at a 45° incidence angle and 580 nm wavelength.

In a work from 1998, Dana investigated the complex nature of surface reflectance and texture and proposed a comprehensive framework for understanding and modeling the properties of real-world samples and the dependence of appearance on the geometry of imaging conditions [23]. In the work, they developed a simple system sustainable for simultaneous BRDF and BTF measurements. The texture representation, called BTF (Bidirectional Texture Function), is discussed. In the work, an object was measured from different illumination and detection angles. The image was captured with a video camera with a frame grabber. The pixel values are converted to radiance values using a calibration scheme. Further, the calibrated images served as the BTF measurements, and the images were averaged over the sample area to obtain the BRDF. For detection, a CCD camera is used.

In comparison with specular glossmeters, BRDF measurements and their setup are complex, and a lot of parameters can influence the results. In 2015, Obein et al. investigated measurements of two high-level goniospectrophotometers [24]. The BRDF values were measured for mat and high-gloss samples independently on the two devices. The results show differences in the specular peak, even for the mat sample. For the high-gloss samples, the differences are more expressive. A larger illumination spot and detection aperture of one of the goniospectrophotometers results in an angular broadening and lower peak value. Furthermore, by rendering the results into luminance maps, the visual differences were more expressed in the high-gloss samples.

While there are some standards related to the BRDF measurements that provide guidelines and procedures for measuring the BRDF [25][26][27], sometimes the impact of roughness and anisotropy is not addressed. Additionally, there may be some disagreement among researchers regarding the appropriate mathematical models or parameters to use when analyzing BRDF data [28][29]. It is important to be aware of these limitations and take appropriate steps to mitigate their impact on BRDF measurements. This may include selecting appropriate measurement equipment, following best practices for sample preparation, controlling environmental conditions, and ensuring appropriate operator training and qualifications [30].

Today, the capture of appearance has improved, but BRDF measurements are still time- and money-consuming. Furthermore, the calculation of gloss values (and other values) from BRDF measurements is still challenging. For quick capture, Dana set up a capture system with a mirror-based camera as a detector. For the illumination, a projector with one light source was used. In between, a parabolic mirror was placed. The specialty is that the mirror cameras can have different geometry, for example, the texture camera which uses a concave off-axis parabolic mirror to replace the angular movements required in a gonioreflectometer. Another mirror-based camera is a multiview radial imaging system that obtains a dense sampling of viewing directions using a conical curved mirror placed in the light path of the camera. The third capture setup is based on multiple cameras and multiple light sources where the turntable rotates, or another setup where there are no moving parts [31]. This type of measurement allows for a more comprehensive characterization of how the reflectance properties of a surface change across its spatial extent. By understanding the spatial variation in BRDF, one can gain a deeper understanding of how gloss properties may vary across a surface, providing valuable information for various applications such as material design, surface inspection, and computer graphics rendering.

In 2021, Saha et al. developed a goniospectrophotometer for BRDF measurements on a microscopic scale (μBRDF) [32]. The device uses a Laser-Driven Light Source (LDLS) as a light source and a Konica Minolta CS-2000 spectroradiometer as a detector. The sample is placed on a six-axis robot arm. When the light gets reflected from the sample, it goes through a custom optical system, which enables a field of view of 300 μm when using the 0.1° CS2000 field of view setting. The diameter of the area measured by the CS-2000 is 263 μm ± 5 μm. With the development of softproofing in different industries, the μBRDF enables more accurate fiber and hair characterization of all appearance attributes, together with gloss.

2.1.2. Perceptual Gloss Measurements

From the previous chapter, it can be noted that quantifying an object’s appearance is a challenging task. While objective measurements such as BRDF and specular glossmeters provide valuable information about the physical properties of surfaces, they do not directly capture the perceptual experience of gloss. Gloss perception involves not only the physical properties of the surface but also the cognitive and psychological processes of the observer. Psychophysical measurements bridge the gap by incorporating human perception and subjective judgments. It is unlikely that one physical scale for “visual appearance” will be possible, and it is necessary to find physical parameters that correlate with the four main appearance attributes, and most importantly, that the physical attributes can be measured [33]. Nonetheless, researchers continue to explore and refine models that provide valuable insights into the correlation between physical properties and human perception of the four main appearance attributes.To ensure that the stimuli used in psychophysical experiments are controlled and consistent, researchers often use specialized setups and equipment to present and measure the stimuli. These setups can vary depending on the type of experiment being conducted.

In addition to equipment, the setup of a psychophysical experiment can also include the design of the experimental task and the selection of the participant sample. The experimental task should be designed to elicit consistent and meaningful perceptual responses [34]. The setup of a psychophysical experiment is critical to ensuring that the stimuli used are controlled and consistent and that the perceptual responses obtained are meaningful and accurate. By carefully designing and implementing a setup for a psychophysical experiment, researchers can gain valuable insights into the relationship between physical stimuli and perception. Unfortunately, psychophysical experiments for appearance, including gloss judgment, still lack standardization and research. However, standards such as ASTM D4449 offer a valuable contribution to the field [35]. ASTM D4449 provides a standardized method for the visual evaluation of gloss differences between surfaces of similar appearance. The standard provides guidelines for simple tasks, but it may overlook other factors that can influence gloss perception, such as surface texture, lighting angles, or environmental conditions. As a result, the standard’s ability to address the full range of gloss perception may be limited. Furthermore, the ASTM D4449 standard does not provide detailed guidelines or procedures for controlling and standardizing experimental conditions, such as illumination or observer training. Inconsistencies in these factors can affect the reliability and reproducibility of gloss evaluations, potentially leading to variations in results across different experiments or laboratories. The lack of explicit guidance in these areas leaves room for differences in implementation and introduces potential sources of error or bias. The present review will show different setups for the psychophysical evaluation of gloss and their outcomes based on the literature references on the topic [36].

Some work that has been conducted in visual gloss evaluation shows that the gloss judgment by the observers does not change with the change in the illumination angle or the angle of observation. Billmeyer and O’Donnell were the first to point this out [37]. In 2004, Obein et al. conducted an experiment using the maximum likelihood difference scaling (MLDS) procedure [12]. The authors chose this scaling method because it showed successful results in quantifying color differences in tristimulus space and the perceived distortion of an image as a function of compression [38][39]. The aim of the experiments was to test the sensitivity of the visual system to the parameters of the specimens’ surfaces. Therefore, the question in the psychophysical experiment is not related to gloss; instead, the observers were asked which of the two pairs exhibits a larger difference. The experiments were performed with 20° and 60° illumination angles to match the standards for specular gloss measurements [7]. The results show that the observers’ gloss sensitivity is lower in the semimat and semigloss ranges (the authors also call it the intermediate range) and that the sensitivity increases with the gloss of the sample. The results suggest that observers obtain information about gloss and appearance other than luminous flux, which is reflected from the observing surface, and a single scale is not sufficient to describe the obtained results from the experiments. However, the results show that there is no significant difference between the results obtained in the 60° and 20° configurations. These results provide evidence for “gloss constancy”. Some other work was carried out that supports this theory, like the work from Nishida and Shinya in 1998 [40] and Fleming at al. in 2003 [41], only with the difference that Obein et al. used real surfaces.

The work can also be a notable example of how the setup of the experiment can affect the results. For example, Obein’s psychophysical gloss scale matches the scaling from other authors’ work, like Judd and Hunter’s [42] for the mat samples and Harrison and Poulter’s in the intermediate part [43], but it does not match with Billmeyer and O’Donnell’s [37]. All the mentioned studies use real-world specimens in their experiments. The used samples are paper-like, painted plaquettes, paint panels, and glass. Also, the difference is in the experimental setup. Obein used MLDS with pair-to-pair comparison, Billmeyer, O’Donnel, and Leloup magnitude estimation, and the Hunter ranking method.

It is already noted that different setups can produce equivalent results, but they are not 100% the same. In the realm of psychophysical experiments for gloss observation, it is important to acknowledge that computer simulations of object gloss may introduce certain deviations from real-world scenarios. One notable aspect to consider is the potential tonal compression that can occur during the rendering process. Tonal compression can lead to differences in the visual appearance of simulated objects compared with their real-world counterparts. Moreover, the specific 3D rendering model applied can significantly impact the perceived glossiness of objects within the simulation. Besides that, studies show that there is indeed a relationship between perceptual attributes and visual, tactile, and subjective attributes [44].

Research conducted by Ged et al. [45] showed that the gloss constancy can be broken for mat objects when the illumination is diffuse. When illuminating a mat object with a diffuse light source, the light comes from more directions. This causes a decrease in the perceived gloss of mat and semimat objects. Researchers can conclude that the incoming light and the nature of the light play a significant role when evaluating the gloss. Ged et al. explained this in their work [46]. He compared two setups for psychophysical experiments. Two equivalent sets of coated paper were used in the experiment in two different institutions. Both institutions performed the experiment with diffuse and specular light sources. The paired comparison was used as the evaluation method: at one institution, the maximum likelihood difference scaling, and at another one, the paired comparison described by Scheffe in 1952 [38][47]. The results show that, despite the differences in illumination ratio between the specular and diffuse ambient scales, the psychometric scales at the second institute in the experiment overlap. It is noted that the presence of a virtual image of light sources on the sample greatly affects the gloss appraisal.

The human eye is used to perceive glossiness under natural light and conditions. Van Assen et al. tested how observers perceive the appearance of round objects (spheres) with illumination with artificial properties [48]. The rendered objects were illuminated with different illumination geometries, which can be like the ones that can be found in real life, but also some artificial, like circles, dots, rings, squares, and a window. They concluded that when illuminating objects with unnatural illumination, the observers lose their sensitivity to gloss perception. This proves that the gloss is implemented in our cognitive system, and by illuminating objects with artificial illumination, the cognitive system has problems reconstructing the scene [49][50]. Later, in 2019, Faul proved that the illumination type has a strong influence on the perceived glossiness. Results from Faul’s work suggest that Fresnel-BRDF is a better approximation than the Ward model, especially when using homogeneous illumination [51]. Furthermore, the author implies that the glossiness of metallic and dielectric materials differ fundamentally with respect to Fresnel effects and that, when judging the glossiness of metallic and dielectric materials, researchers use different cues and mechanisms in both material classes. Unfortunately, for the three psychophysical experiments, the exact experiment question is not stated.

Since a change in diffuseness can result in a difference in the appearance of an object, it is important to determine the diffuseness condition that is most suitable for reproducing the surface appearance of an object. In 2022, Mizushima and Mizomaki investigated which light diffuseness faithfully reproduces the surface appearance of an object as seen in a natural environment [52]. Five observers evaluated the fidelity and “ideality” of the object’s appearance under four or five diffuseness conditions. The objects were made from different materials, namely polyresin balls, fur charms, wooden cubes, and stainless-steel cubes. In their work, the most faithful reproduction was under moderate diffuseness; furthermore, the ideal diffuseness depends on the material of the object. This implies that the choice of materials for the psychophysical experiments can be crucial when evaluating the appearance.

References

- Palmer, S.E. Vision Science: Photons to Phenomenology; MIT Press: Cambridge, MA, USA, 1999.

- Wagemans, J. (Ed.) The Oxford Handbook of Perceptual Organization, online ed.; Oxford Library of Psychology: Oxford, UK, 2014.

- Fairchild, M.D. Color Appearance Models; John Wiley & Sons: Hoboken, NJ, USA, 2013.

- Eastman Kodak Company. Kodak Color Handbook; Eastman Kodak Company: Rochester, NY, USA, 1950.

- Hunt, R.W.G. The Reproduction of Colour; John Wiley & Sons: Hoboken, NJ, USA, 2005.

- Hunter, R.S.; Harold, R.W. The Measurement of Appearance; John Wiley & Sons: Hoboken, NJ, USA, 1987; p. 432.

- ISO 2813; Paint and Varnishes—Determination of Gloss at 20 Deegress, 60 Degress and 85 Degrees. International Standardization Organisation: Geneva, Switzerland, 2014.

- CIE S 017/E:2011; International Lighting Vocabulary. CIE Bureau Central: Vienna, Austria, 2011.

- Chadwick, A.C.; Kentridge, R. The perception of gloss: A review. Vis. Res. 2015, 109, 221–235.

- ASTM Standard D 523-89; Standard Test Method for Specular Gloss. ASTM Committee: West Conshohocken, PA, USA, 2000.

- Ji, W.; Pointer, M.R.; Luo, R.M.; Dakin, J. Gloss as an aspect of the measurement of appearance. J. Opt. Soc. Am. A 2006, 23, 22.

- Obein, G.; Knoblauch, K.; Viénot, F. Difference scaling of gloss: Nonlinearity, binocularity, and constancy. J. Vis. 2004, 4, 711–720.

- Pointer, M.R. New Directions-Soft Metrology Requirements for Support from Mathematics, Statistics and Software: Recommendations for the Software Support for Metrology Programme 2004–2007; NPL Publications: Teddington, UK, 2003.

- Leloup, F.; Hanselaer, P.; Forment, S. BRDF and gloss measurements. In Proceedings of the CIE Expert Symposium on Visual Appearance, Paris, France, 19–20 October 2006.

- Leloup, F.B.; Obein, G.; Pointer, M.R.; Hanselaer, P. Toward the soft metrology of surface gloss: A review. Color Res. Appl. 2014, 39, 559–570.

- Gevaux, L.; Dupiau, A.; Morvan, K.; Obein, G. The Measurement of Specular Gloss using a Conoscopic Goniospectrophotometer. Lond. Imaging Meet. 2023, 4, 10.

- Nicodemus, F.E.; Richmond, J.C.; Hsia, J.J.; Ginsberg, I.W.; Limperis, T. Geometrical Considerations and Nomenclature for Reflectance. In National Bureau of Standards Monograph; U.S. Government Printing office: Washington, DC, USA, 1977; pp. 1–52.

- Koenderink, J.J.; Doorn, A. Representation of Local Geomtry in the Visual System. Biol. Cybern. 1987, 55, 367–375.

- Nicodemus, F.E. Directional Reflectance and Emissivity of an Opaque Surface. Appl. Opt. 1965, 4, 767–775.

- Zou, Y.; Zhang, L.; Zhang, J.; Li, B.; Lv, X. Developmental Trends in the Application and Measurement of the Bidirectional Reflection Distribution Function. Sensors 2022, 22, 1739.

- Pompea, S.; McCall, S. OPTICAL COATINGS | Optical Black Surfaces. In Encyclopedia of Modern Optics; Citeseer: State College, PA, USA, 2005; pp. 349–360.

- Le Breton, R.; Ged, G.; Obein, G. Out of plane BRDF Measurements at LNE-CNAM using “ConDOR”. In Proceedings of the 28th Session of the CIE, Manchester, UK, 28 June–4 July 2015.

- Dana, K.J.; Van Ginneken, B.; Nayar, S.K.; Koenderink, J.J. Reflectance and Texture of Real-World Surfaces. ACM Trans. Graph. 1999, 18, 1–34.

- Obein, G.; Audenaert, J.; Ged, G.; Leloup, F.B. Metrological issues related to BRDF measurements around the specular direction in the particular case of glossy surfaces. Meas. Model. Reprod. Mater. Appear. 2015, 9398, 93980D.

- ASTM E2387-11; Standard Practice for Goniometric Optical Scatter Measurements. ASTM Committee: West Conshohocken, PA, USA, 2000.

- ISO 13697; Optics and Optical Instruments—Test Methods for Reflectance Factor and Bidirectional Reflectance Factor of Surfaces and Materials. ISO: Geneva, Switzerland, 2006.

- ISO 13594; Optics and Photonics—Spectral Reflectance. ISO: Geneva, Switzerland, 1995.

- Simonot, L.; Obein, G. Geometrical considerations in analyzing isotropic or anisotropic surface reflections. Appl. Opt. 2007, 46, 2615–2623.

- Schmitt, J.; Ferrero, A.; Simonot, L. Standards for BRDF measurements: Are we there yet. In Proceedings of the SPIE—The International Society for Optical Engineering, Jena, Germany, 7–10 September 2015; Volume 9667.

- Kirschner, M.; MacAdam, D. BRDF measurement: Limitations and recommendations. In Proceedings of the Conference on Lasers and Electro-Optics & Quantum Electronics and Laser Science Conference, Washington DC, USA, 4–9 May 2008; pp. 1–2.

- Dana, K.J.; Wang, J. Device for convenient measurement of spatially varying bidirectional reflectance. J. Opt. Soc. Am. 2004, 21, 1–12.

- Saha, D.; Gevaux, L.; Cances, T.; Richard, A.; Obein, G. Development of a Mbrdf Goniospectrophotometer for Brdf Measurement on Tiny Surfaces. In Proceedings of the CIE 2021 Midterm Conference, Kuala Lumpur, Malaysia, 27–29 September 2021; pp. 327–334.

- Eugène, C. Measurement of “total visual appearance”: A cie challenge of soft metrology. In Proceedings of the 12th IMEKO TC1 Education and Training in Measurement and Instrumentation and TC7 Measurement Science Joint Symposium on “Man, Science and Measurement” 2008, IMEKO, Budapest, Hungary, 3–5 September 2008; pp. 61–65.

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper, 5th ed.; Sage Publications: Thousand Oaks, CA, USA, 2019.

- ASTM D4449; Standard Test Method for Visual Evaluation of Gloss Differences Between Surfaces of Similar Appearance. ASTM Committee: West Conshohocken, PA, USA, 2021.

- Karlovic, I.; Novaković, D. Effect of different coating amounts on the surface roughness and print gloss of screen coated offset prints. J. Imaging Sci. Technol. 2011, 55, 1–10.

- Billmeyer, F.W.; O’Donnell, F.X.D. Visual gloss scaling and multidimensional scaling analysis of painted specimens. Color Res. Appl. 1987, 12, 315–326.

- Maloney, L.T.; Joong, N.Y. Maximum likelihood difference scaling. J. Vis. 2003, 3, 573–585.

- Knoblauch, K.; Charrier, C.; Cherifi, H.; Yang, J.; Maloney, L. Difference Scaling of image quality in compression-degraded images. Perception 1998, 27, 174.

- Nishida, S.; Shinya, M. Use of image-based information in judgements of surface-reflectance properties. J. Opt. Soc. Am. 1998, 15, 2951–2965.

- Fleming, R.W.; Dror, R.O.; Adelson, E.H. Real-world illumination and the perception of surface reflectance properties. J. Vis. 2003, 3, 347–368.

- Hunter, R.S.; Judd, D.B. Development of a Method of Classifying Paints According to Gloss. Technical Report; ASTM: Philadelphia, PA, USA, 1939.

- Harrison, V.G.; Poulter, S.R. Gloss measurement of papers—The effect of luminance factor. Br. J. Appl. Phys. 1951, 2, 92–97.

- Filip, J.; Kolafová, M. Perceptual attributes analysis of real-world materials. ACM Trans. Appl. Percept. (TAP) 2019, 16, 1–19.

- Ged, G.; Rabal-Almazor, A.M.; Himbert, M.E.; Obein, G. Assessing gloss under diffuse and specular lighting. Color Res. Appl. 2020, 45, 591–602.

- Ged, G.; Leloup, F.; De Wit, E.; Obein, G. Intercomparison of visual gloss psychometric scales. In Proceedings of the 4th CIE Expert Symposium on Colour and Visual Appearance, Prague, Czech Republic, 6–7 September 2016.

- Scheffé, H. An analysis of variance for paired comparisons. J. Am. Stat. Assoc. 1952, 47, 381–400.

- van Assen, J.J.R.; Wijntjes, M.W.; Pont, S.C. Highlight shapes and perception of gloss for real and photographed objects. J. Vis. 2016, 16, 1–14.

- Marlow, P.J.; Kim, J.; Anderson, B.L. The perception and misperception of specular surface reflectance. Curr. Biol. 2012, 22, 1909–1913.

- Olkkonen, M.; Brainard, D.H. Perceived glossiness and lightness under real-world illumination. J. Vis. 2010, 10, 5.

- Faul, F. The influence of Fresnel effects on gloss perception. J. Vis. 2019, 19, 1–39.

- Mizushima, S.; Mizokami, Y. Diffuseness of illumination suitable for reproducing a faithful and ideal appearance of an object. J. Opt. Soc. Am. A 2022, 39, 401.

More

Information

Subjects:

Others

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

781

Revisions:

2 times

(View History)

Update Date:

03 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No